Method and apparatus for thermal jet printing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041]In one embodiment, the disclosure relates to a method and apparatus for depositing a film in substantially solid form on a substrate. Such films can be used, for example, in the design and construction of OLEDs and large area transistor circuits. In one embodiment, the disclosure relates to a method and apparatus for depositing a film of material in substantially solid form on a substrate. In another embodiment, the disclosure relates to a method and apparatus for depositing a film of material substantially free of solvent of a substrate. Such films can be used, for example, in the design and construction of OLEDs and large area transistor circuits. The materials that may be deposited by the apparatuses and methods described herein include organic materials, metal materials, and inorganic semiconductors and insulators, such as inorganic oxides, chalcogenides, Group IV semiconductors, Group III-V compound semiconductors, and Group II-VI semiconductors.

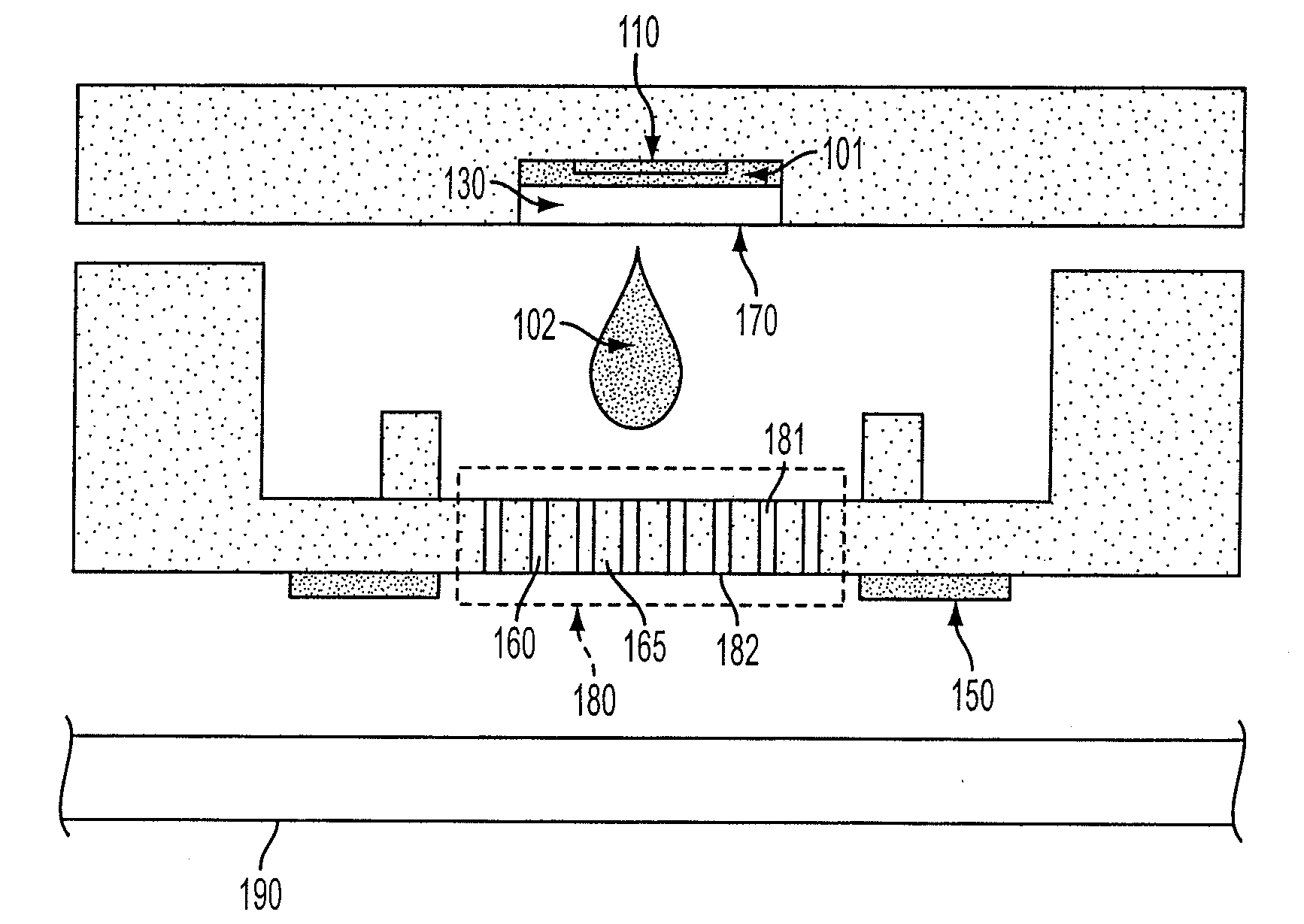

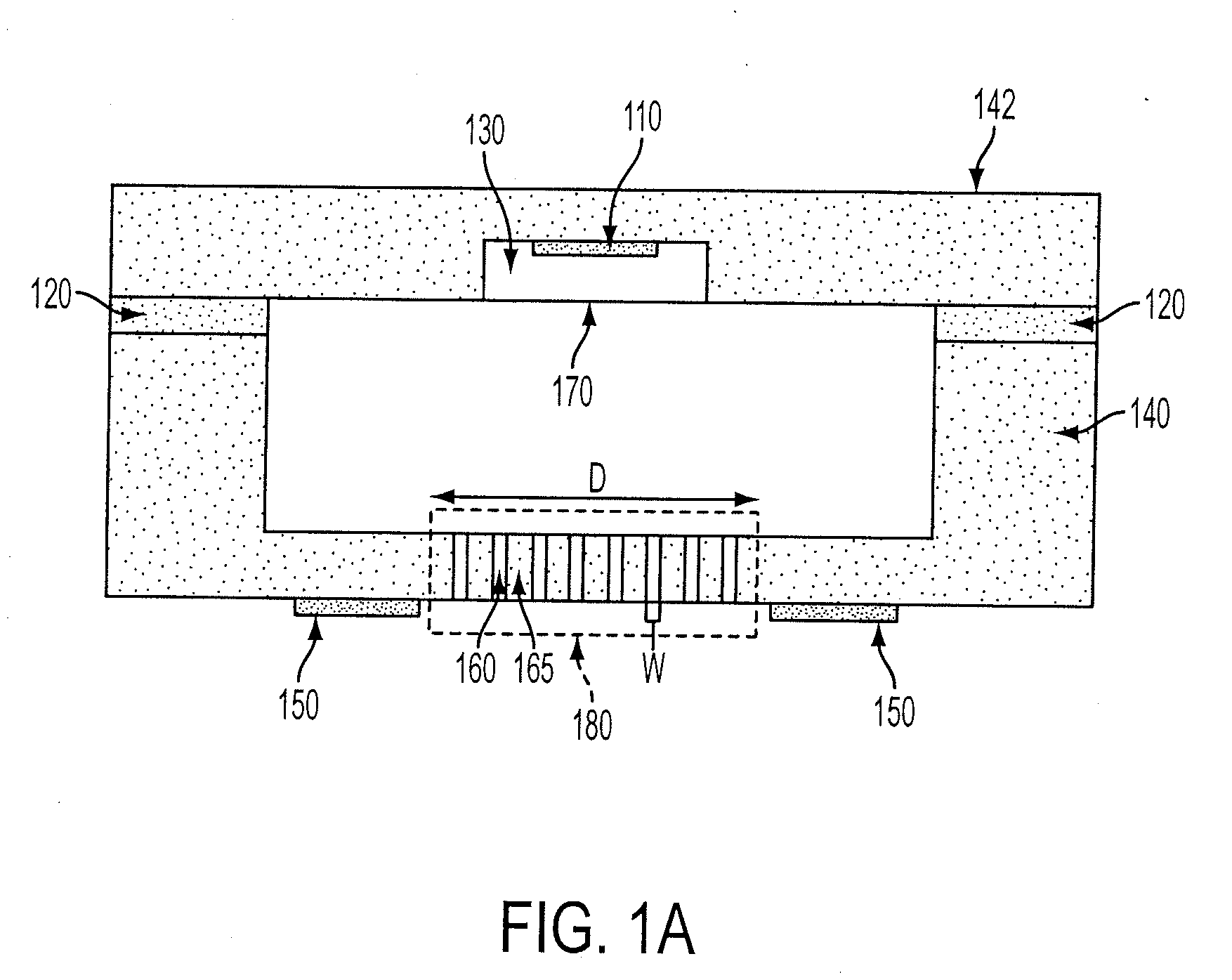

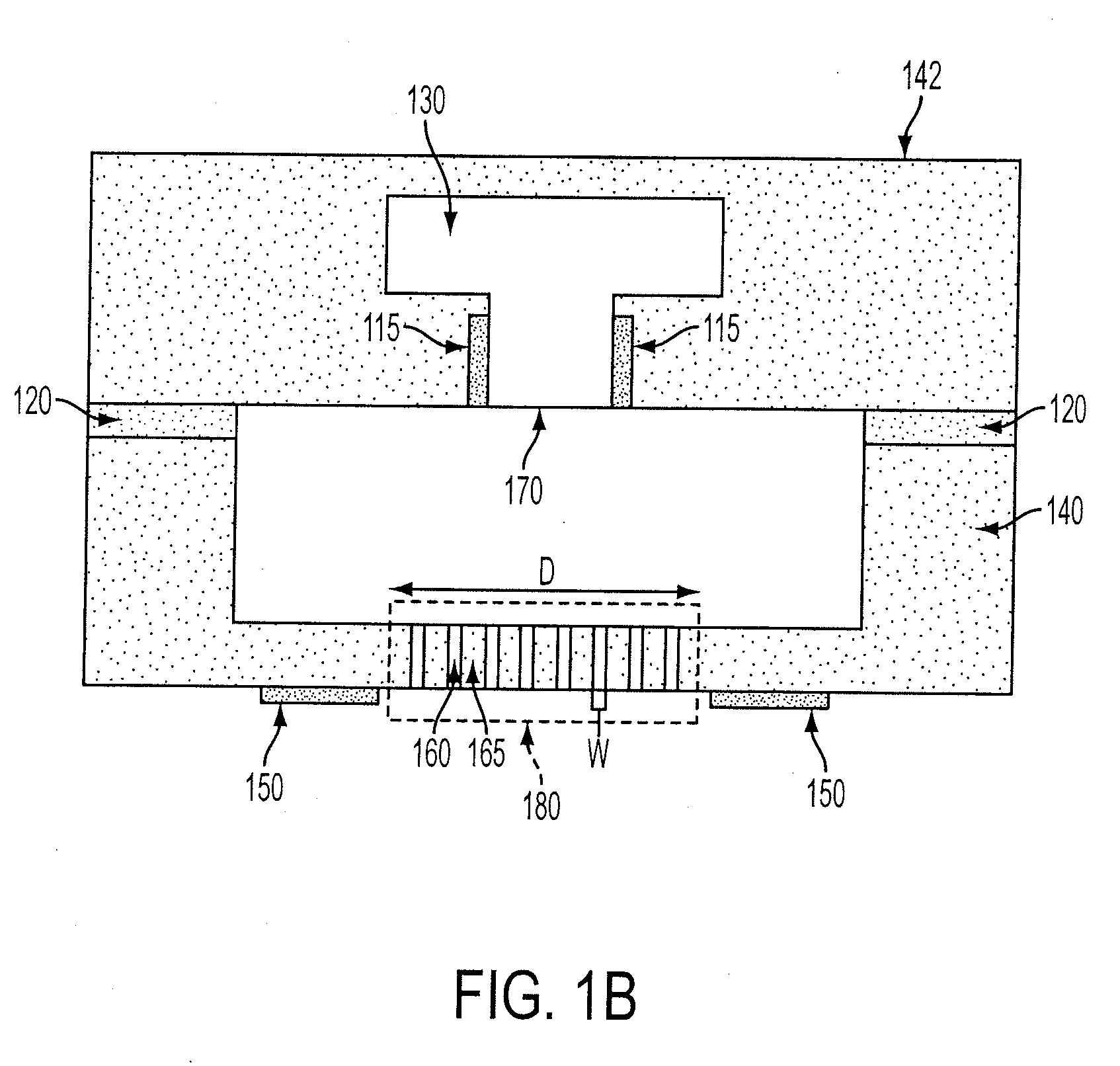

[0042]FIG. 1A is a schemat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com