Structural column wrap assembly

a wrap assembly and structure technology, applied in the direction of scaffold accessories, washstands, lighting support devices, etc., can solve the problems of difficulty in offsetting, and labor-intensive installation of the wrap assembly, and achieve the effect of easy and inexpensive assembly and easy installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

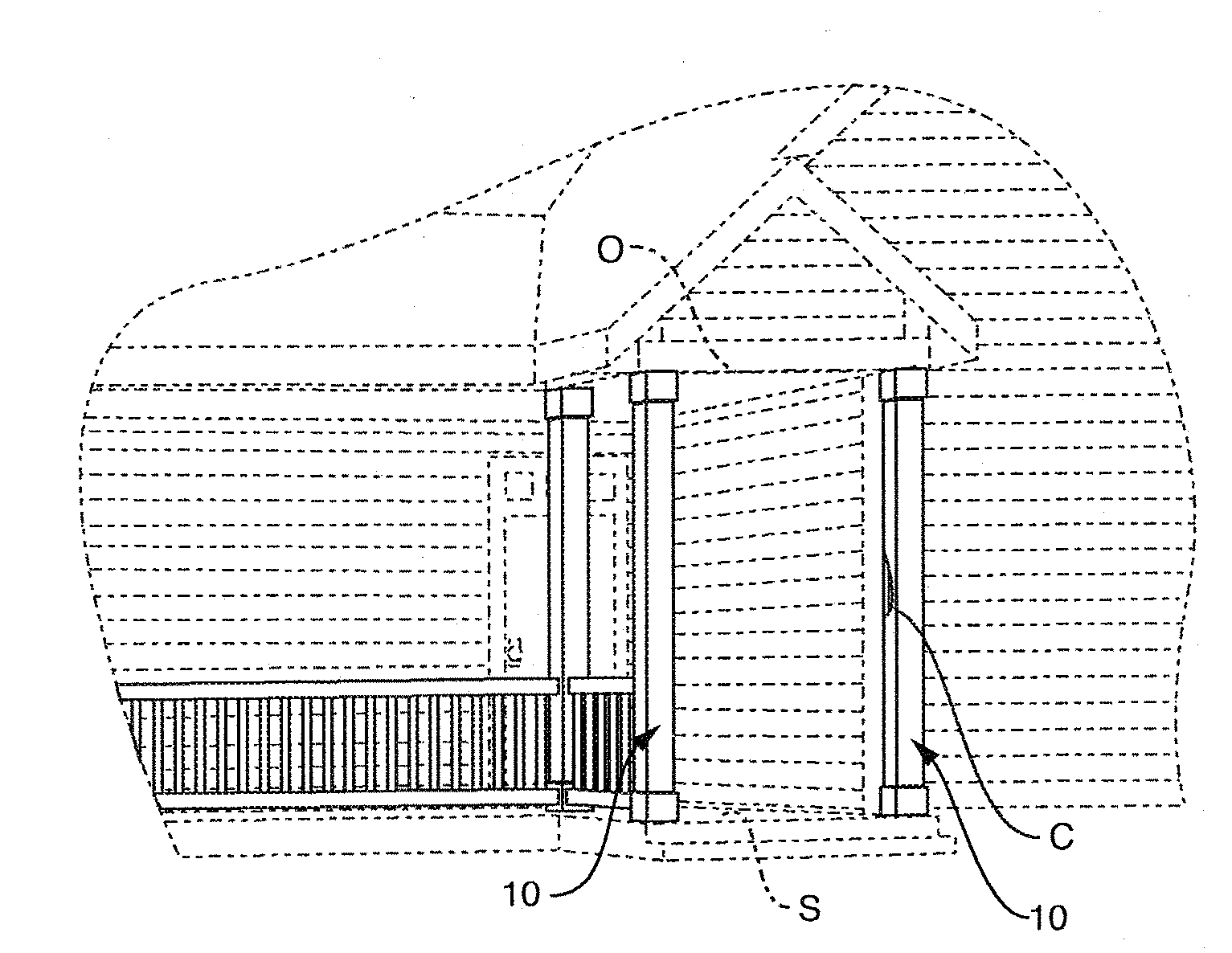

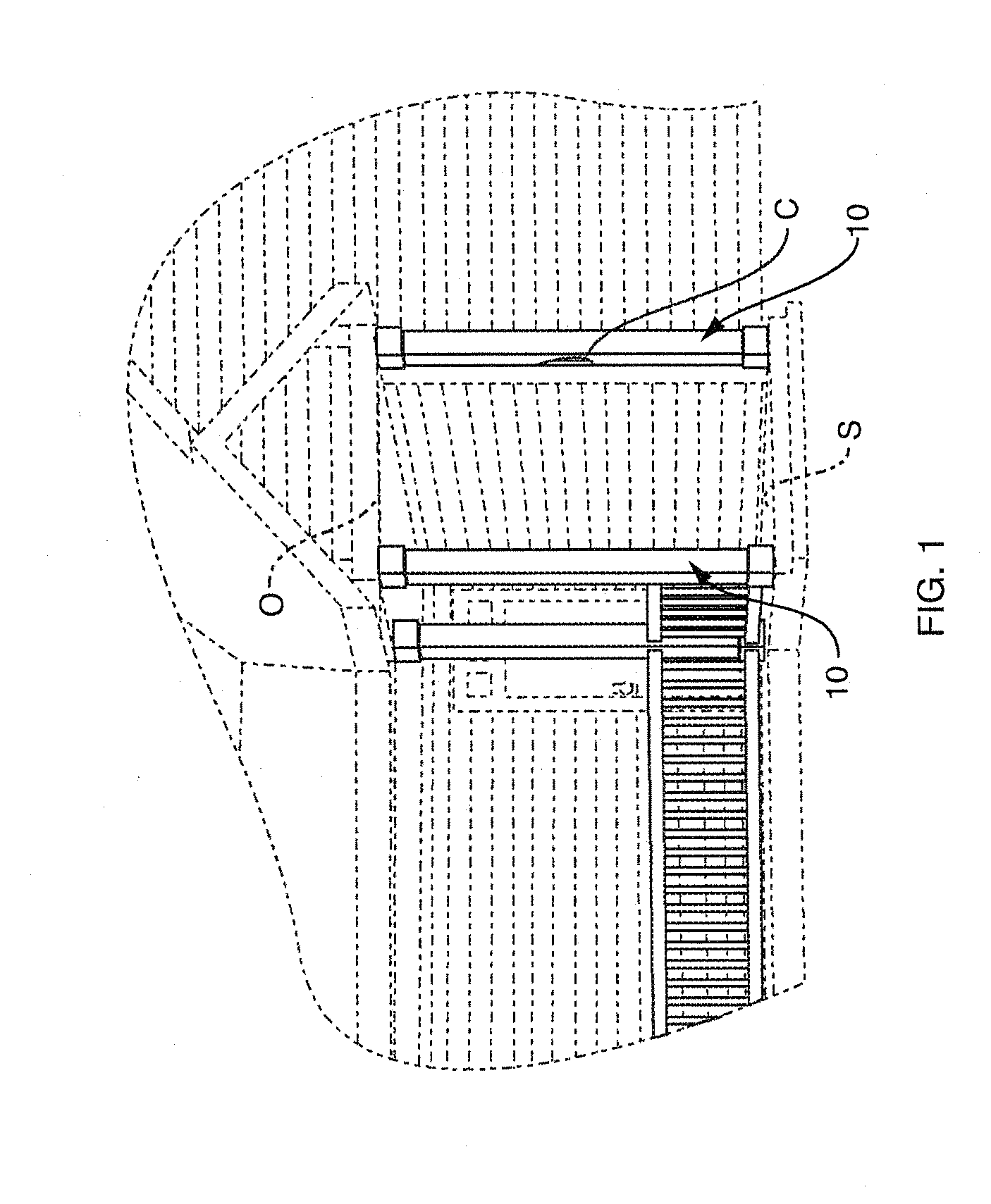

[0025]Referring to the drawing, FIG. 1 illustrates an entryway comprising a plurality of vertical structural or support columns C extending between a support surface S such as a floor or deck and an overhead support O such as a ceiling or beam. Each column C, e.g. a 4×4 in. length of wood, is covered by a column wrap assembly shown generally at 10 which adds apparent girth to the column and provides a smooth, paintable and / or decorative exterior surface around the otherwise unfinished column.

