Washing and drying machine

a technology of washing machine and drying chamber, which is applied in the direction of washing machine with receptacle, other washing machines, textiles and paper, etc., can solve the problems of increasing energy consumption for drying the laundry, increasing sudden rise of energy costs such as electric charges, so as to reduce the contact time between the laundry and the heated air, the effect of efficient evaporated laundry

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

embodiment 1

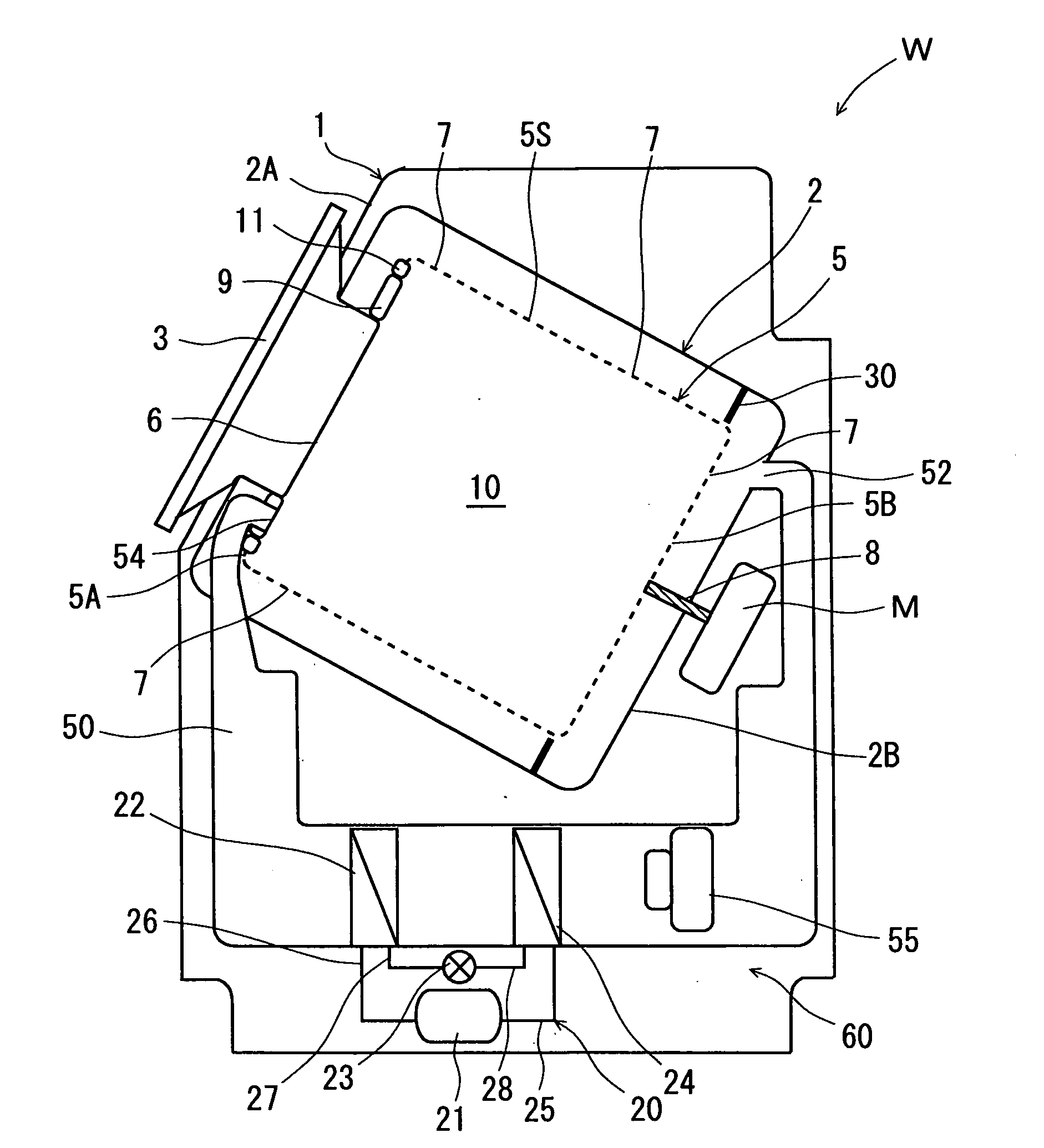

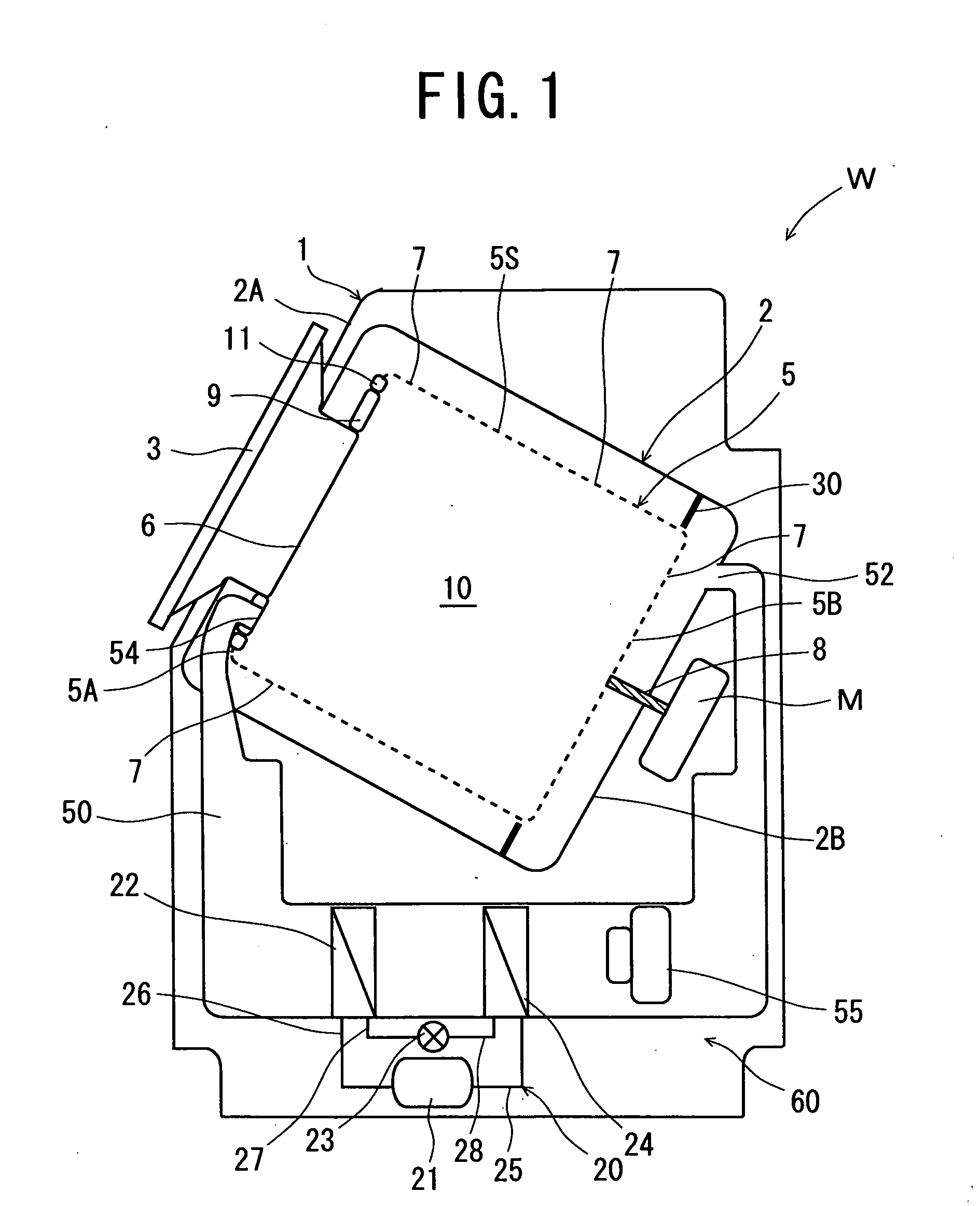

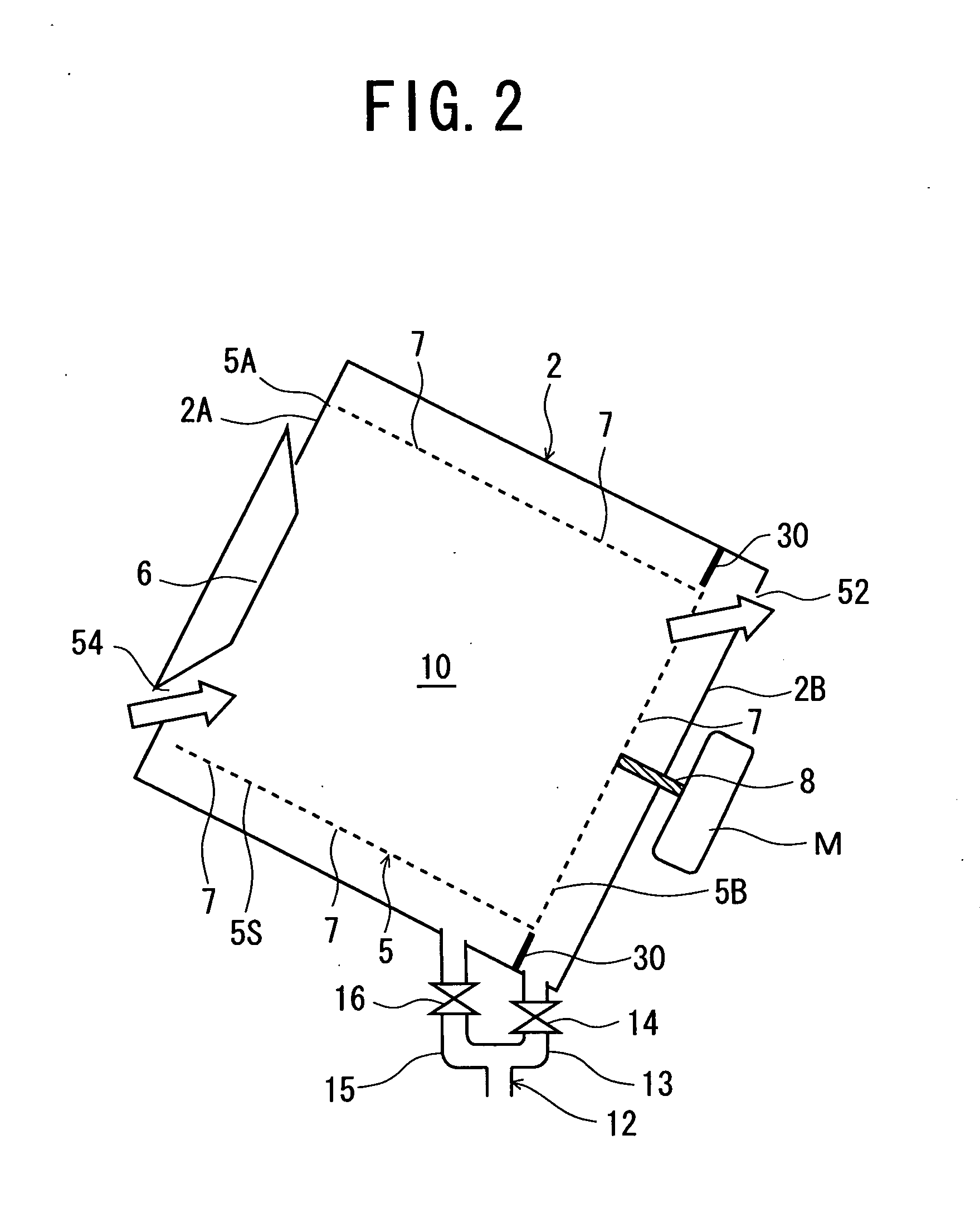

[0031]FIG. 1 is a diagram showing a schematic constitution of a washing and drying machine W according to one embodiment of the present invention, and FIG. 2 is a diagram schematically showing a part of the washing and drying machine W. The washing and