Modular mattress system

a mattress and module technology, applied in the field of mattresses, can solve the problems of fatigue or memory, the more difficult it becomes for the consumer to flip the mattress, and the difficulty, if not impossible, of one person (especially an elderly person) to flip the mattress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

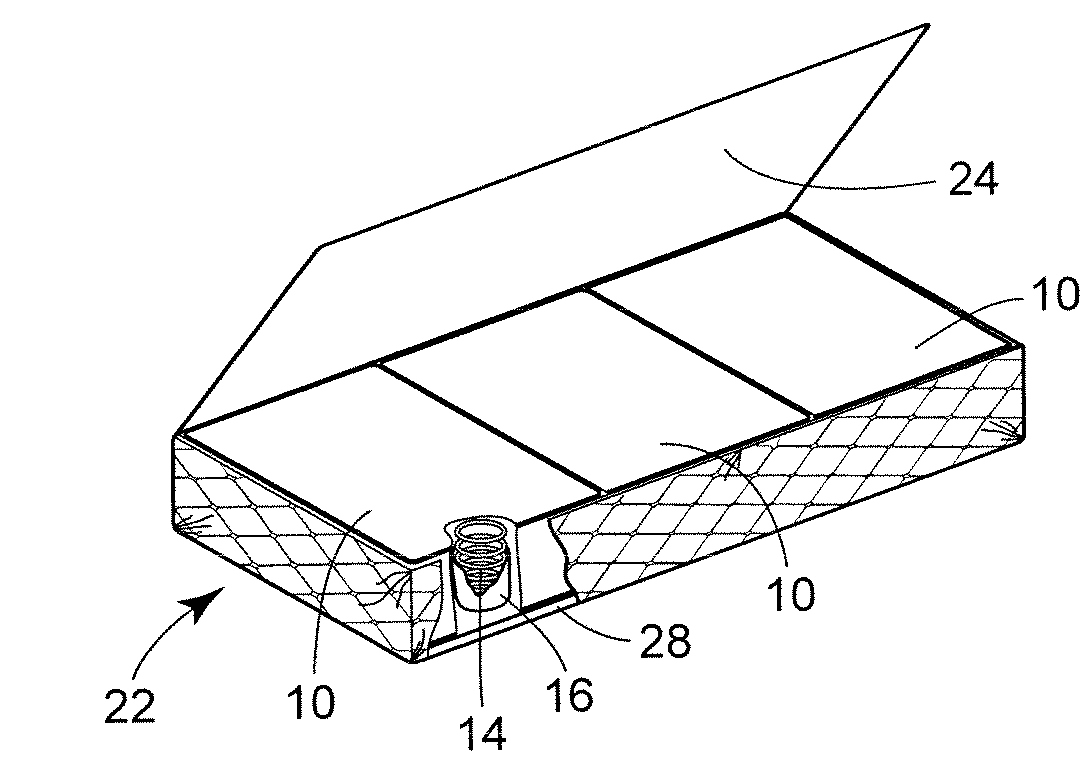

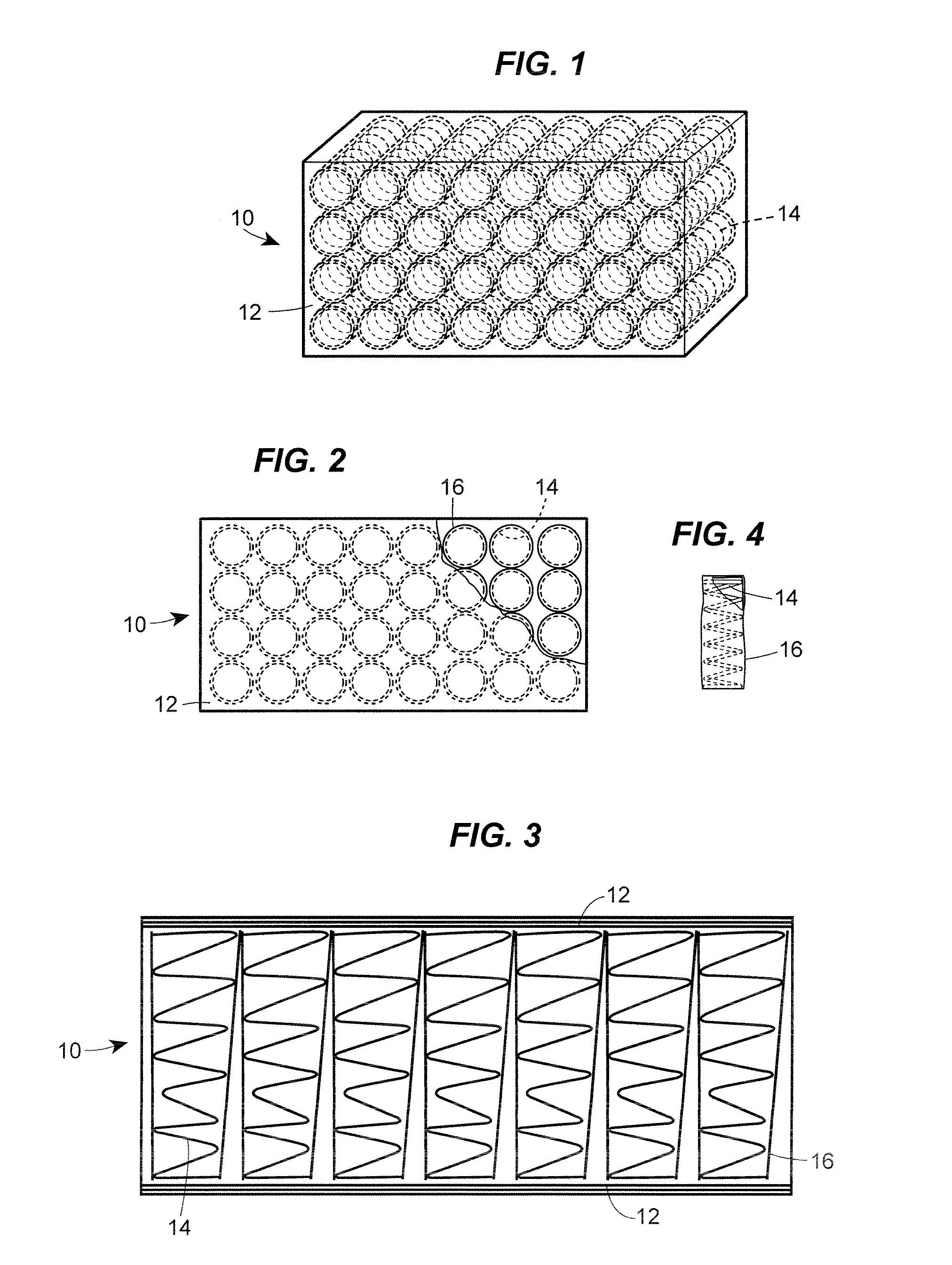

[0045]Having reference to the drawings, where like reference numbers comprise like elements, there is shown in FIG. 1 and FIG. 2 a mattress block, generally denoted by reference number 10. The mattress block 10 includes a covering material 12 which encloses an array of resilient coil springs 14, with each coil spring 14 preferably surrounded by a compressible cloth wrapping 16. FIG. 3 shows a cross-sectional view of the mattress block 10, including an array of coil springs 14, each surrounded by a cloth wrapping 16, all enclosed within covering material 12. FIG. 4 shows a cross-sectional view of a typical coil spring 14 surrounded by its cloth wrapping 16.

[0046]Each coil spring 14, with its cloth wrapping 16, is designed to move independently of any other coil spring 14. The coil springs 14 are tightly packed adjacent to one another within covering material 12 such that no gap or crease is felt between rows or columns of the coil springs 14. For any given size of mattress block 10, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com