Robot joint space point-to-point movement trajectory planning method

a robot and trajectory planning technology, applied in the direction of electric programme control, programme-controlled manipulators, programme control, etc., can solve the problems of affecting the efficiency of the robot in actual machining, failing to meet the requirements of real-time control, etc., to reduce the number of trajectory planning, reduce the effect of ensuring the operation efficiency of the robot, and small calculation amoun

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

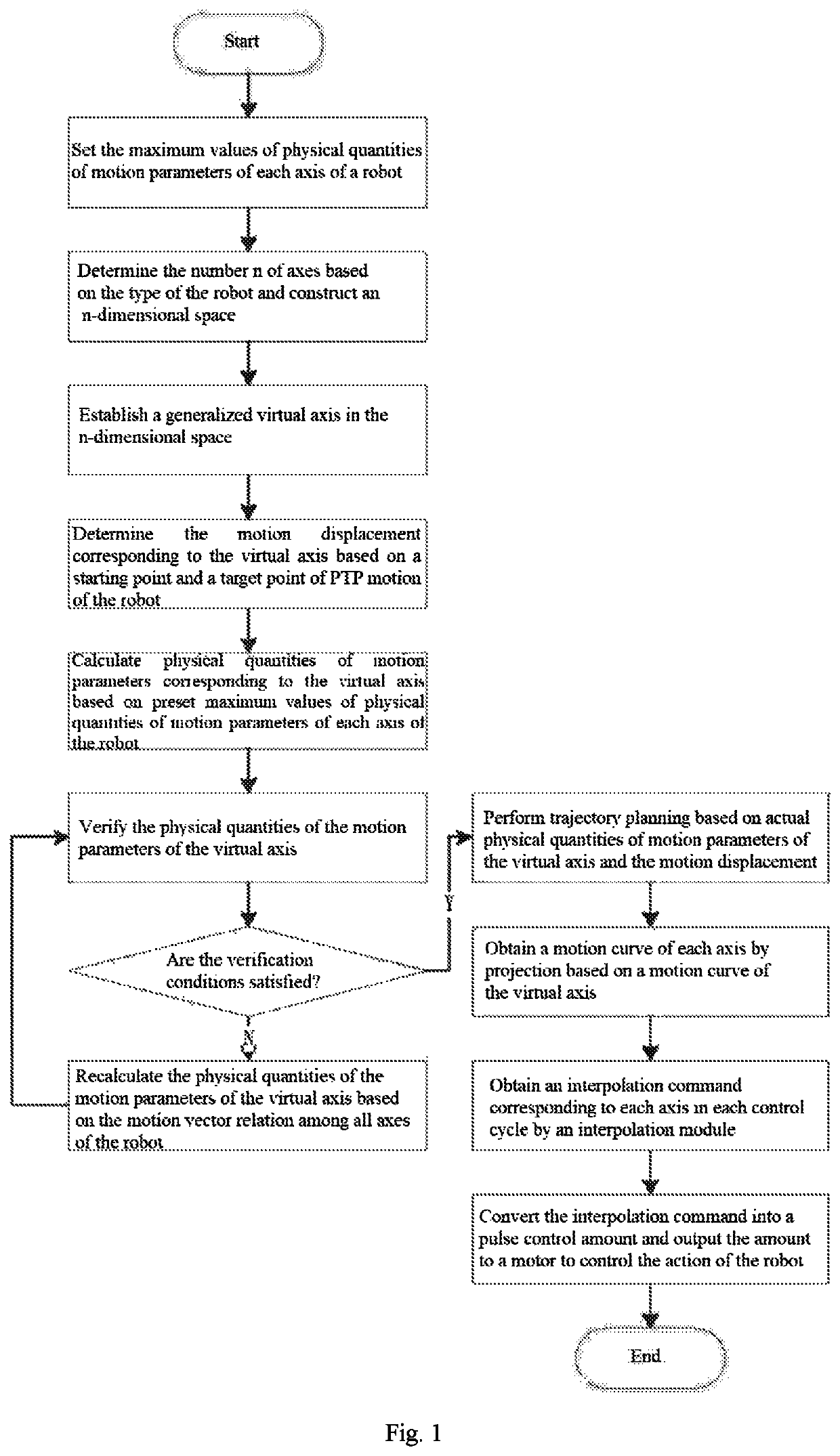

[0027]In order to make the objects, technical solutions and advantages of the invention clearer, the invention will be further described below in detail with reference to the drawings and particular embodiments.

[0028]An SCARA robot will be taken as an example to illustrate the specific implementation of the method of the invention.

