Heat exchanger assemblies having hybrid tanks

a technology of heat exchangers and hybrid tanks, applied in indirect heat exchangers, lighting and heating apparatus, coatings, etc., can solve the problems of increased welding costs, limited heat exchangers, and certain limitations of heat exchangers, and achieve the strength and performance characteristics of plastic tank systems of lower temperature and/or lower pressure environment, and the profile cost is reduced

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] Heat exchanger assemblies, and, especially, heat exchanger assemblies operating in high temperature and / or pressure environments, allow increased temperature and pressures range of application of lower weight and cost tanks. Hybrid tanks, as in the various aspects of the present invention, are therefore useful to replace cast aluminum, or even other metal tanks, such as stamped and brazed aluminum tanks.

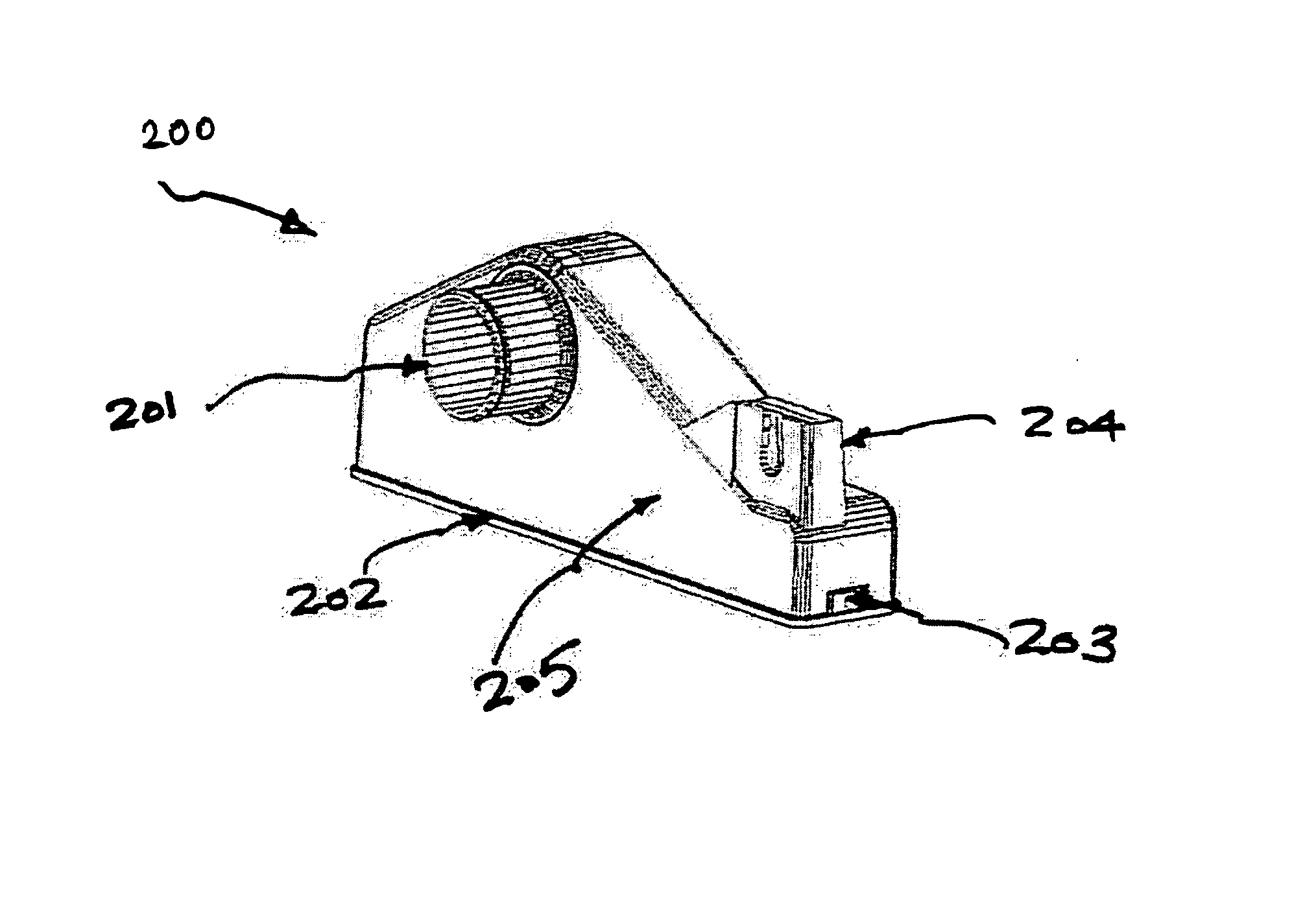

[0033] The present invention, in one embodiment, provides for a heat exchanger for an automotive vehicle comprising: a first end tank; a second end tank opposite the first end tank; a plurality of essentially parallel tubes in fluid communication with the first and second end tanks; at least one fin contacting at least two of the plurality of tubes, with the parallel tubes and the fins being generally co-planar relative to each other; wherein at least the first end tank or the second end tank is a hybrid tank made of a first material and a second material.

[0034] When the sec...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperatures | aaaaa | aaaaa |

| internal pressure | aaaaa | aaaaa |

| thermally dissipative | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com