A-frame barricade

a barricade and frame technology, applied in the direction of roads, roads, constructions, etc., can solve the problems of reducing the effect of wind and requiring the barricade to be walked along, and achieve the effect of high efficiency, compact storage, and high specific gravity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

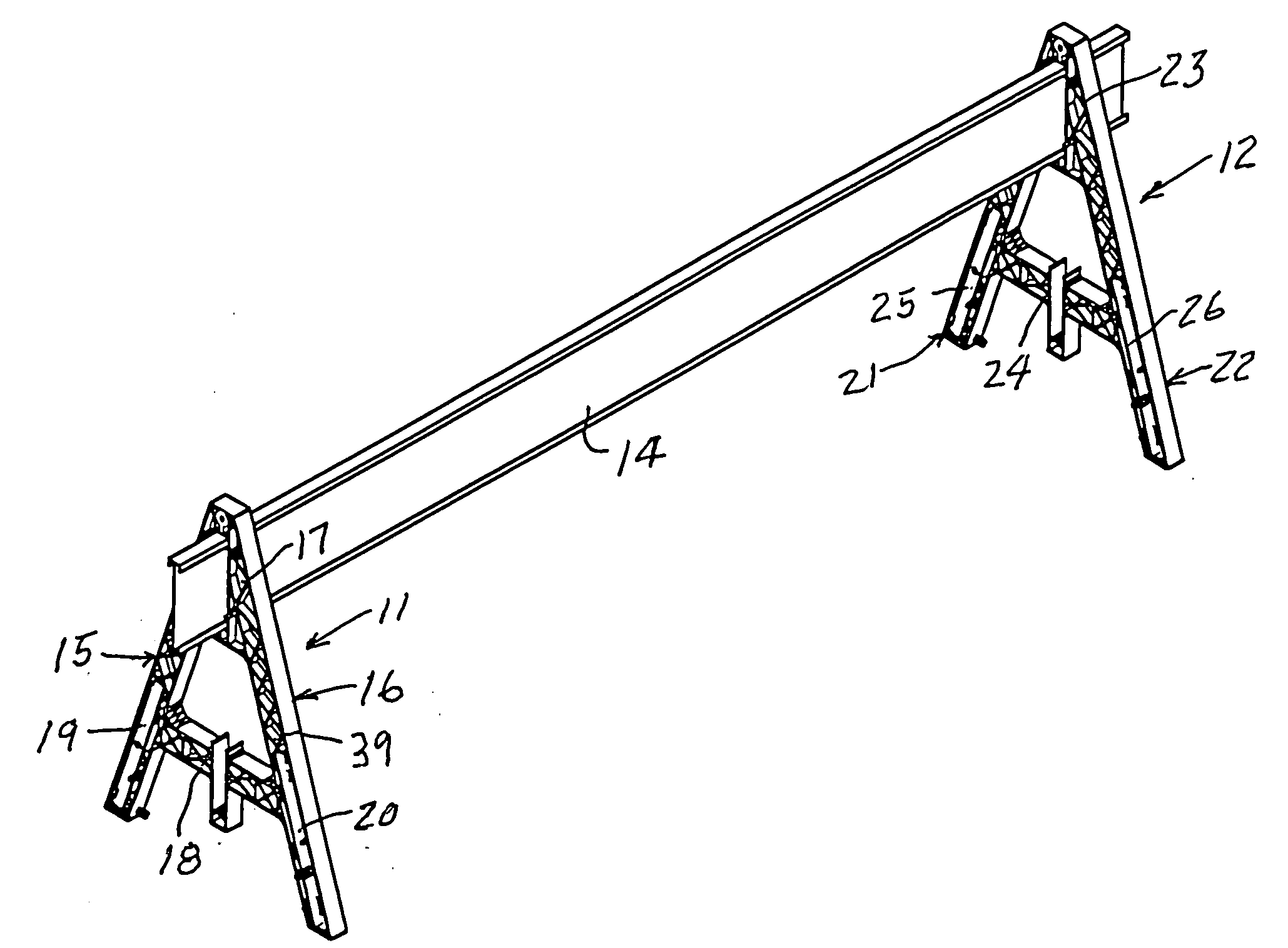

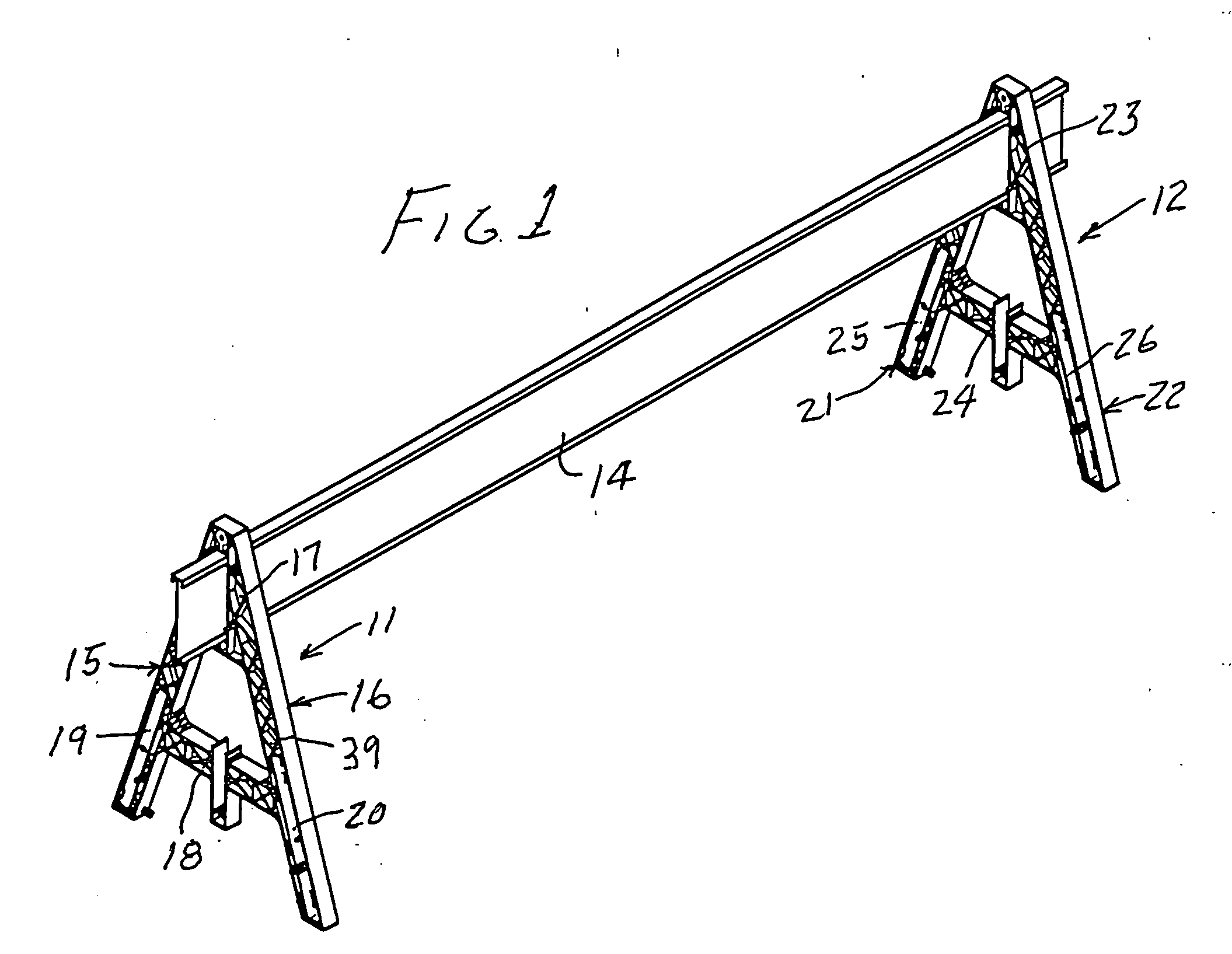

[0023]In FIG. 1, reference numeral 10 generally designates an A-frame type of barricade constructed in accordance with the invention. The barricade 10 includes two A-frame members 11 and 12 shown supporting an elongated beam 14. The member 11 includes two legs 15 and 16 which extend angularly upwardly toward each to meet an apex portion 17 which is formed with an opening through which one end of the supported member 14 extends. The member 11 also has a portion 18 that extends between and connects portions of the legs 15 and 16 at an intermediate level. The member 11 thus has an overall shape like that of the letter A.

