Zipper head structure

a zipper head and zipper technology, applied in the direction of snap fasteners, slide fasteners, press-button fasteners, etc., can solve the problems that the conventional zipper head b>10/b> is not convenient when opening or closing the zipper

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

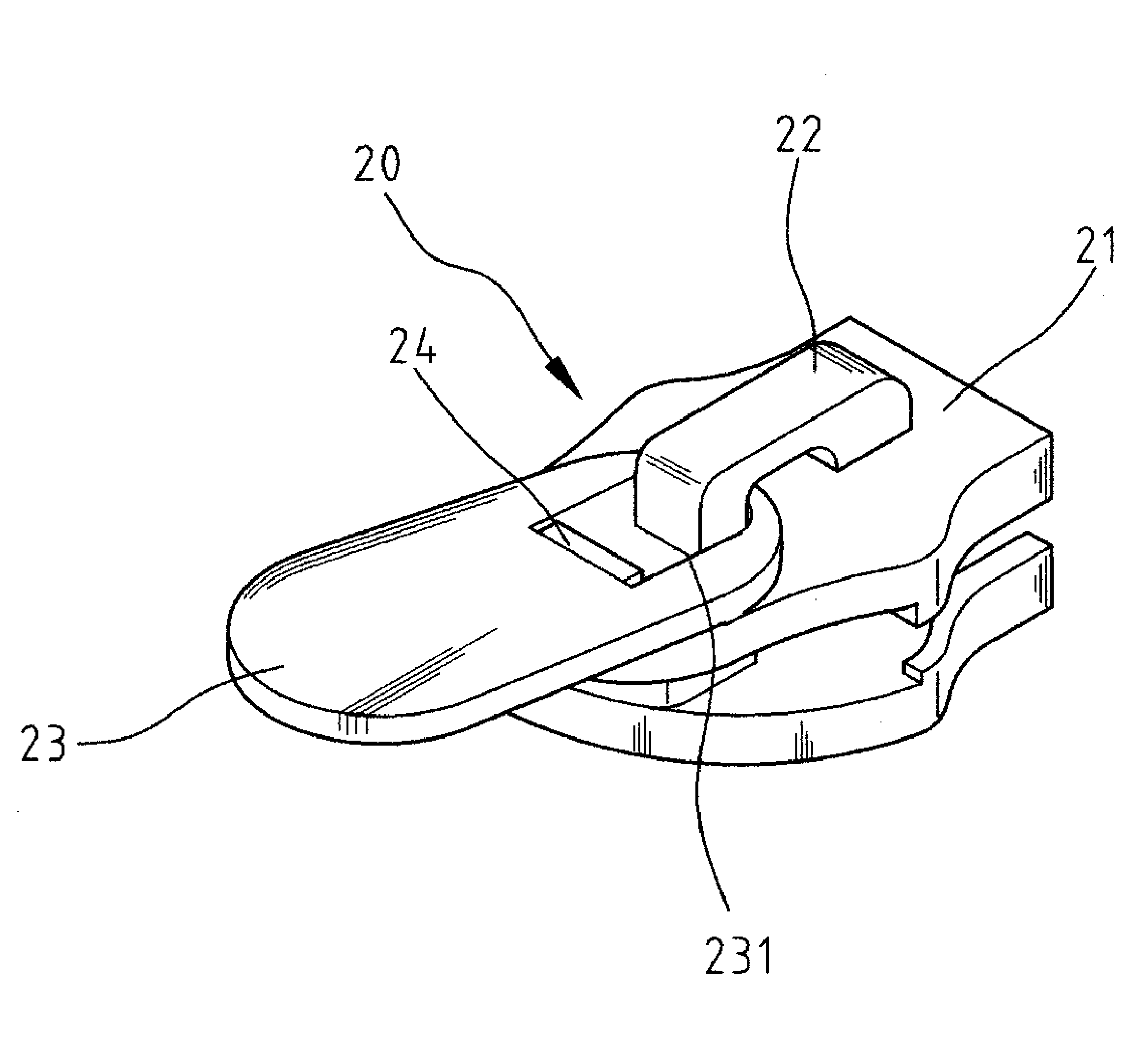

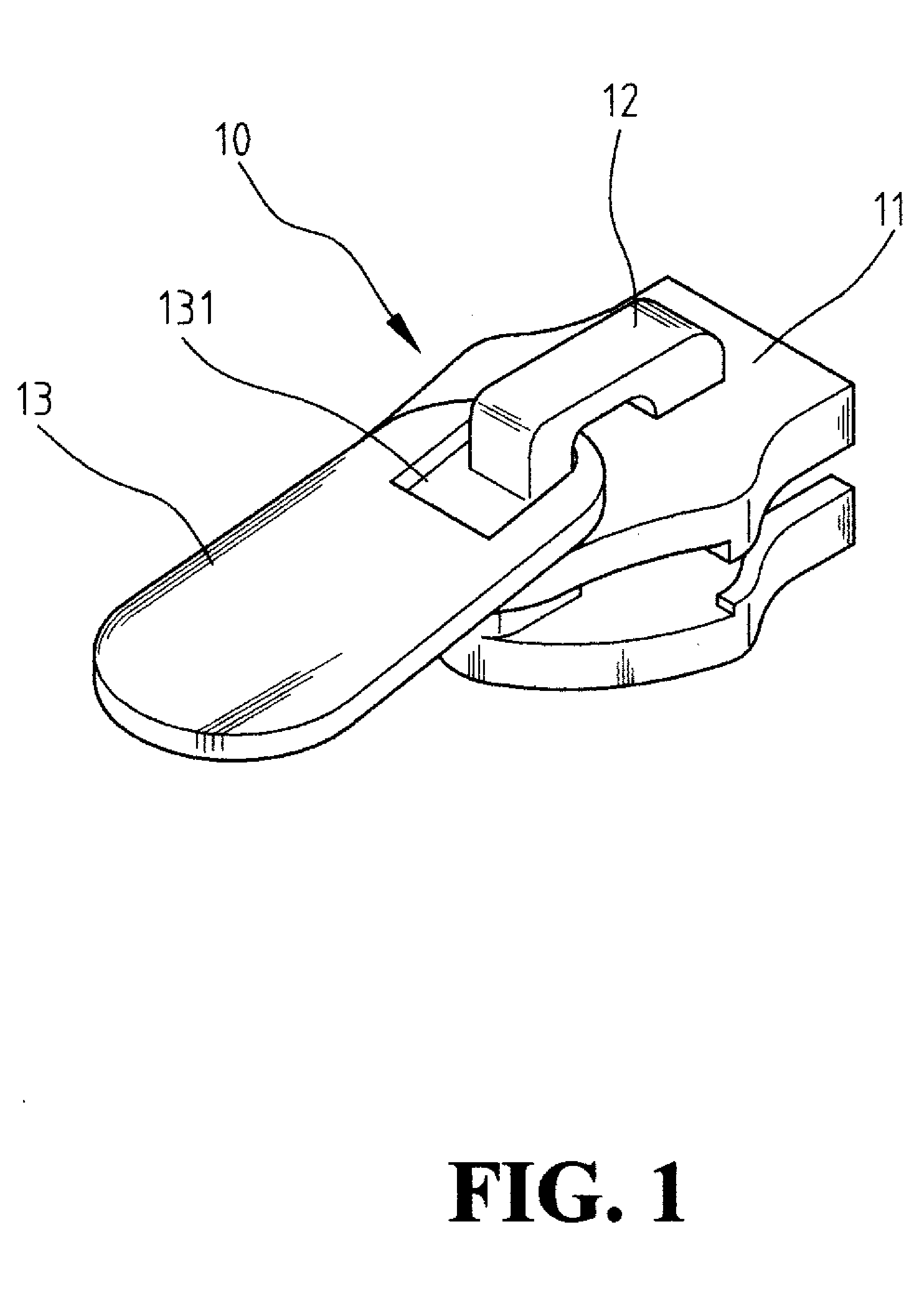

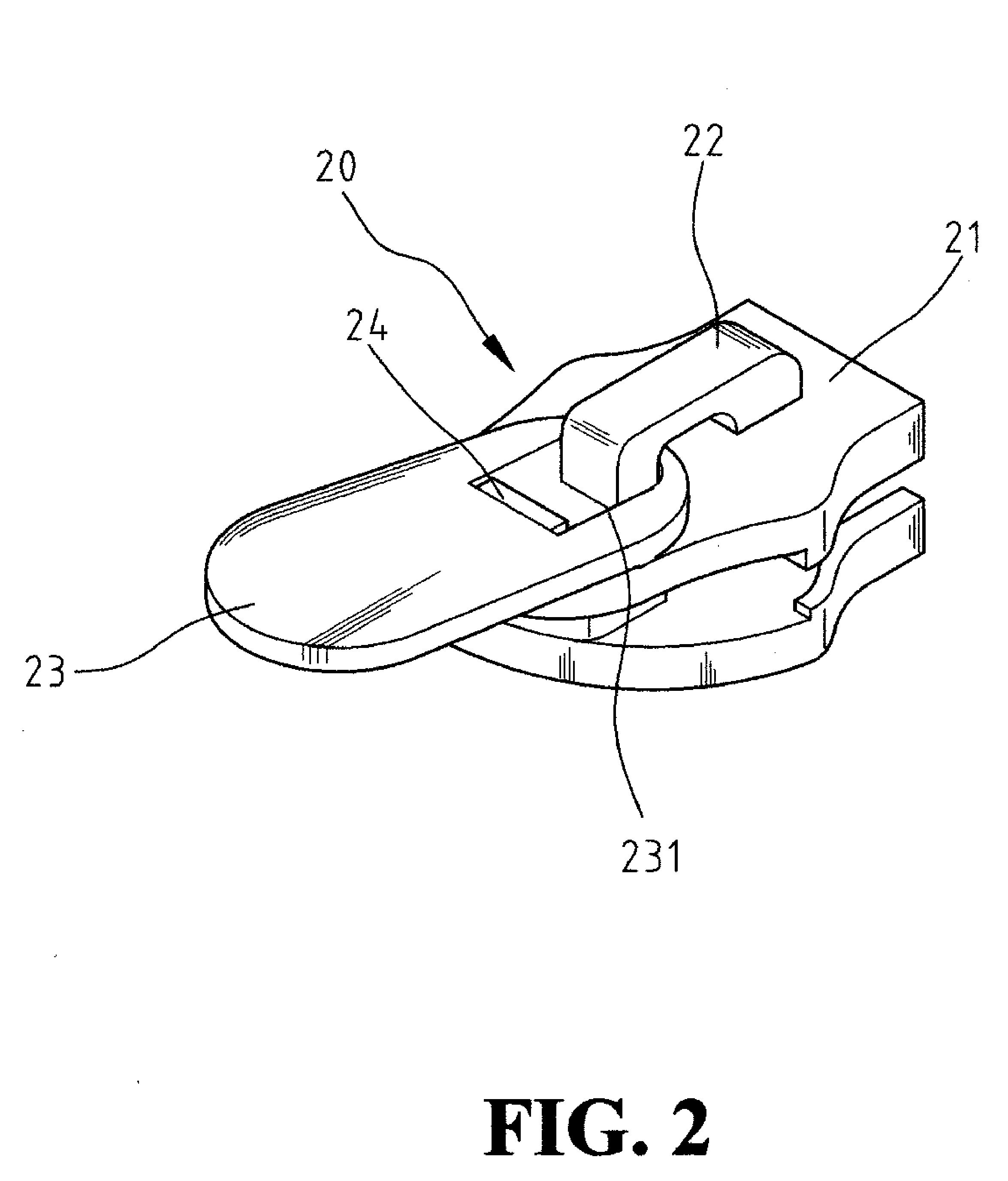

first embodiment

Please refer to FIG. 4, which shows a lateral view of first embodiment of the present invention. The blocker 24 is a wedge shape whose bottom gradually becomes smaller toward its top and the direction of the wedge could be from left to right or from front to back. In the embodiment, the blocker 24 has a first inclined surface 241 inclines upwards toward the rear end of the pull tag 20. When the pull tag 23 is put down, it first encloses the top end of the blocker 24, and when the pull tag 23 is further laid down, it engages on the first inclined surface 241 because of the slope of the inclined surface 241 and thereby the pull tag 23 is set in a predetermined angle (please refer to FIG. 5). Please refer to FIG. 6, following the same principle, a second inclined surface 242 of the blocker inclines upwards towards the front end of the blocker 24. The pull tag 23 has an engaging hole 232 corresponding to the second inclined surface, therefore, when the pull tag is released, the pull tag...

second embodiment

[0020]FIG. 6 shows a view of the present invention.

[0021]FIG. 7 shows a view of a second embodiment of the present invention after the pull tag eased.

third embodiment

[0022]FIG. 8 shows a view of the present invention.

[0023]FIG. 9 shows a view of a forth embodiment of the present invention.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com