Patents

Literature

30results about How to "Wear characteristic" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

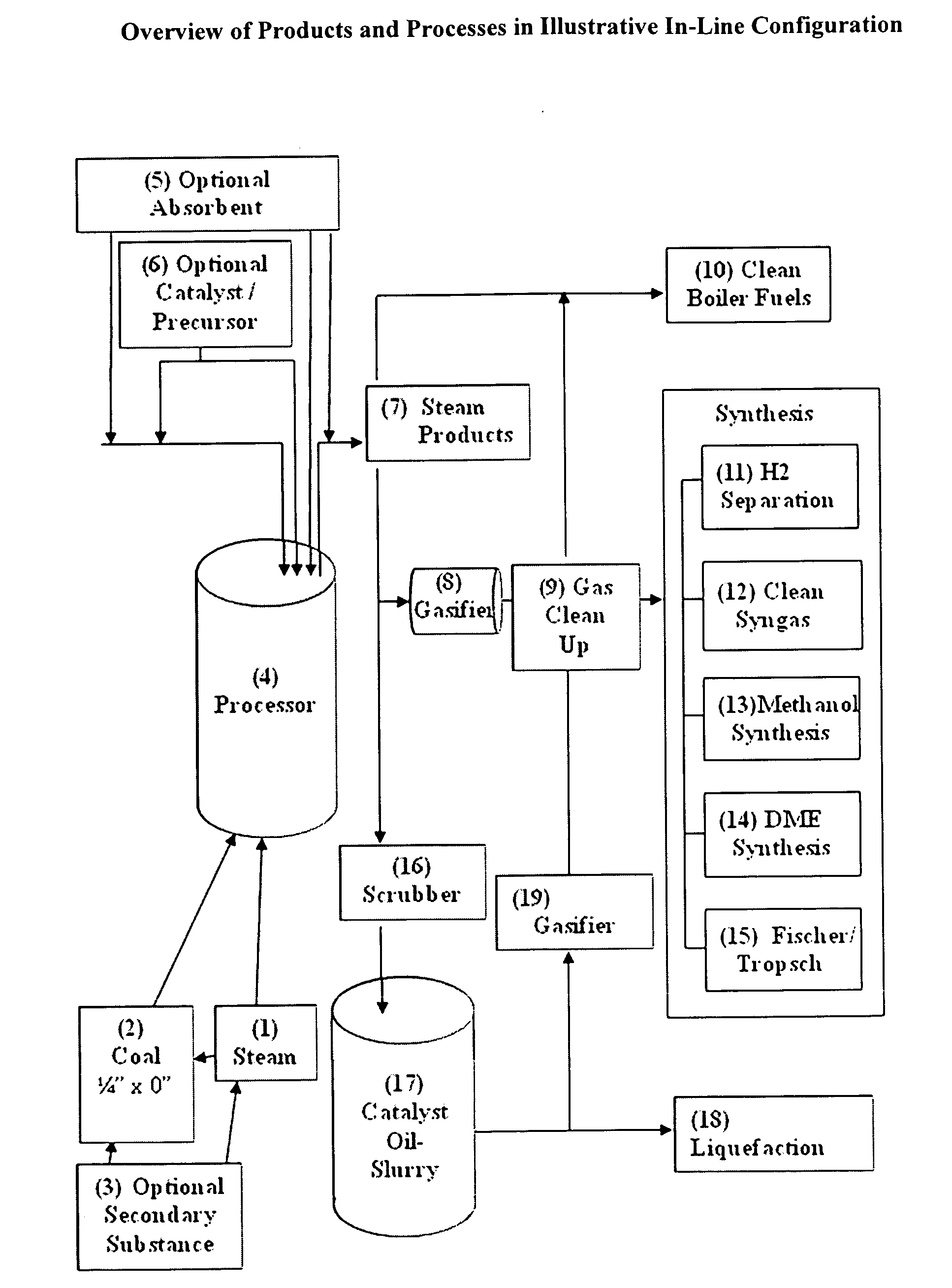

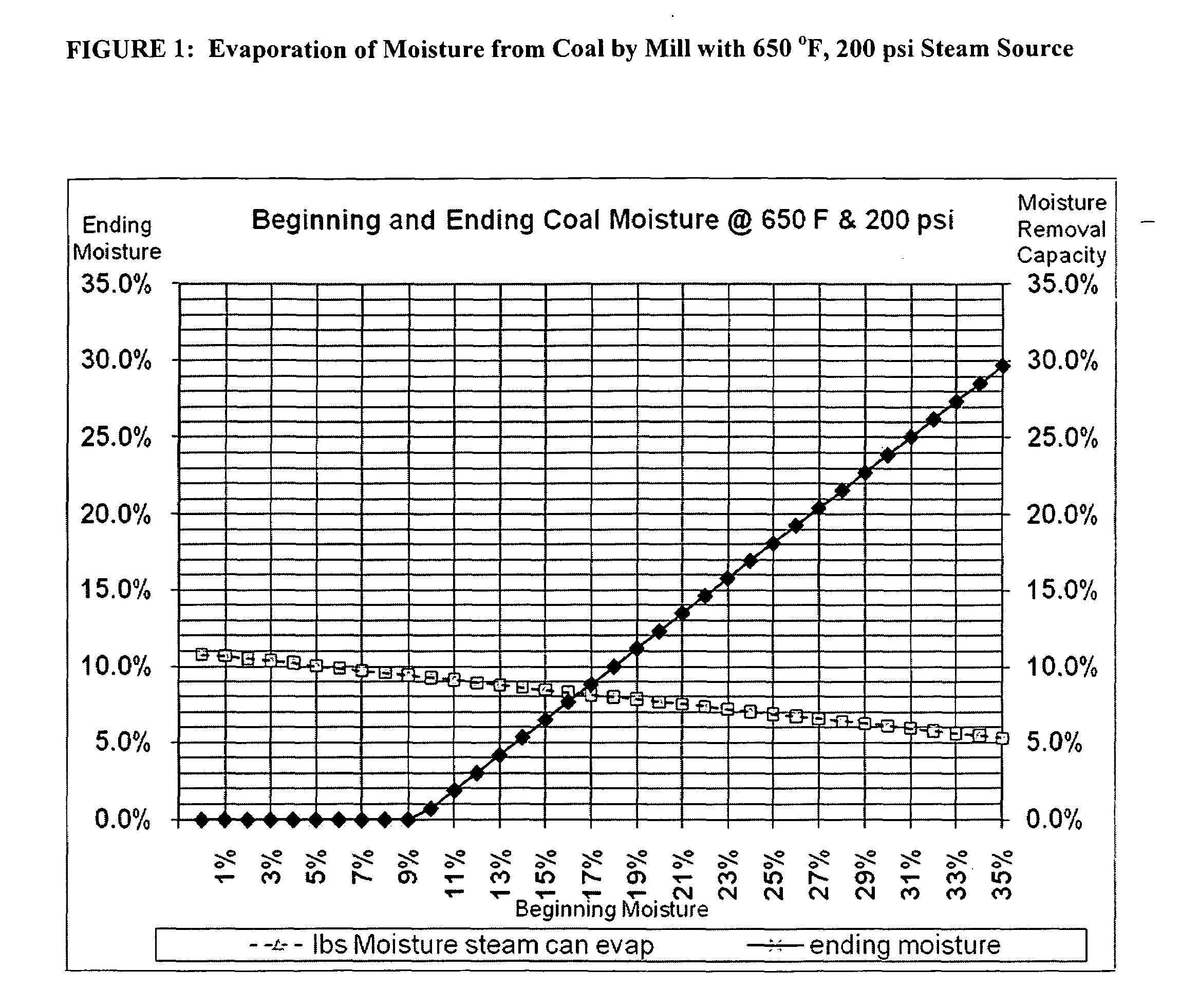

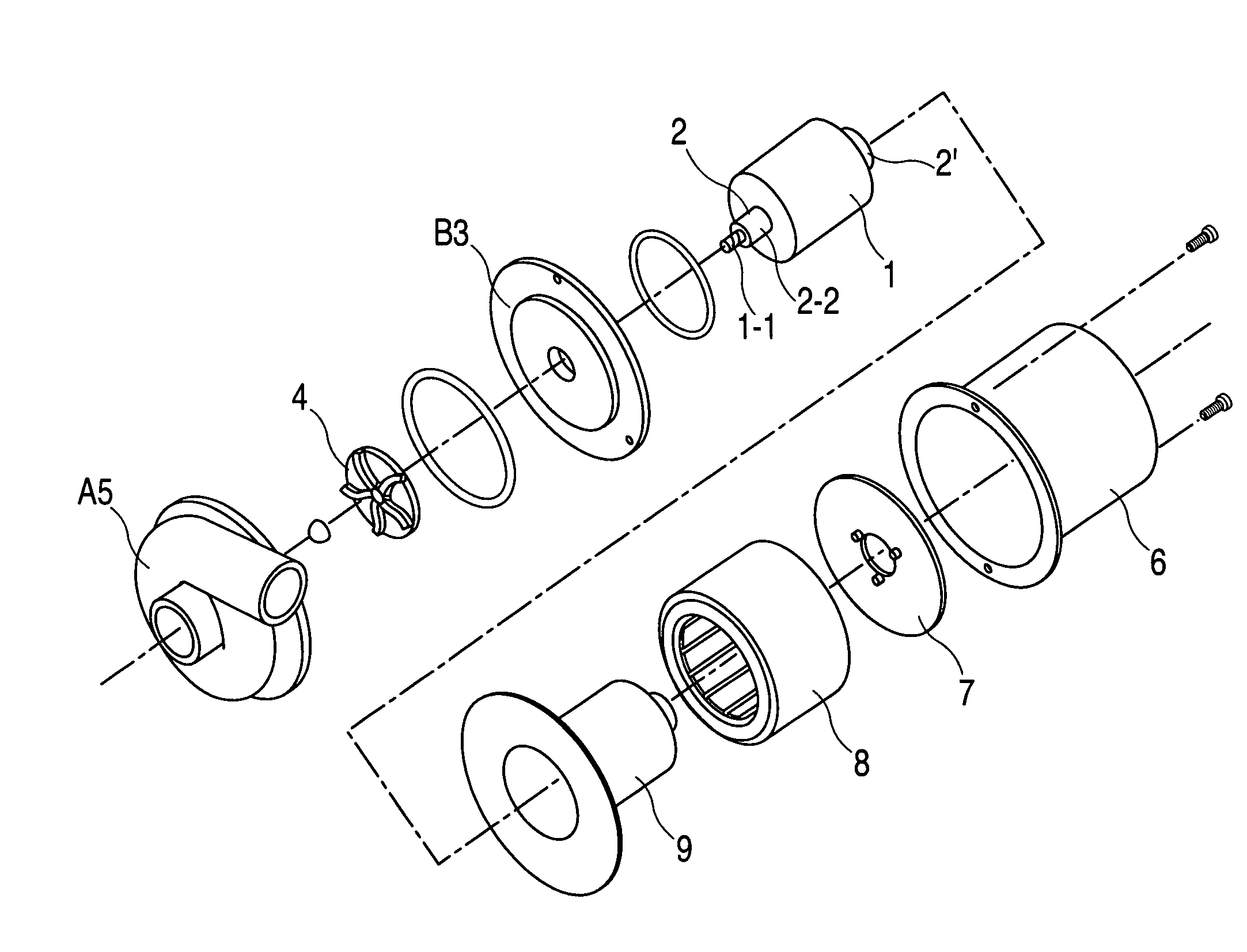

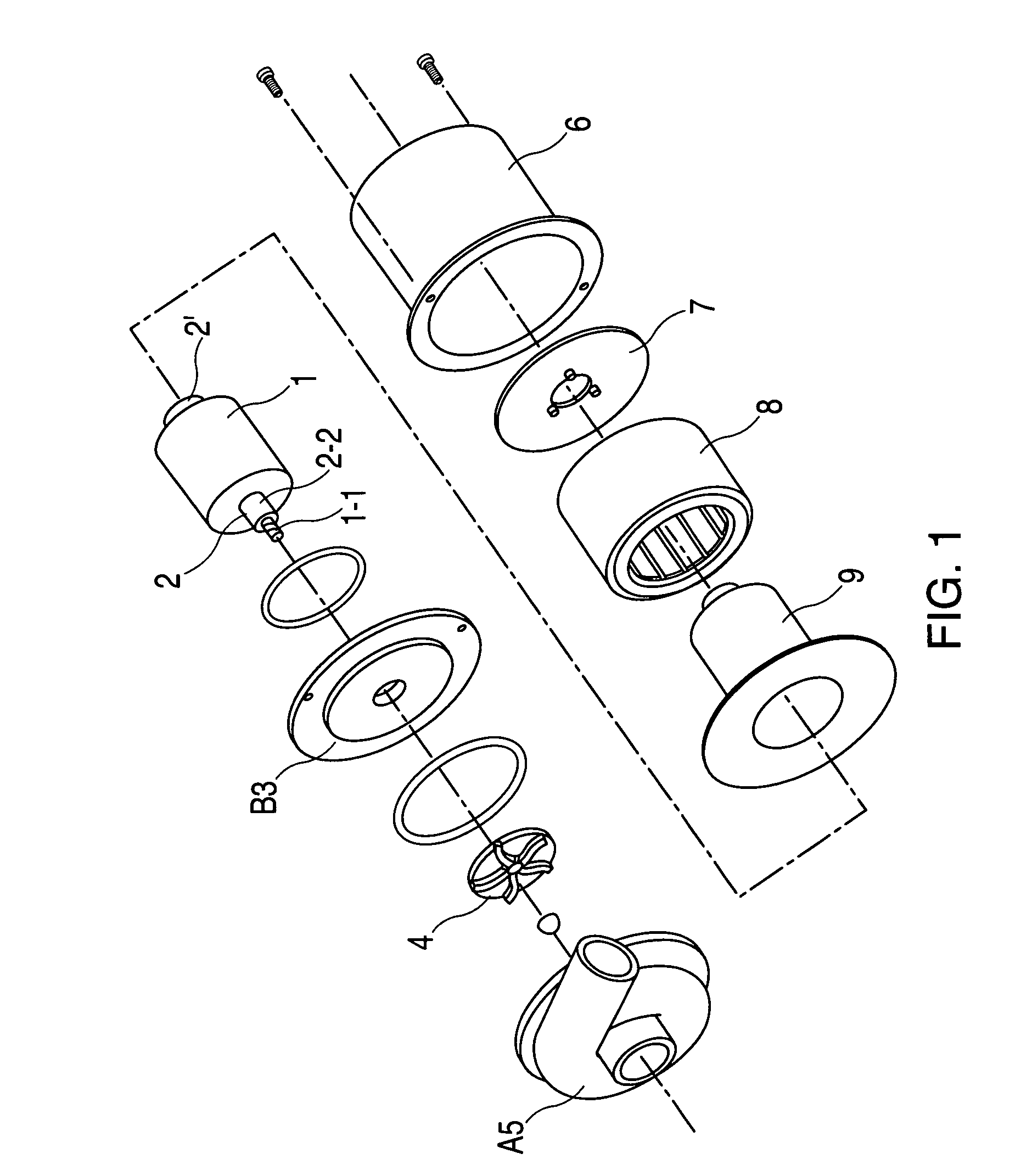

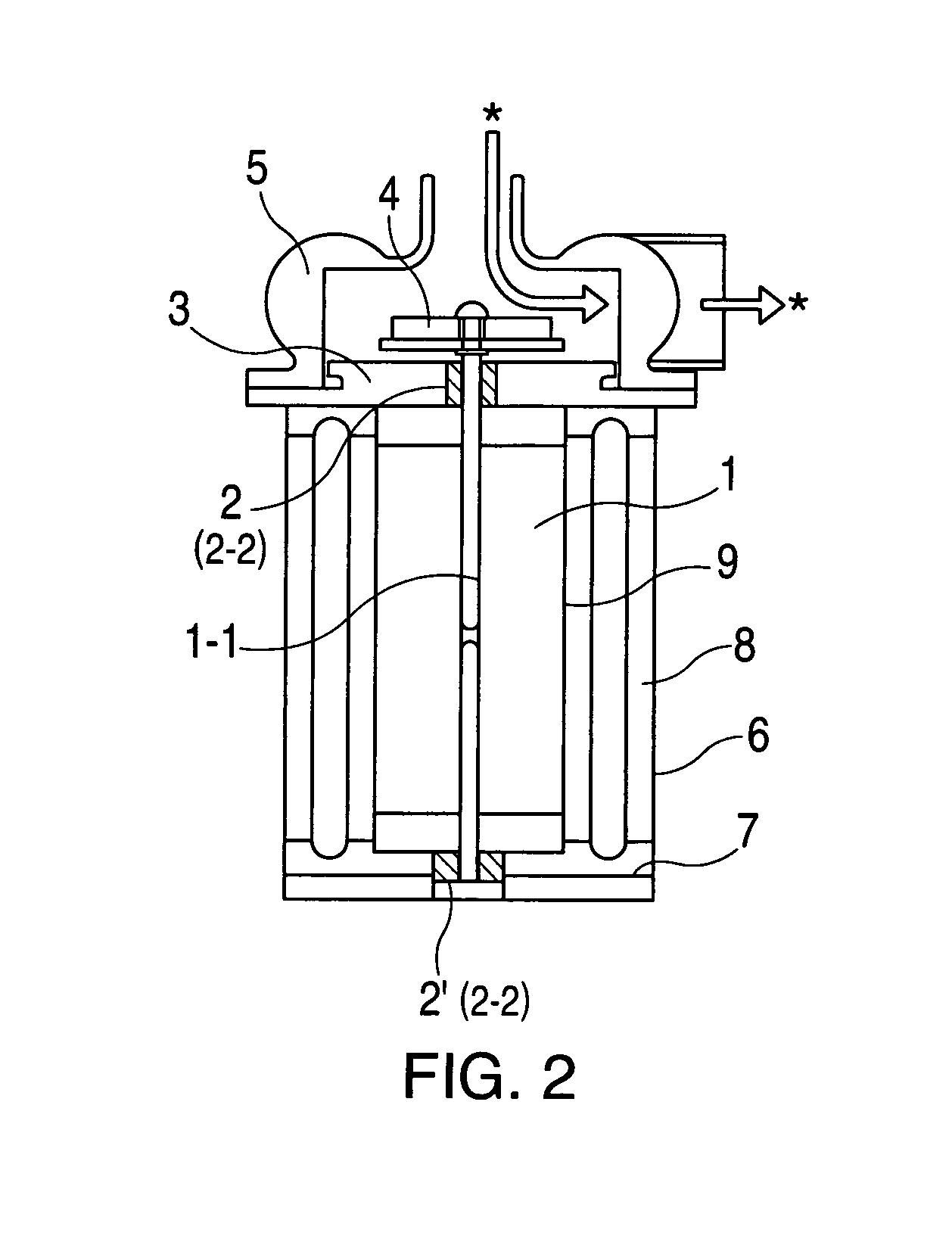

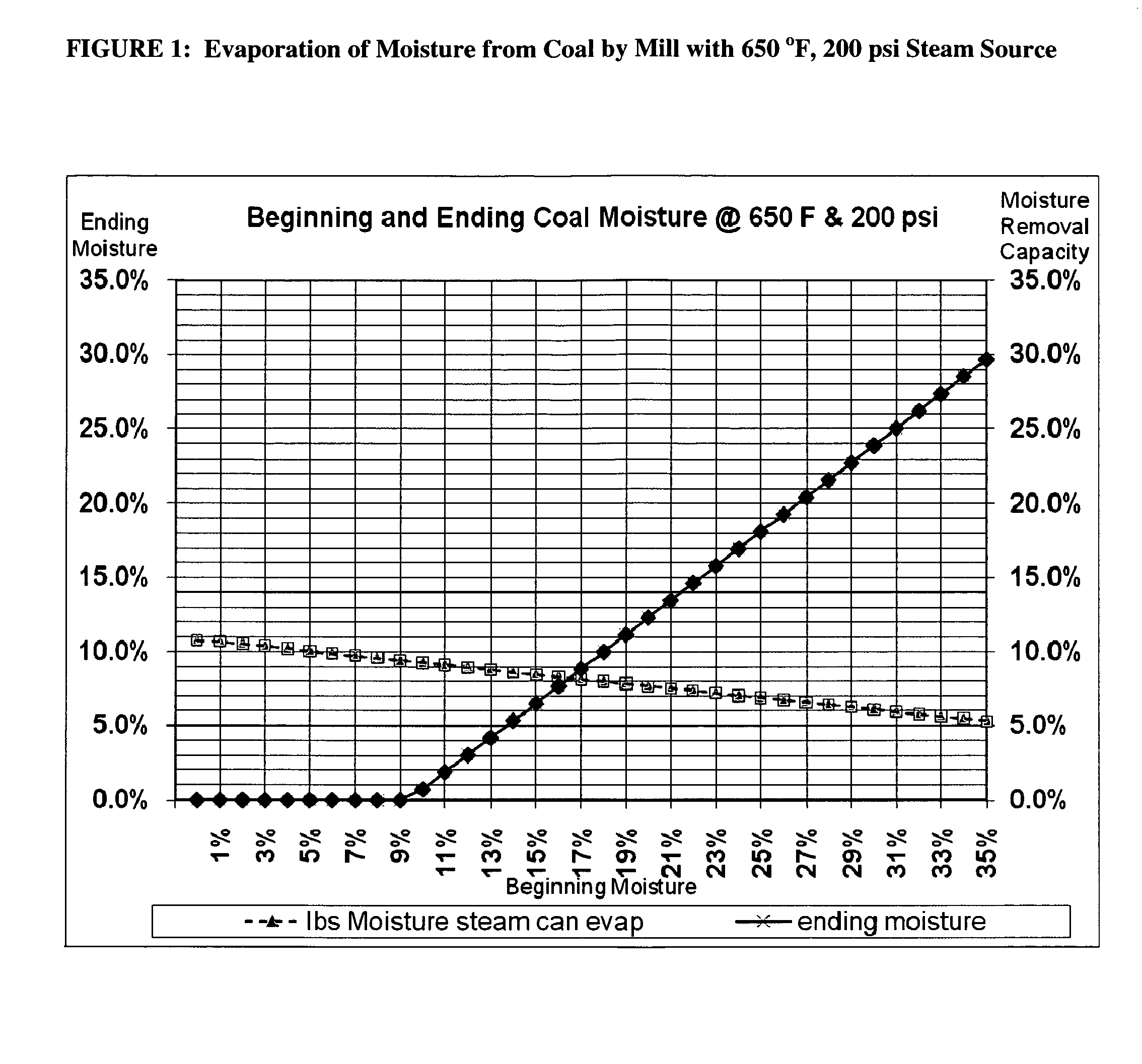

Processing device for improved utilization of fuel solids

InactiveUS20090199425A1Little wearRapid and uniform and fuel efficient gasificationDrying gas arrangementsWaste based fuelCombustionNitrogen oxides