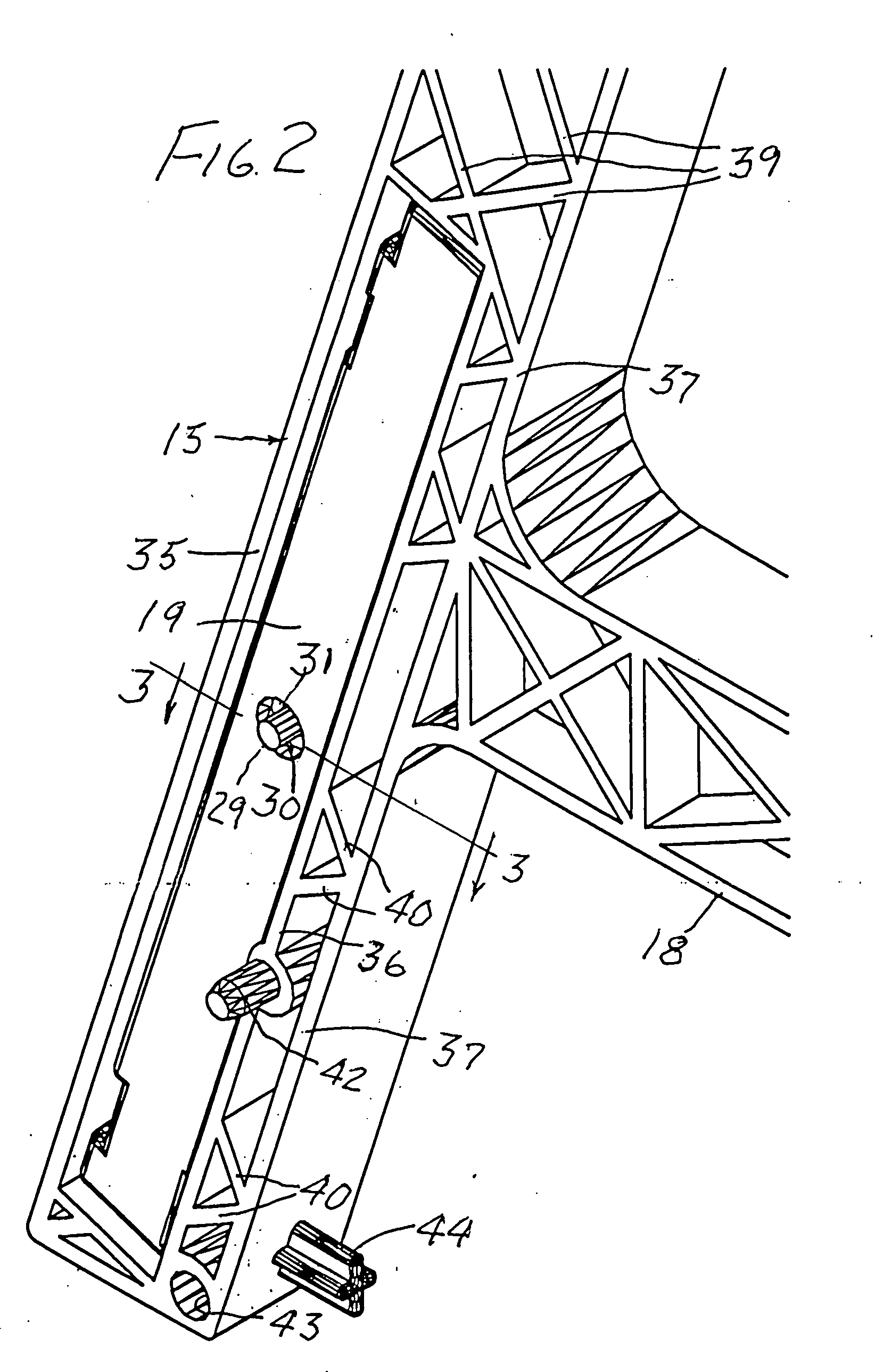

[0024]In accordance with the invention, the legs 15 and 16 are formed with recesses which provide pockets for receiving two elongated weight cartridges 19 and 20. Through the force of gravity acting thereon, the cartridges 19 and 20 function to resist tilting movement of the members 11 and 12. Thus cartridge 19 in leg 15 develops a stabilizing torque equal to the produc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com