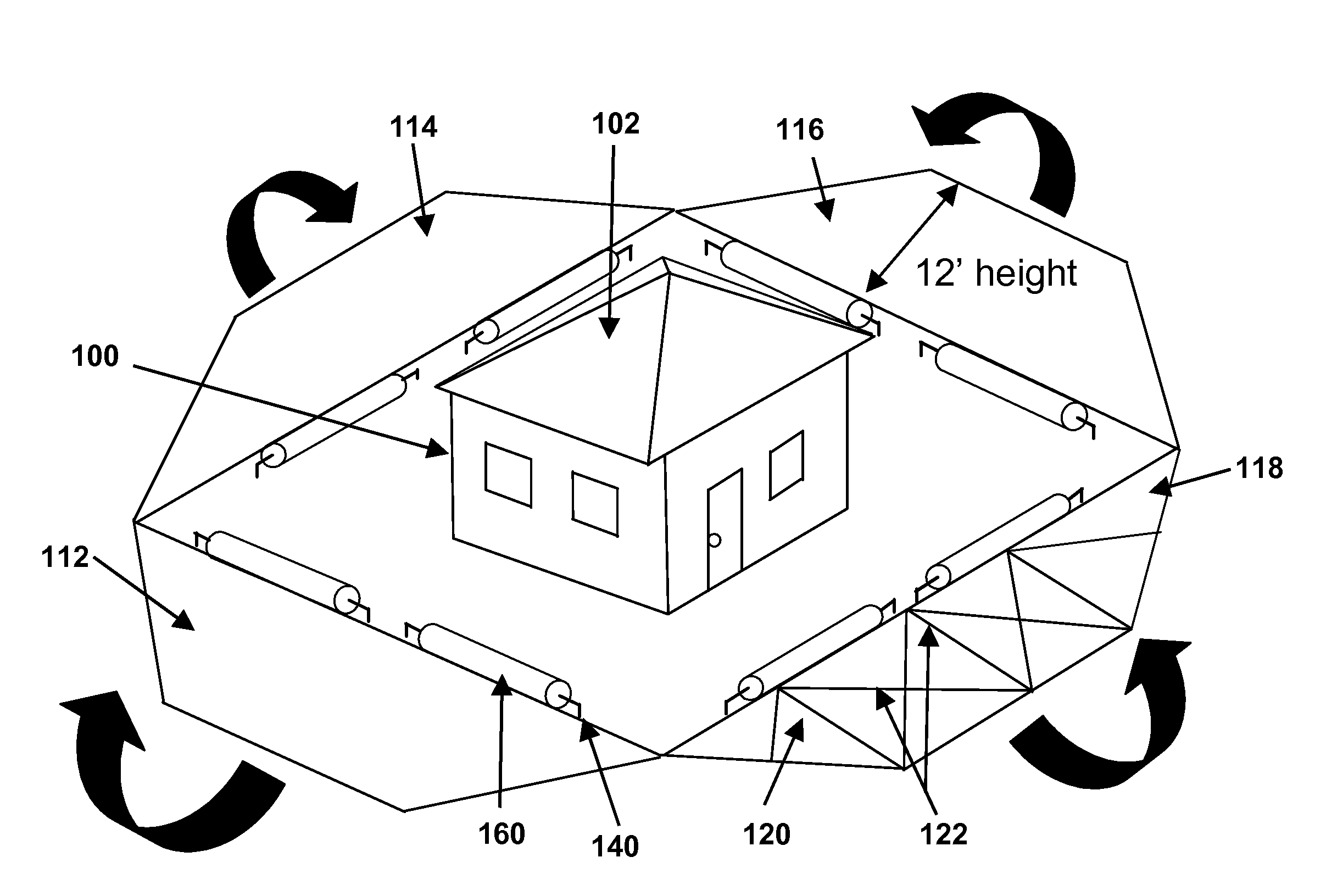

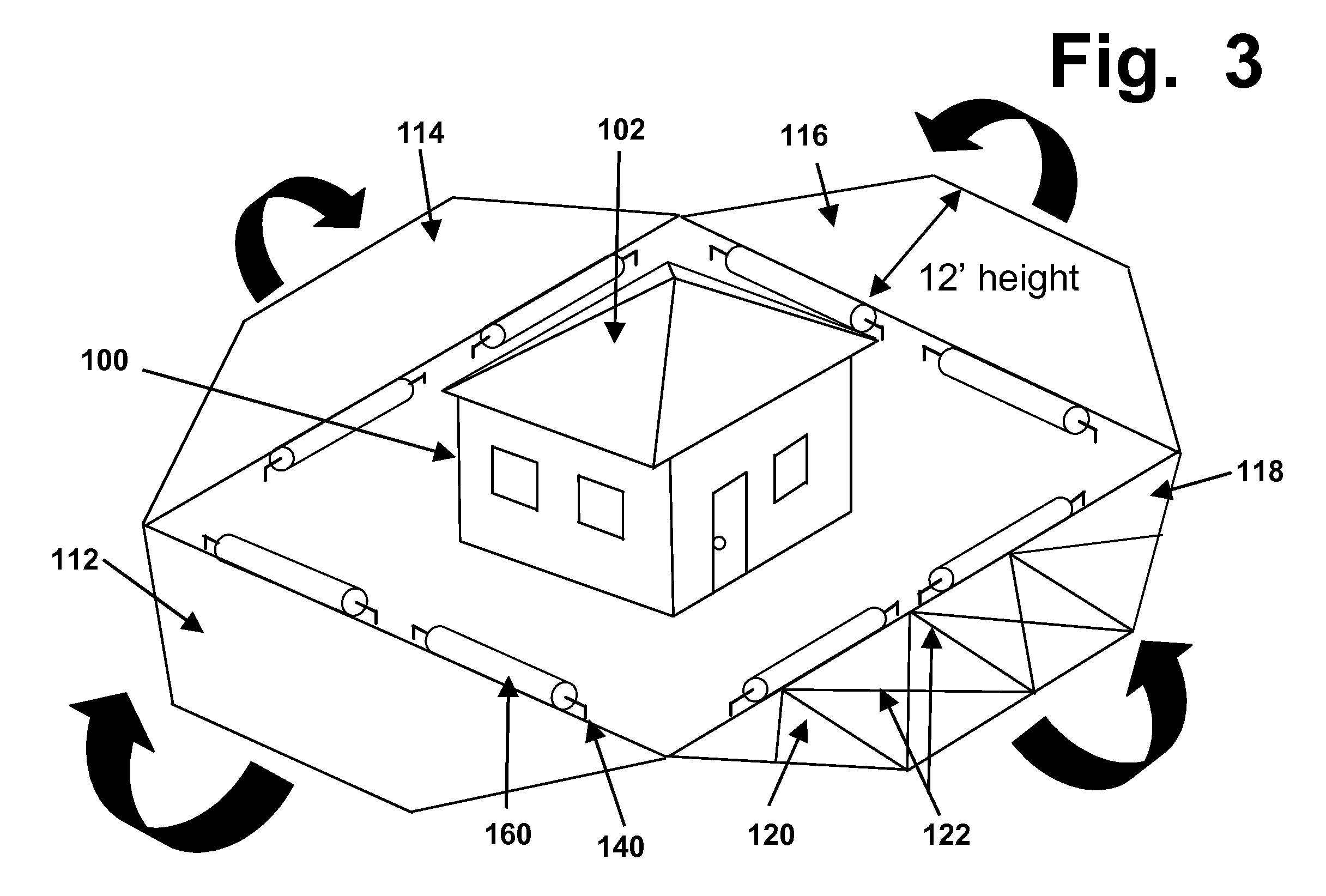

Movable sloped panels to modify building profiles and reduce wind resistance, to protect buildings during high winds

