Locking intramedullary jig

a technology of locking and intramedullary jigs, applied in the field of alignment jigs, can solve the problems of slipping, affecting the adjustment function, and the amount of torque that can be applied, and achieves the effect of precise adjustment and easy adjustment of the adjustment and locking function for the user

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

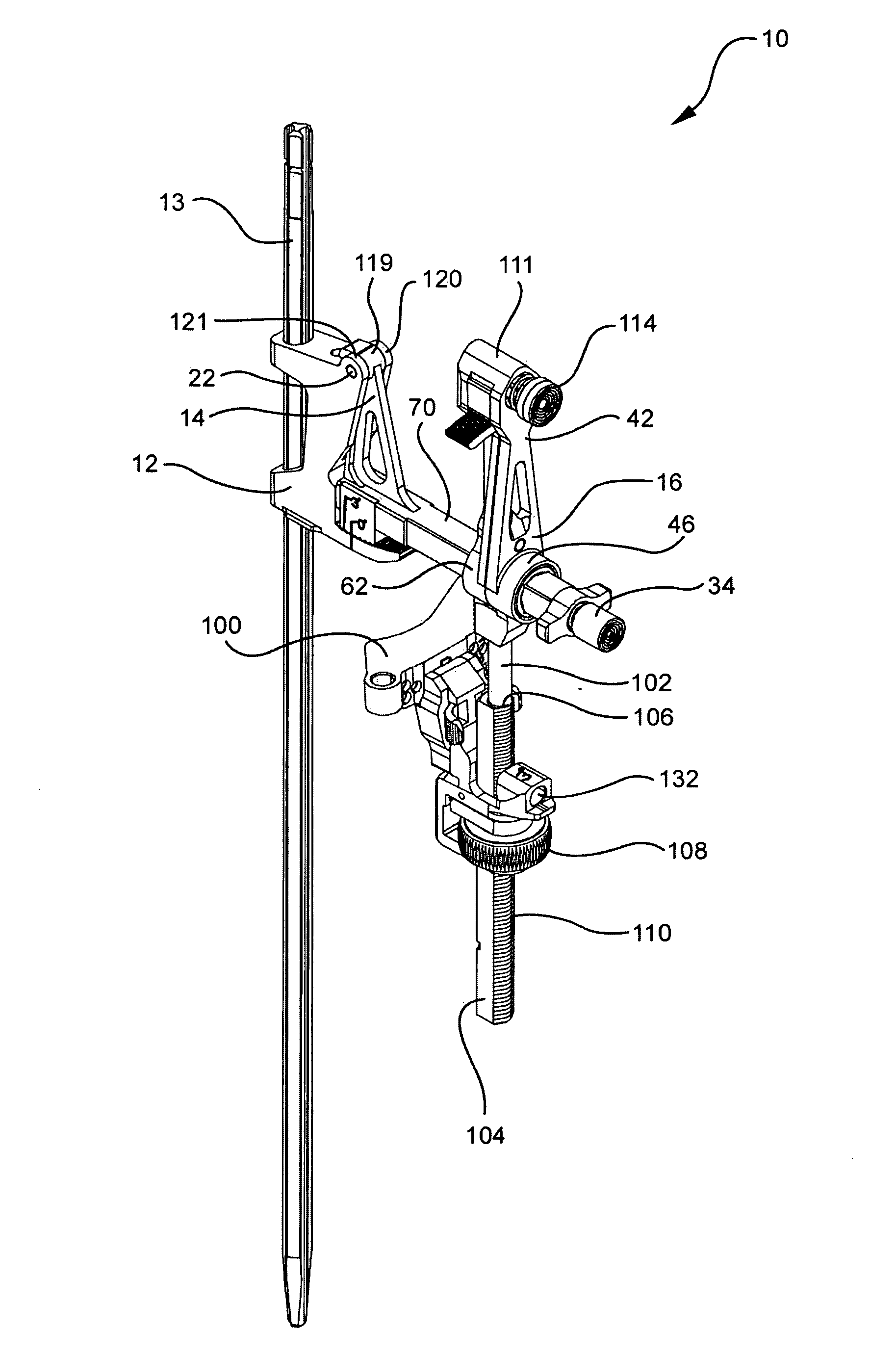

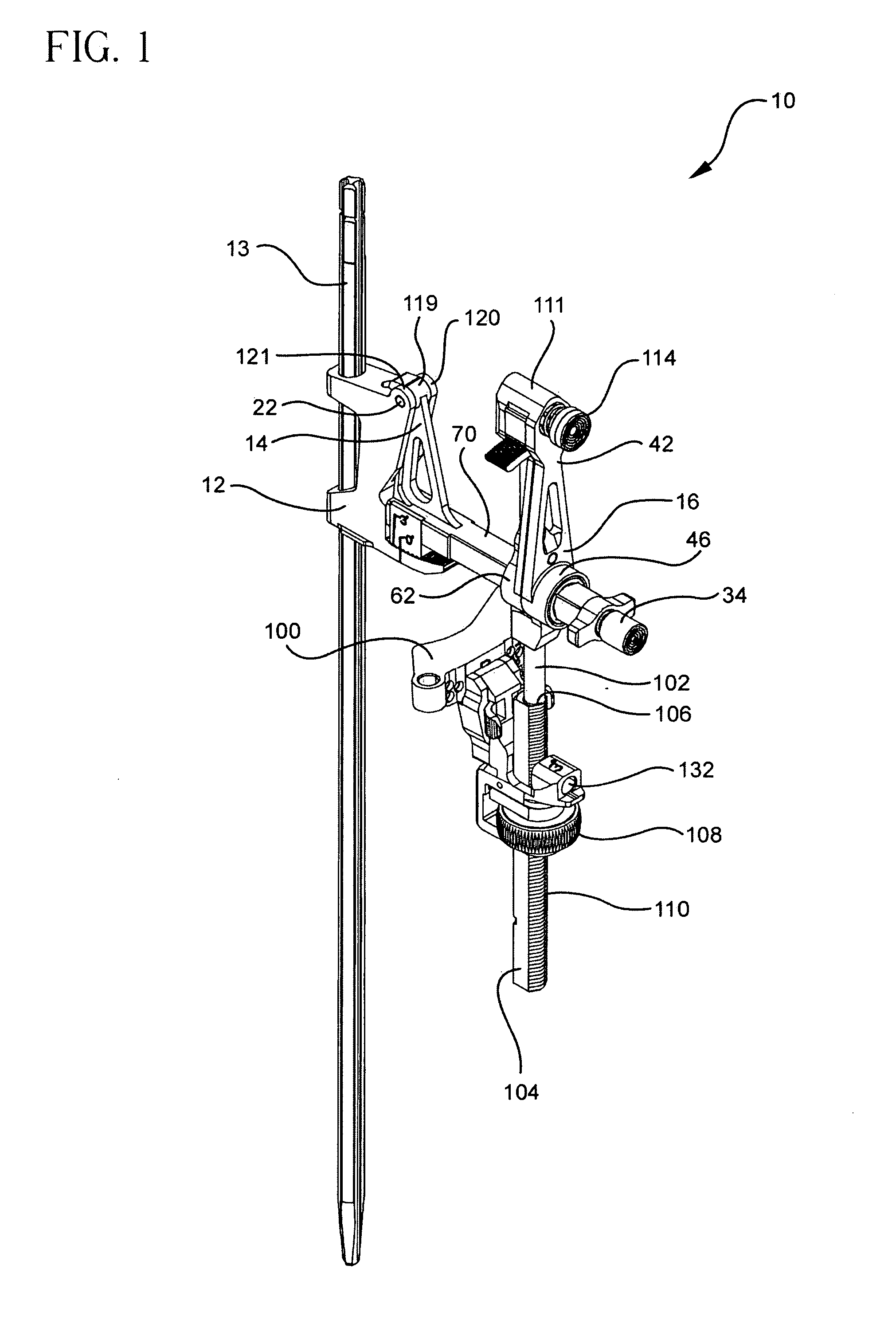

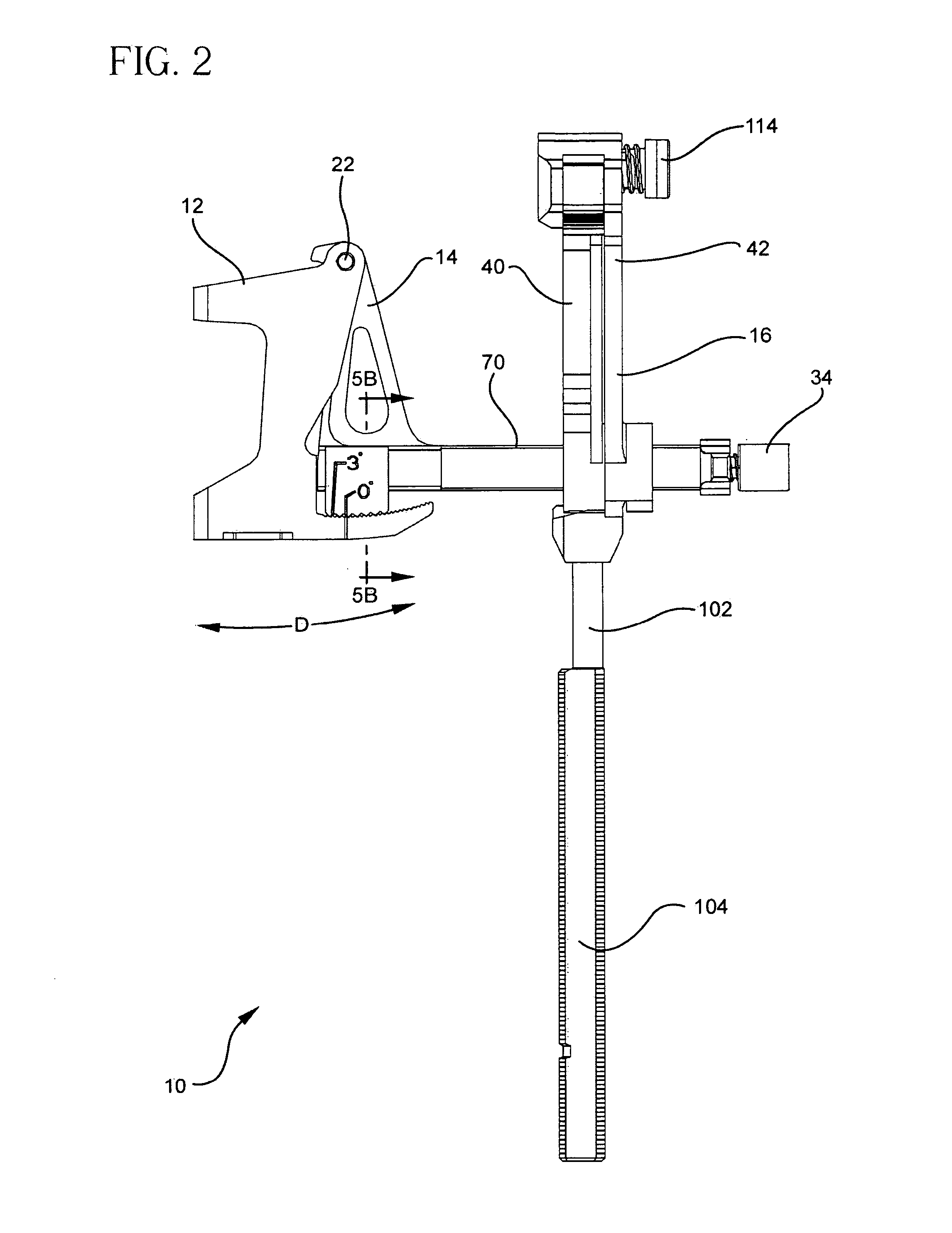

[0024]Referring to FIGS. 1 to 4 there is shown the tibial jig of the present invention generally denoted as 10. Jig 10 consists of an assembly containing three main functional elements: a main anchoring block 12, which connects to an IM rod 13 via bore 18 for sliding movement therealong. A first rotatable body or arm 14 is pivotally coupled to block 12 to adjust flexion-extension settings and a second body or arm 16 which includes a rotating part 42. Rotatable part 42 is coupled to slide block 12 via body 14 to adjust varus-valgus settings. Body 16 may be connected, either directly or indirectly via body part 14 to slide block 12. IM rod 13 is inserted into the medullary canal of a long bone such as the tibia (not shown) in a standard manner.

[0025]Cutting jig 10 further includes a cutting guide block 100 mounted thereon for vertical, i.e. proximal-distal movement with respect to a rod 104 mounted on body part 16. Block 100 is slidably adjusted along the length of a rod 104 and can b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com