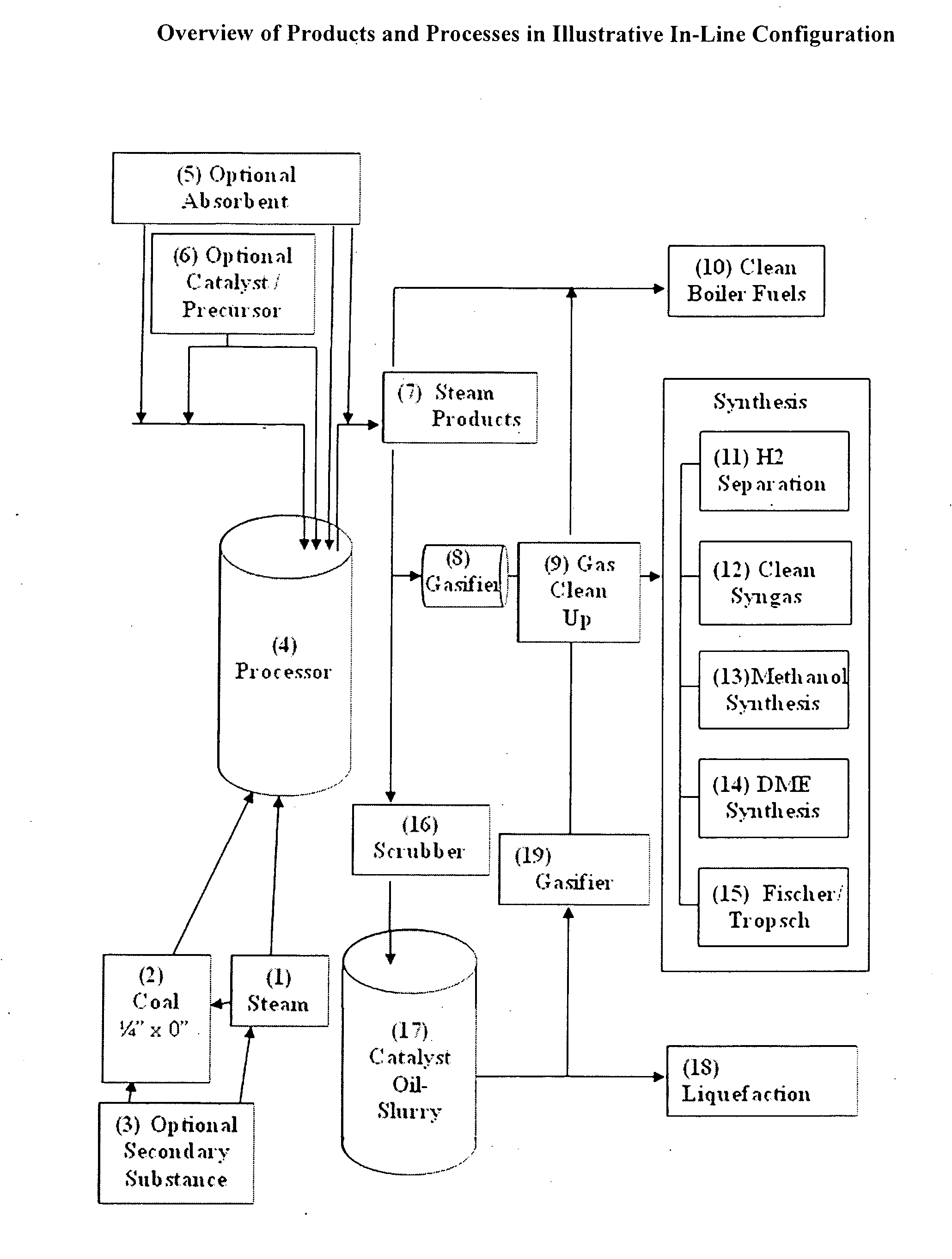

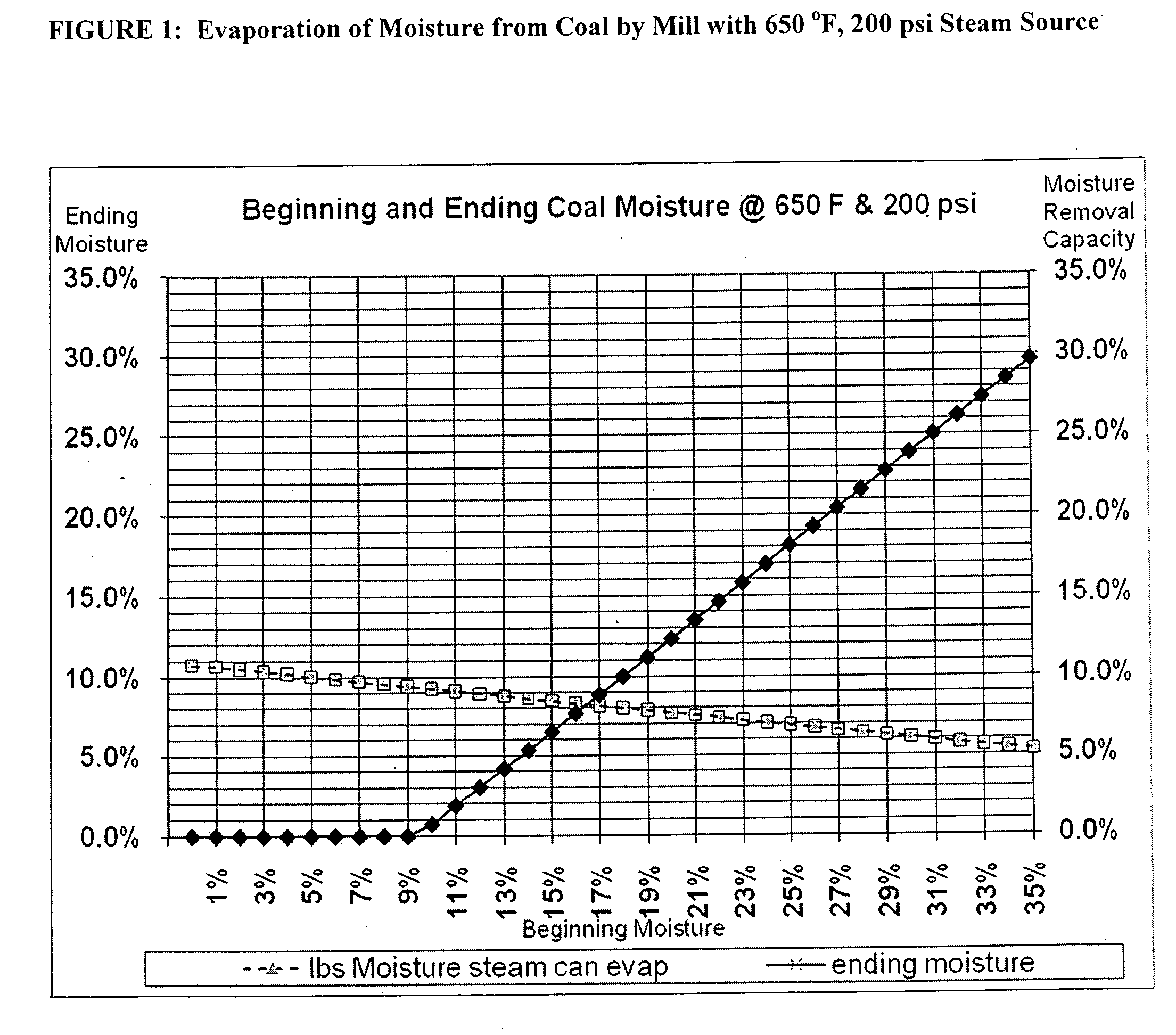

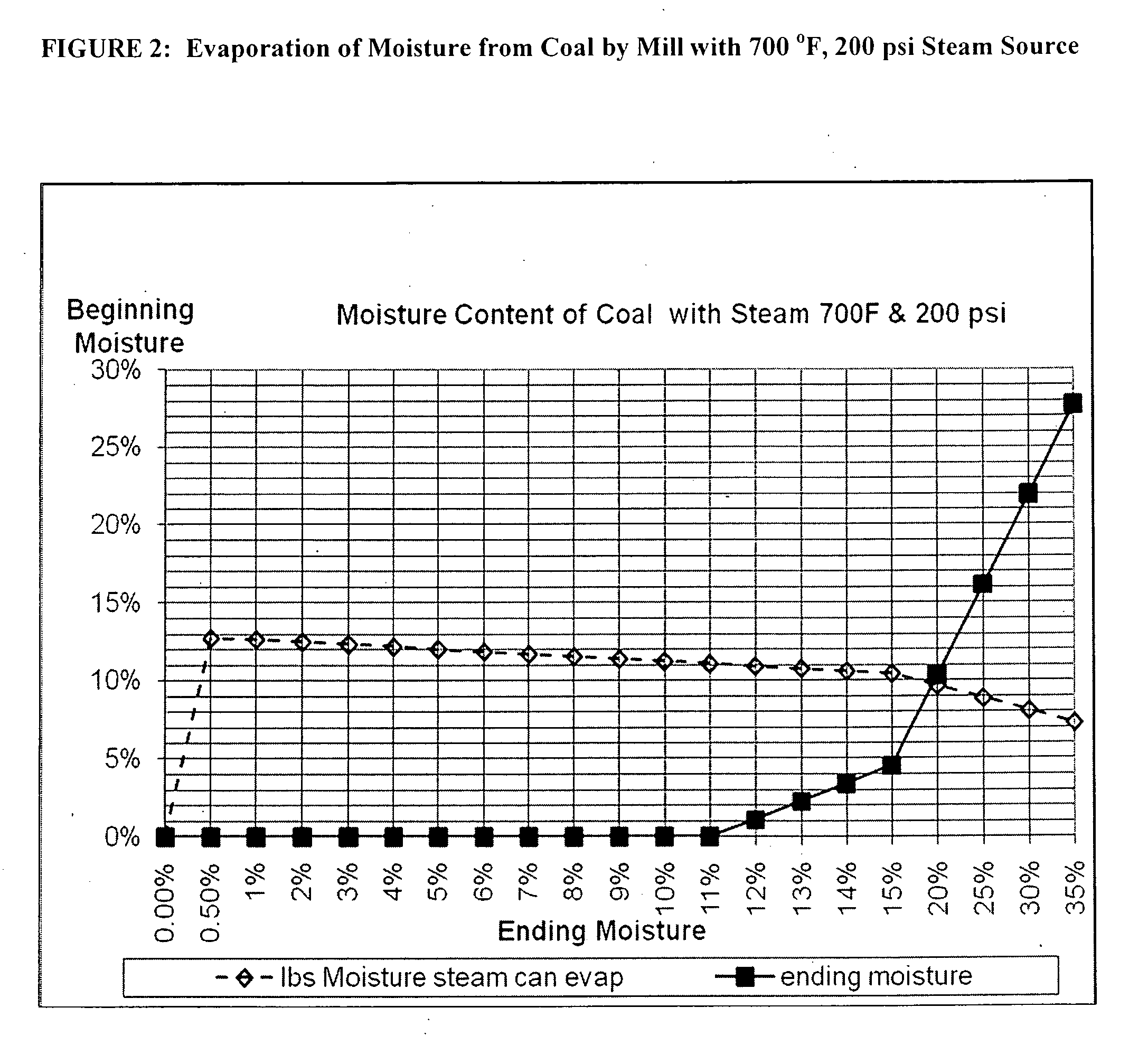

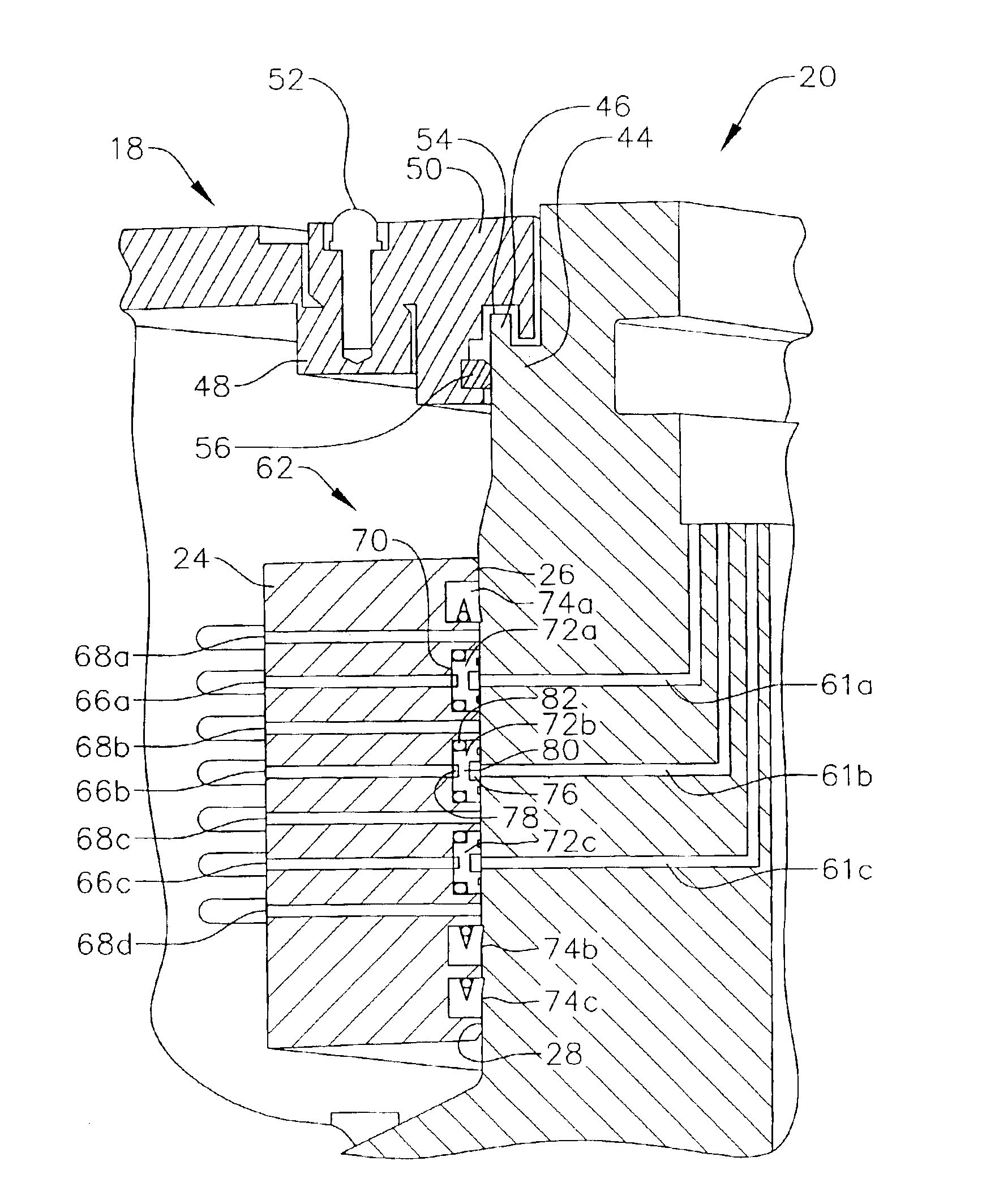

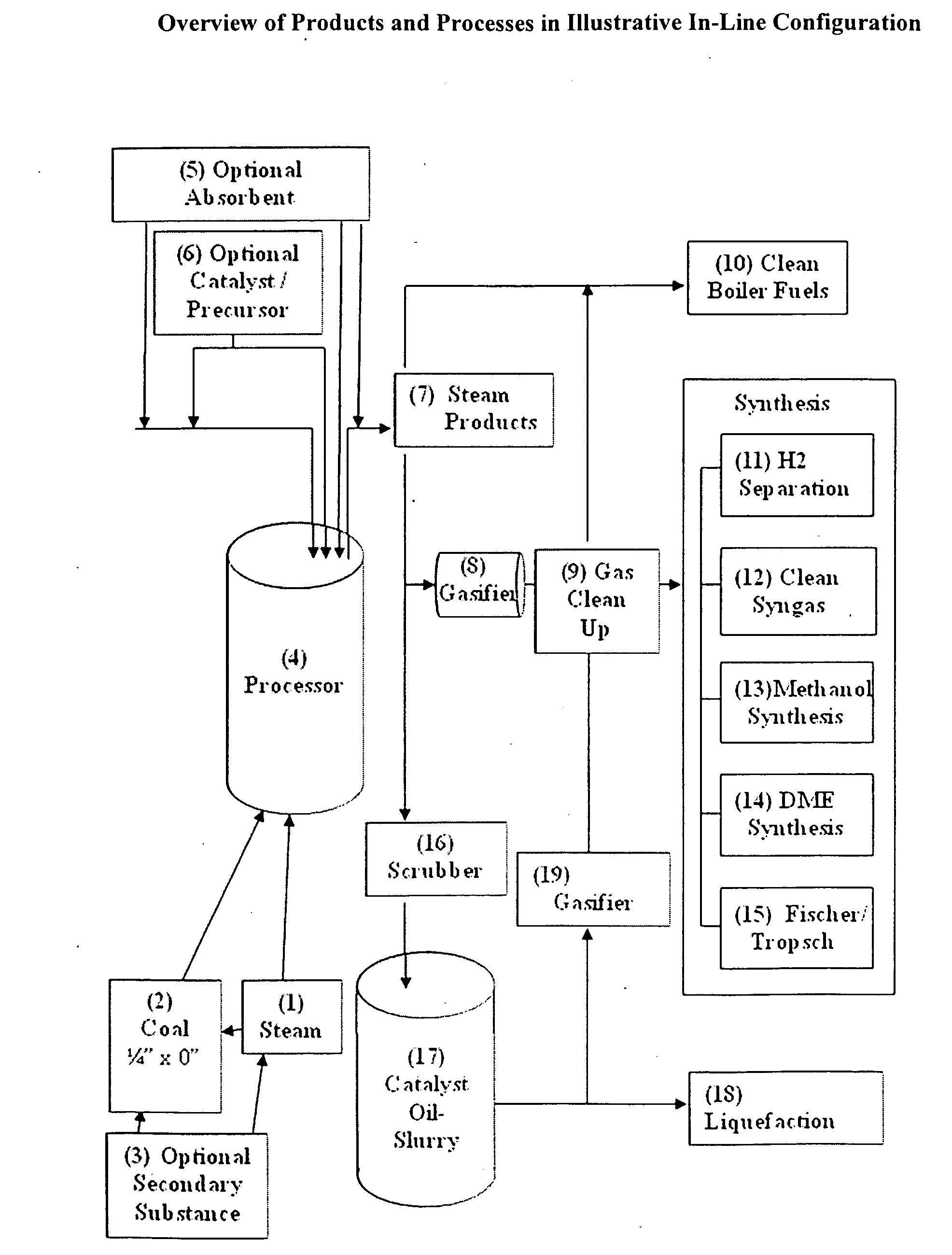

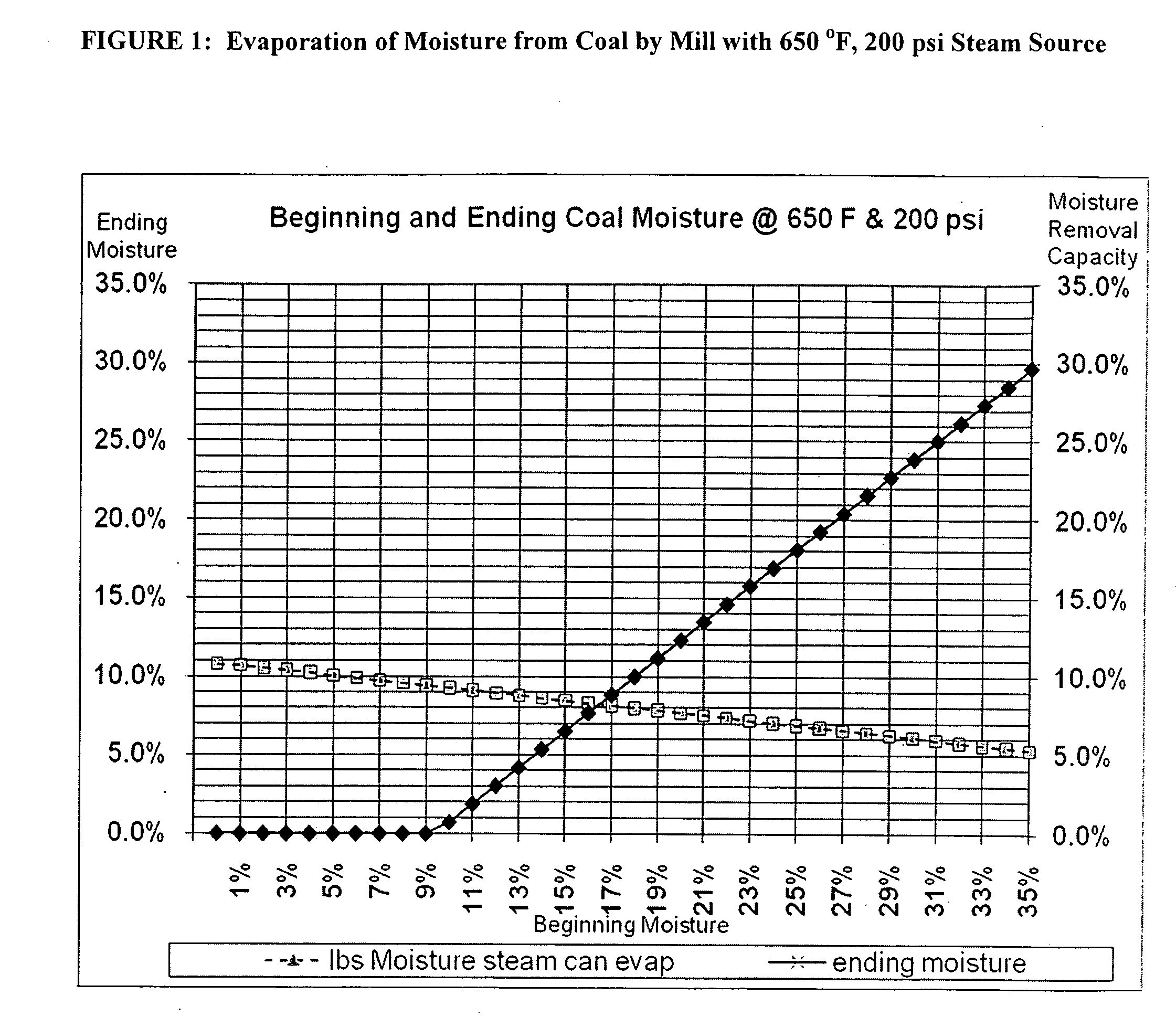

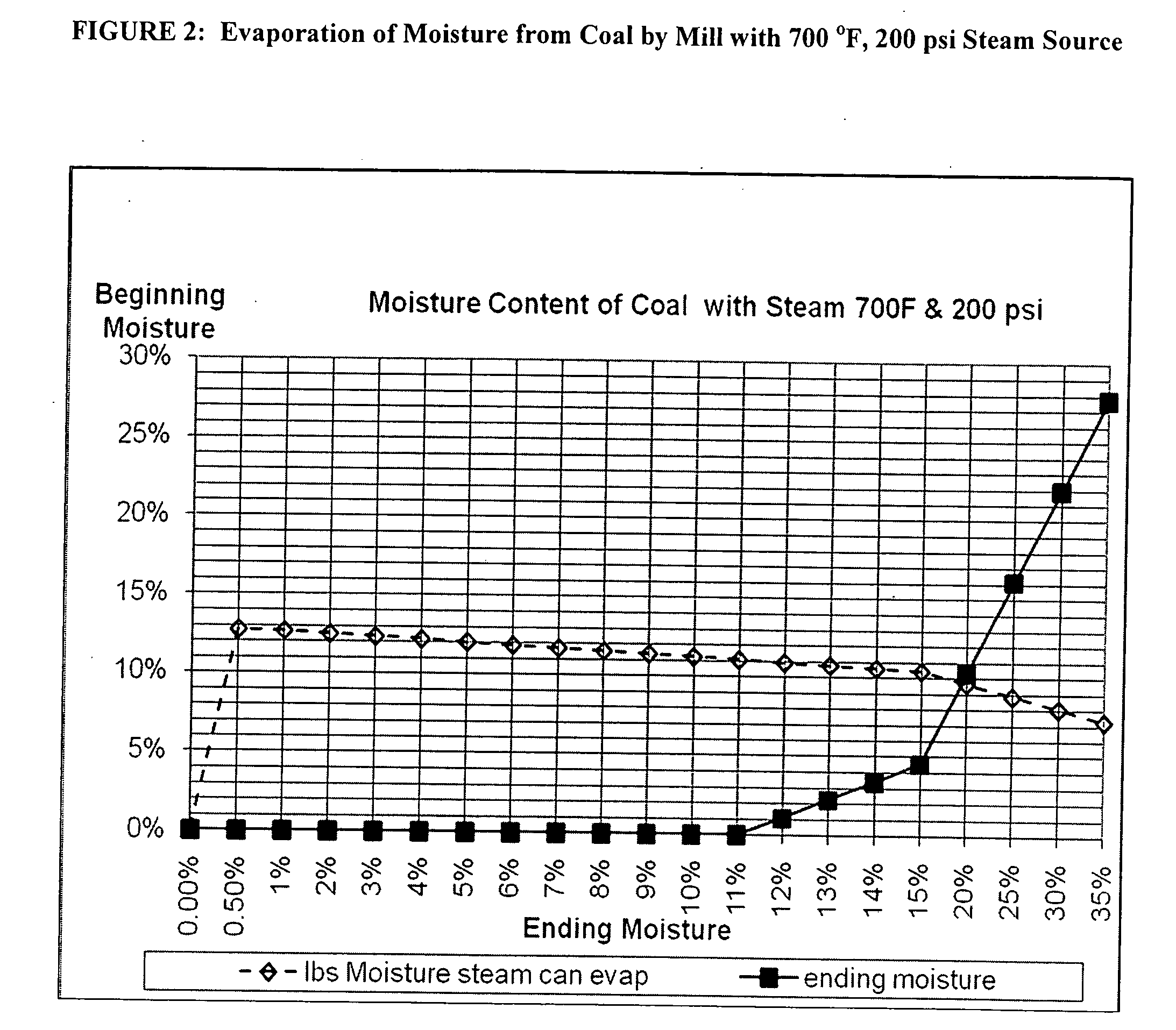

