Coffee Pod Including Inner Frame

a technology of coffee pods and inner frames, which is applied in the field of coffee pods, can solve the problems of difficult construction of extraction systems using conventional pods, and achieve the effect of simple design and production, and simple manufacturing of opened cavities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

embodiment 1

[0122]When the pod 10 is progressively extracted, the opening step is performed as follows:[0123]primary transportation step: as shown in FIG. 4b, the pod 10 is received in the cavity 91.[0124]secondary loading step: the pod 10 is accommodated in the inside of the cavity 91 and the cavity is engagedly closed.[0125]tertiary perforating (opening) step: as shown in FIG. 4b, the cavity 91 is closed so that it is isolated from the outside to thereby define a water-tightly sealed circumstance and concurrently the pod 10 is penetrated to be opened by means of the orifice 93.[0126]quaternary extraction step: the heated water supplied from the device is injected into the pod 10 through the orifices 93, and the extraction solution flowed out from the contents 30 due to the heated water is, as shown in FIG. 4b, discharged to the outside through the orifice 93 and then the extraction exit 95.

embodiment 2

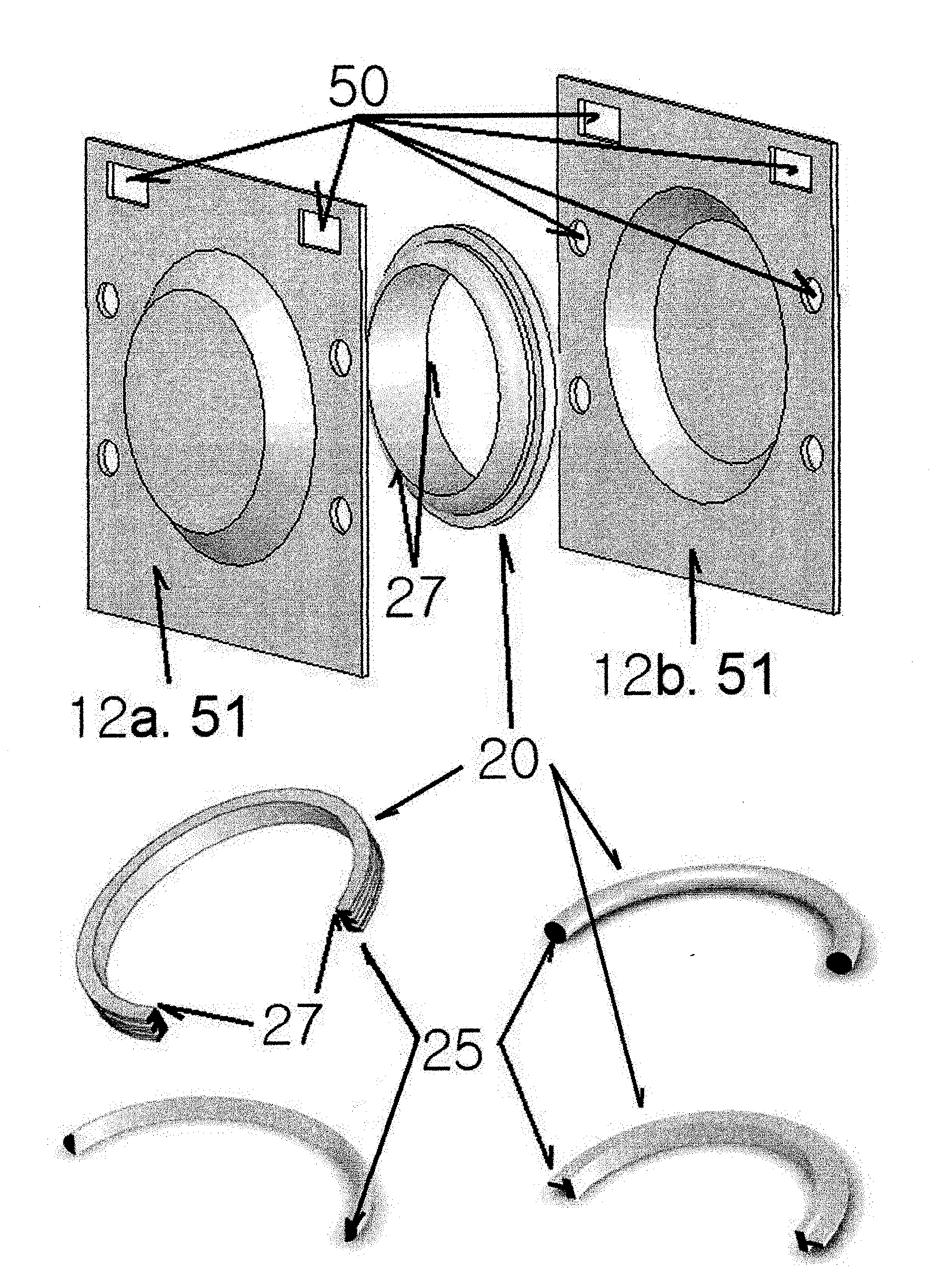

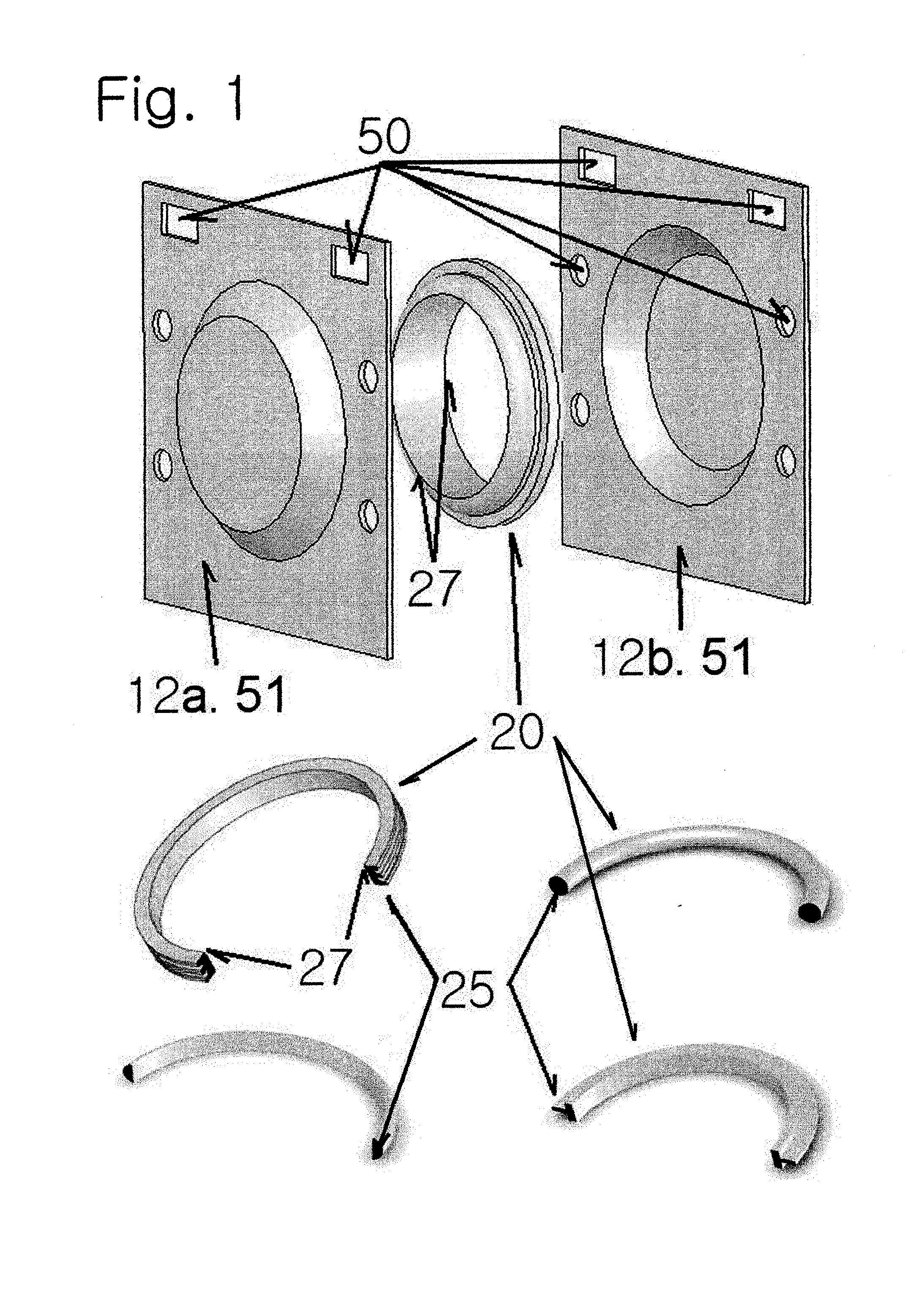

[0127]When the pod 10 is extracted from the opened cavity 91, the opening step is performed as follows:[0128]primary transportation step: as shown in FIG. 5b, the pod 10 is received in the cavity 91.[0129]secondary loading step: the pod 10 is accommodated in the inside of the cavity 91 to be held in place and the cavity is compressed while being engaged with the mouth lips 27 to the maximum.