Liquid-crystal display device and method of fabricating the same

a liquid crystal display and display device technology, applied in non-linear optics, instruments, optics, etc., can solve the problems of inability to read markers formed in the non-display region, inability to read markers on the panel, and inability to read markers, so as to minimize the enlargement of the picture frame region of the lcd panel due to markers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

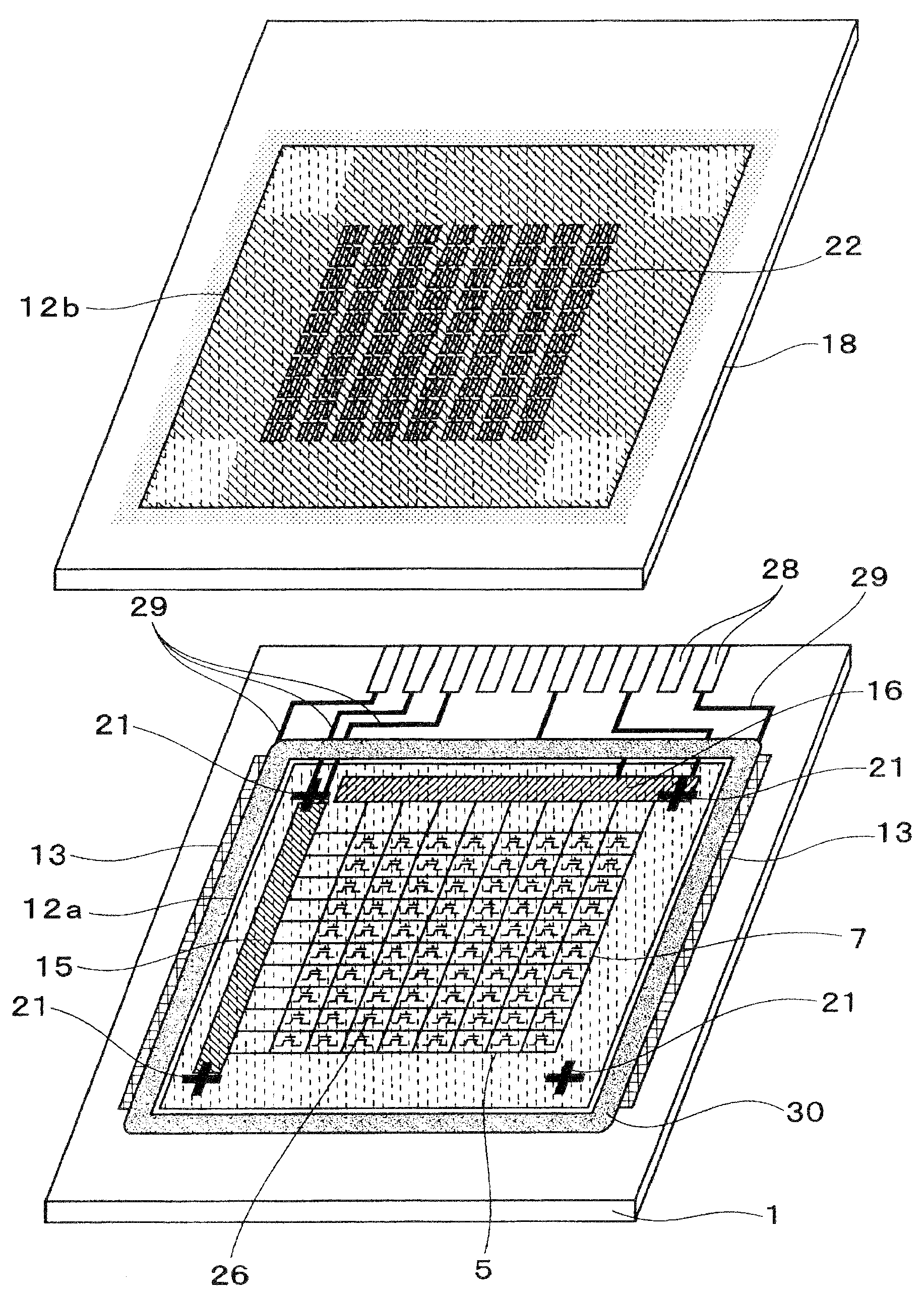

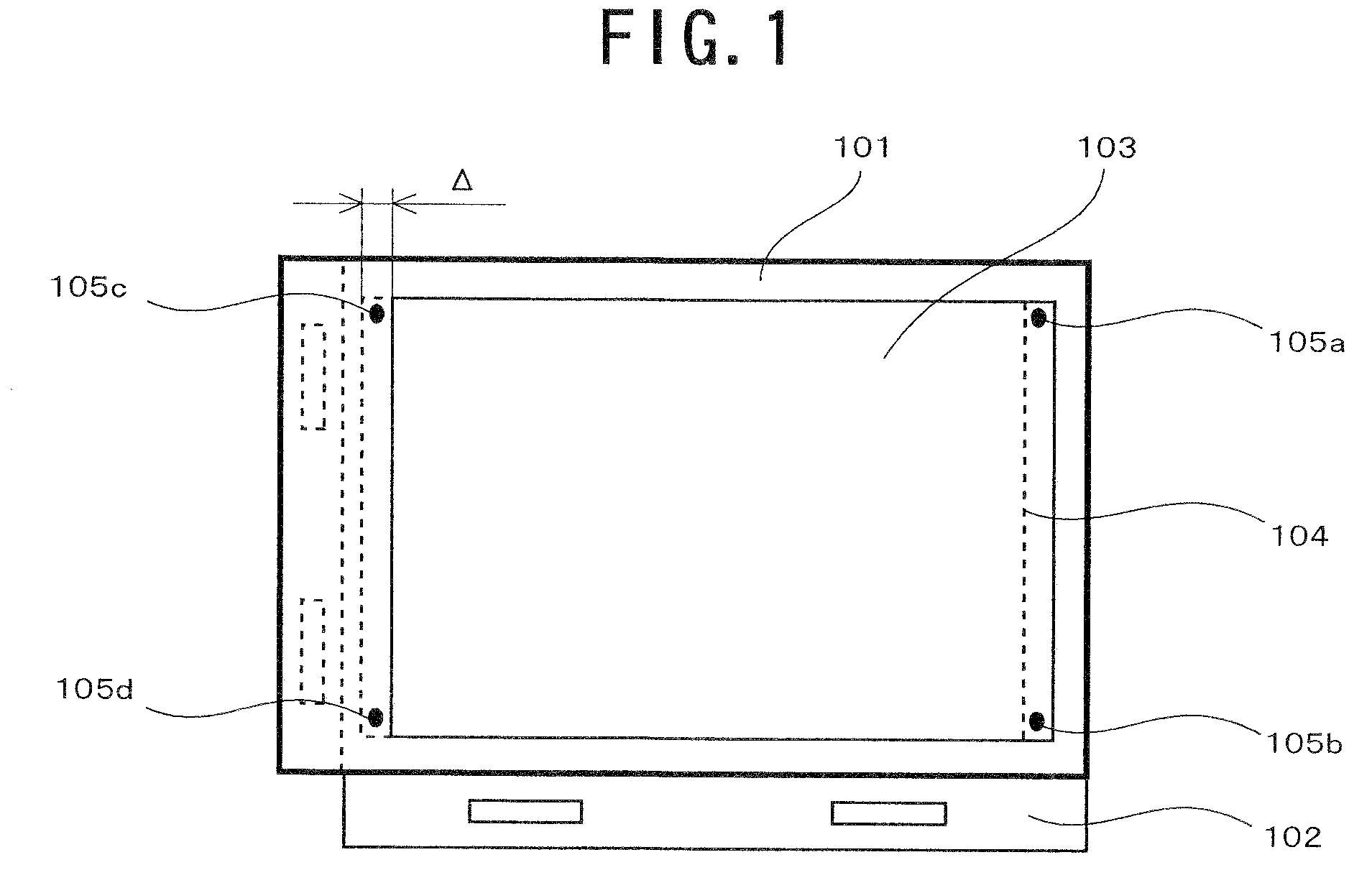

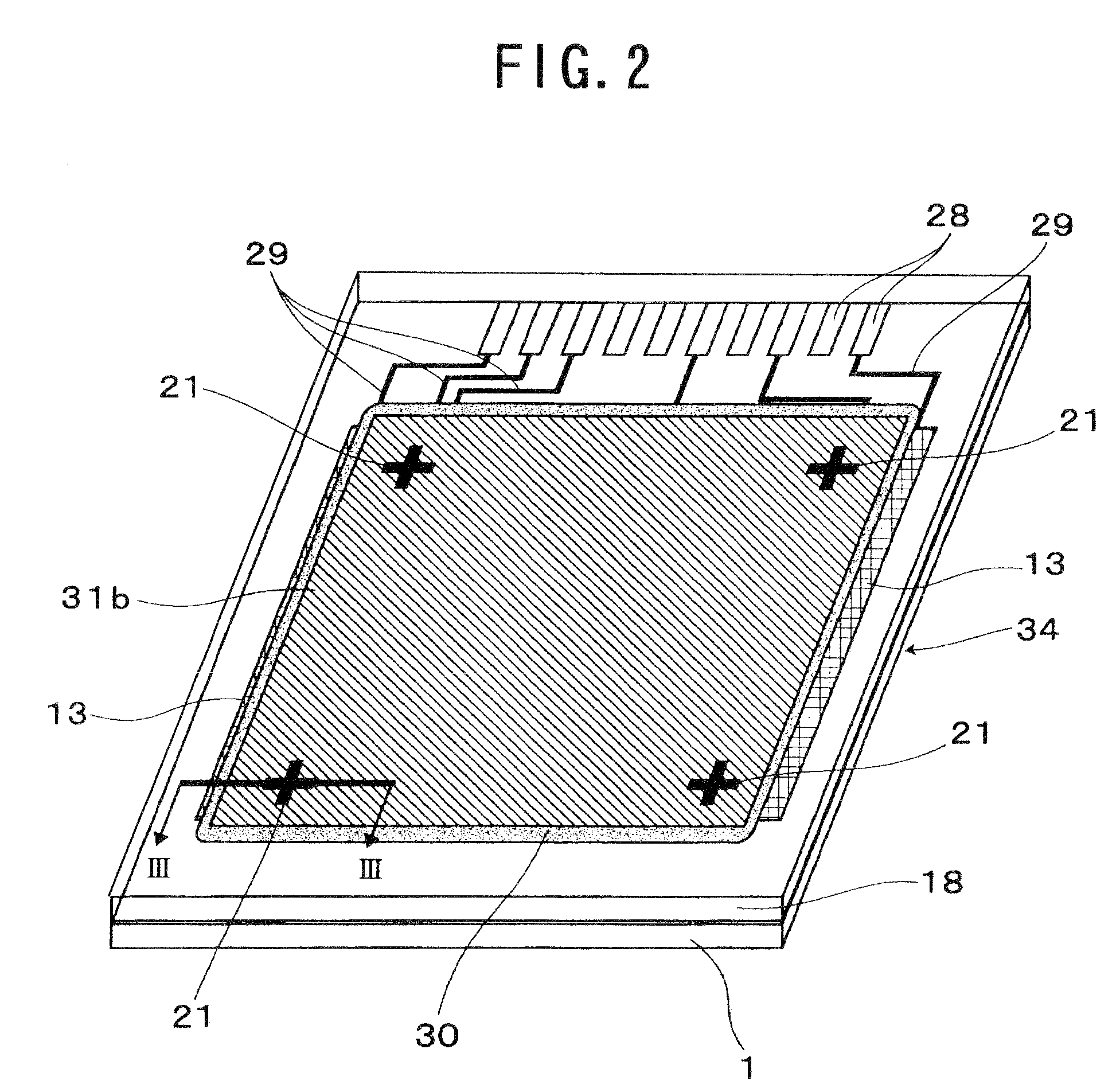

[0070]The schematic structure of a LCD device according to a first embodiment of the present invention is shown in FIGS. 2 and 3, where the LCD device is designed to operate in the normally white mode.

[0071]In FIGS. 2 and 3, the reference numeral 34 denotes a LCD panel incorporated into the LCD device according to the first embodiment of the invention. The LCD panel 34 comprises a driver substrate 1 as a main substrate, an opposite substrate 18 coupled with the driver substrate 1 to be opposite thereto, a liquid crystal 35 (see FIG. 3) enclosed in the gap between the driver and opposite substrates 1 and 18, polarizer plates 31a and 31b attached