Valve, in particular for compressors

a compressor and valve body technology, applied in the field of valves, can solve the problems of high opening/closing frequency, increase in the reliability problems of the abovementioned components, wear of varying nature and varying degrees, etc., and achieve the effect of preserving the wear of the components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

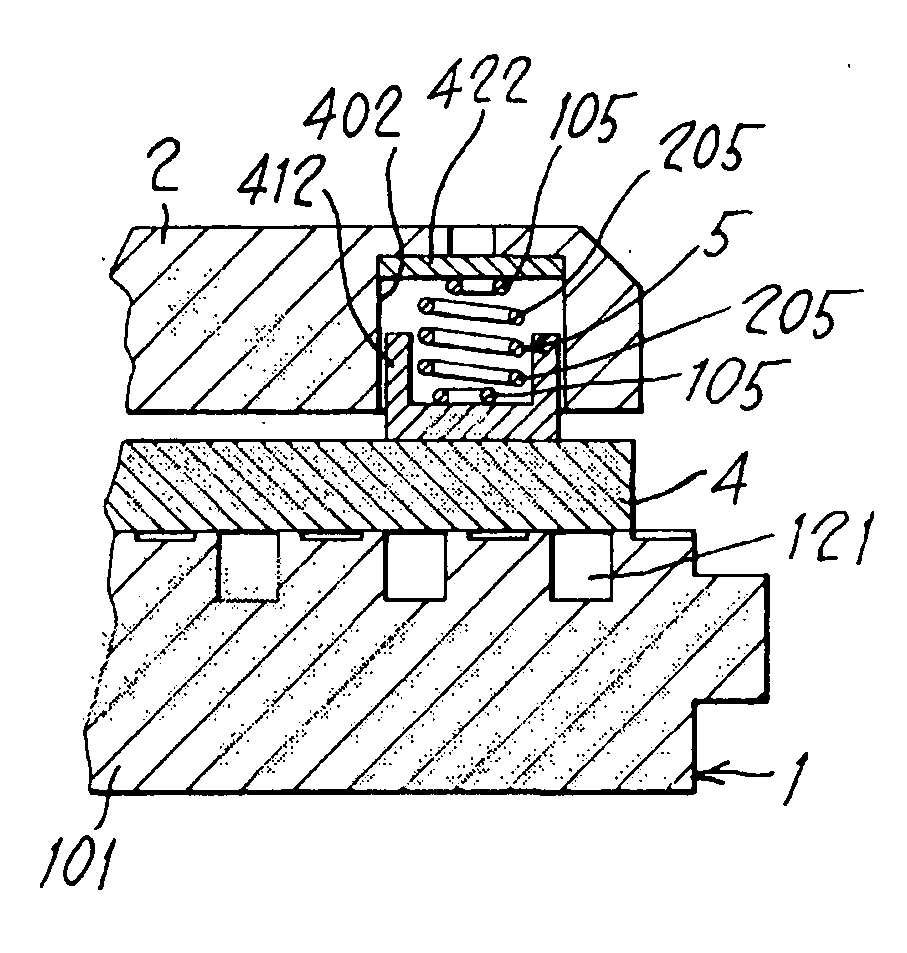

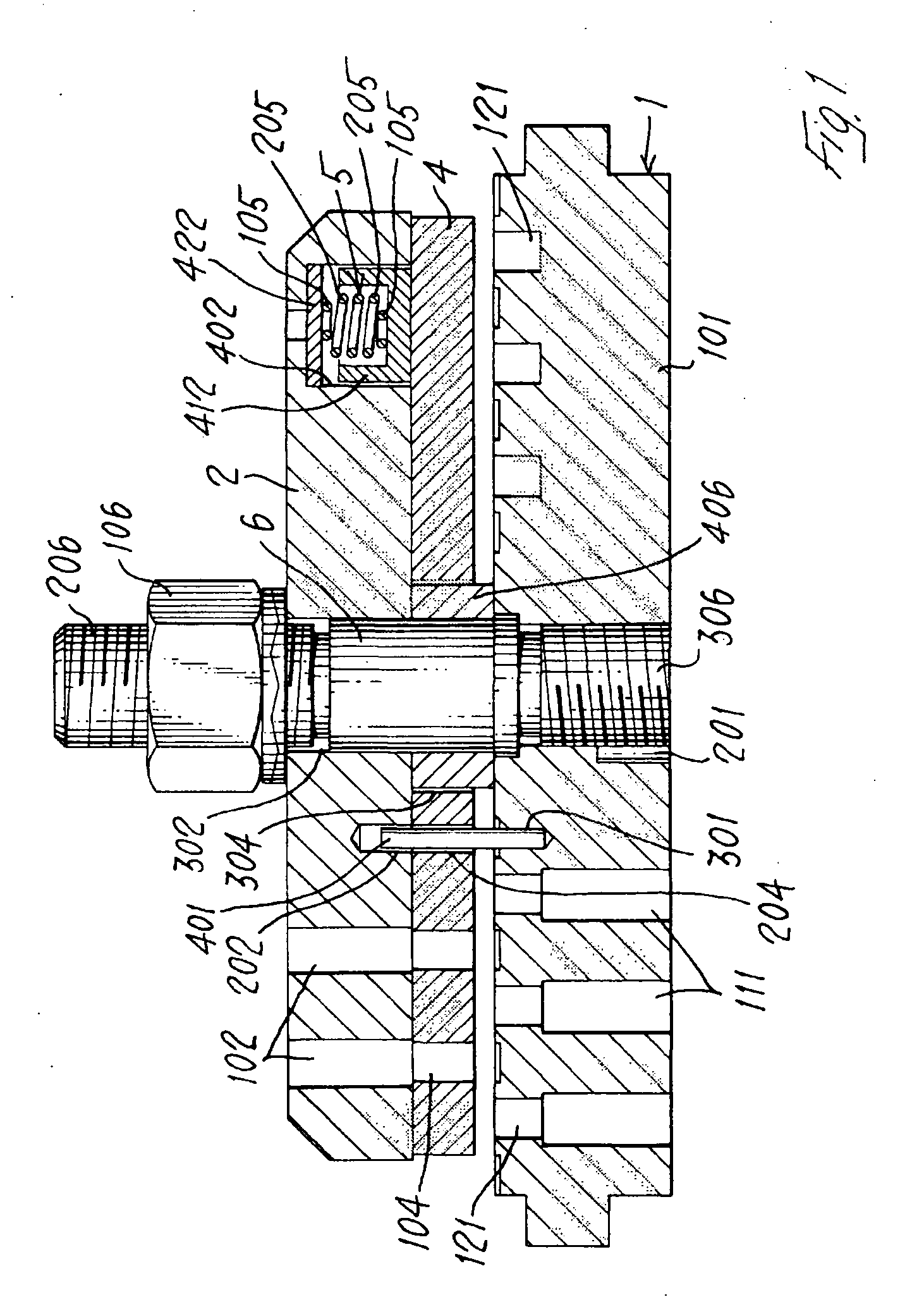

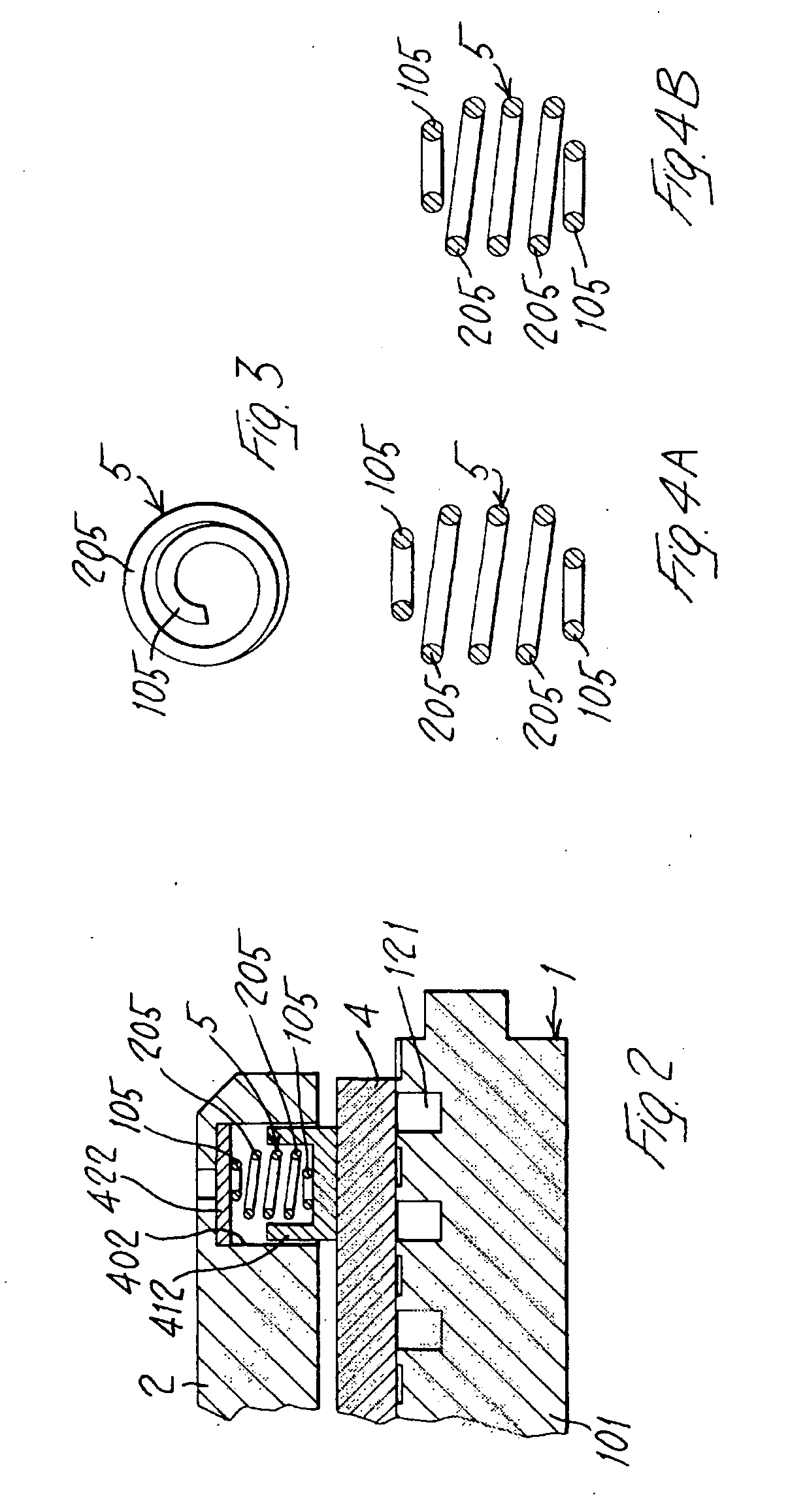

[0018]FIG. 1 shows an embodiment of the valve according to the present invention; 1 denotes the seat of the said valve, comprising a plate 101 provided with a plurality of axial and eccentric through-holes 111 acting as flow ways for the fluid and having a central, axial, threaded, through-hole 201 with which the threaded end 306 of the bolt 6 mates. The plate 101 also has formed therein the grooves 121 which communicate with the through-holes 111. The central portion of the bolt 6 also has, mounted thereon, the bush 406 and the counter-seat 2 provided with a central axial through-hole 302; the seat 1, bush 406 and counter-seat 2 are fixed together by means of the nut 106 screwed onto the threaded end 206 of the bolt 6. The axial through-ducts 102 are formed in the counter-seat 2.

[0019]The obturator 4 is arranged between the seat 1 and the counter-seat 2, being coaxial and concentric with the bush 406 and axially slidable along it by means of its central axial hole 304. The obturato...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com