[0130]tertiary perforation (opening) step: as shown in FIG. 5b, when the cavity 91 presses the mouth lip 27 of the frame 20, the inside of the frame 20 is isolated from the outside to thereby define a water-tightly sealed circumstance and concurrently the packaging means 12 is penetrated to be opened by means of the orifice 93.[0131]quaternary extraction step: as shown in FIG. 5b, the heated water supplied from the device is injected into the pod 10 through the orifice 93, and the extraction solution flowed out from the contents 30 due to the heated water is discharged to the outside through the ...

embodiment 3

[0132]In case where the pod 10 of the present invention is continuously extracted by using an automatic extracting device together with the functions described in the previously filed specification, the extracting step is performed as follows irrespective of the kind of the cavity:[0133]primary waiting step: the extraction instruction is awaited at the initial state in which several pods 10 are arranged to wait for in sequence;[0134]secondary cut step: if the extraction instruction is received, a shear line is cut between the first pod 10 and the second pod 10 among the plurality of pods 10 waiting in a state arranged in parallel, so that the pod 10 can be transported to the extraction portion 90;[0135]tertiary transportation step: the transportation mechanism is transported to an accurate extraction position along the slide or the rotary shaft and is held in position together with the engagement opening of the pod 10 being engaged with the hook, while counting the number of the sen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com