Heat exchanger tube for heating system

a technology heat exchangers, which is applied in the field of heat exchanger tubes, can solve the problems of polluting the majority of heating containers in the central heating system, rusting to pollute hot water, and low temperature in those countries or regions, so as to reduce energy consumption, increase heat exchange surface, and reduce energy consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022]Reference will now be made in detail to the preferred embodiments of the invention, which is illustrated in the accompanying figures.

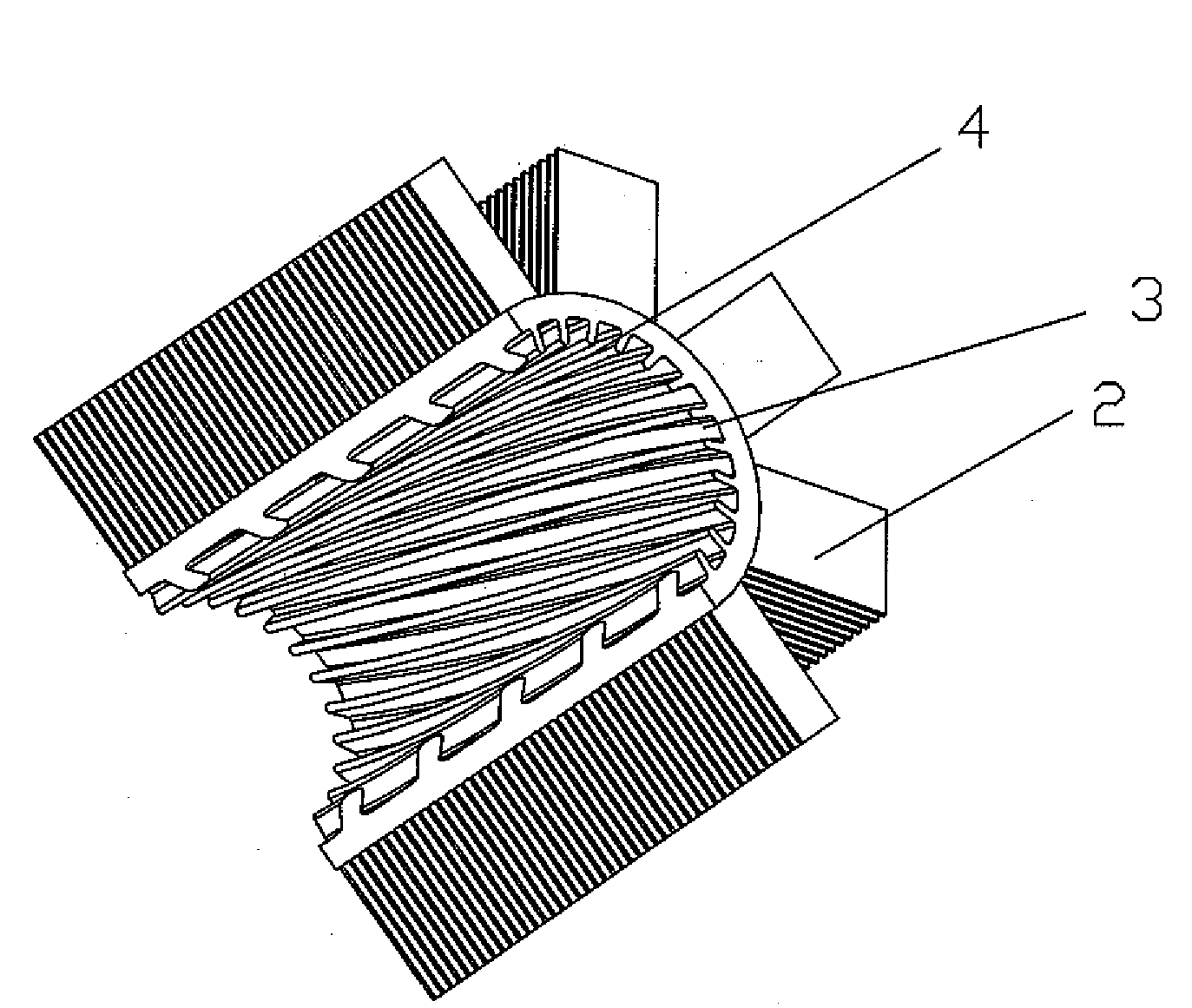

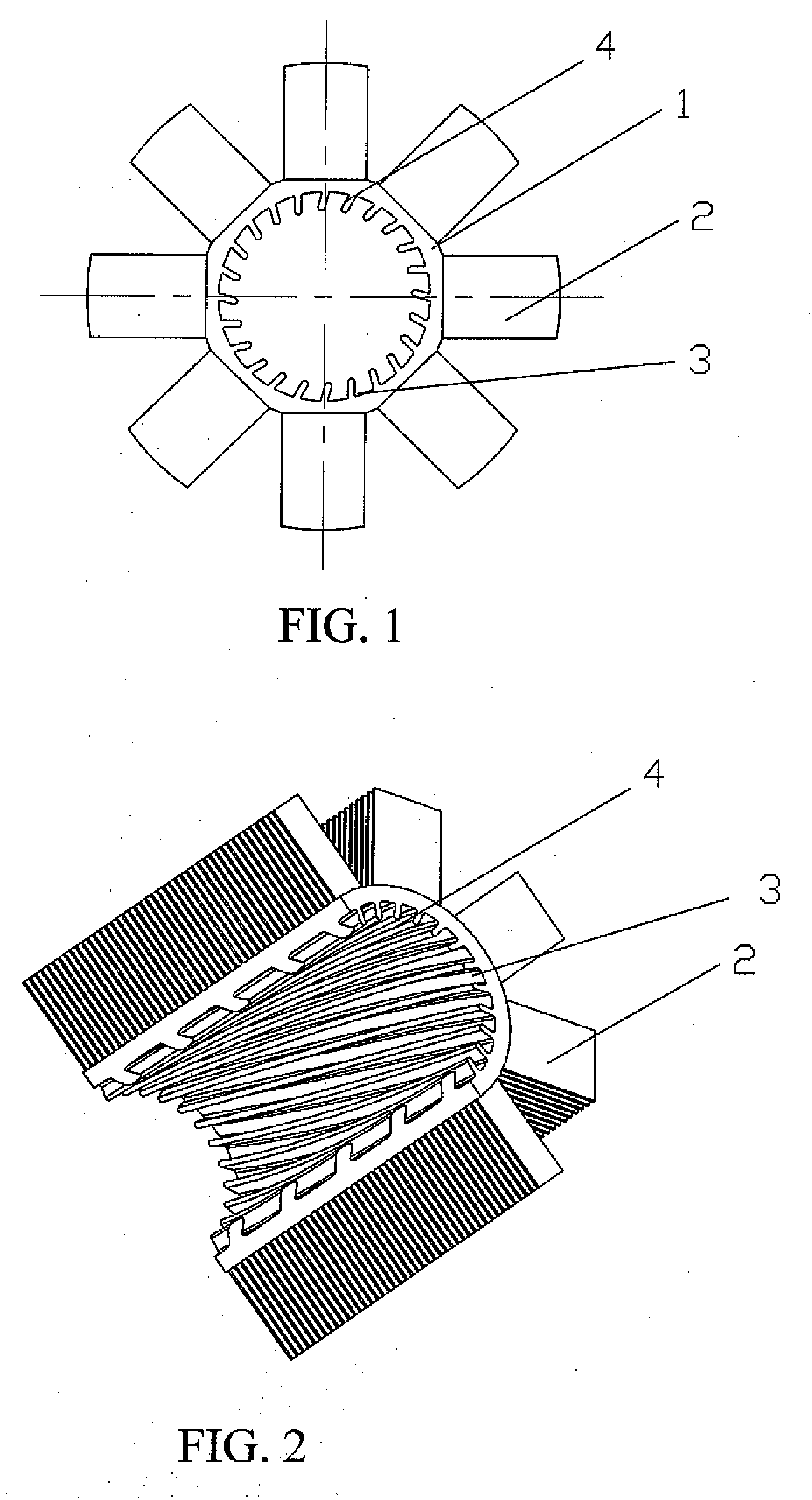

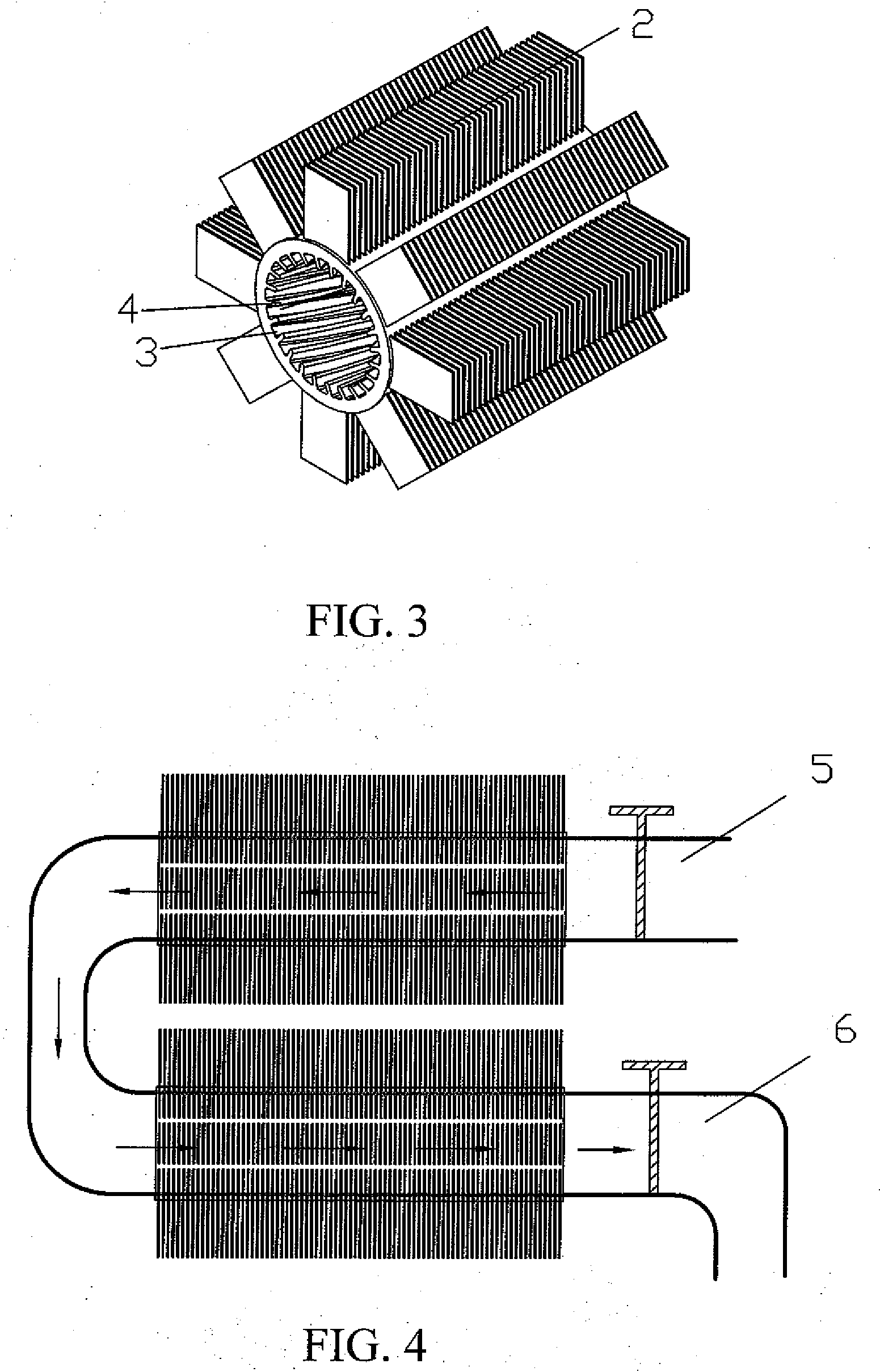

[0023]As shown in FIGS. 1-3, the heat exchanger tube of the present invention comprises a tube body 1, which includes an inside surface 3 exposed to a heating medium and an outside surface exposed to the air. The traversal cross section of the tube body could be in any suitable shape, such as a polygon, a circle, a rectangle and so on.

[0024]A plurality of lobes 2 are formed on the outside surface of the tube body 1 around the peripheral of the tube body 1. Preferably, each of the lobes 2 is formed along the whole length of the tube body 1. The lobes 2 could be formed by any means known in the related art. For example, the lobes 2 may be formed integrally with the tube body 1, or the lobes 2 could be formed by means of cutting the outside surface of the tube body 1. Preferably, the lobes 2 are systematical with respect to a longitude axis of the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com