Channel Anchoring Device For The Construction Industry

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

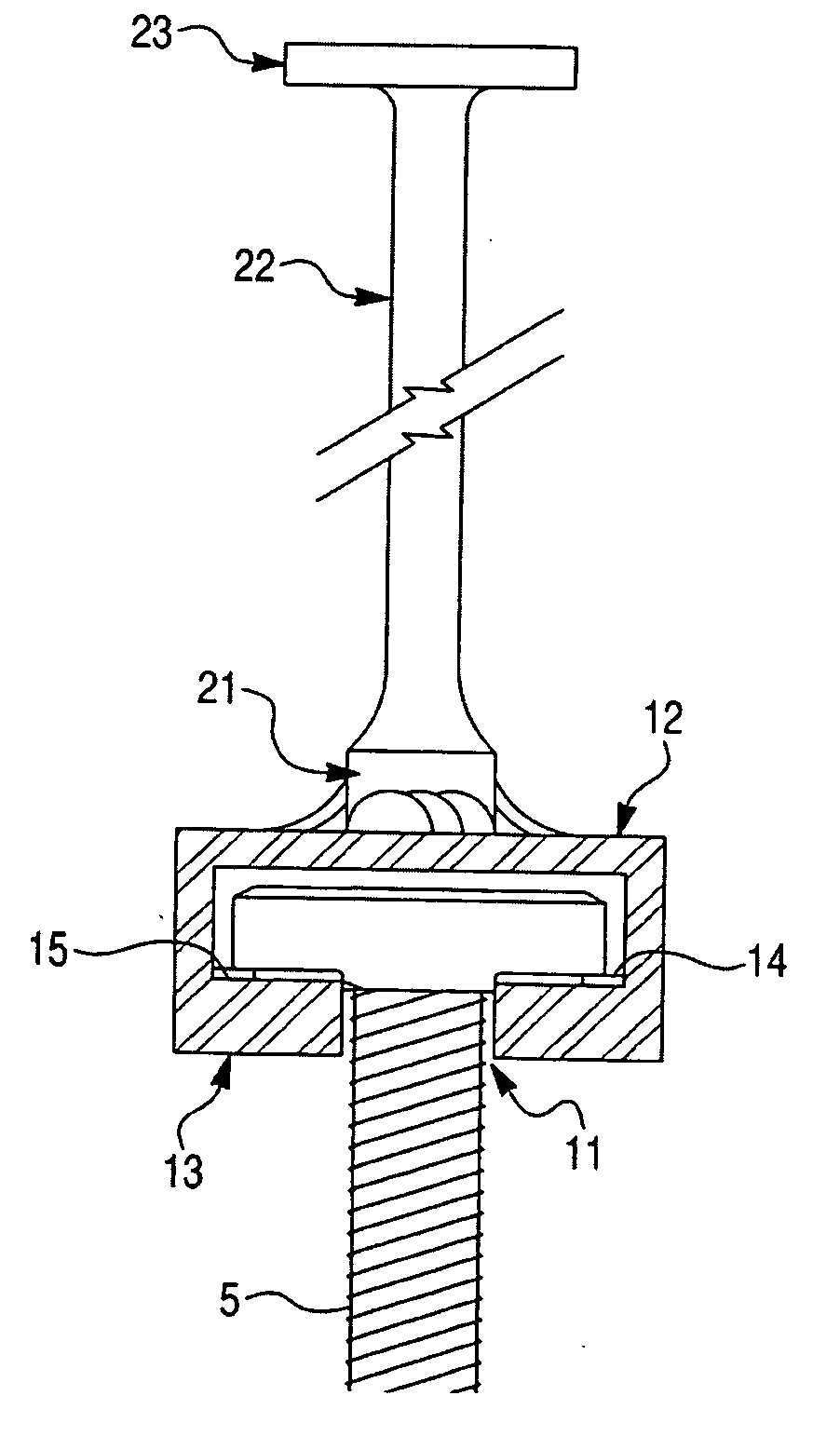

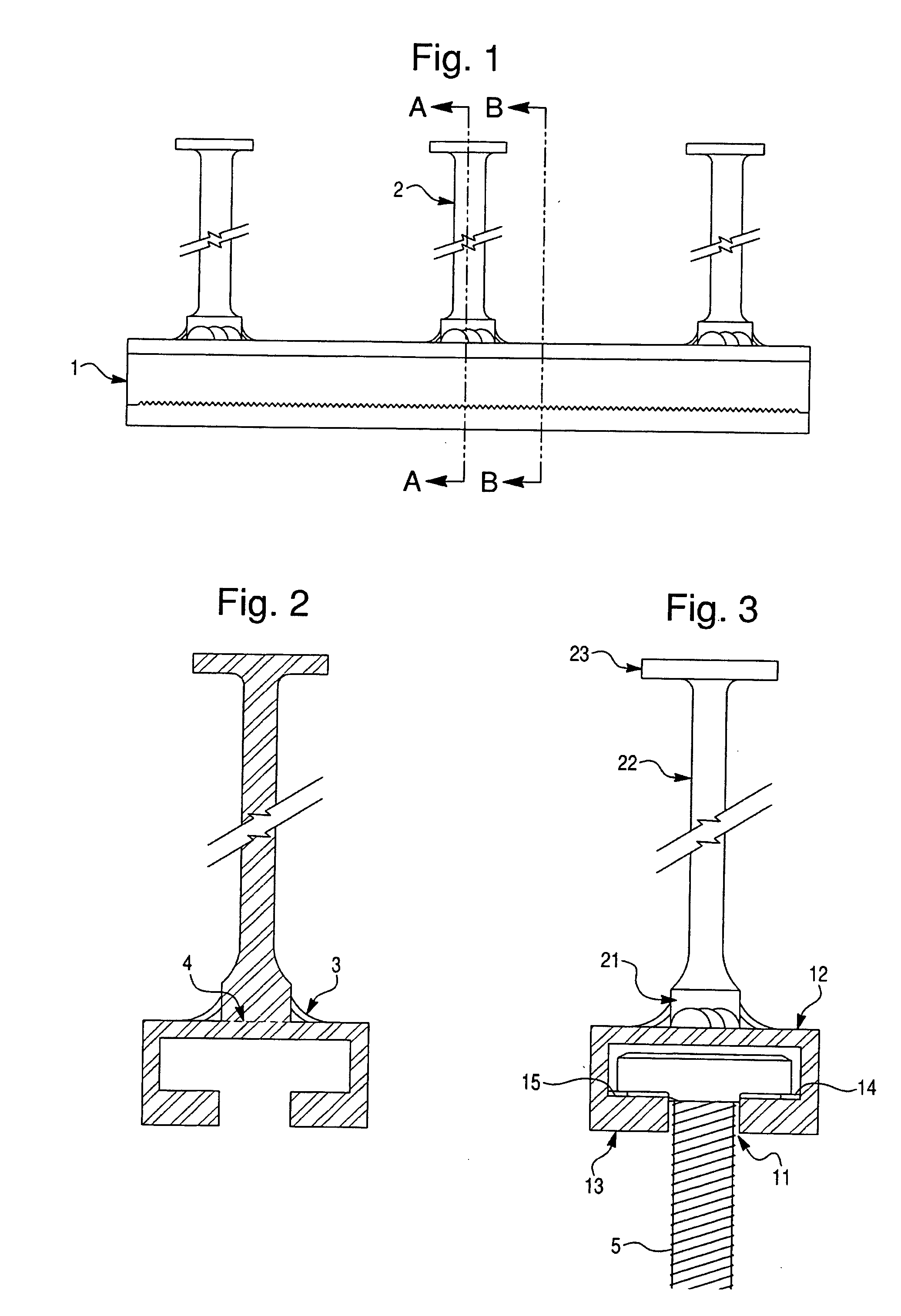

[0023]Referring now to FIG. 1 to FIG. 3, one embodiment of a channel anchoring device for construction industry in accordance with this invention is manufactured from hot rolled steel or stainless steel material, which is applicable to be cast into concrete structure. With the function as a coupling device, this channel anchoring device can attach with any construction elements and transfer the load from the attached element to the concrete.