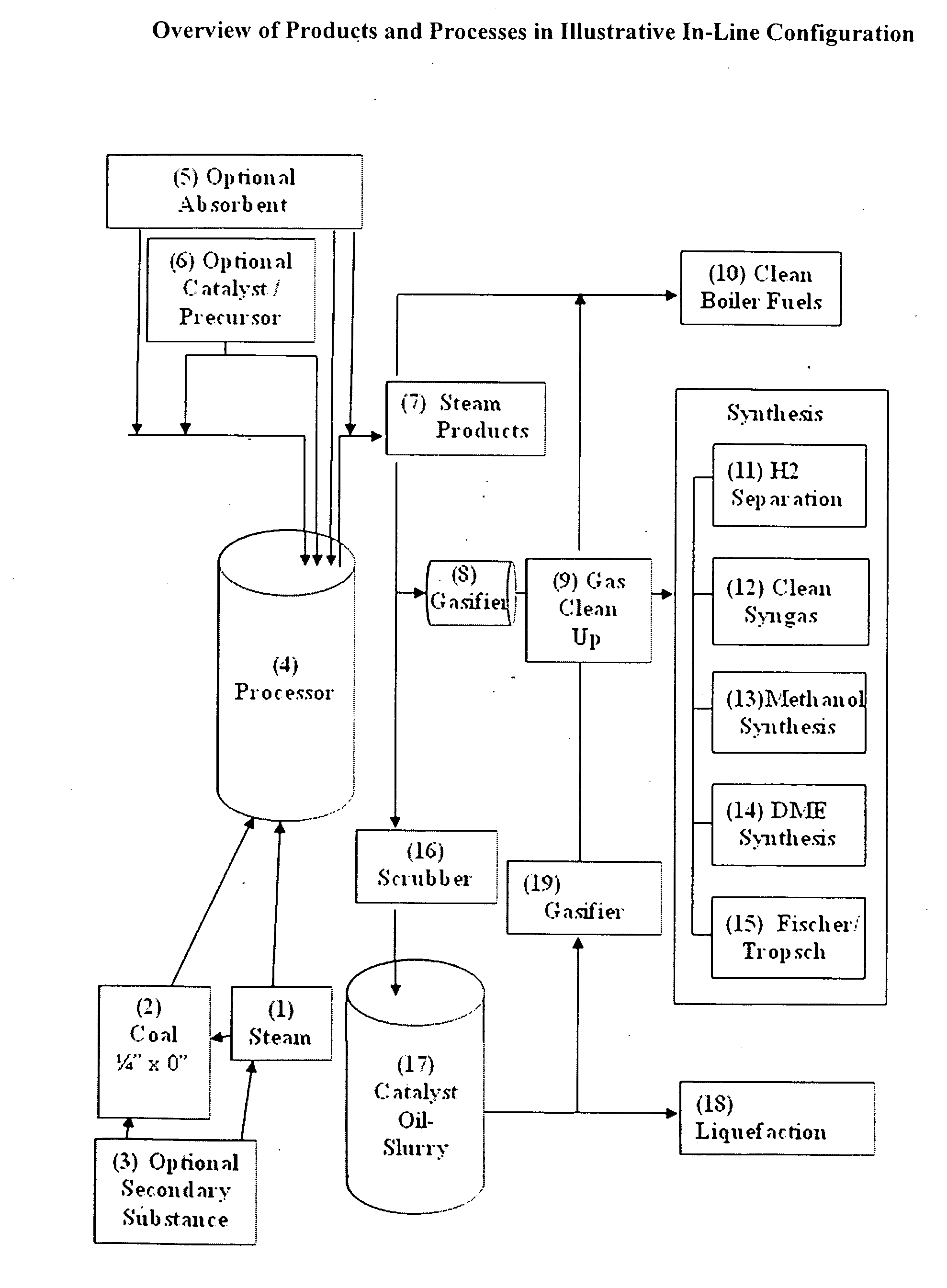

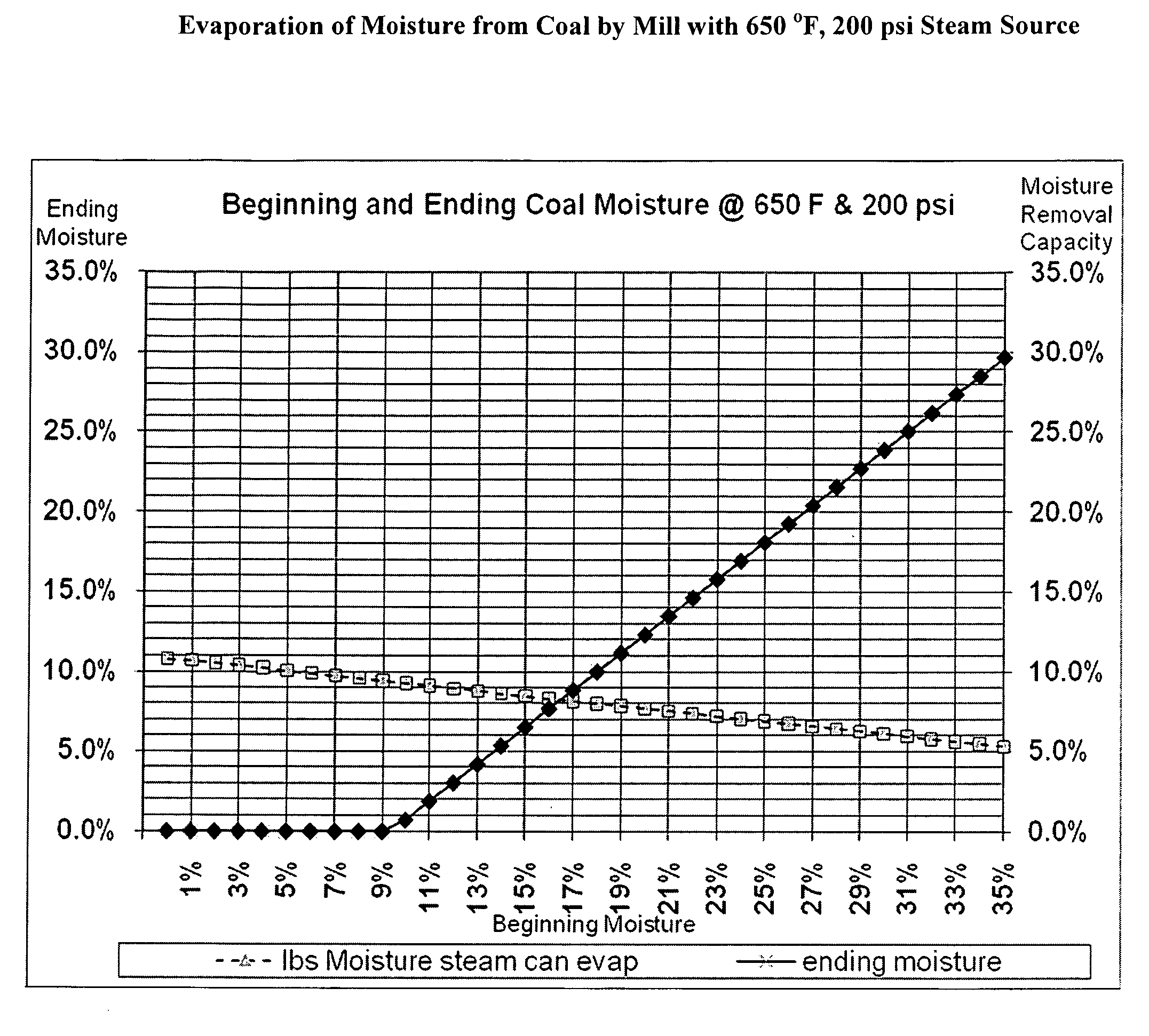

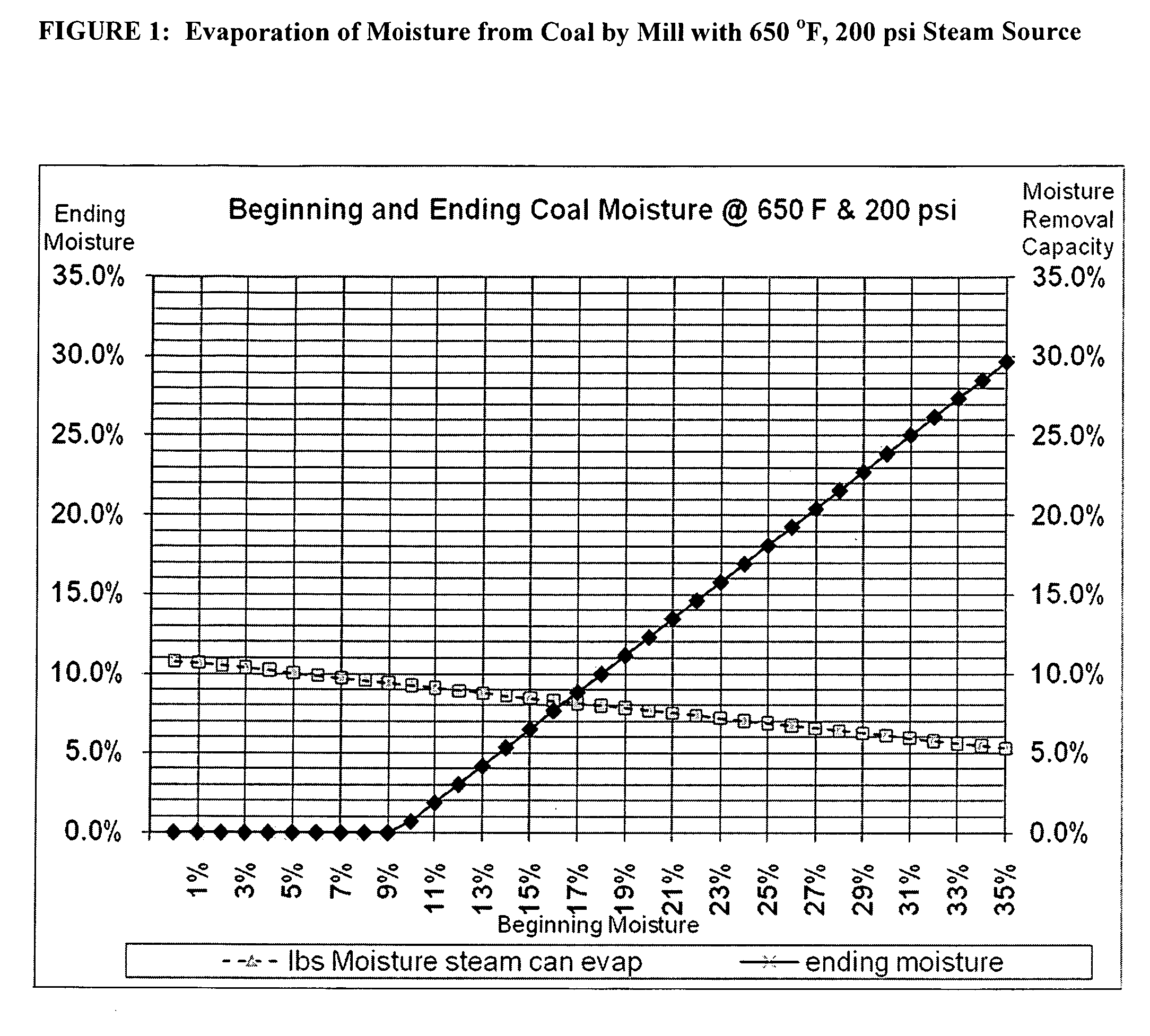

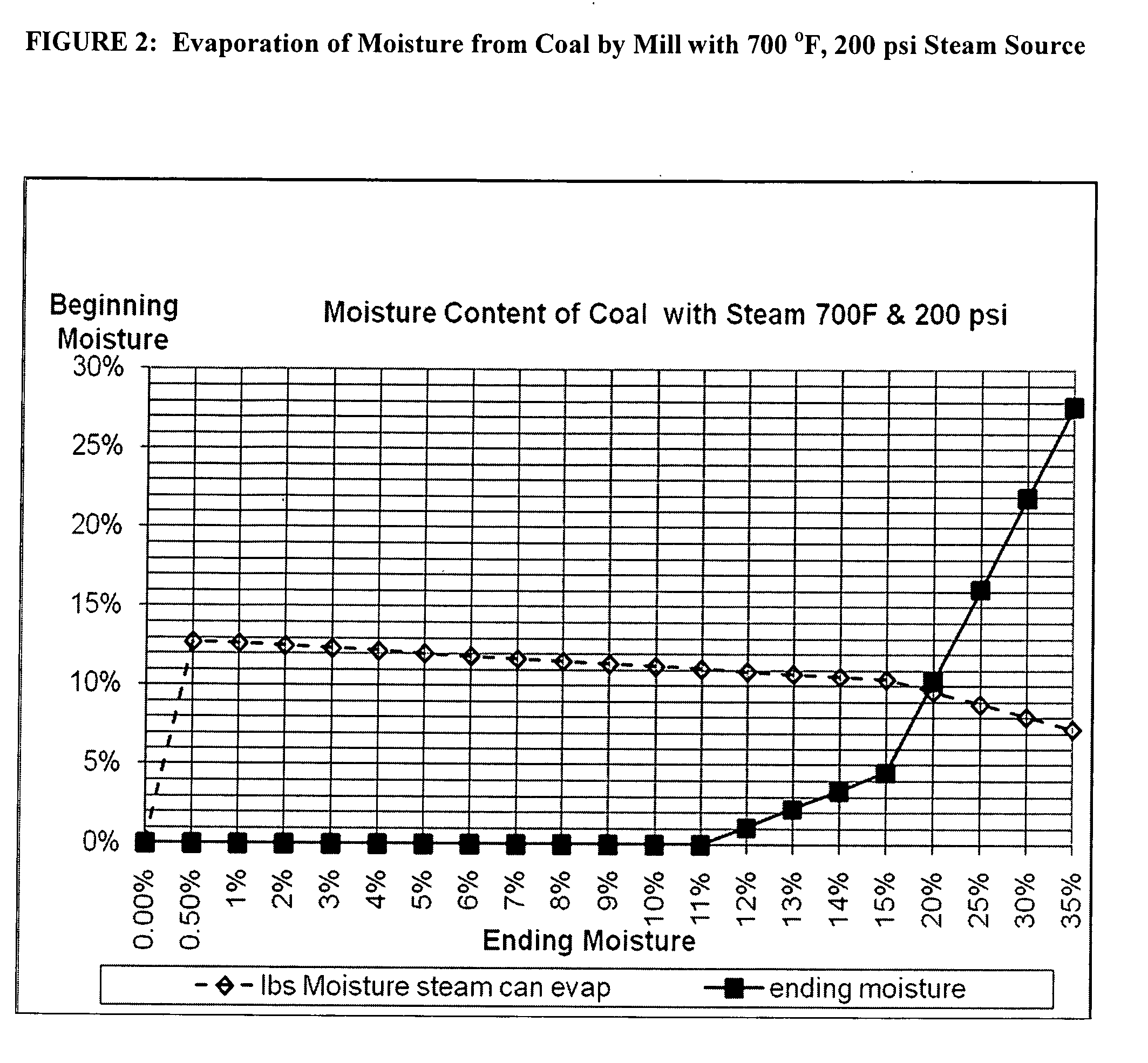

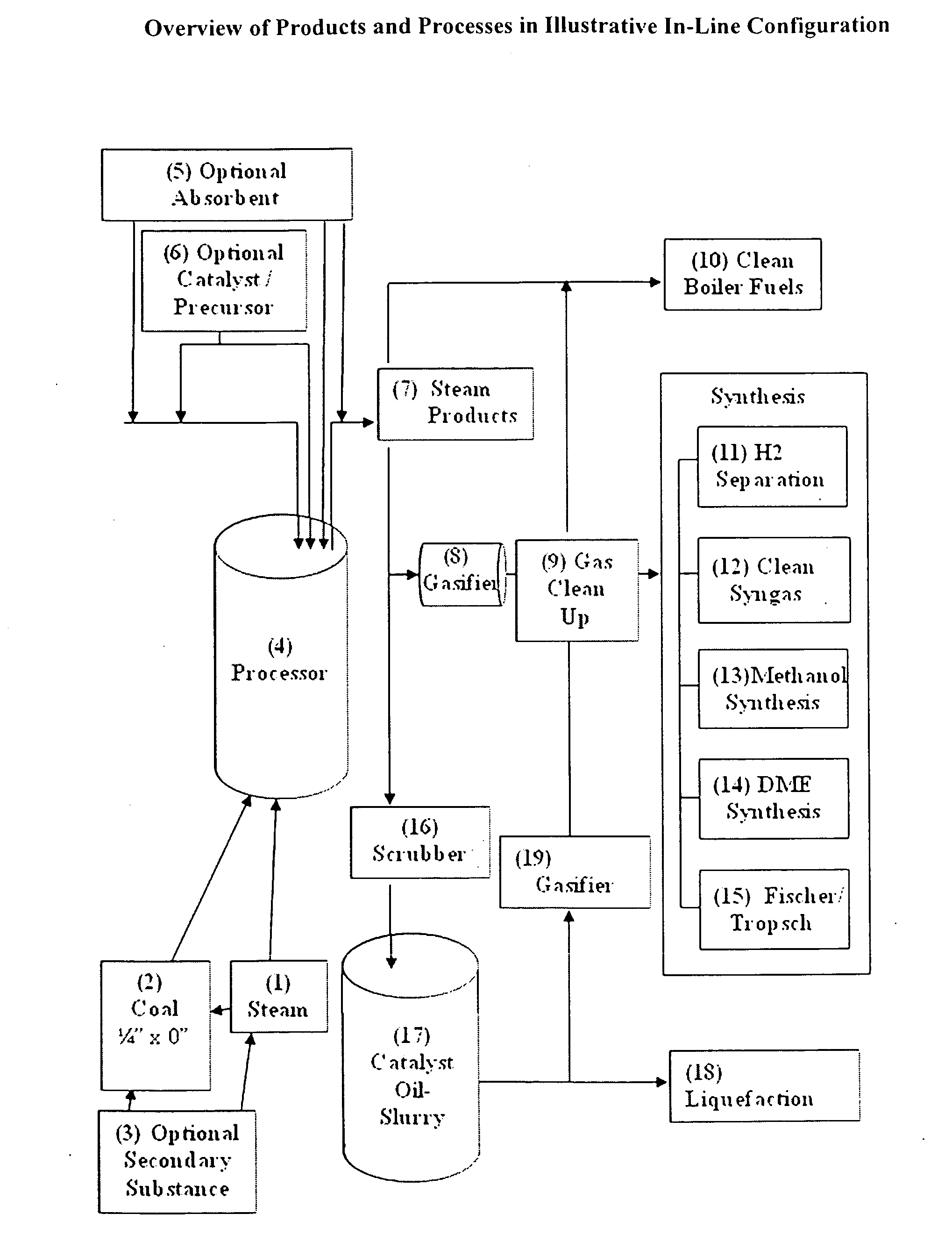

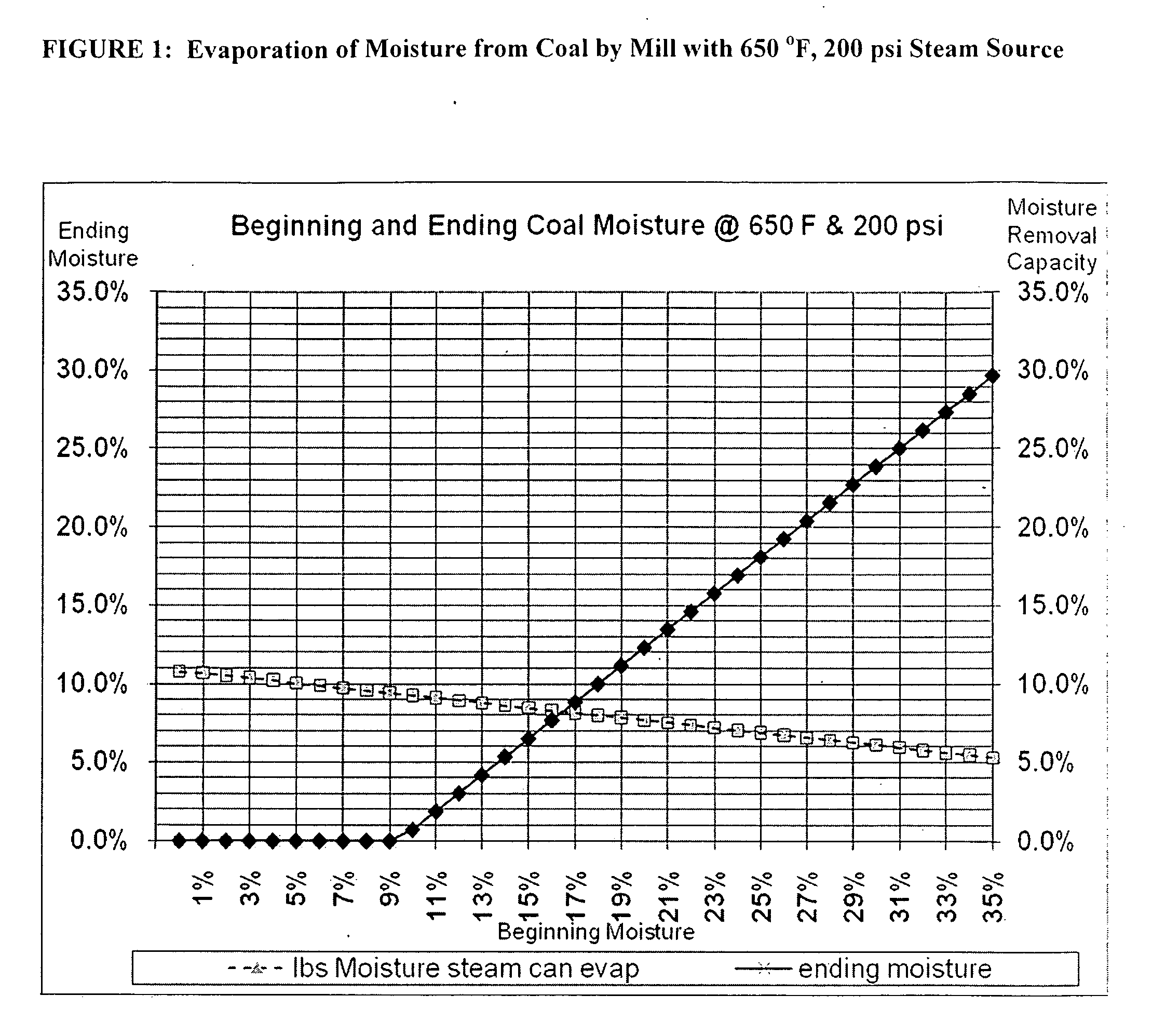

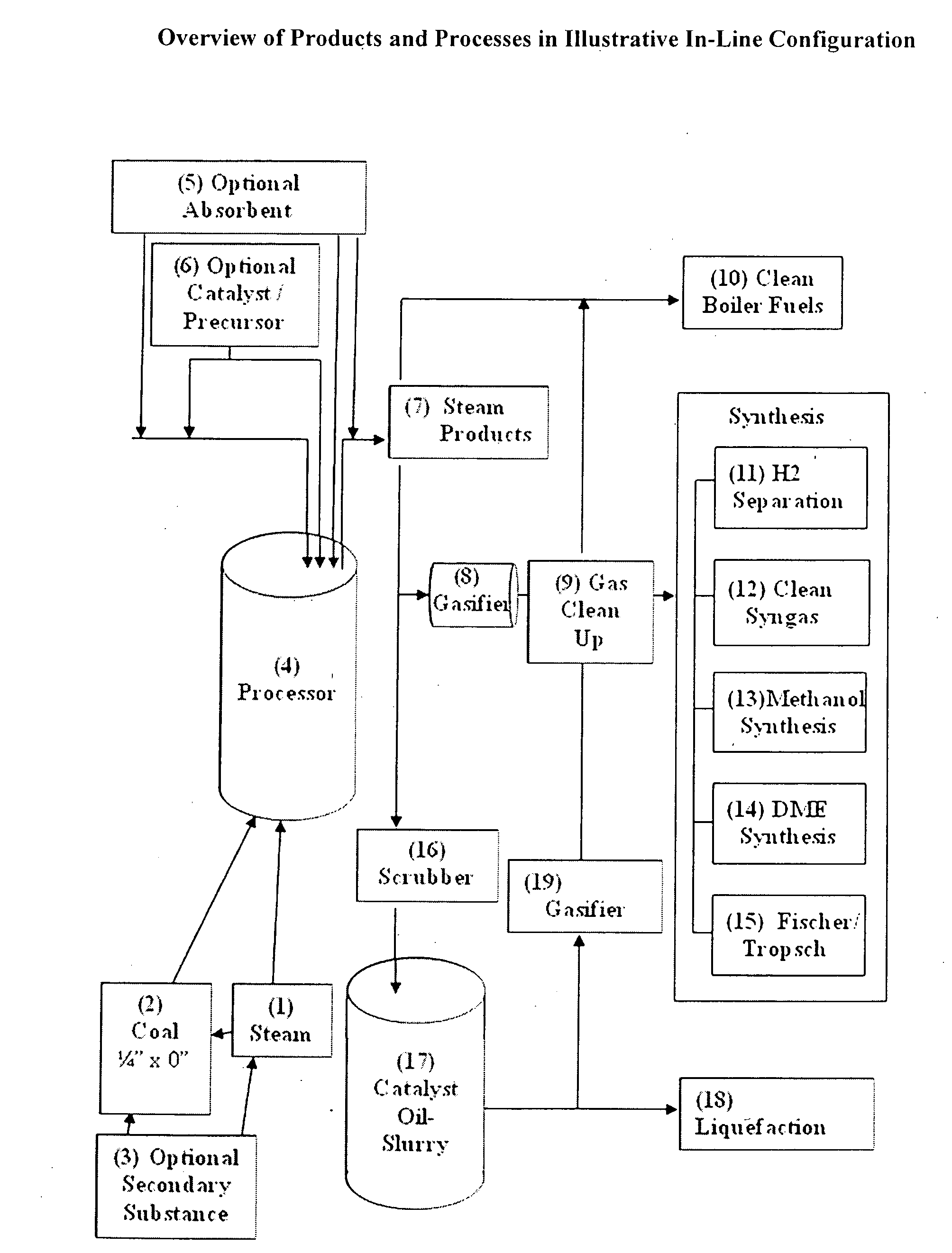

