Aerodynamic transformable truck cap assembly

a truck and truck bed technology, applied in the direction of roofs, load coverings, transportation and packaging, etc., can solve the problems of reducing fuel economy, increasing aerodynamic drag, and substantial loss of interior volume, so as to reduce vehicle wind resistance and drag, increase cargo space, and increase fuel efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

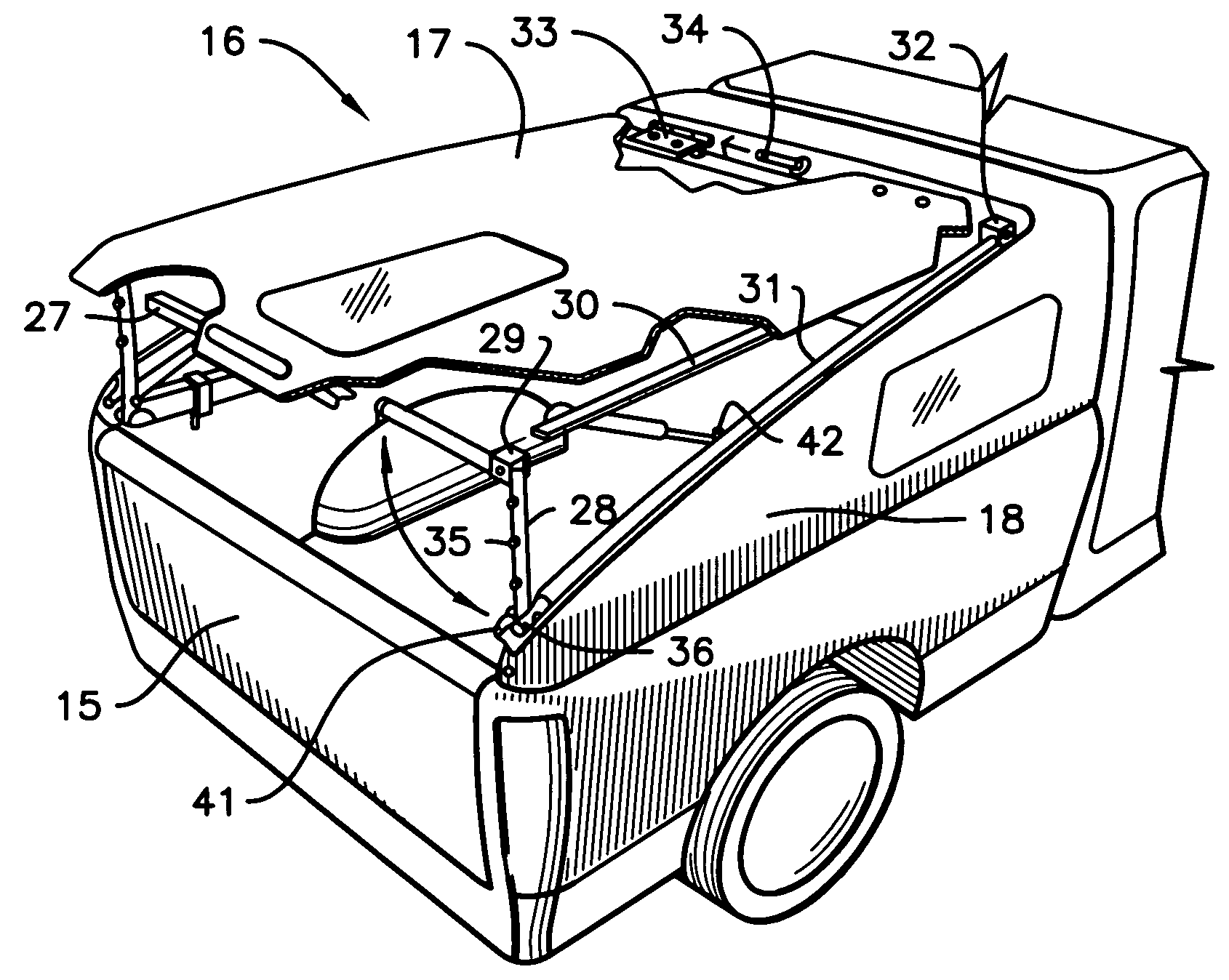

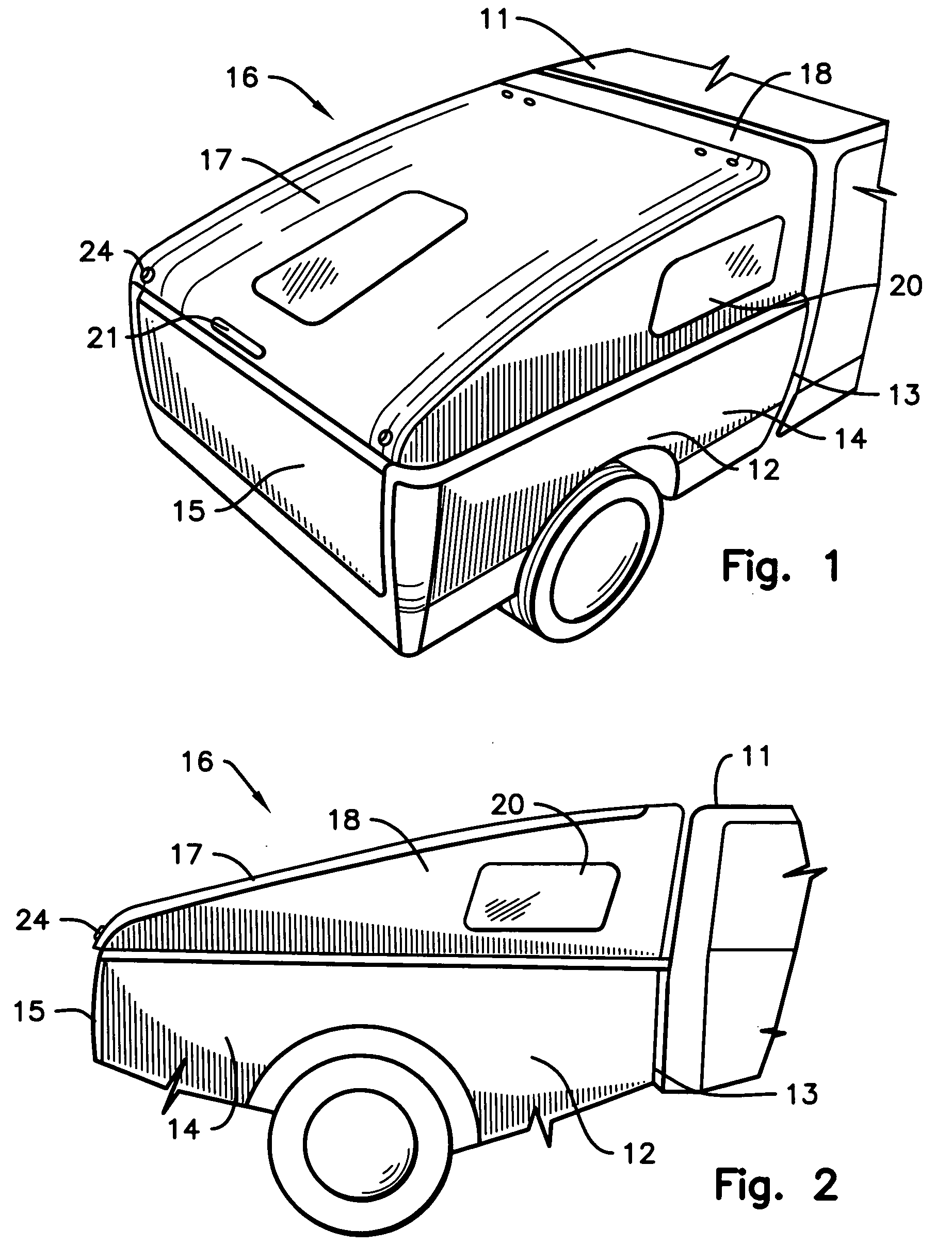