respectively to the outer surfaces of the driver and opposite substrates 1 and 18, and four markers 21 formed respectively at the positions that overlaps with the polarizer plate 31b on the opposite substrate 18. The markers 21, each of which is made of a material with a light-shielding property (i.e., an opaque material), are used for positi...

second embodiment

[0121]FIGS. 14 and 15 show the LCD panel incorporated into a LCD device according to a second embodiment of the invention. Unlike the above-described first embodiment, this LCD device is designed to operate in the normally black mode. FIG. 14 is a partial cross-sectional view showing the structure of the LCD panel 34 in the vicinity of one of the markers 21, and FIG. 15 is an explanatory partial plan view showing the alignment state of the liquid-crystal molecules in the vicinity of the said marker 21 and the display region. The markers 21 used in the second embodiment are the same as those used in the first embodiment.

[0122]With the LCD device designed to operate in the normally black mode, the markers 21 are unable to be recognized visually even if the alignment direction of the molecules of the liquid crystal 35 in the vicinities of the markers 21 is equalized to that of the molecules of the liquid crystal 35 in the display region. This is because light does not penetrate through...

third embodiment

[0134]FIG. 16 is a partial cross-sectional view of the vicinity of one of the markers 21, which shows the LCD panel 34 incorporated into a LCD device according to a third embodiment of the invention. The markers 21, which are the same as those used in the first embodiment, are located on the inner surface of the opposite substrate 18 (concretely speaking, on the surface of the overcoat film 19). Illustration of the sealing material 30 is omitted in FIG. 16.

[0135]The LCD panel 34 shown in FIG. 16, which is designed to operate in the normally black mode like the above-described second embodiment, comprises pairs of electrodes for applying a voltage to the liquid crystal in the vicinities of the markers 21, in other words, pairs of electrodes for regulating the alignment direction of the liquid-crystal molecules near the markers 21. These pairs of electrodes serve as the alignment direction regulators and therefore, they may be termed “alignment direction regulating electrodes”. Here, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| voltage | aaaaa | aaaaa |

| weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com