Container closure assembly

a container and assembly technology, applied in the direction of liquid handling, caps, applications, etc., can solve the problems of high removal torque, high standard deviation of removal torque, high force for elderly users, etc., and achieve the effect of easy opening of containers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

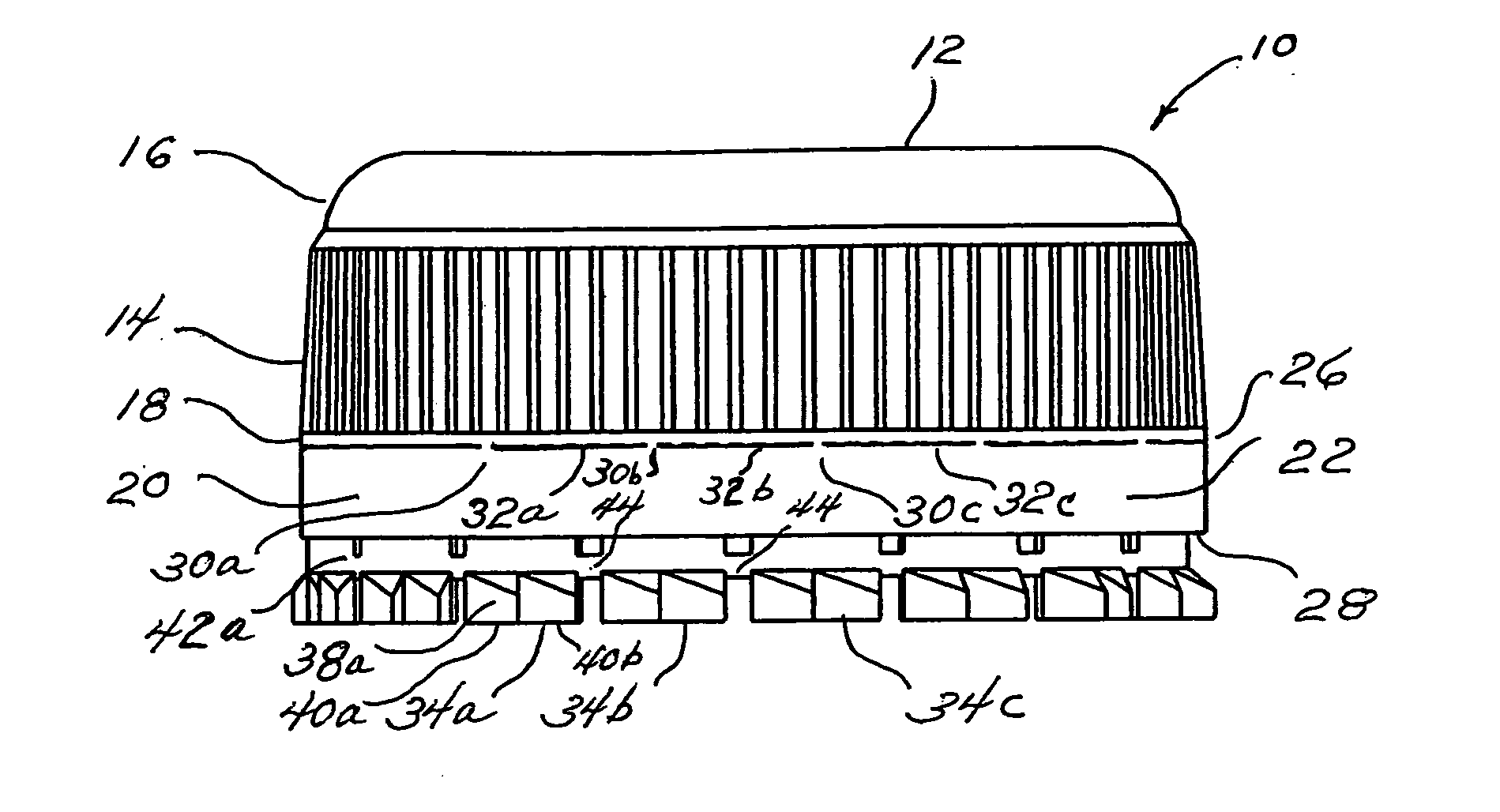

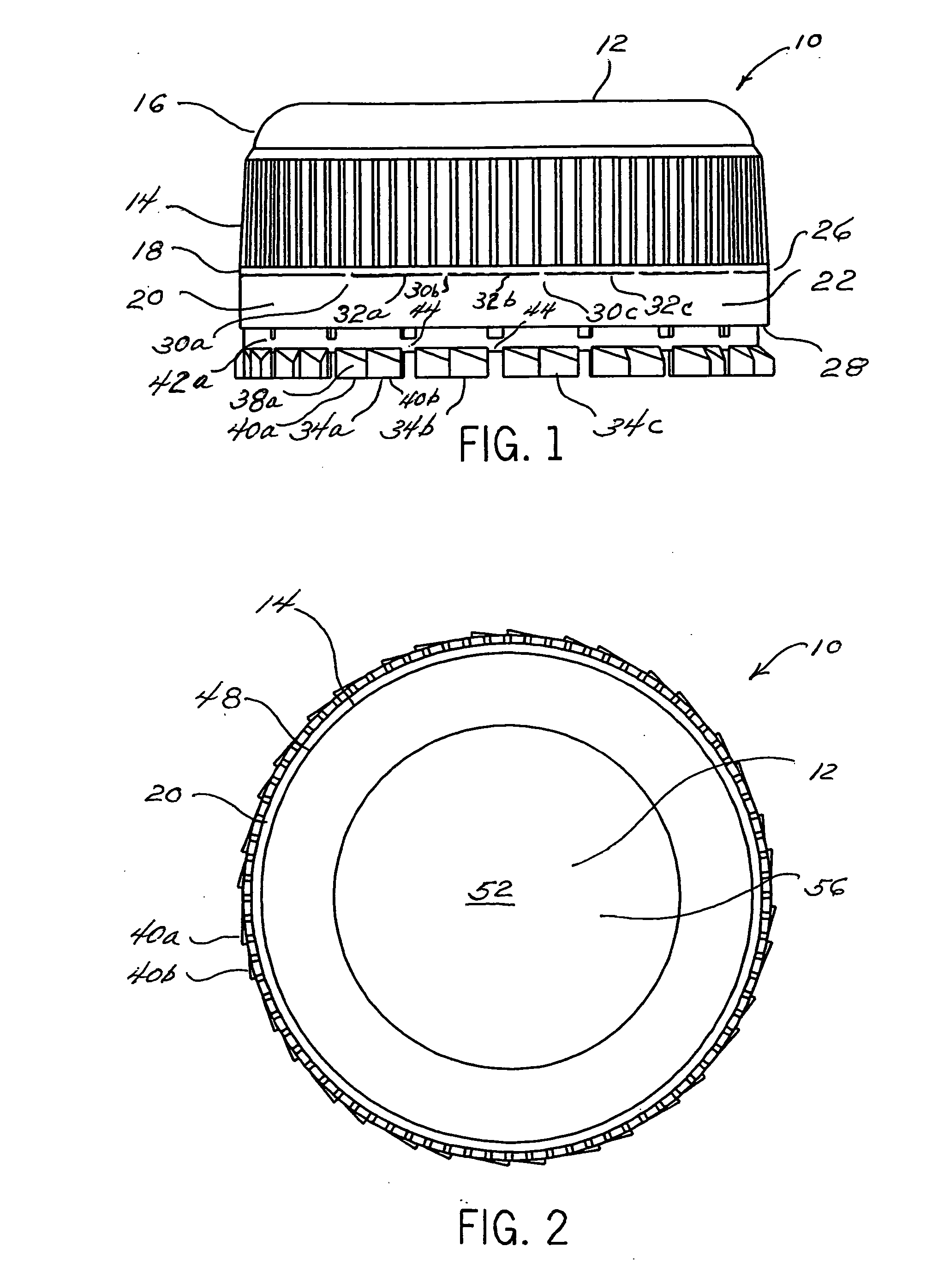

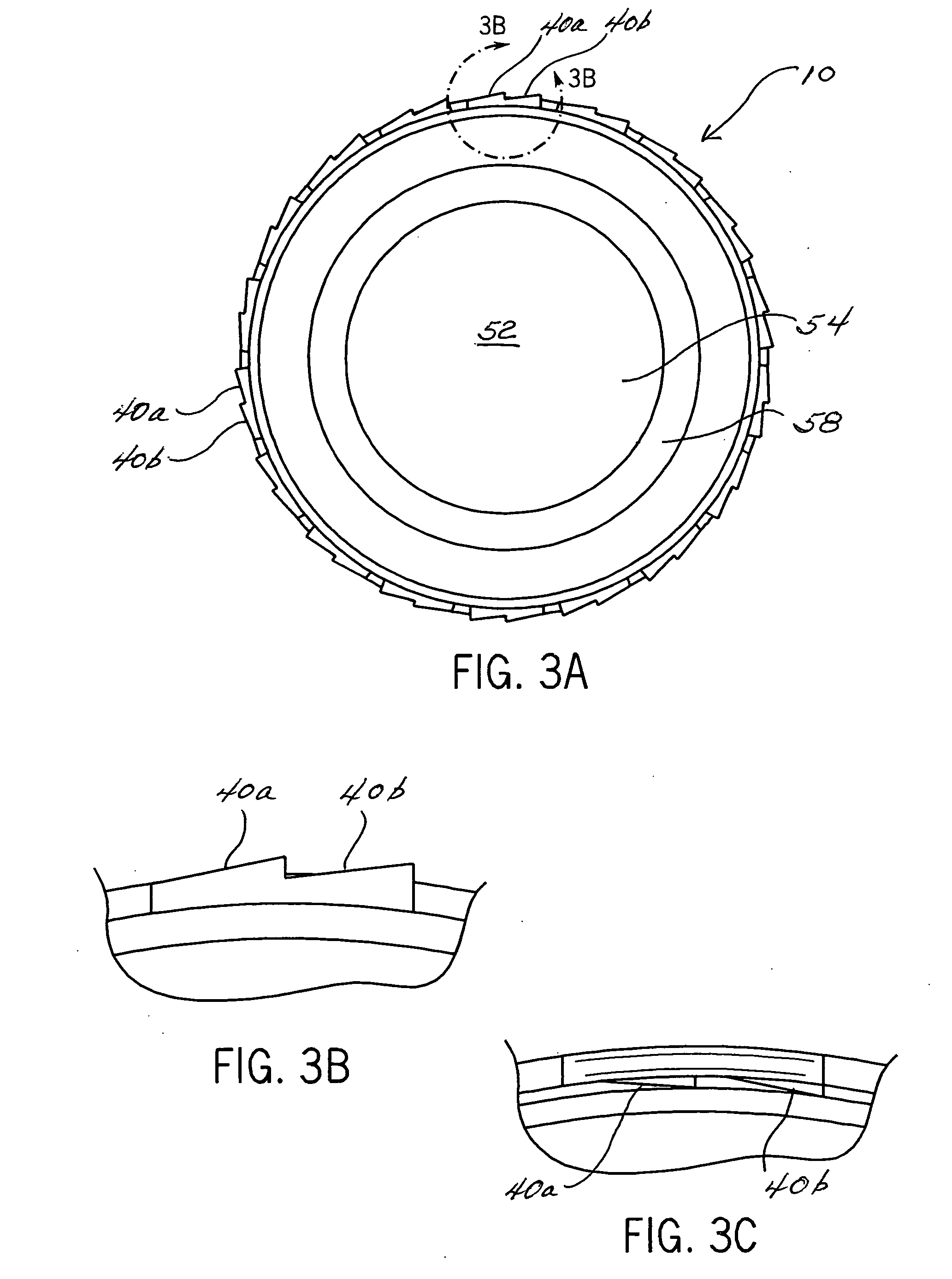

[0029]As used herein term “side wall” means that portion of a closure depending from the top wall of the closure. The term “side wall” is synonymous with the term “skirt.” As used herein, the expression “top wall” means a panel that covers the opening of the closure that is positioned distally from the neck of the container. The expression “top wall” is synonymous with the expressions “end wall”, “cover”, “end panel”, “upper portion”. As used herein, the term “tooth” means a projecting part resembling a tooth, as on a saw. The expression “sloping tooth” is synonymous with the term “ratchet.” As used herein, the expression “closure / container assembly” means a combination of the closure and the container to make a completed product. As used herein, the term “closure” means an object that closes the mouth of a container. As used herein, the term “container” means a receptacle for holding or carrying a material. As used herein, the term “etc.” is indicative of a situation in which compo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com