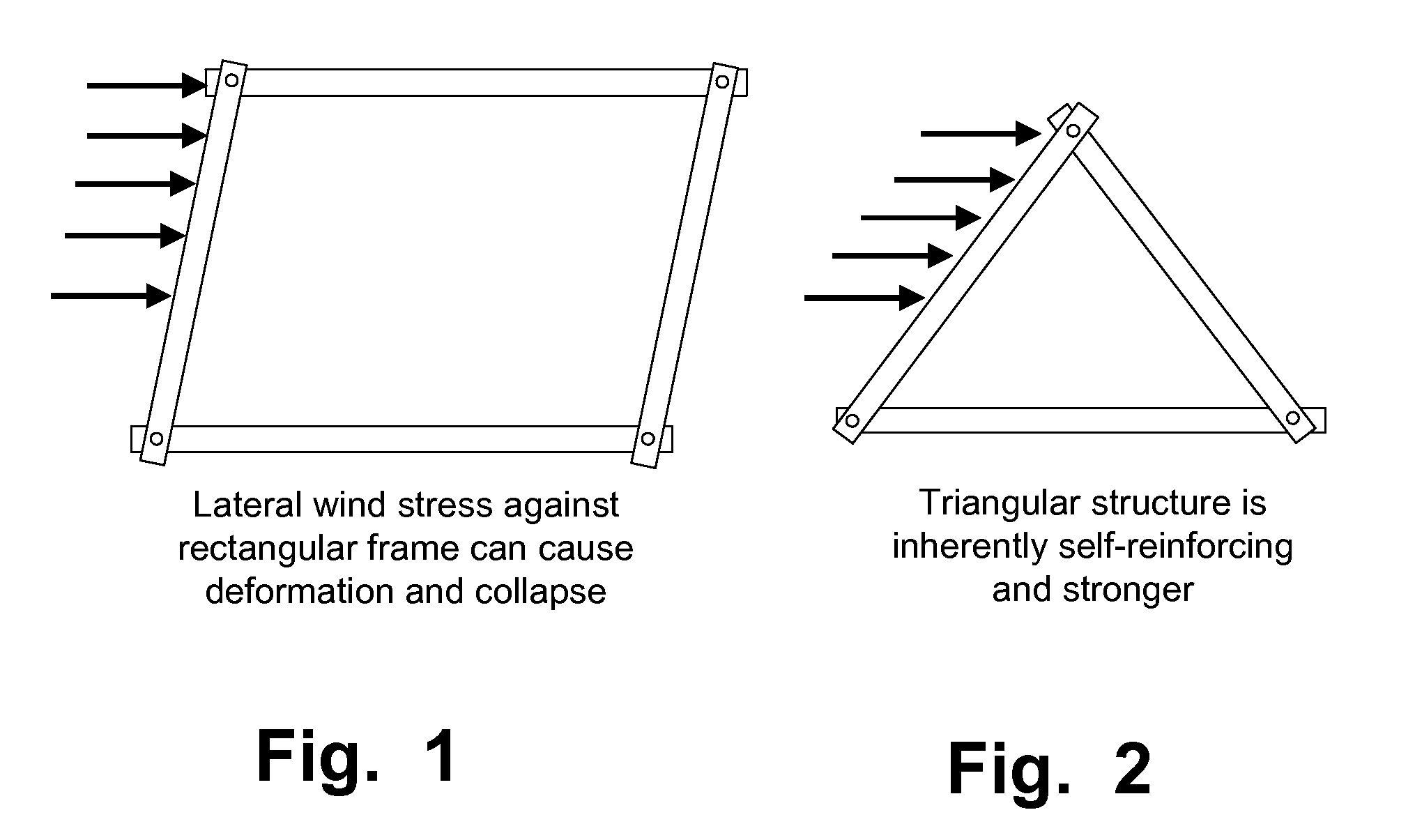

a technology of building profiles and slopes, applied in the field of building design, can solve the problems of deformation of the frame, structural design cannot be retrofitted (without great difficulty and expense), and the rectangular frame is inherently unstable, so as to reduce the profile, reduce the risk of deformation, and reduce the effect of wind resistan

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031]As summarized above, designs and materials are disclosed that can render buildings much better able to withstand hurricanes and other very high winds and severe storms. For convenience, the discussion below will focus upon and refer to homes, surrounded by yards and grass. These teachings can be adapted to other types of buildings that may be surrounded by asphalt or concrete parking lots, sand, or other surfaces, using methods known to those skilled in the art. For example, anchoring sleeves that are installed beneath asphalt or concrete, rather than beneath a layer of grass, can be covered by removable plates or caps, comparable to manhole covers, or to the caps used to cover and protect various types of water valves, gas shutoff valves, and other utilities.

[0032]The panels discussed herein should be strong and waterproof. A preferred class of materials for making such panels comprises composite materials made of recycled synthetic fibers, such as nylon fibers from shredded ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com