Robotic apparatus

a robot and a technology of robots, applied in the field of robots, can solve the problems of affecting the accuracy of the robot, the tip of the instrument may move in the opposite direction, and the surgeon is deprived of three-dimensional depth cues,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

Mechanism Overview

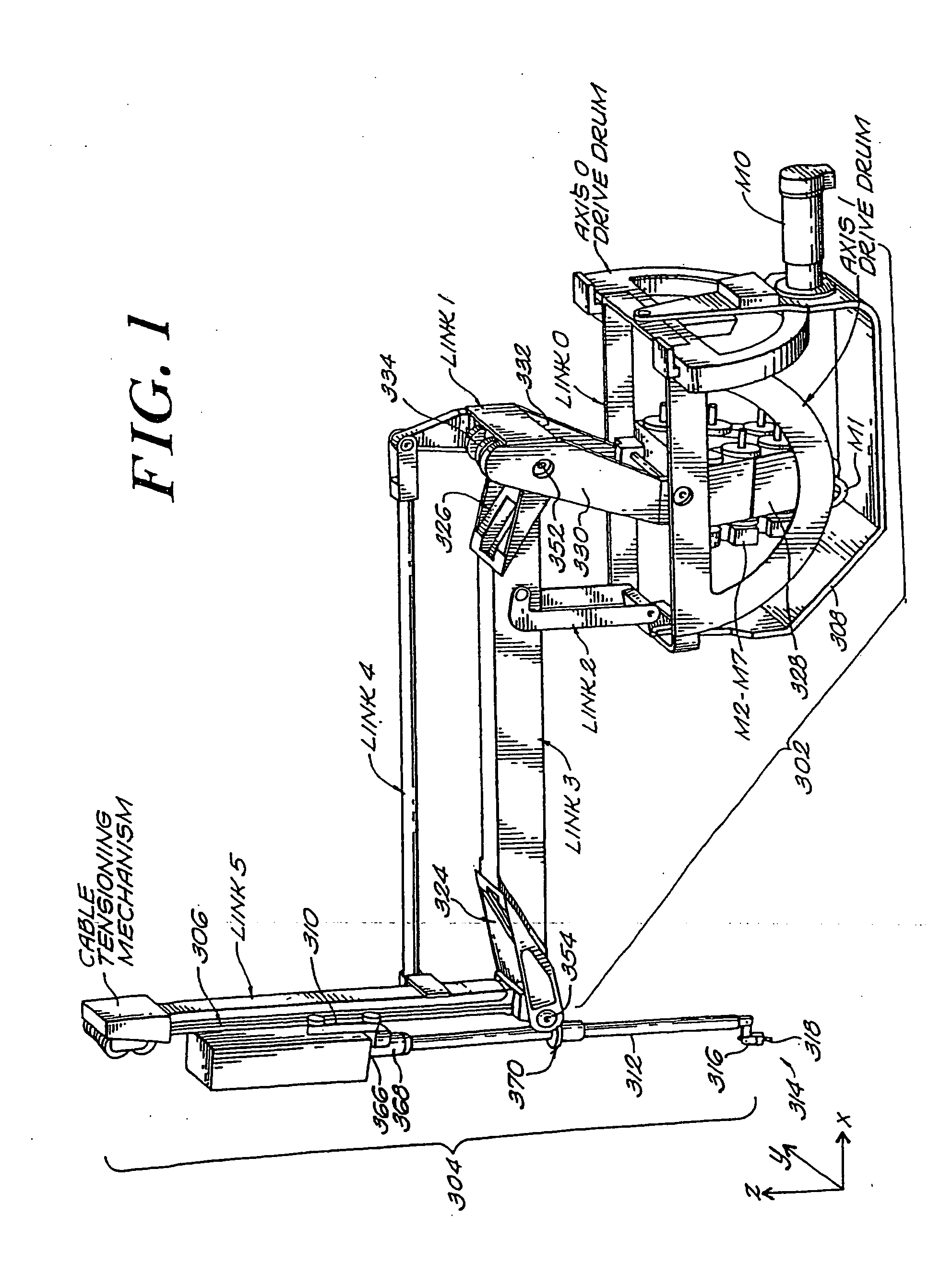

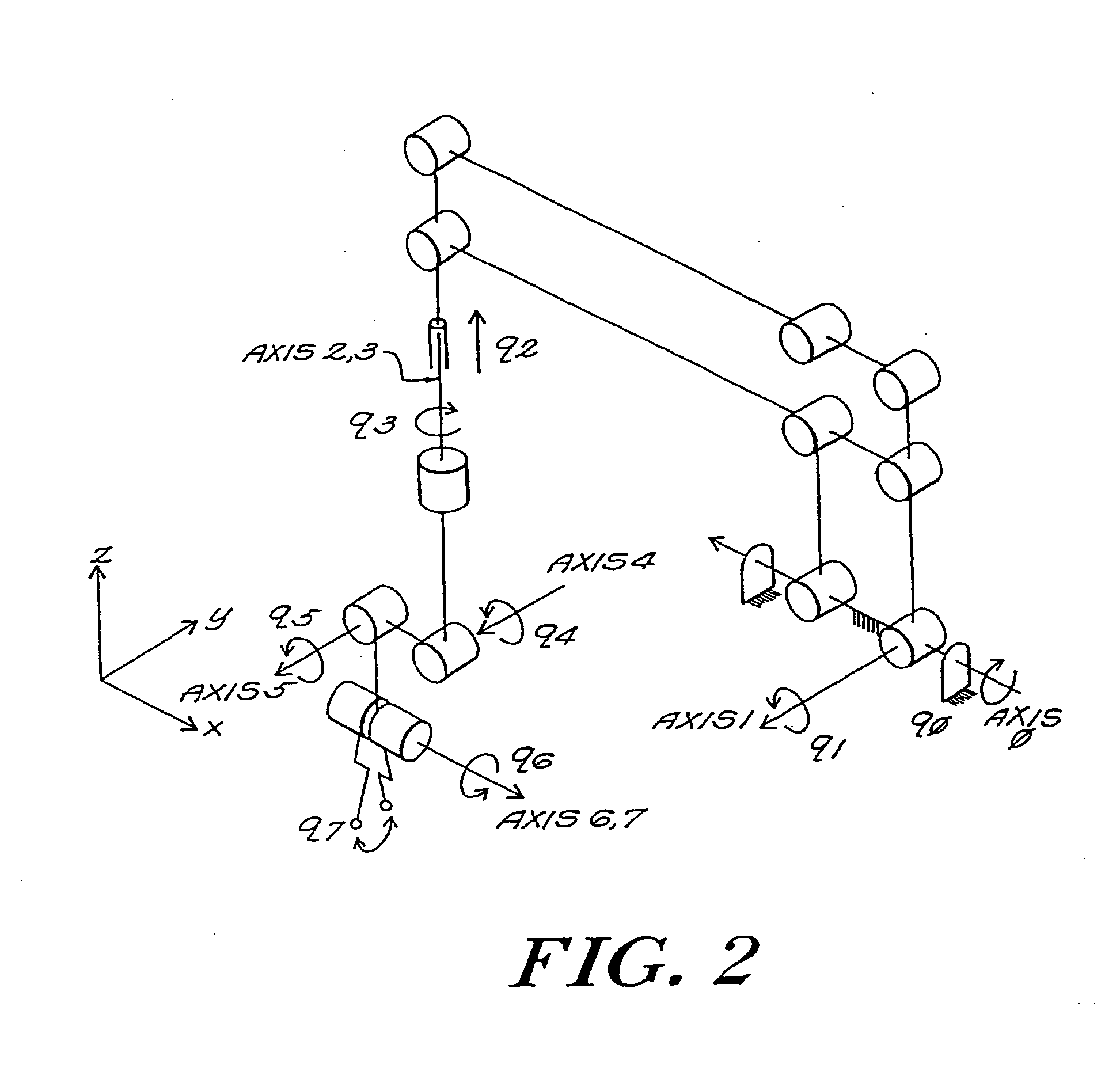

[0081]The following is an overview of the system. More details are provided in subsequent sections. A preferred embodiment of a slave apparatus of the invention is shown in FIG. 1 and consists of two main subsystems, a base unit 302 and a wrist unit 304. The base unit contains all of the actuators M0-M7 for the entire system, the links link 0-link 5 and provides a mechanical interconnect 306 for the wrist unit 304, which wrist is a passive (i.e. contains no actuators) detachable instrument. The following components are referred to in FIG. 1, and the kinematic structure, including axis and link numbers, is defined in the schematic drawing FIG. 2. Eight joints are labeled 0-7. (The links are not necessarily associated with respectively numbered axes.) The system is grounded through a ‘U″-shaped stationary base bracket’308. A spindle link 0, rotates within this base about axis 0. Motor M0 actuates this axis 0 using a cable drive connected to the axis 0 drive drum. Lin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com