Low and reverse pressure application hydrodynamic pressurizing seals

a technology of hydrodynamic pressure and low pressure, applied in the direction of engine seals, mechanical equipment, engine components, etc., can solve the problems of chemical modification of oil, adverse to the performance of the equipment where the seal is used, and affecting the performance of the gas turbin

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

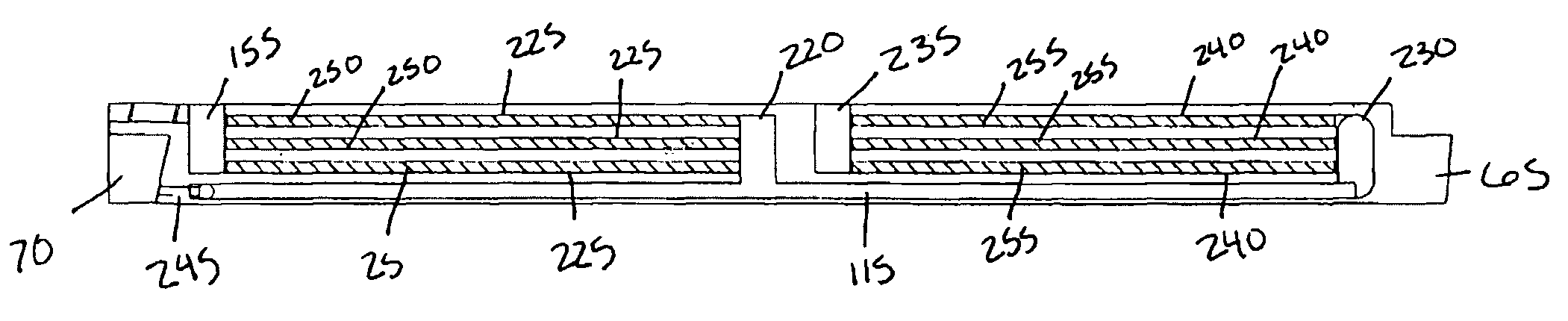

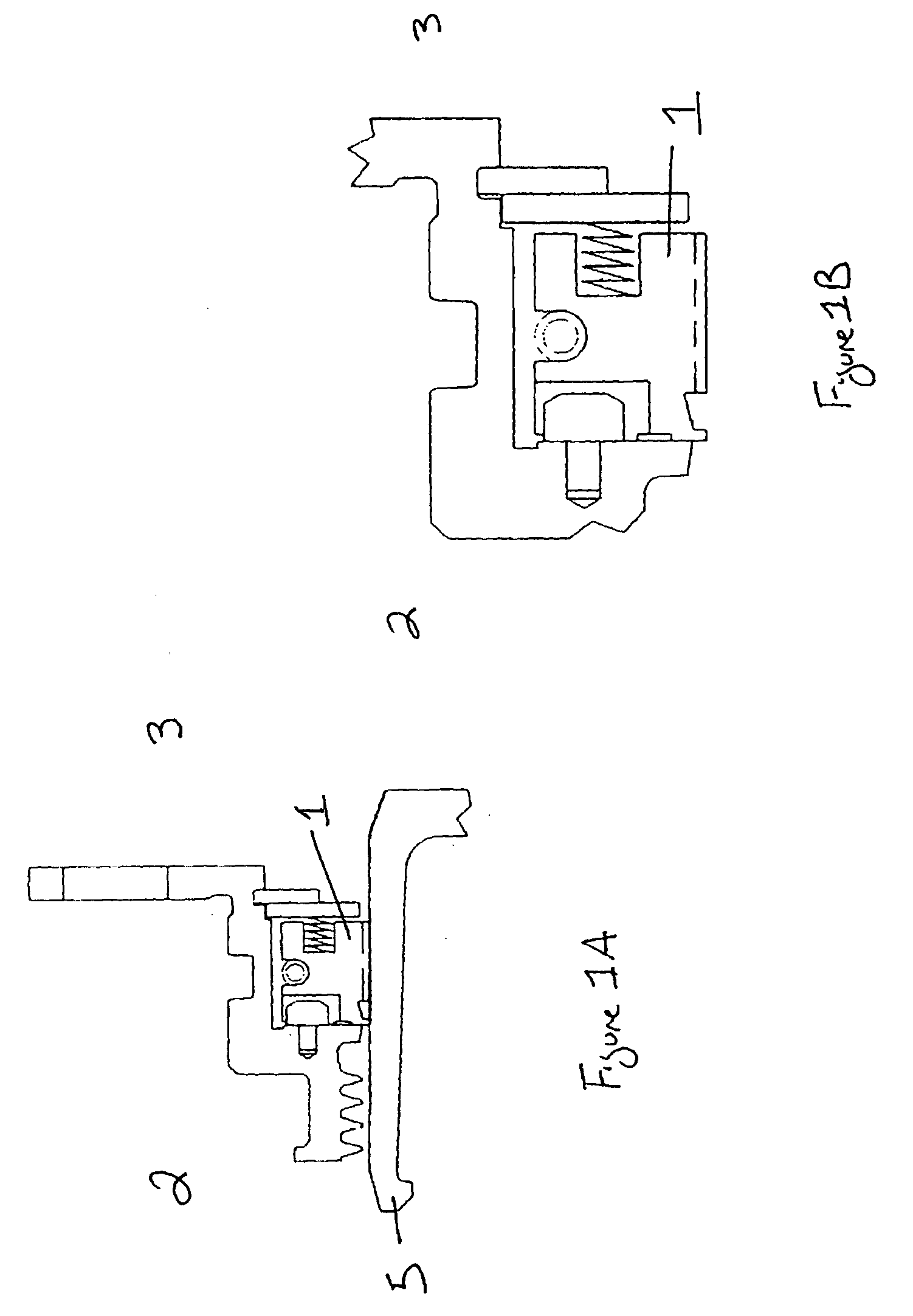

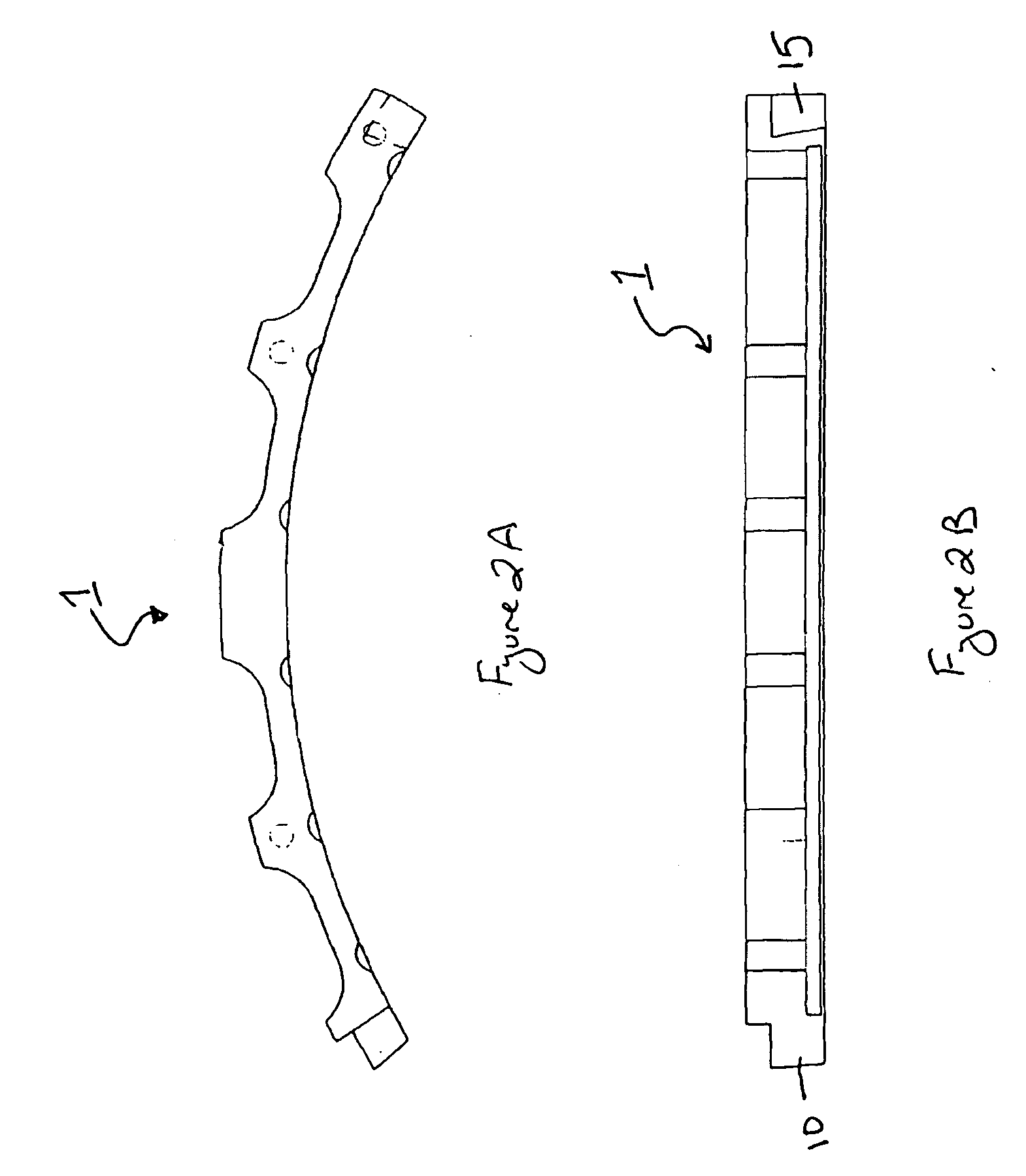

[0045]The seal ring segments 60 are specifically machined to contain a plurality of grooves along a shaft-side face of the each segment such that these grooves generate high gas pressures across seal rings and the shaft. This increased pressure prevents fluid from leaking within spaces between the shaft 40 and the seal segments 60 during the operation of the shaft 40. In a first embodiment the grooves along the shaft-side face 110 of the seal segments 60 are a dead end circumferential groove 115 and at least one or a plurality hydrodynamic inclined pumping grooves 105. The circumferential dead end groove of each segment extends along the