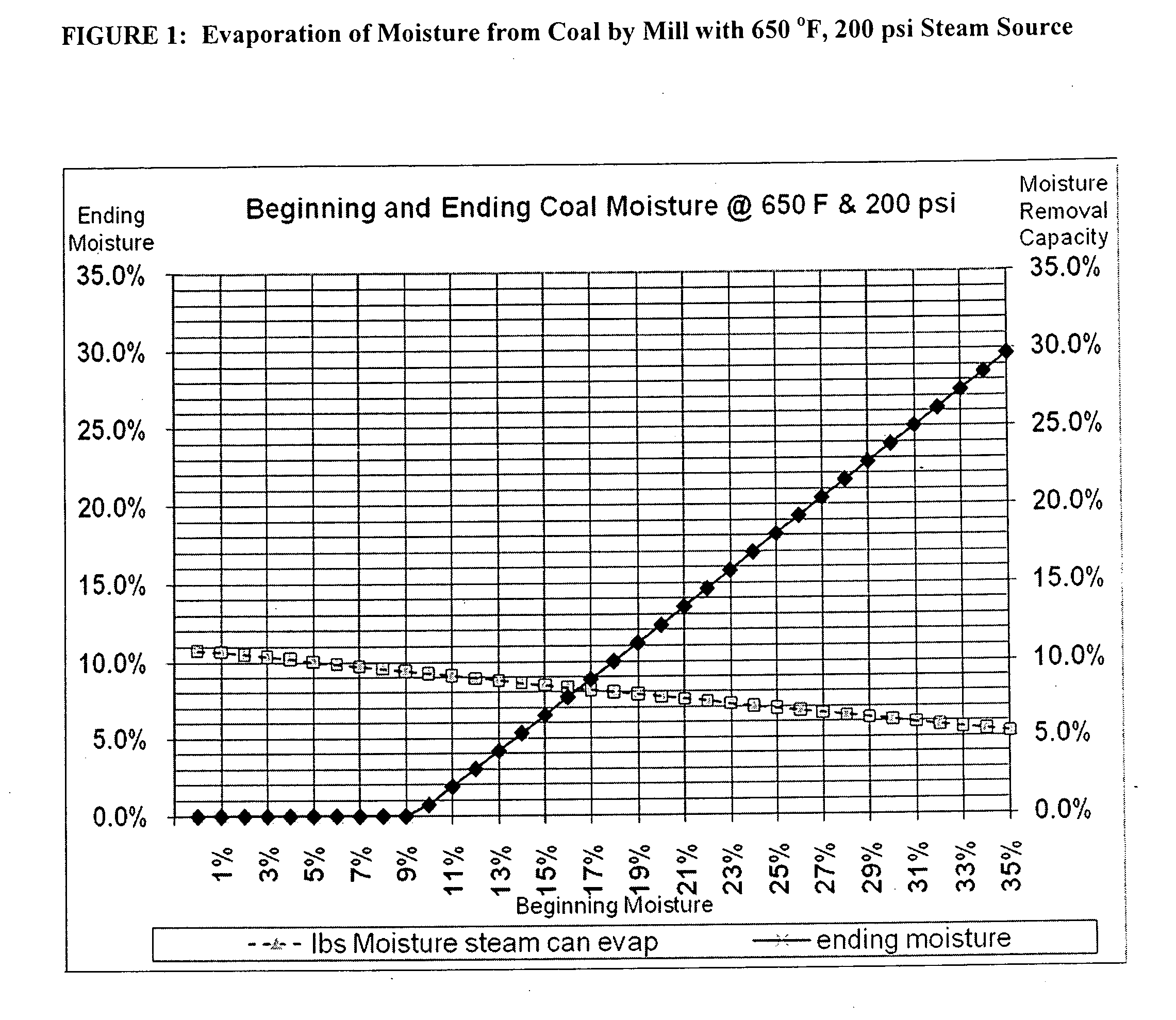

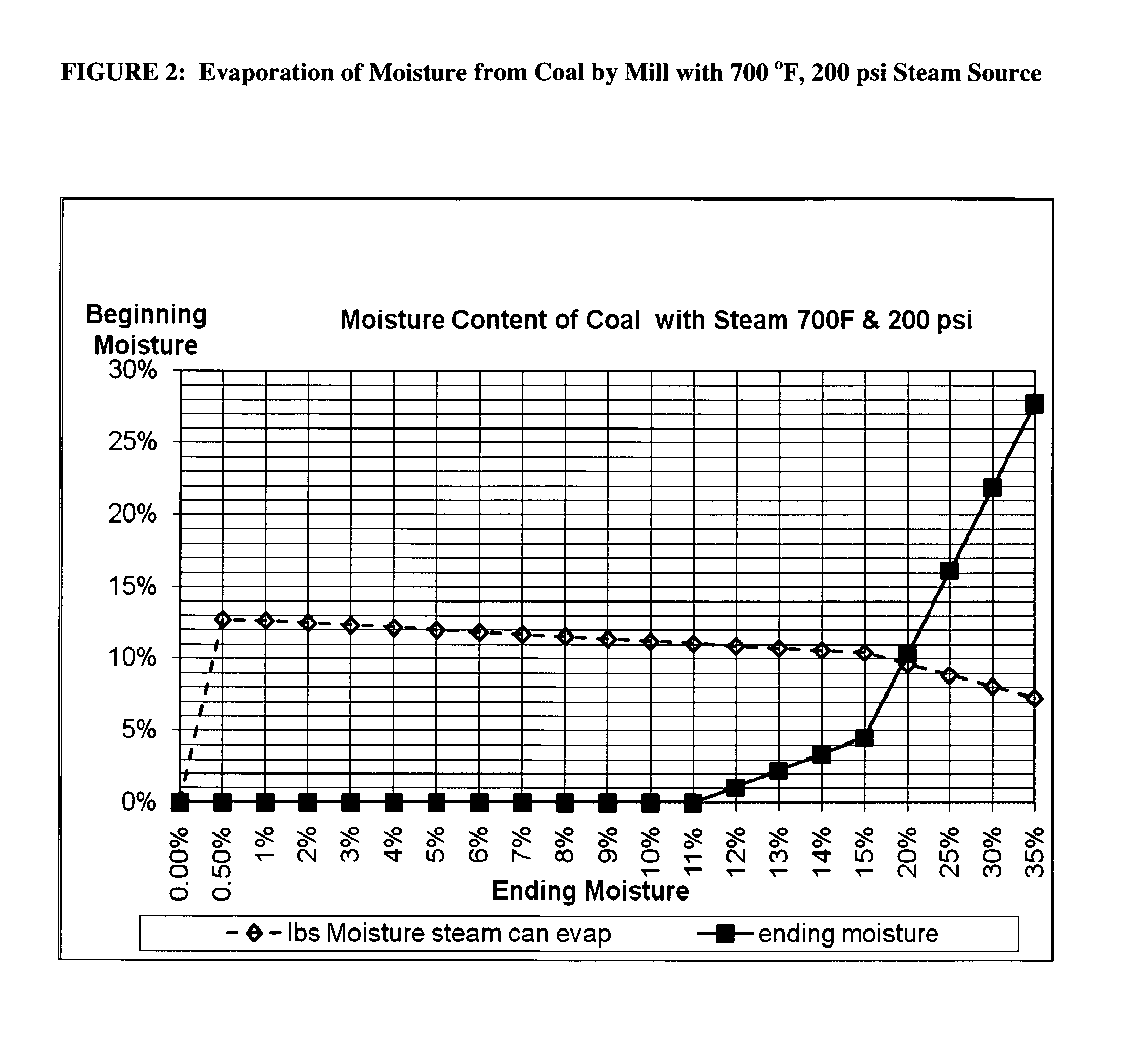

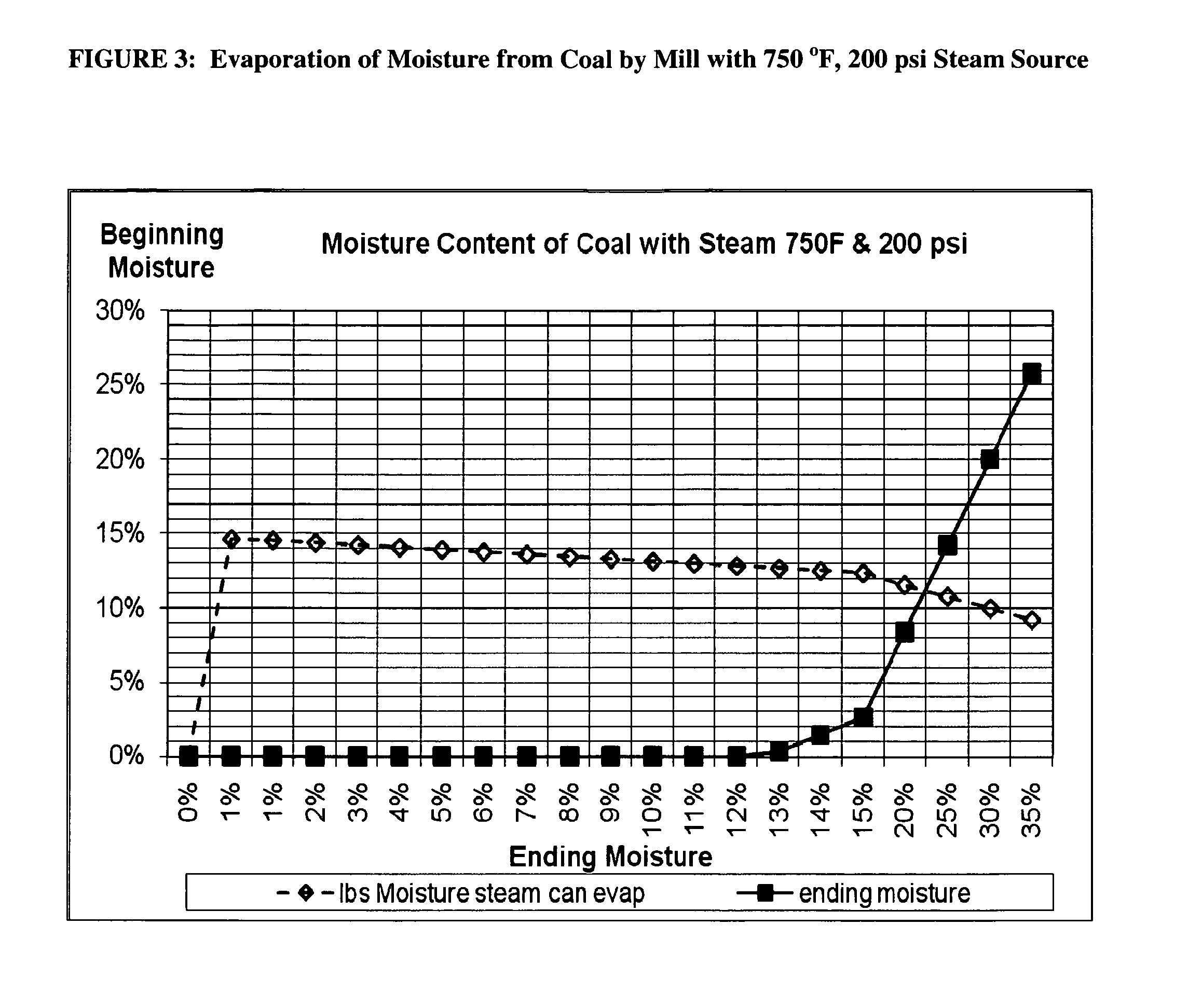

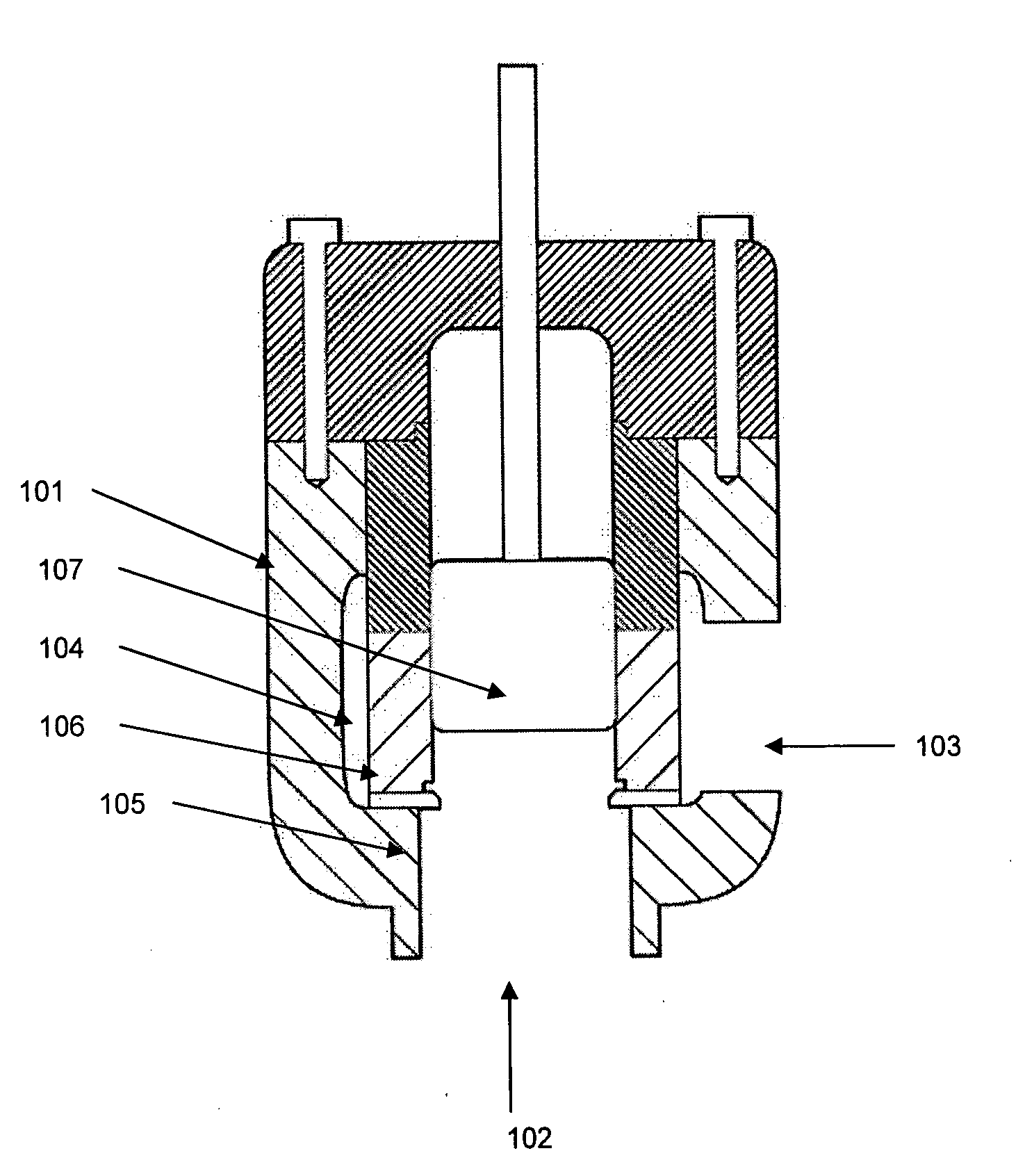

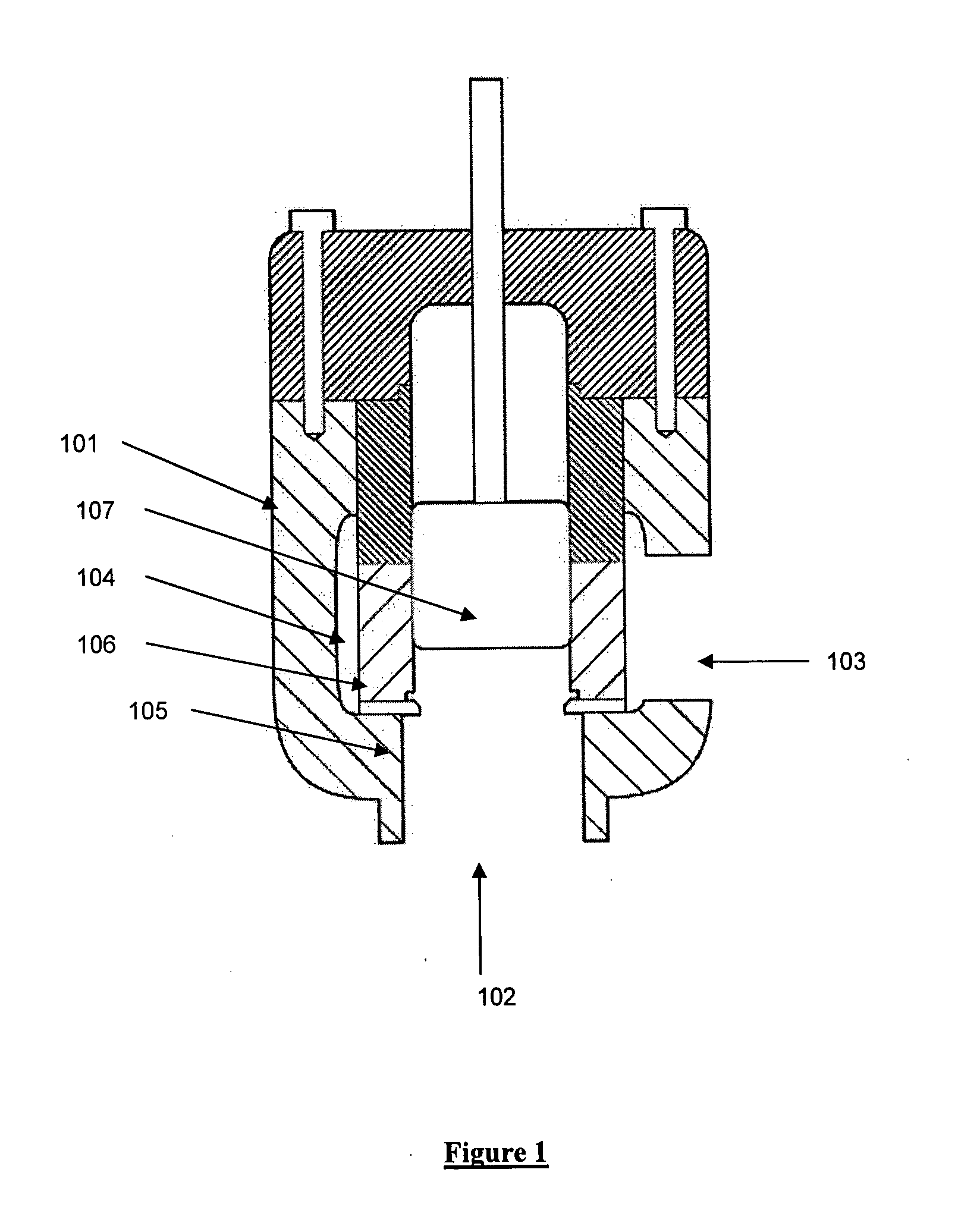

The invention provides an apparatus for comminuting coal or other fuel solids in a shear field, and for optionally coating the solids with catalysts for combustion, liquefaction, and or gasification during the milling process. The apparatus further provides for control of water content in the solids may be controlled before, during and after the milling in order to obtain micronized solids with fine hydration layers. The output fuel solids of the apparatus can burn at low temperatures, avoiding emissions of nitrogen oxides, and they also have improved properties for surfactant-free suspension in either water or oil media, as well as for liquefaction and gasification.

