Bathtub waste and overflow assembly

a bath tub and waste technology, applied in the field of bath tub waste and overflow assemblies, can solve the problems of many trial and error attempts to get the piping length, inefficiency and increased costs, and installation problems of installers,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

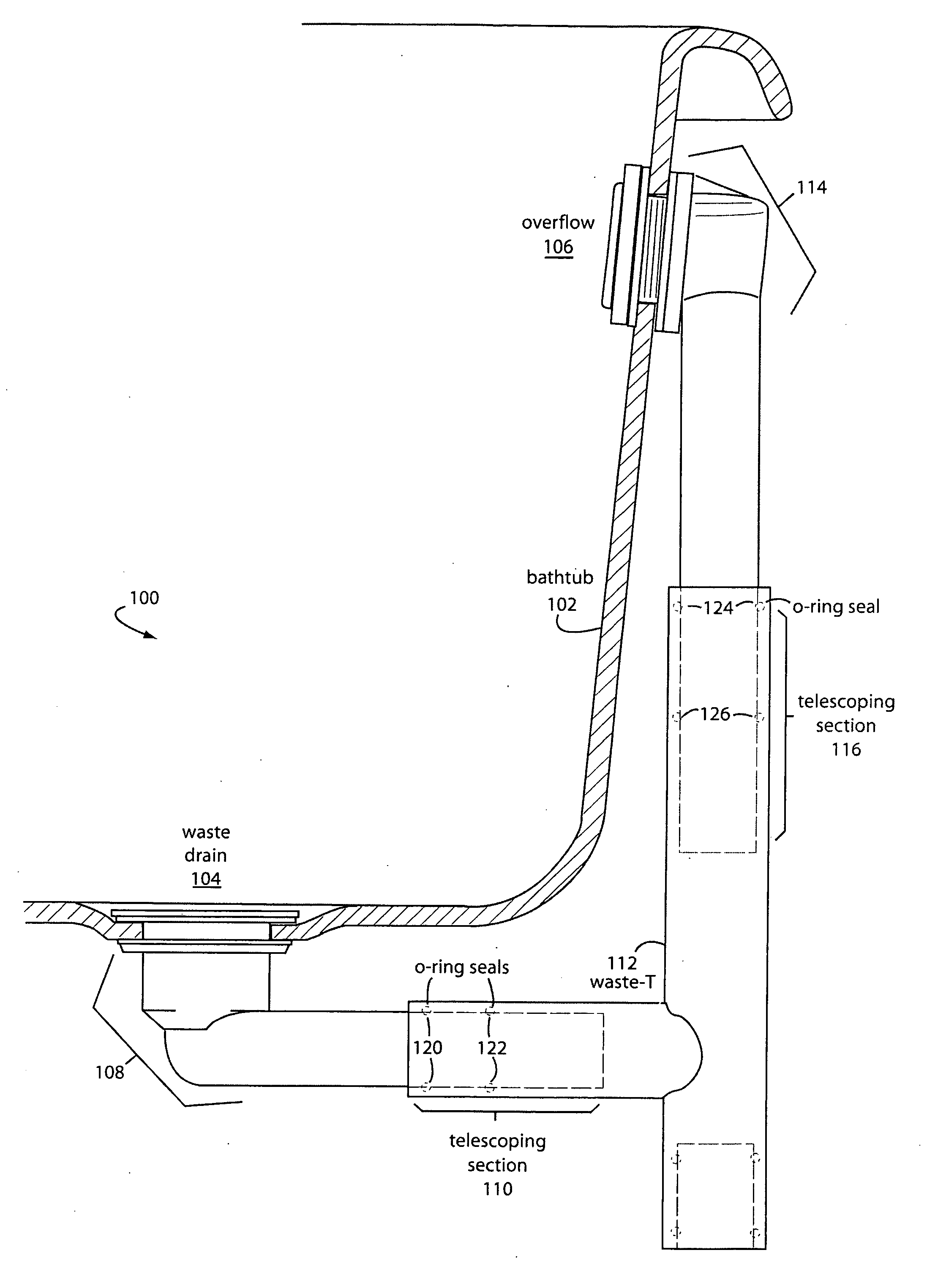

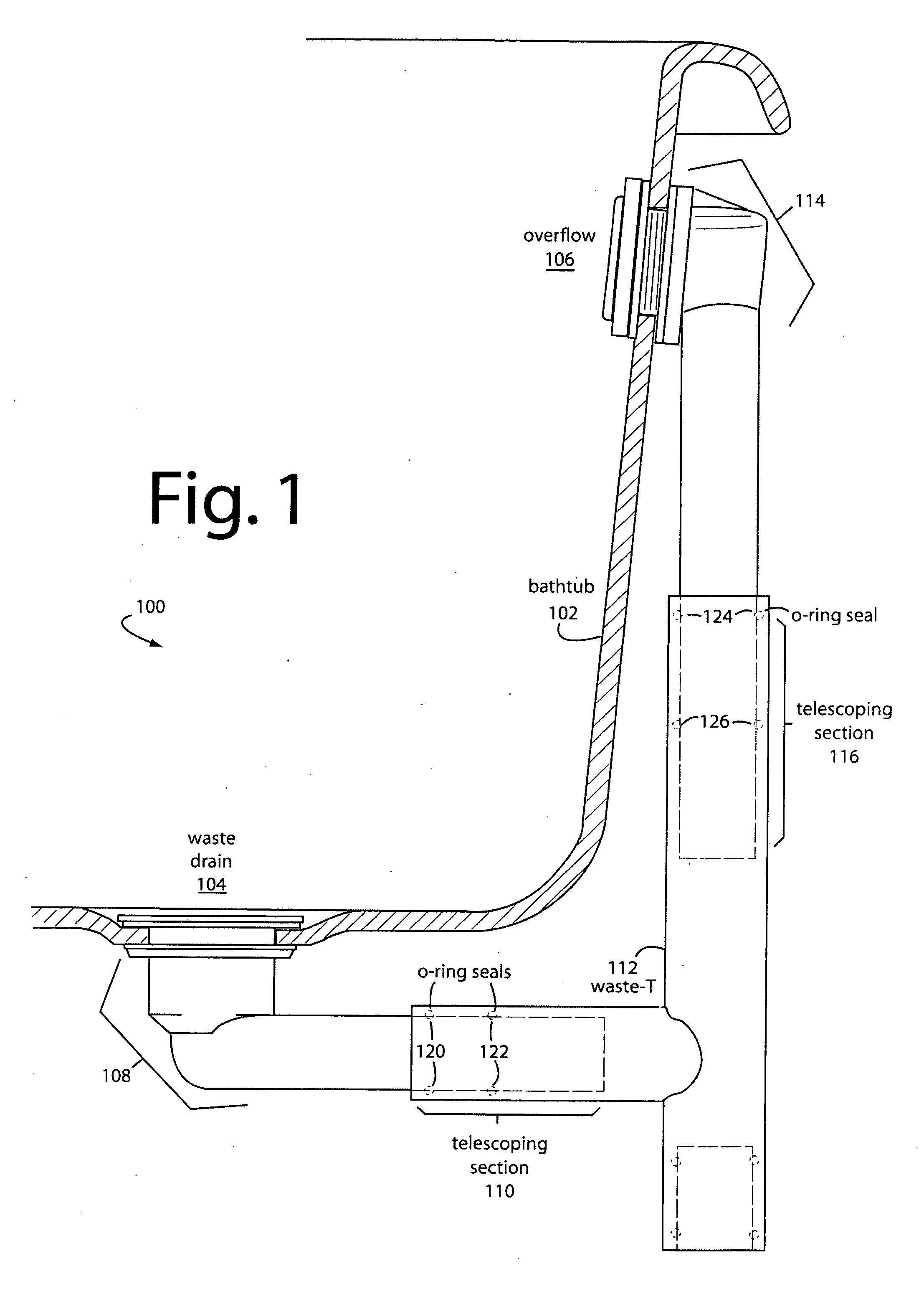

[0012]FIG. 1 represents a bathtub waste and overflow drain assembly embodiment of the present invention, and is referred to herein by the general reference numeral 100. A typical bathtub 102 has a waste drain 104 and an overflow port 106. A waste assembly 108 can slip in-and-out and twist inside a first telescoping section 110 of a waste T-fitting 112. Similarly, an overflow assembly 114 can slip in-and-out and twist inside a second telescoping section 116 of waste T-fitting 112.

[0013]Both the waste assembly 108 and overflow assembly 114 require no nuts, clamps, or collars to be tightened in order to maintain water-tight seals within respective telescoping sections 110 and 116. Instead, any number of different acceptable methods can be employed to seal the joint connections. For example, FIG. 1 shows two sets of O-ring seals, 120 and 122, and 124 and 126. In alternate embodiments just one O-ring may be used, and in other embodiments stops may be provided to prevent the telescoping p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com