longitudinal axis of the shaft-face of the ring segment 60 such that, when the segments are linked, the dead end circumferential groove extends arcuately in the direction of shaft rotation. Preferably, a bore dam is spaced between the dead end circumferential groove and the lubricant side of the chamber. The width and depth of the grooves 115 and 10...

second embodiment

[0057]In the present invention, referring to FIGS. 9A and B, the additional grooves along the shaft-side face 110 of the seal 60 are formed by at least one hydrodynamic shallow pocket 129, comprised of a pocket 130, inlet 135 and outlet 140, and a dead end circumferential groove 115. Specifically, the pockets 130 may be substantially square shaped, as illustrated. However, the pocket is not limited to this configuration. Rather, the pocket 130 may be rectangular, circular, oval, or any other aerodynamic and / or hydrodynamic configuration understood in the art. Extending from one end of each pocket 130 which is distal to the dead end circumferential groove is an inlet 135 wherein the inlet 135 extends from the pocket 130 such that it is adapted to receive fluid flow from the rotatable shaft, as discussed below. Extending from an opposing end of each pocket 130, which is proximal to the dead end circumferential groove 115, is an outlet 140 wherein the outlet 140 places each pocket 130 ...

third embodiment

[0065]In the present invention, referring to FIG. 11, the additional grooves along the shaft-side face of the seal 60 is at least one axial bore groove 155, which extends perpendicularly to the longitudinal axis of the seal segment, and a dead end circumferential groove 115. The axial bore groove 155 is desirably on one end of the seal segment 60 that is proximal to the segment's tongue 65. However, the present invention is not limited to this embodiment. The axial bore groove 155 may be substantially square or rounded with a depth within the range of 0.0005 to 0.035 inches wherein the depth is desirably between 0.20 to 0.025 inches in depth. The depth of the axial bore groove 155 may be dependent upon multiple factors including, but not limited to, the engine application, shaft rotational speeds, desired seal life and the like. The axial bore may also be aerodynamically or hydrodynamically tapered such that air flow generated by the rotation of the shaft is received by the axial bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com