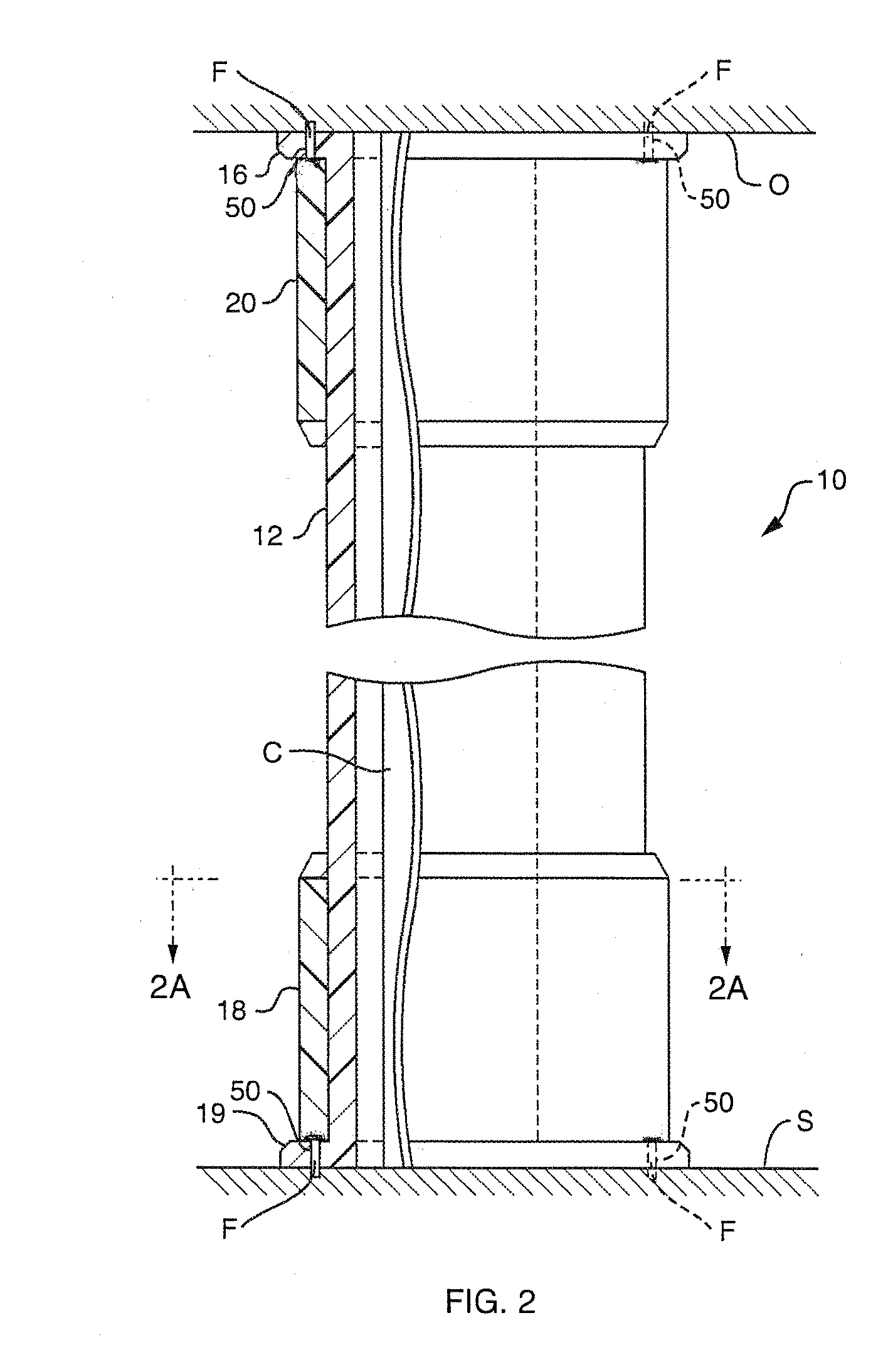

[0026]Referring to FIG. 2, each column wrap assembly 10 comprises a tubular shaft 12 having an integral exterior fastening cleat 14 at its lower end. A second, annular fastening cleat 16 is provided at the upper end of the shaft but which, as we shall see, is separate from the shaft. Suitable fasteners F may be driven through cleats 14 and 16 into support surface S and the overhead support O, respectively, to fix the position of shaft 12 with respect to column C.

[0027]In order to add decorative ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Electrical resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com