[0029]An SCARA (Selective Compliance Assembly Robot Arm) is a cylindrical coordinate industrial robot. The SCARA robot comprises 4 axes, 3 of which are rotary axes whose axial lines are parallel to each other for positioning and orientation in a plane, and the other one of which is a moving axis for completing the motion of an end piece perpendicular to the plane.

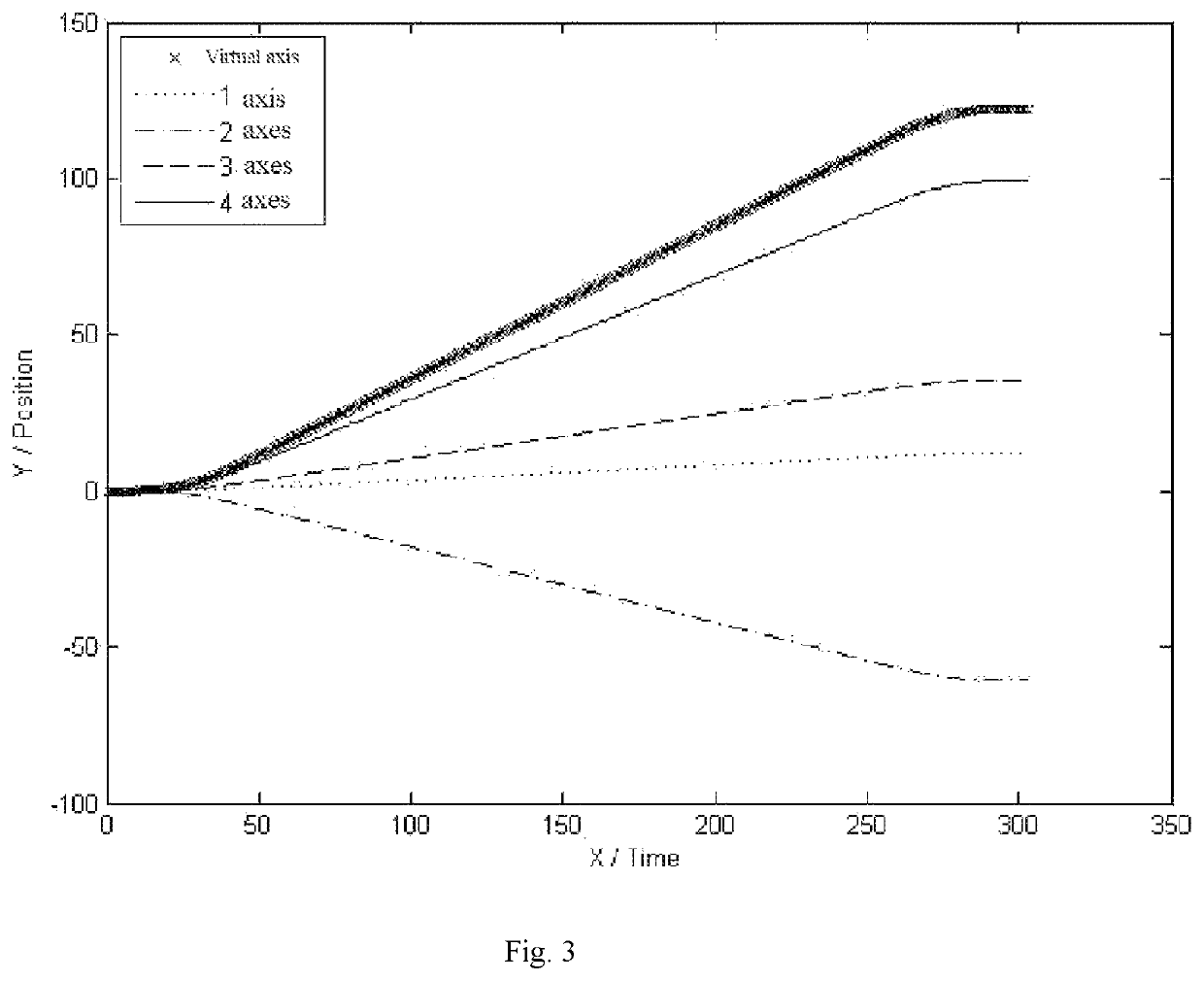

[0030]In the actual working process, the maximum velocity of all the axes of the SCARA robot can be set to 100° / s, 100° / s, 100 mm / s and 100° / s respectively; the maximum acceleration thereof can be set to 1000° / (s*s), 1000° / (s*s), 1000 mm / (s*s) and 1000° / (s*s) respectively; and the maximum jerk the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com