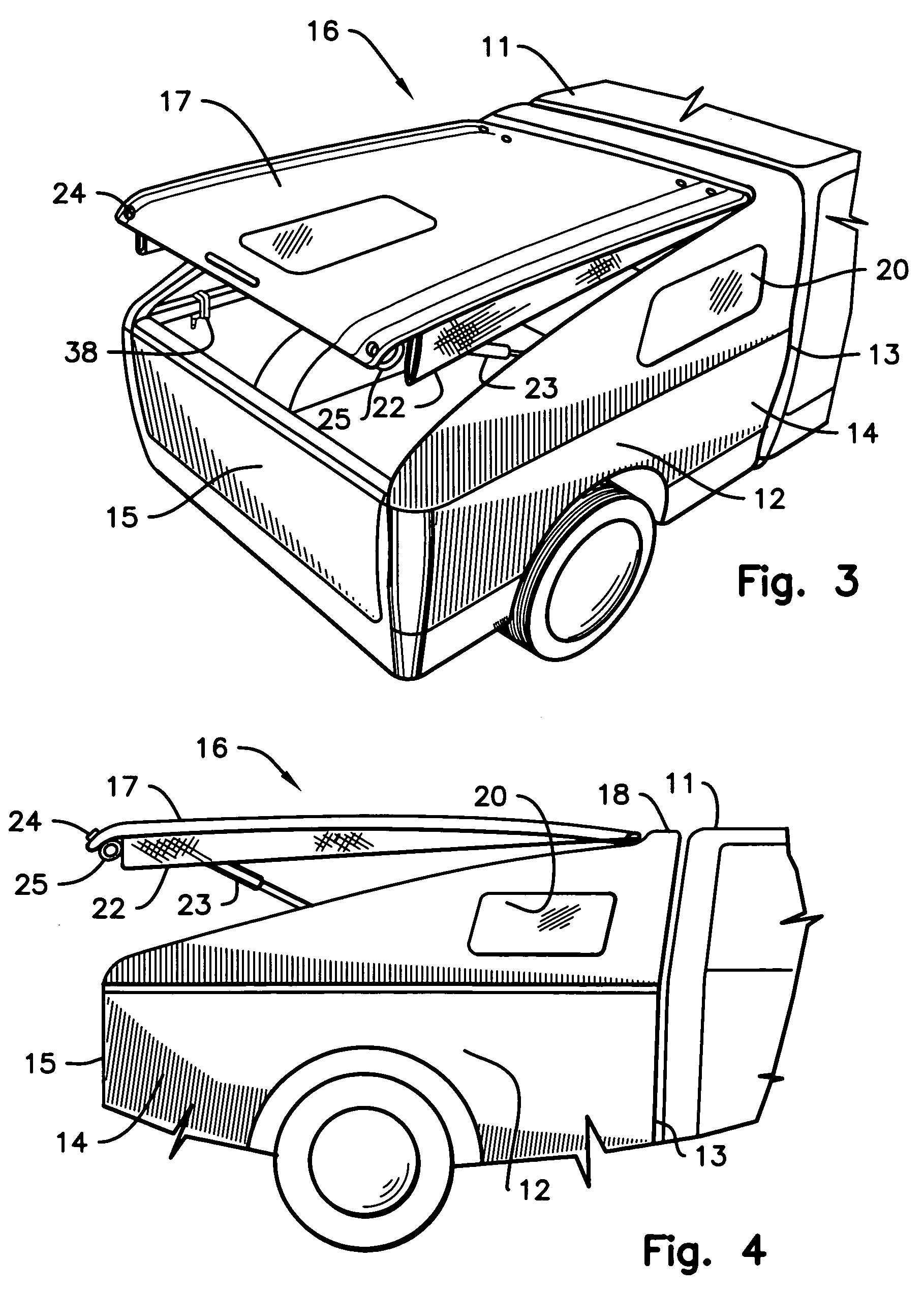

[0033]With initial reference directed to FIGS. 1 and 2 of the appended drawings, a conventional pickup truck having a cab 11 includes a conventional, rear truck bed 12 behind the cab 11, over and upon which my new truck cap is to be installed. The conventional truck bed 12 is defined by upstanding front panel 13 opposite cab 11, side panels 14, and a tailgate 15. My new transformable truck cap cover assembly, constructed in accordance with the best mode of the invention, has been generally designated by the reference numeral 16. Assembly 16 preferably comprises an aerodynamically configured, removably mounted cover 17 operationally associated with a preferably fiberglass shell 18 that is fitted to the truck bed rear peripherally about the bed. During use, shell 18 remains on the truck bed, but cover 17 may be removed completely.

[0034]When installed, the substantially rigid, preferably fiberglass cover 17 is disposed upon shell 18 over bed 12, between truck side panels 14. The cover ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com