drying machine W for use in washing and drying a laundry such as clothing is provided with an opening / closing door 3 which is attached to an upper part of a side surface of a main body 1 forming an outer shell and which openably closes a takeout port 6 for taking or introducing the laundry. An operation panel (not shown) provided with various operation switches and a display section is provided on a side part of the opening / closing door 3 or an upper part of the main body 1.

[0032]In the main body 1, a cylindrical outer drum 2 capable of receiving water and made of a resin is provided so that a cylindrical shaft of this outer drum 2 is disposed in an oblique direction. Then, inside this outer drum 2, a substantially cylindrical inner d...

embodiment 2

[0077]It is to be noted that in Embodiment 1 described above, the blowing regulation means is constituted of the partition wall 30 for dividing the space between the outer drum 2 and the inner drum 5 into the other end 5B side from which the air for drying flows and the other part. However, the present invention is effective, even when an opening / closing member for openably closing through holes 7 . . . around a side surface 5S of an inner drum 5 constitutes the blowing regulation means. FIG. 10 is a schematic diagram showing an outer drum 2 and the inside of the drum in a washing and drying machine Y according to this embodiment. In the present embodiment, an opening / closing member to openably close the through holes 7 . . . around the side surface 5S of the inner drum 5 is constituted of a plurality of valves 80 . . . . It is to be noted that the washing and drying machine Y of the present embodiment is different from the washing and drying machine W of Embodiment 1 described abov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com