Anchor structure for electronic card connectors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

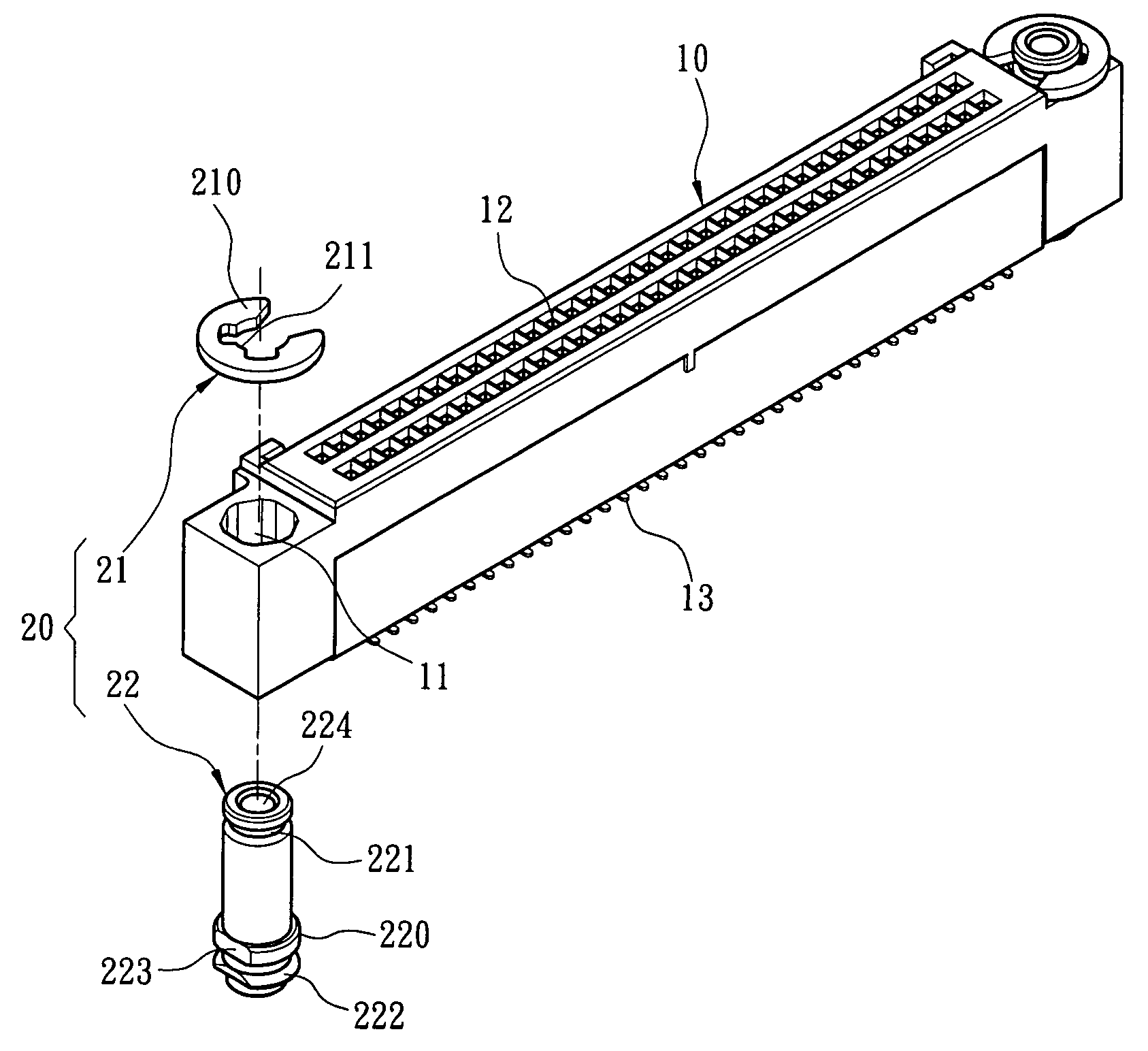

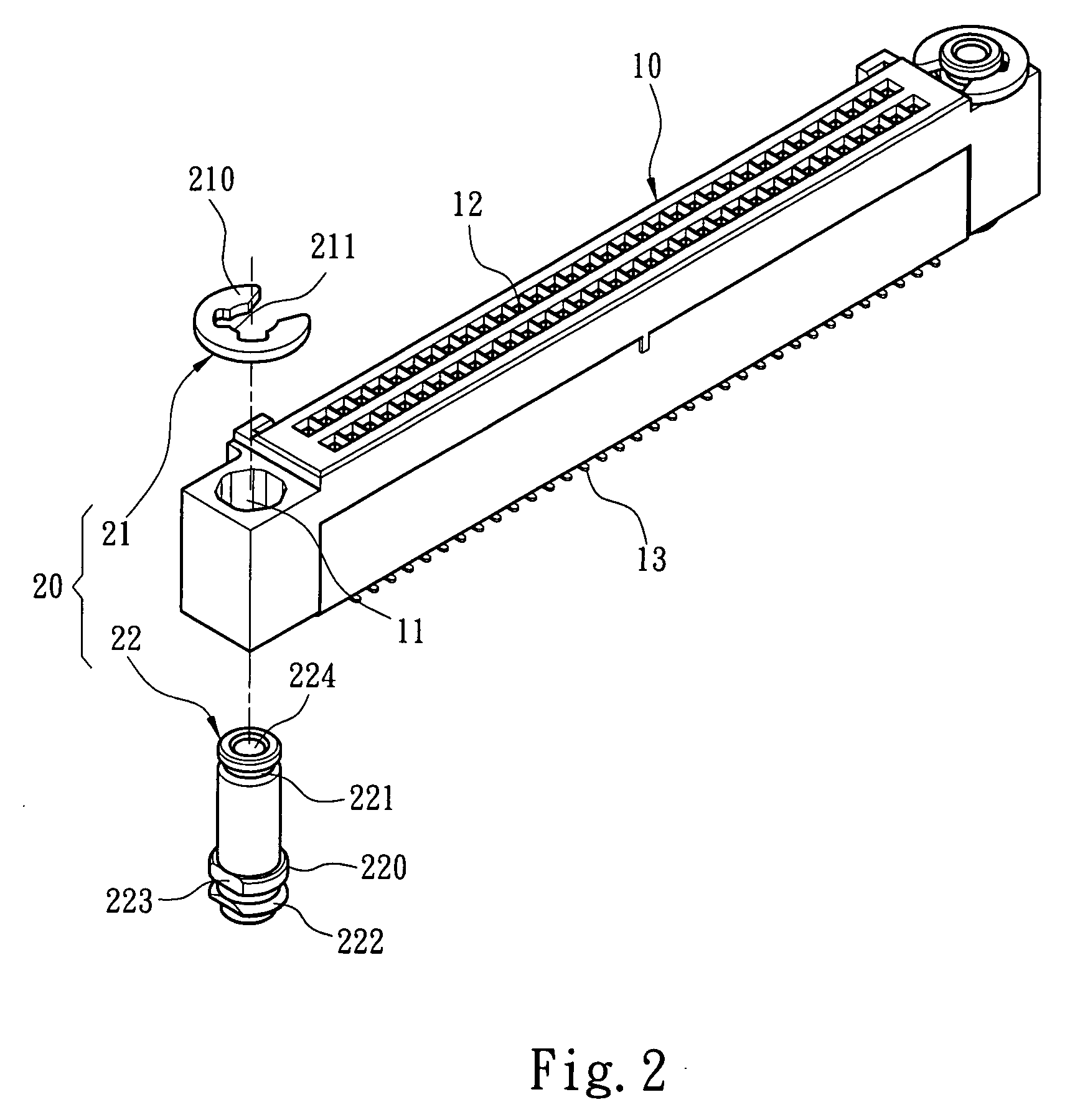

[0016]Please refer to FIGS. 2, 3 and 4, the anchor structure for electronic card connectors according to the invention includes a body 10 and a fastening element 20. The body 10 has a holding bore 11 to hold the fastening element 20. The fastening element 20 includes an anchor member 21 and an anchor seat 22. The anchor member 21 and anchor seat 22 have respectively an extended portion 210 and 220 that have an outer diameter greater than the fastening element 20. The anchor member 21 has a first anchor portion 211. The fastening seat 22 has a corresponding second anchor portion 221. In an embodiment of the invention the first and second anchor portions 211 and 221 are a C-shaped clip and a groove that mate each other so that they can be coupled or disengaged with each other.

[0017]In an embodiment of the invention, the anchor structure is coupled with a connector 30 and installed at a desired location on a circuit board 40. The connector 30 is inserted into an orifice 12 to be connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com