Owner:HYDROCOAL TECH

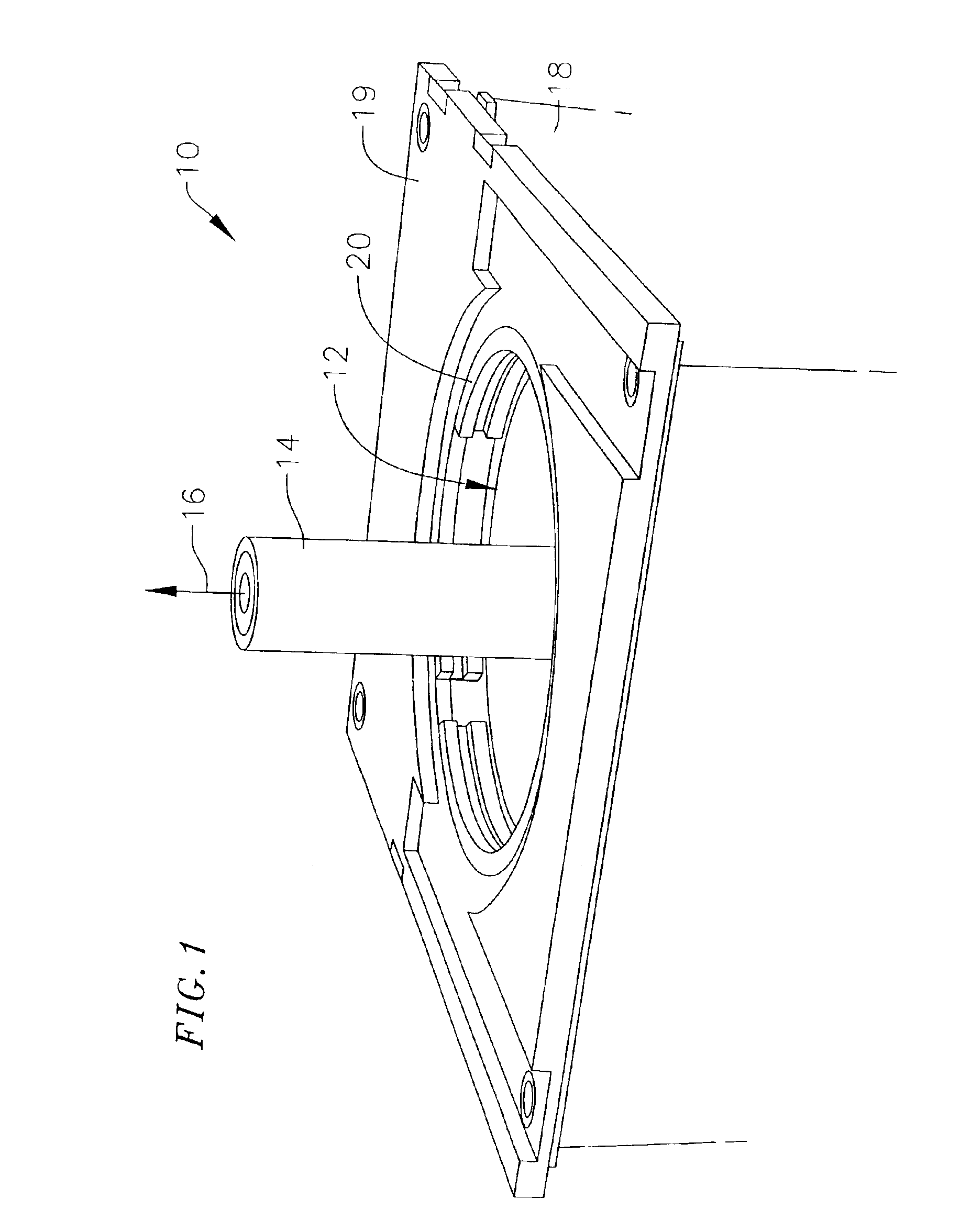

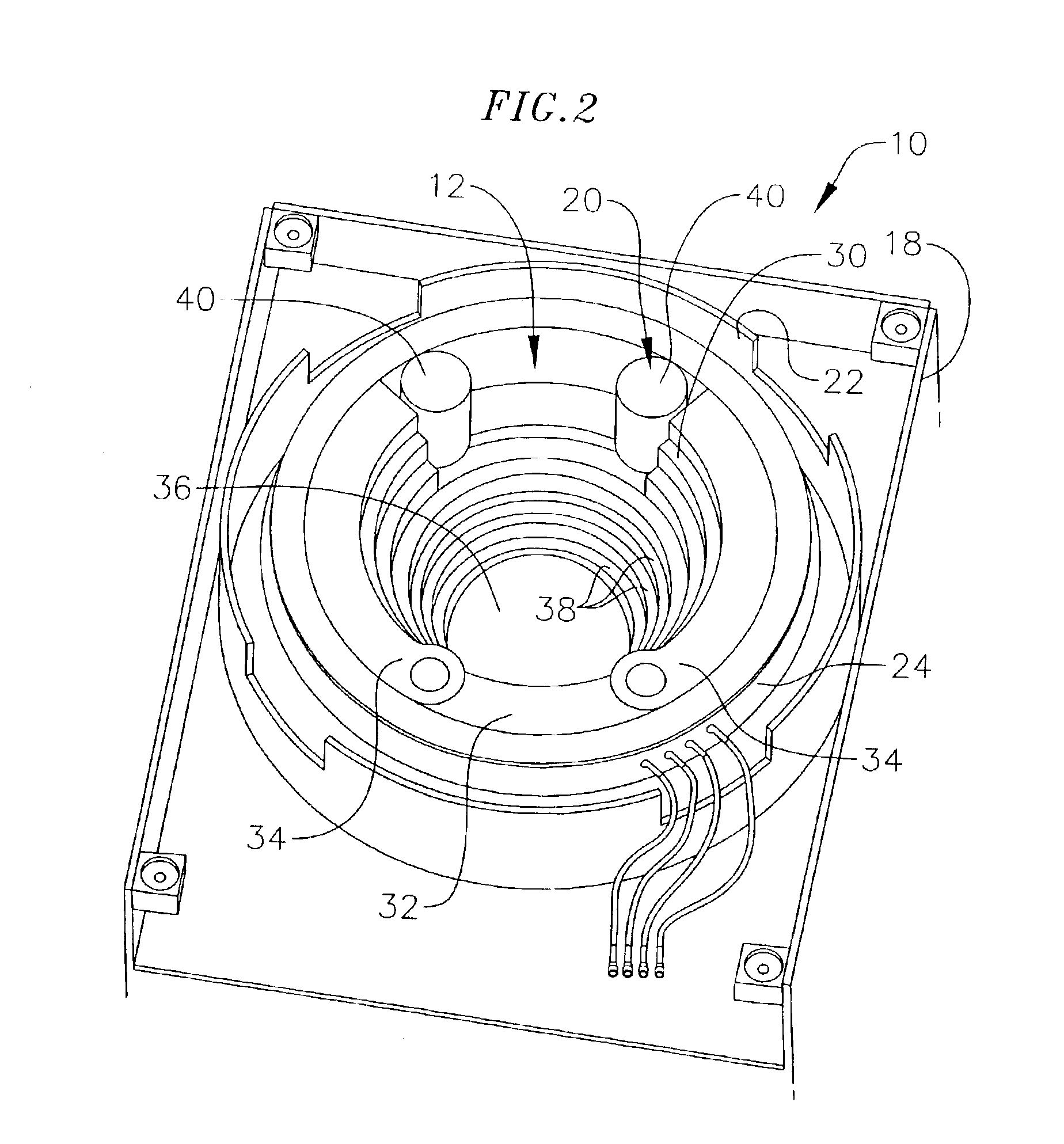

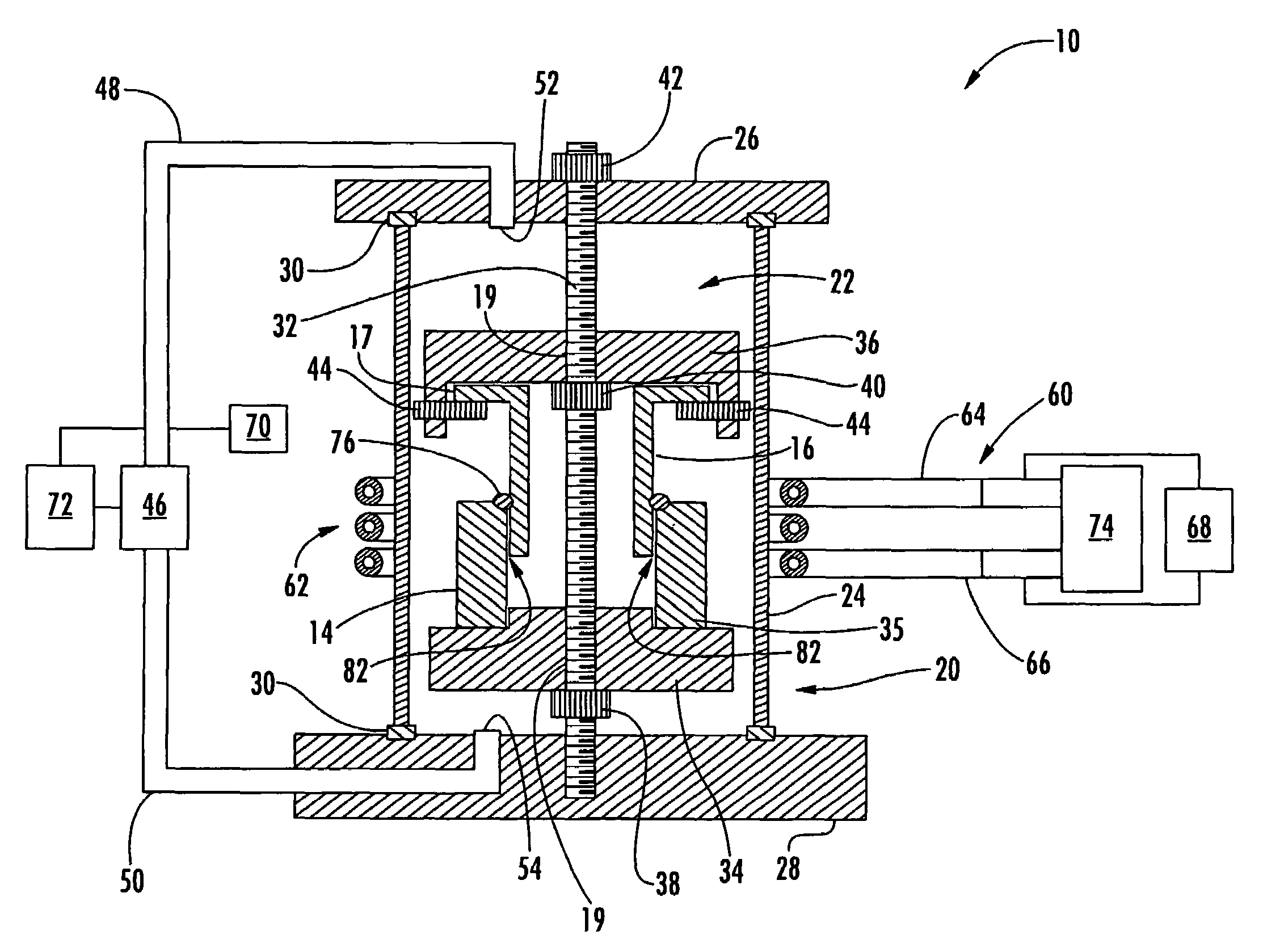

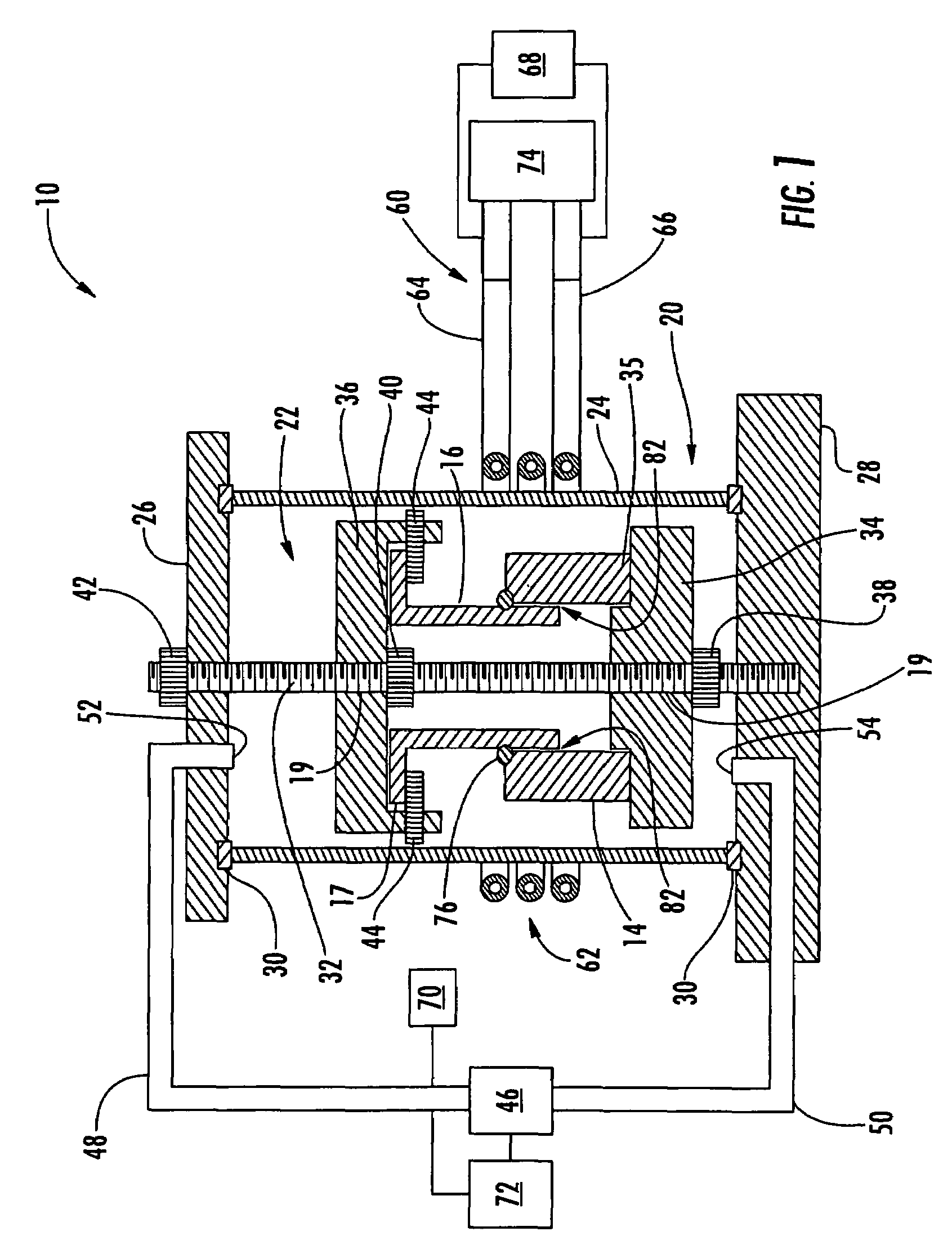

Rotary support table

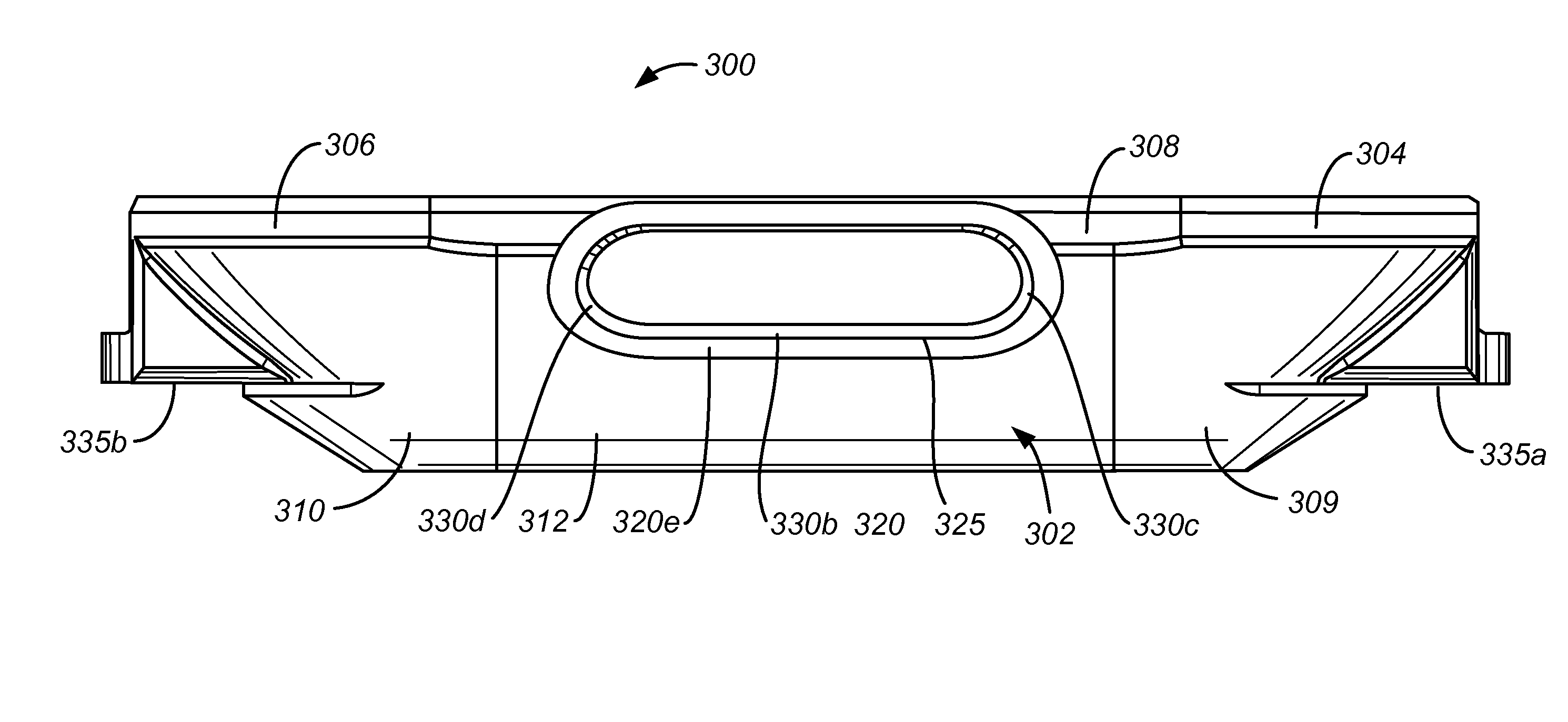

A rotary seal assembly for a rotary support table for use in drilling systems and the like to provide pressurized fluid to a rotary slip assembly disposed within the rotary support table is provided. The rotary seal assembly is designed to be coupled to an existing rotary support table which is used to rotate a drill string, and includes a powered slip that is powered into an engaged position to securely engage a pipe segment, for example, a casing segment. The rotary seal assembly generally comprises a ribbon of expandable material having an outer surface in fluid communication with a source of pressurized