Oven or Grill Burner

a technology of oven or grill, which is applied in the direction of combustion process, heating fuel, application, etc., can solve the problems of obviating the drawback associated with proper positioning, affecting the quality of the oven, so as to facilitate assembly and speed up the manufacturing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

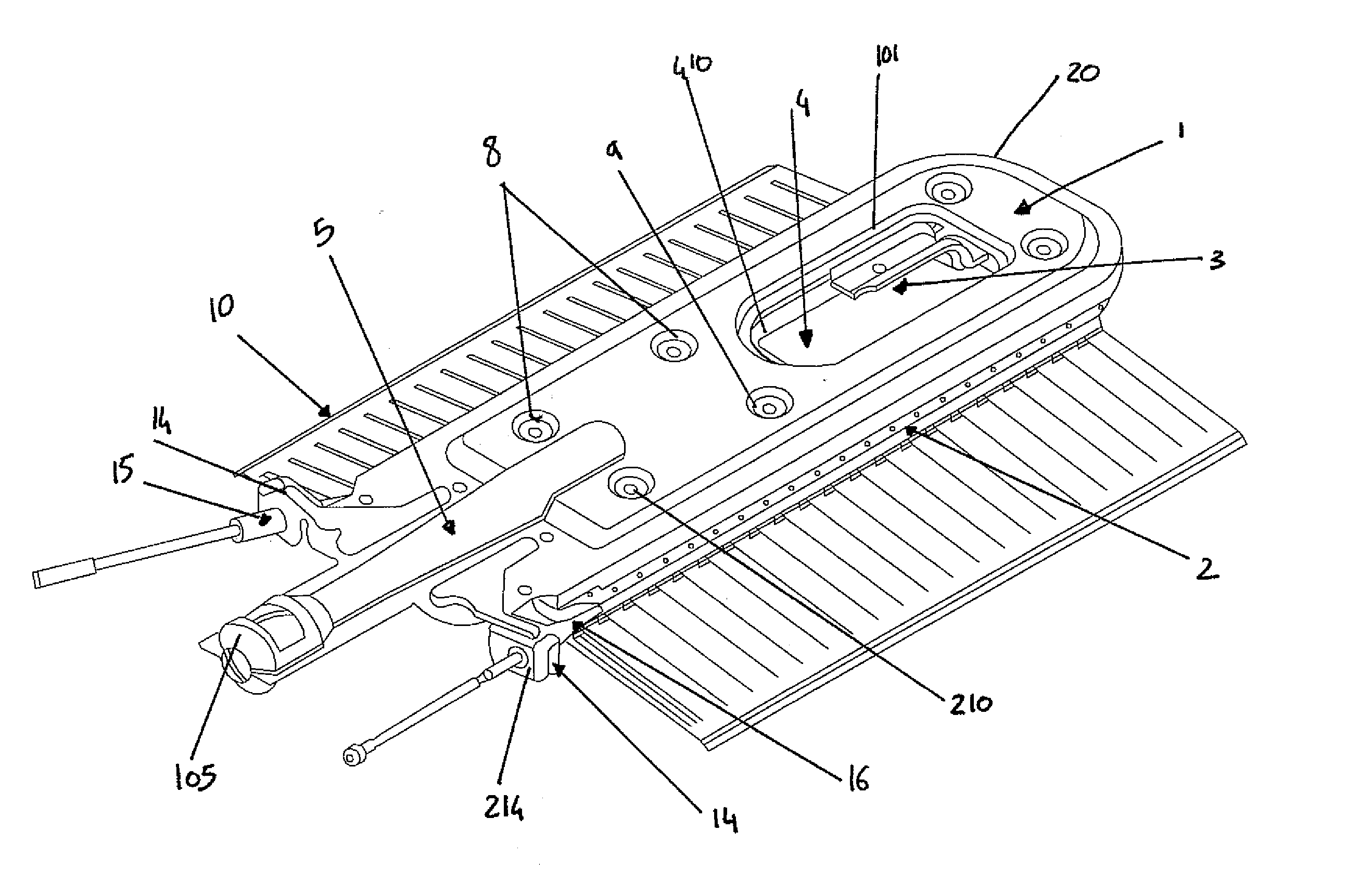

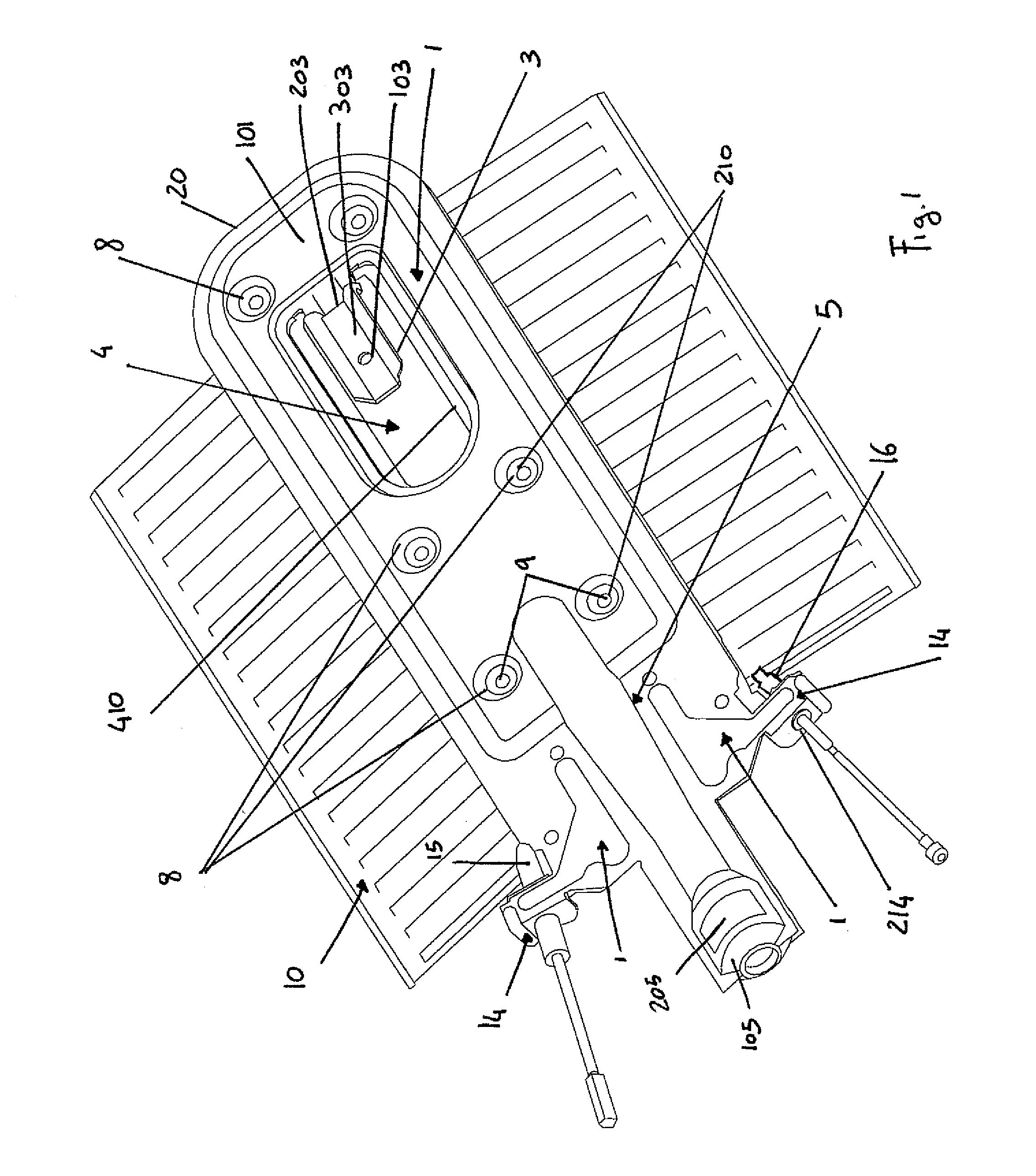

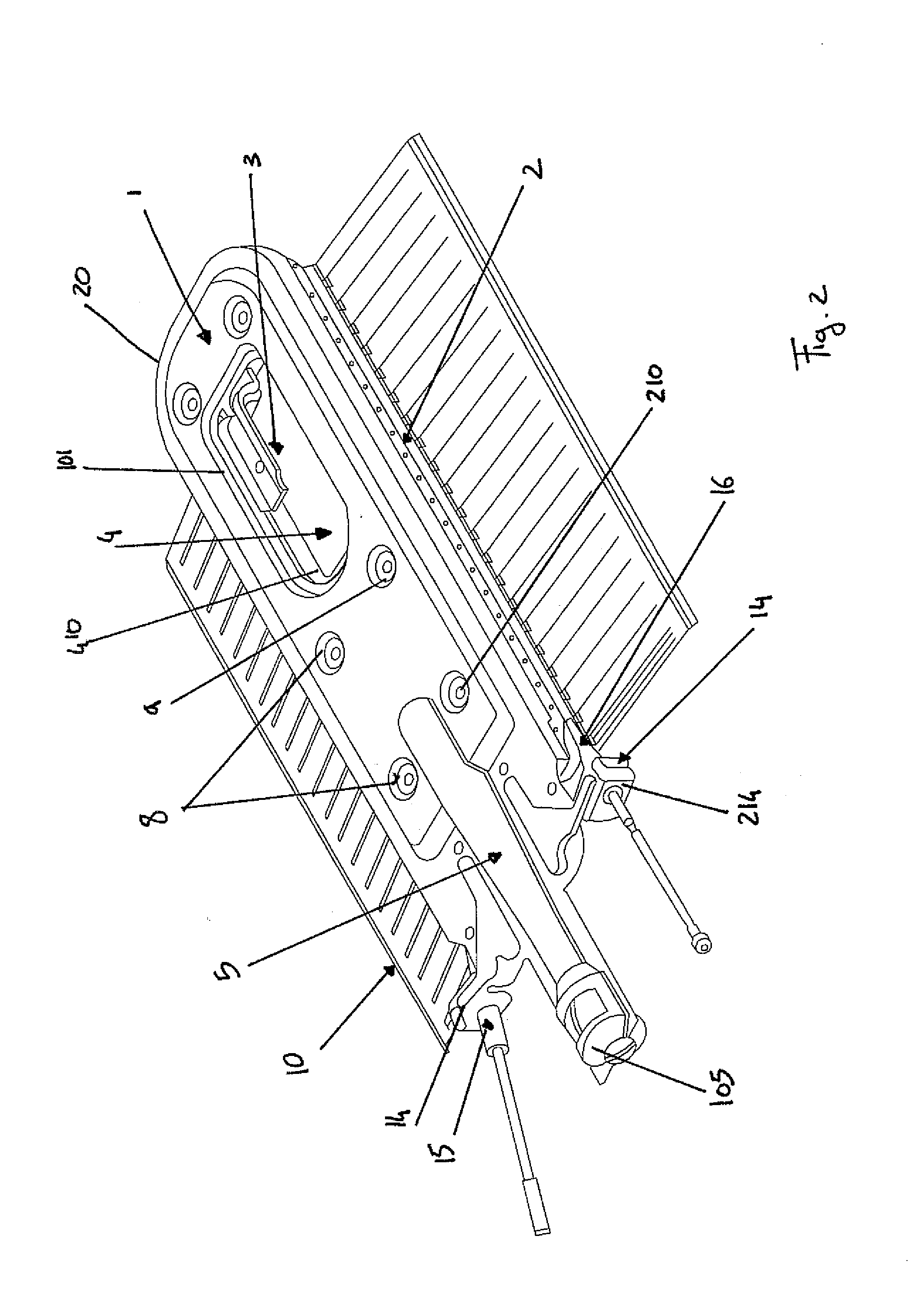

[0036]The preferred embodiment of a burner according to the present invention is composed of two half shells mechanically tightly connected together by the mutual bending and pressing of flanges.

[0037]It should be understood that the present description of the preferred embodiment is not limitative of the features of a burner according to the present invention, which can be also be manufactured by other techniques.

[0038]With reference to the figures, the preferred embodiment of a burner according to the present invention includes a first upper half shell and a second lower half shell indicated by 1 and 2 respectively. In this regard, it shall be noted that the words upper and lower are used herein in relation to a burner fitted inside the oven on the bottom wall or immediately beneath the top wall thereof (grill). The two half shells 1, 2 are elongated and respectively have an upper face 101 and a lower face 102 and peripheral outer edges that can be mechanically and tightly connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com