Fluid pump

a technology of fluid pump and pump body, which is applied in the direction of pump, positive displacement liquid engine, machine/engine, etc., can solve the problem of substantially unaffected delivery and achieve the effect of minimizing leakag

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

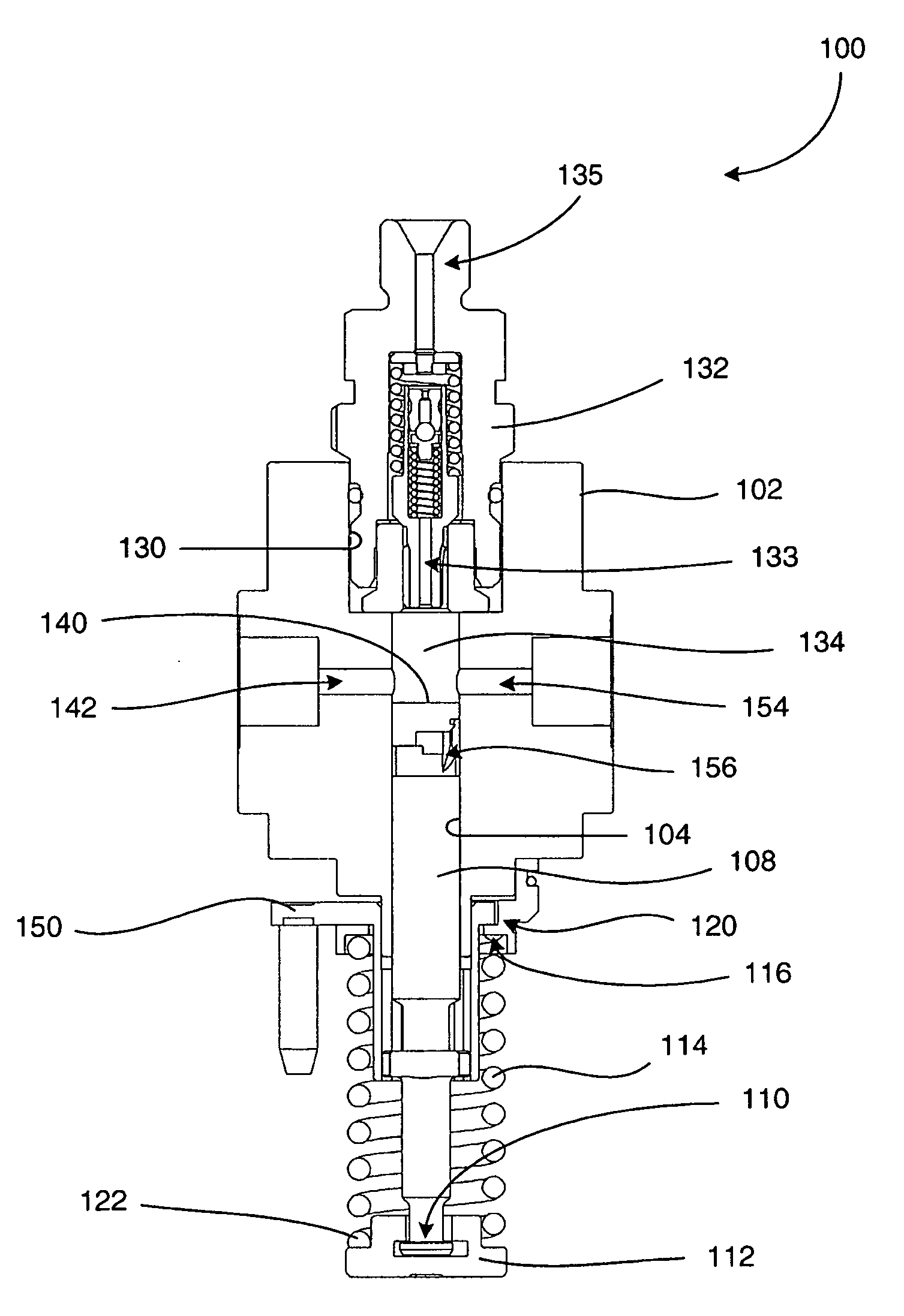

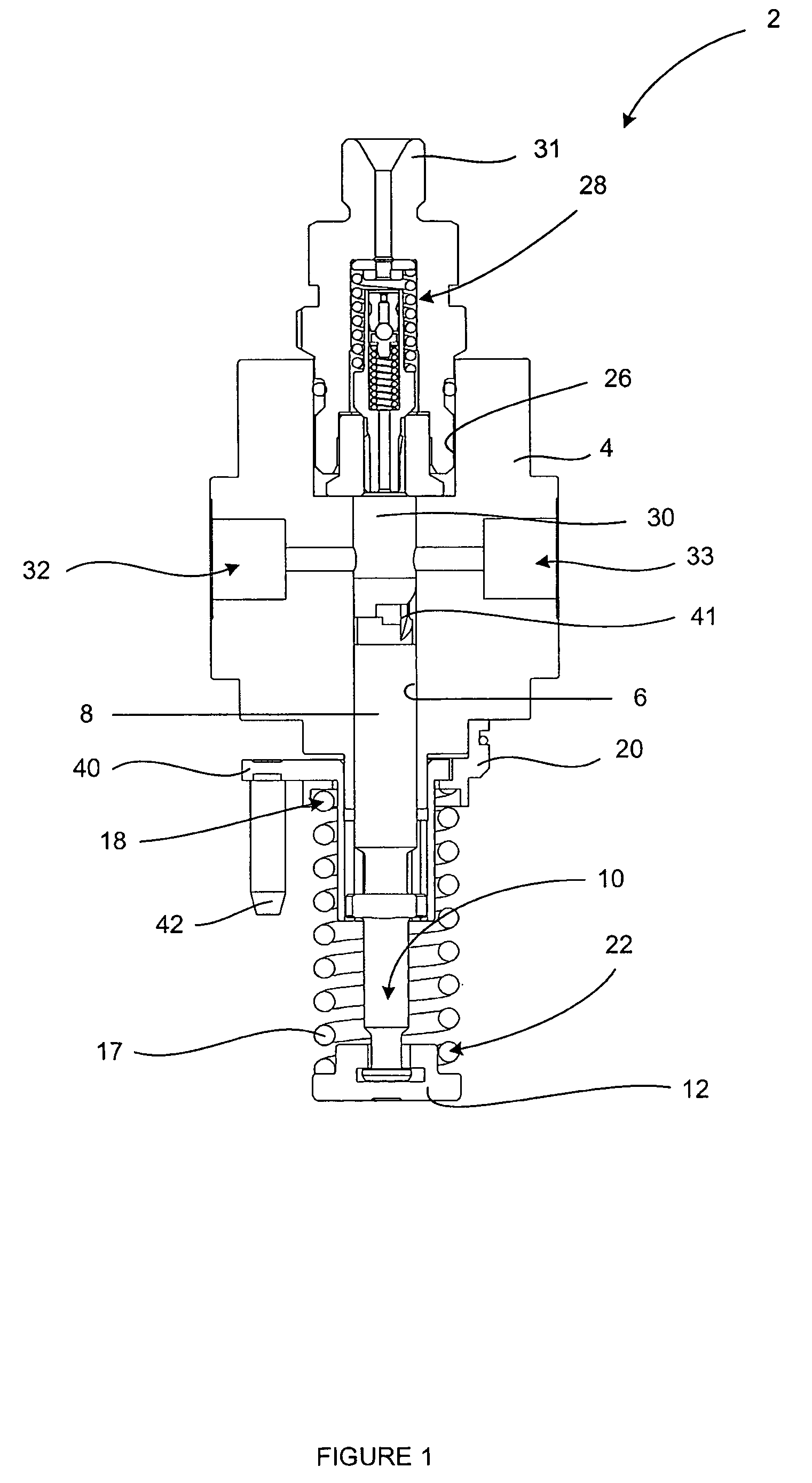

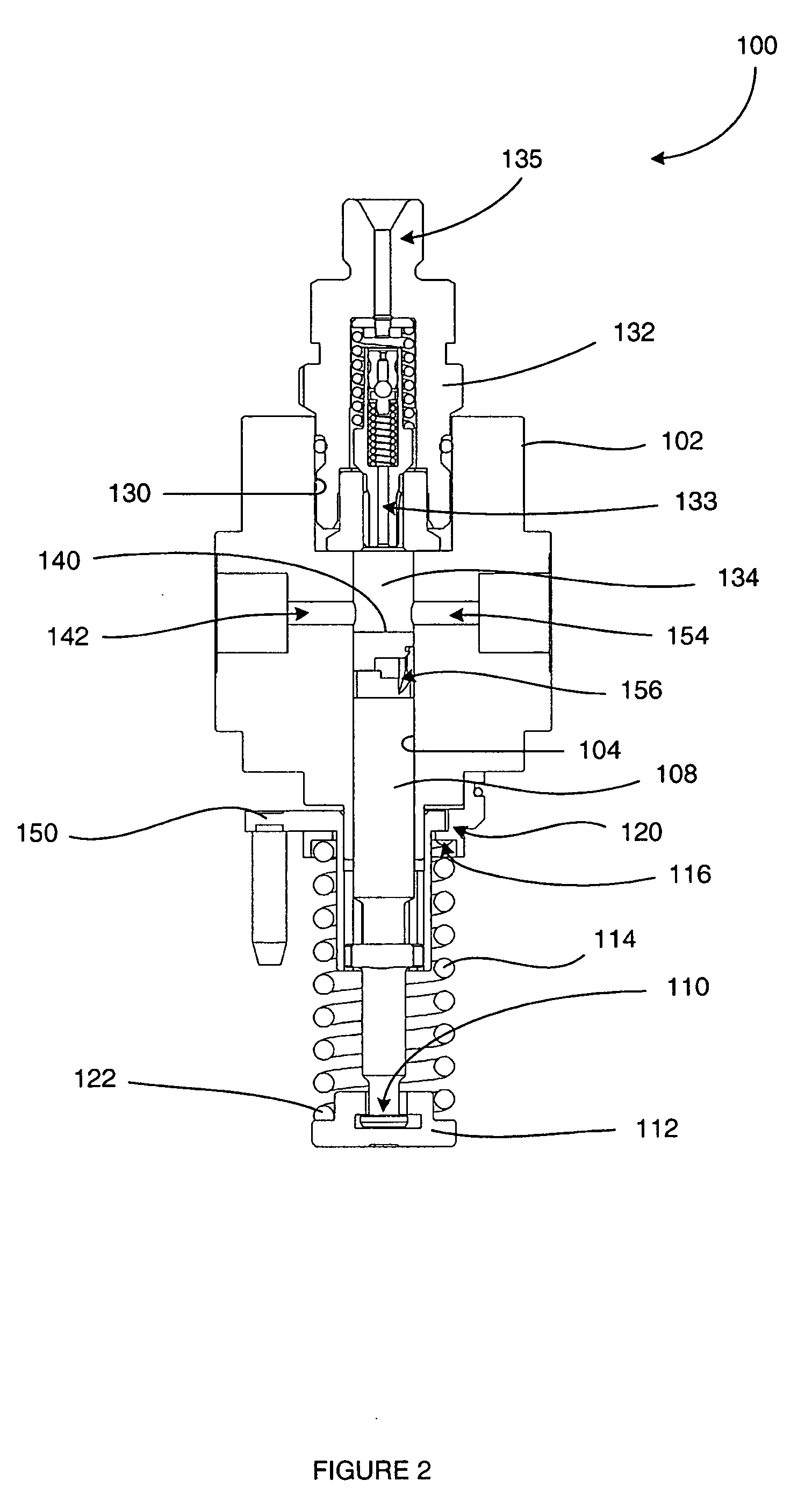

[0032]Referring to FIG. 2, a mechanical fuel injection pump 100 (hereinafter ‘fuel pump’) is shown that is similar to the fuel pump 2 described above with reference to FIG. 1.

[0033]The fuel pump 100 includes a block-like pump body, or housing 102 having an axially disposed bore 104 within which a pumping plunger 108 is slidable. The plunger 108 has a lower end 110 (in the orientation shown in FIG. 2) that is coupled to a lower spring plate 112 for transmitting reciprocating motion to the plunger 108. Although not shown in the diagram, a tappet and cam member (not shown) may be arranged with respect to the lower spring plate 112 such that rotation of the cam member causes reciprocation of the plunger 108. This form of plunger drive arrangement is known in the art.

[0034]A biasing means in the form of a helical spring 114 is received over the plunger 108 such that the spring 114 is disposed between the pump housing 102 and the lower spring plate 112. An upper end 116 of the spring 114 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com