Integrated fixing frame for a solar energy module

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017]While this invention is capable of embodiment in many different forms, shown in the drawings and herein described in detail is the preferred embodiment of the invention. The preferred embodiment is disclosed with the understanding that the present description is but one example of the principles of the invention and is not intended to limit the broad aspects of the invention to the single embodiment illustrated.

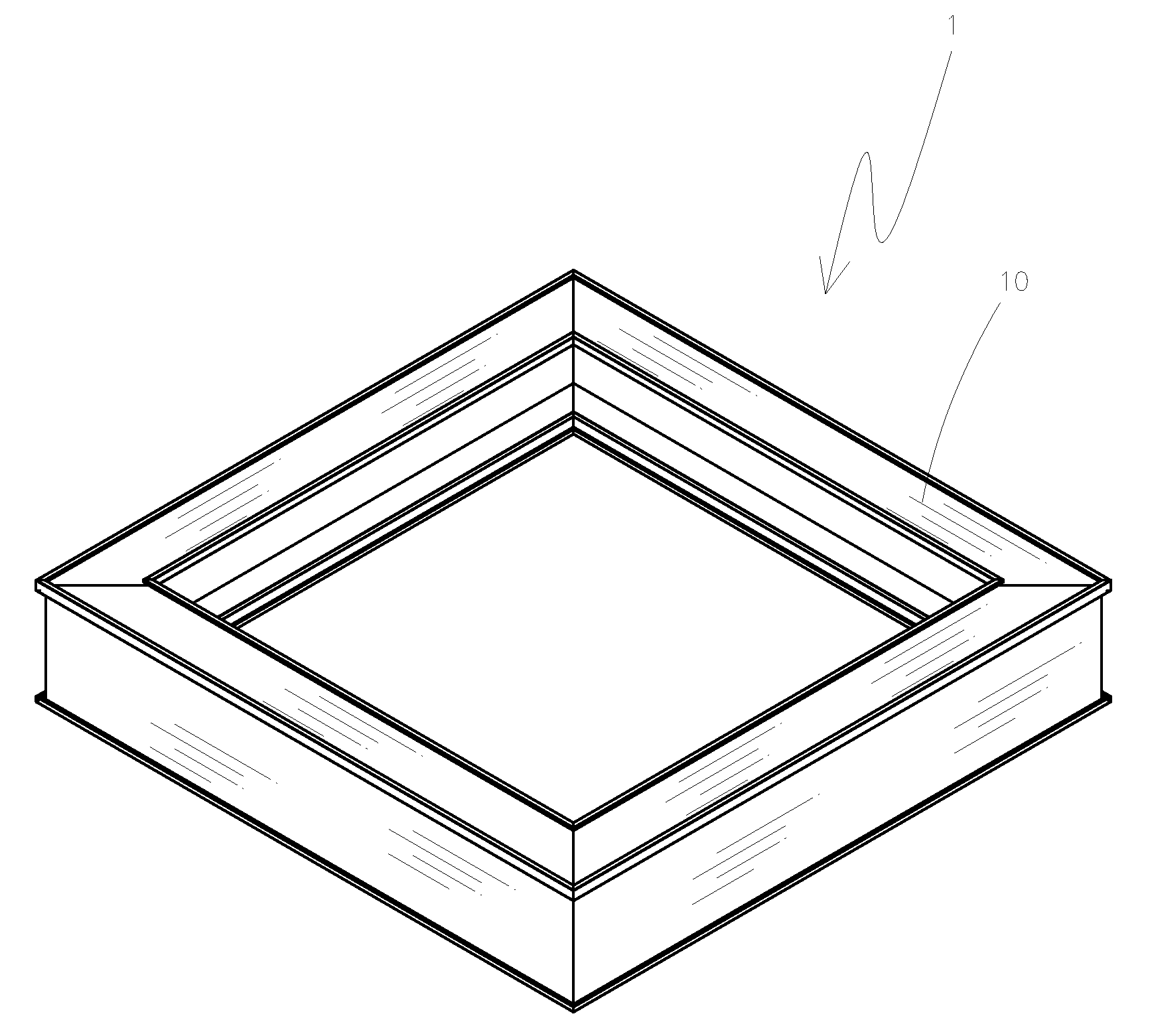

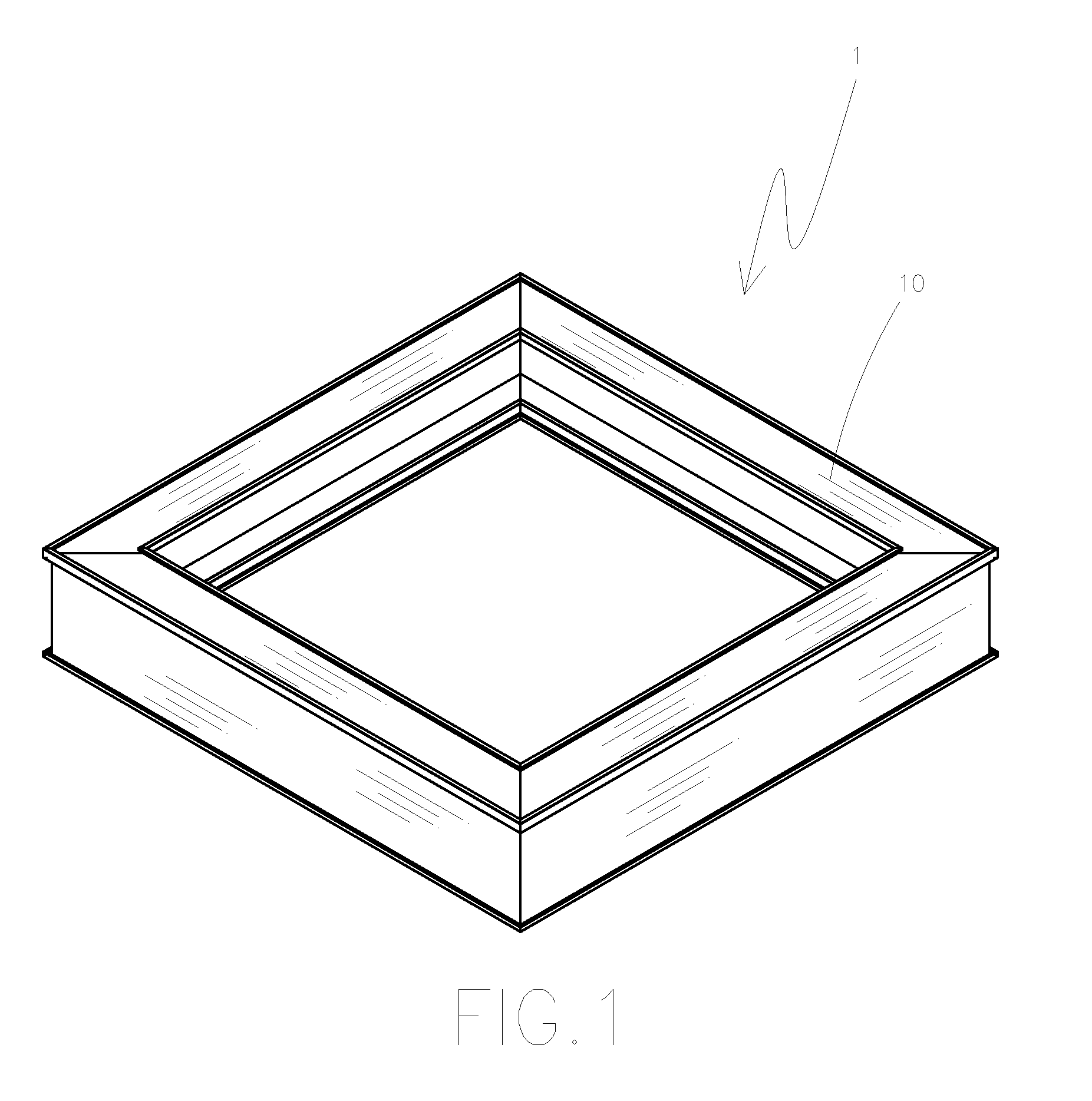

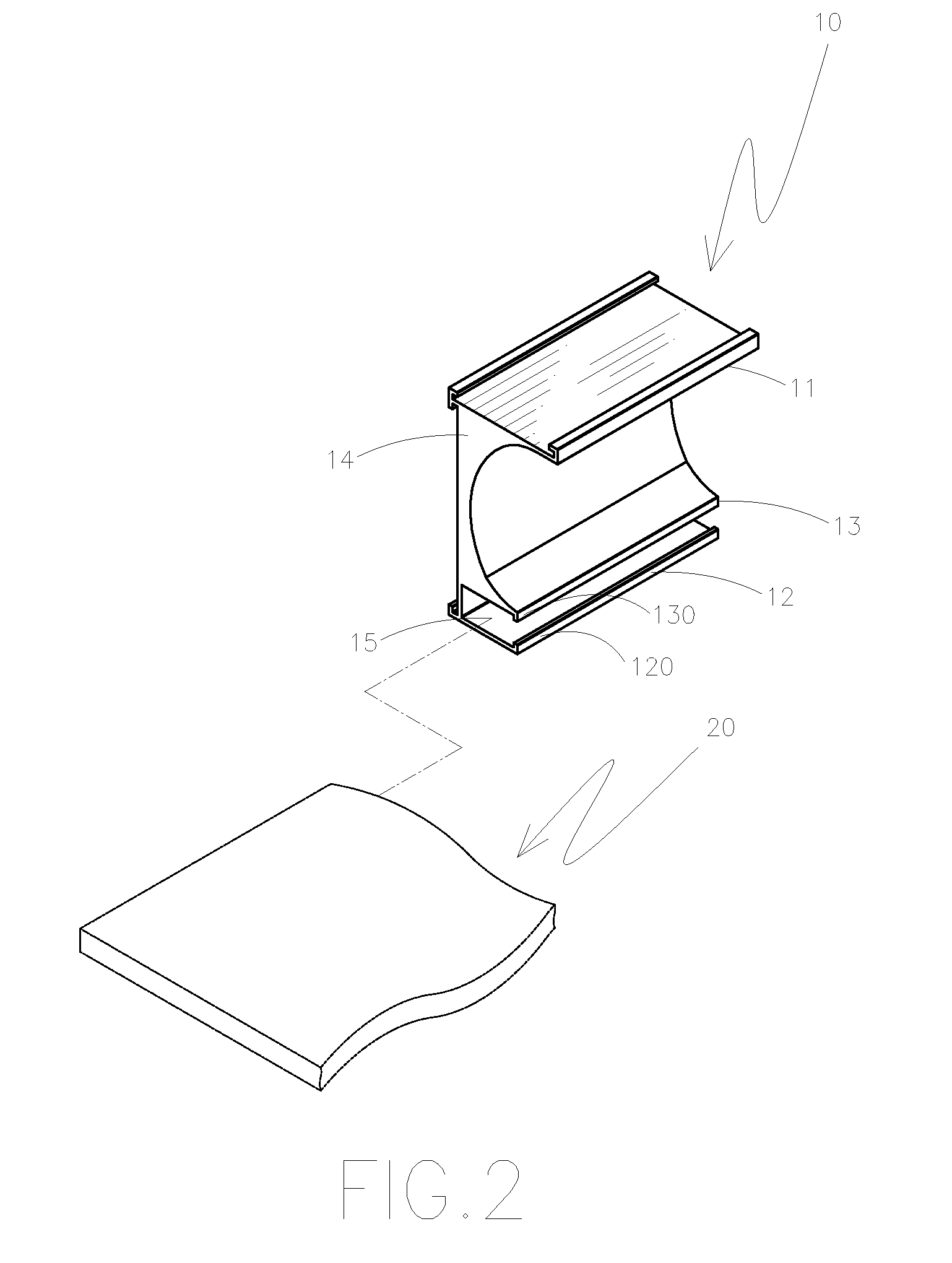

[0018]FIGS. 1 to 3 are perspective, segmented perspective and sectional views schematically showing a fixing frame for a solar energy module of the present invention.

[0019]The frame comprises:

[0020]a frame body 1 having a plurality of assembling frames 10;

[0021]a plurality of assembling frames 10, each of them further comprises a first sideboard 11 and a second sideboard 12. Between the first sideboard 11 and the second sideboard 12, an inner board 13 is installed closing to the second sideboard 12. A curving rib 14 is installed in between the first sideboard 11 and the...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap