Depolymerization method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 4

Depolymerization of Native Barley Starch at 60° C.

[0072]A 150 mg (1 mmol) sample of oven dried native barley starch (Raisamyl) was added into ionic liquid (BMIMCl, 3 ml) and the resulting clear mixture was stirred 2 hours at 60° C. The clear reaction mixture was analyzed with GPC. The GPC spectrum showed no changes compared to starting material spectrum.

example 5

Depolymerization of Native Barley Starch at 45° C.

[0073]A 150 mg (1 mmol) sample of oven dried native barley starch (Raisamyl) was added into ionic liquid (BMIMCl, 3 ml) and the resulting clear mixture was stirred 2 hours at 45° C. The clear reaction mixture was analyzed with GPC. The GPC spectrum showed no changes compared to starting material spectrum.

[0074]The percentages in this specification refer to % by weight unless otherwise specified.

example 1

Depolymerization of Native Barley Starch at 150° C.

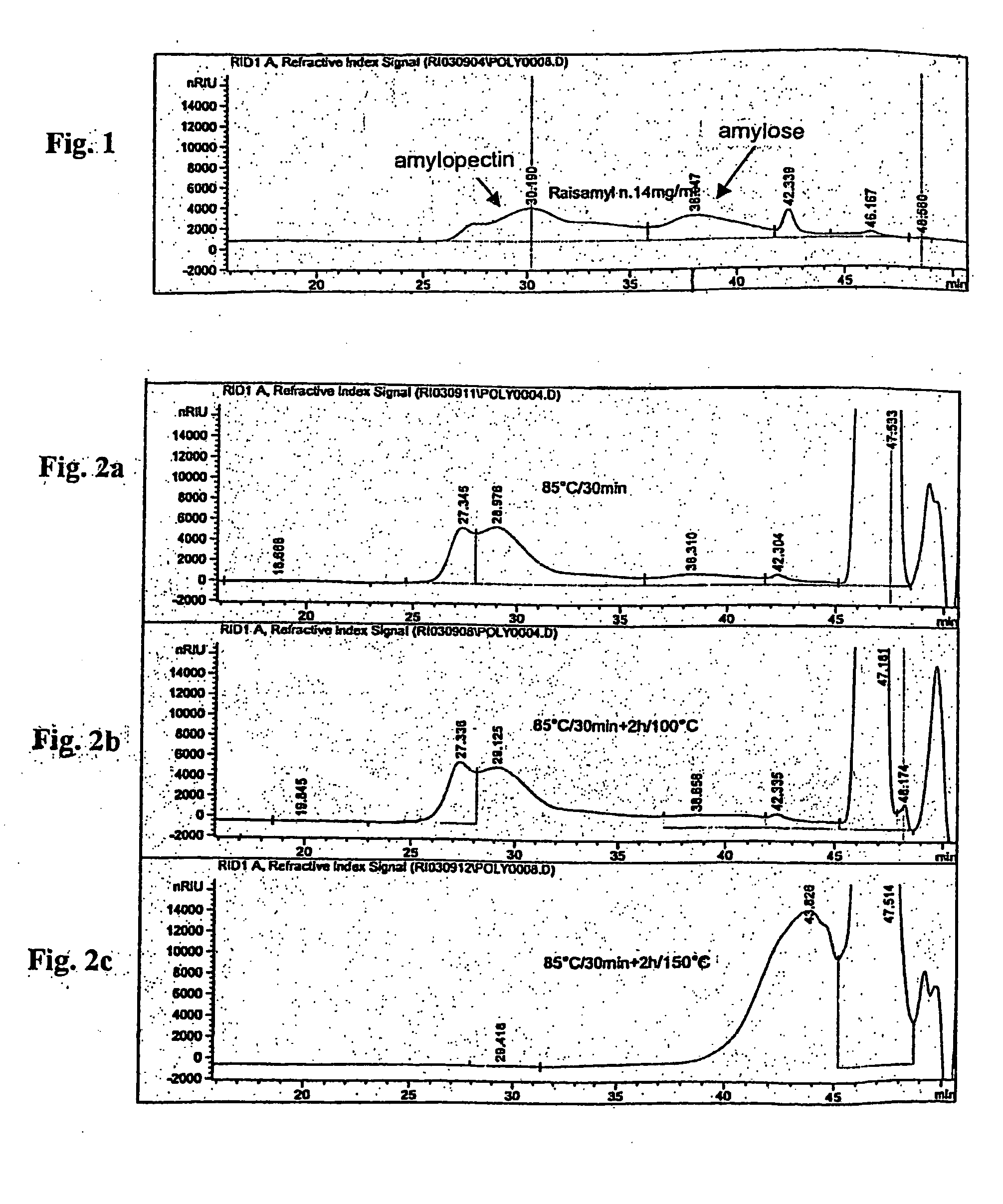

[0076]A 1.50 mg (1 mmol) sample of oven dried native barley starch (Raisamyl) was added into ionic liquid (BMIMCl, 3 m) and the resulting clear mixture was stirred 30 minutes at 85°(and at. 150° C. for 2 hours. The pale brown reaction mixture was analyzed with GPC. All the starch was depolymerized into monomeric products, see FIG. 2c.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com