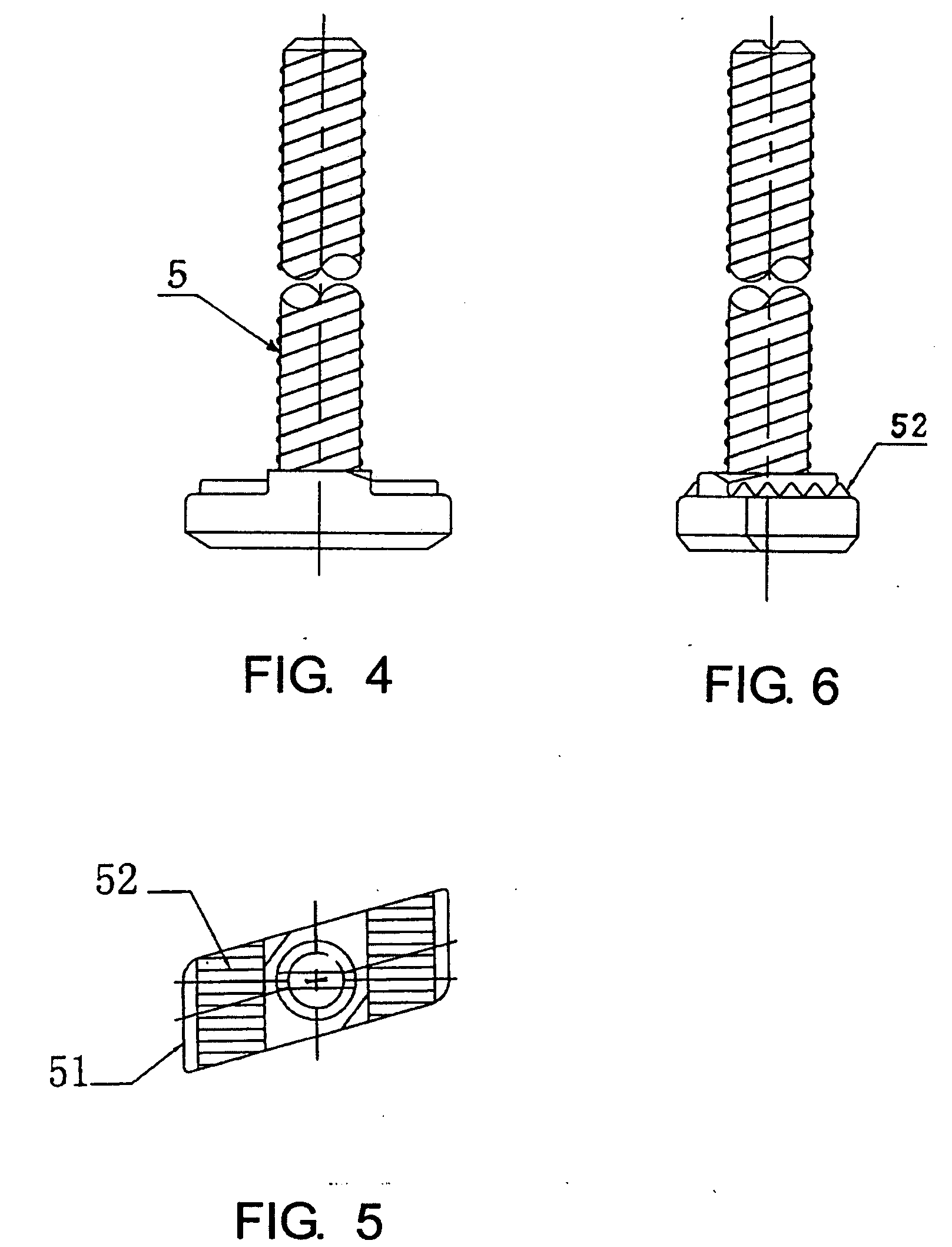

[0024]Referring now to FIG. 4 to FIG. 6, the channel anchoring device of this invention comprises an anchor channel 1 that is made from hot rolled C-shaped steel (or stainless steel) and a T-bolt 5, a plurality of ordinary steel (or stainless steel) anchor shafts 2 installed onto the anchor channel 1, which are cast into the concrete structure. The T-bolts 5 are inserted to install within the anchor channel 1.

[0025]The anchor channel 1 is a channel rail with a hollow interior, which is made from hot rolled steel or stainless steel material by the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com