fluid, and an inner surface cooperative with a rotary housing, the rotary seal having a plurality of openings capable of communicating fluid between said outer and inner surfaces, wherein the outer seal surface has a surface area greater than the inner surface such that when the pressurized fluid is conducted to the outer surface of the seal a differential pressure between the outer and inner surfaces is created such that the inner surface of the seal is expanded to engage the rotary housing and form an annular fluid duct providing fluid communication between the pressurized fluid source and the rotary housing. A method of operating a rotary table and powered slip assembly utilizing the rotary slip assembly of the current invention is also provided.

Owner:VARCO I P INC

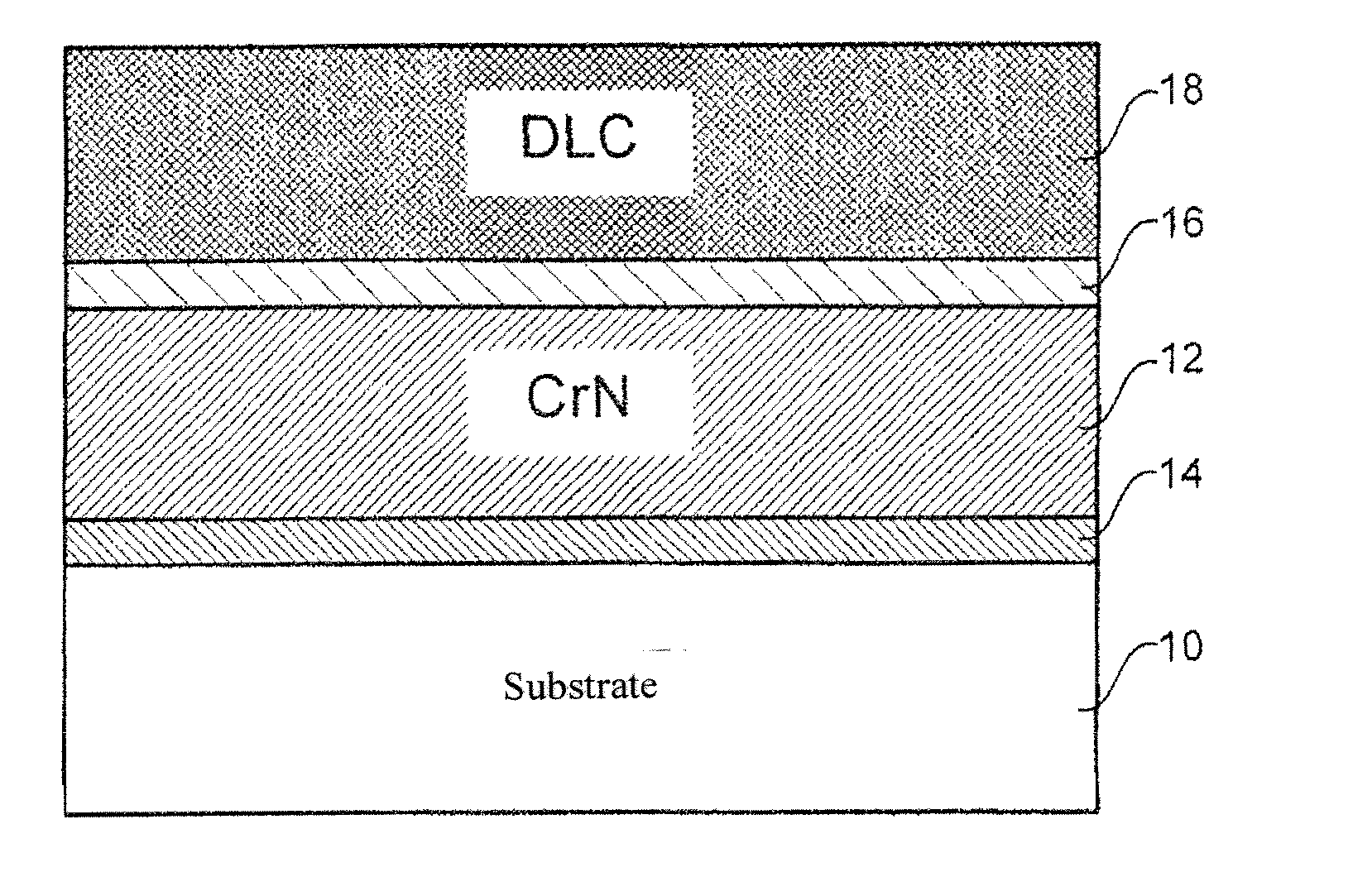

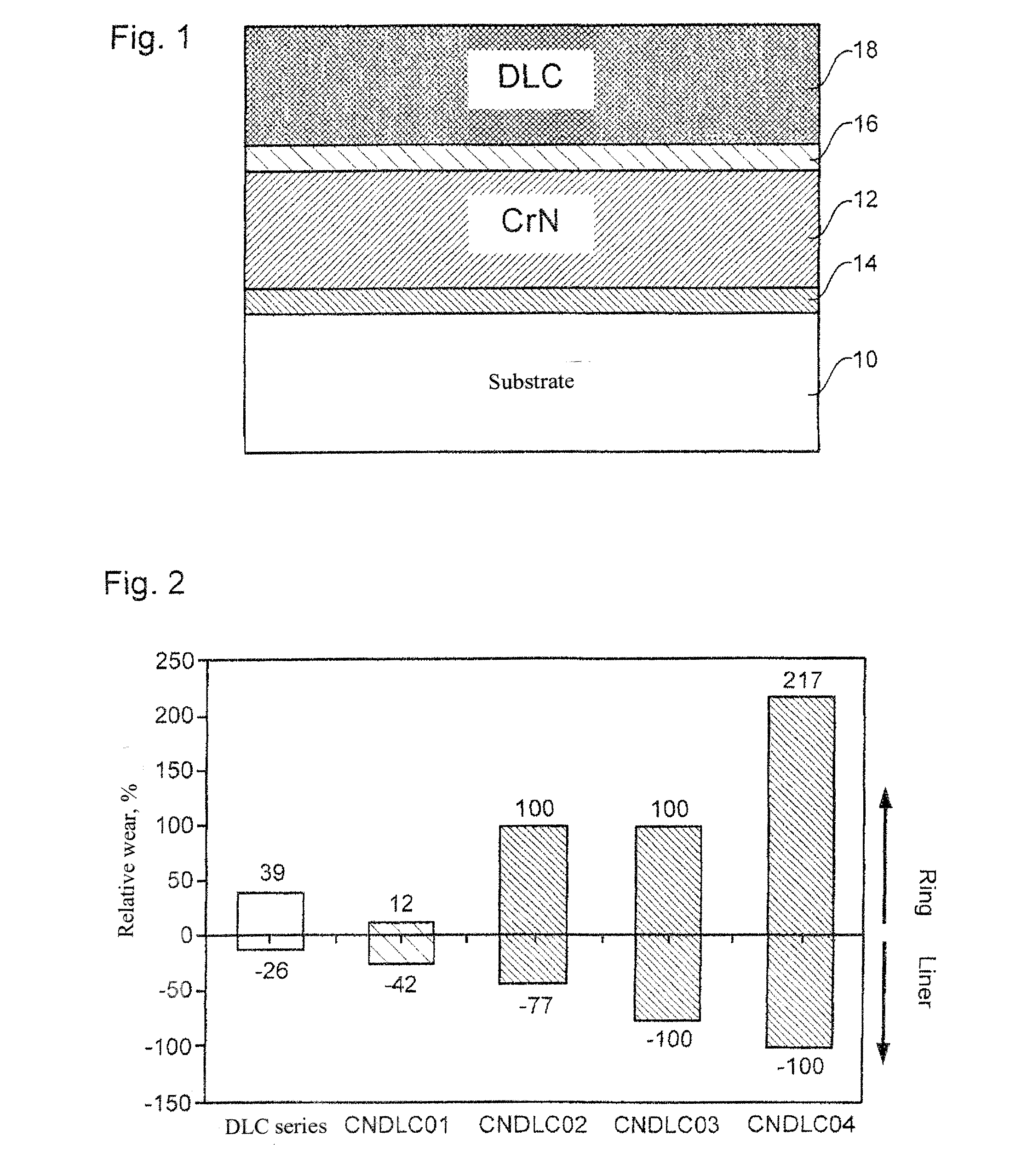

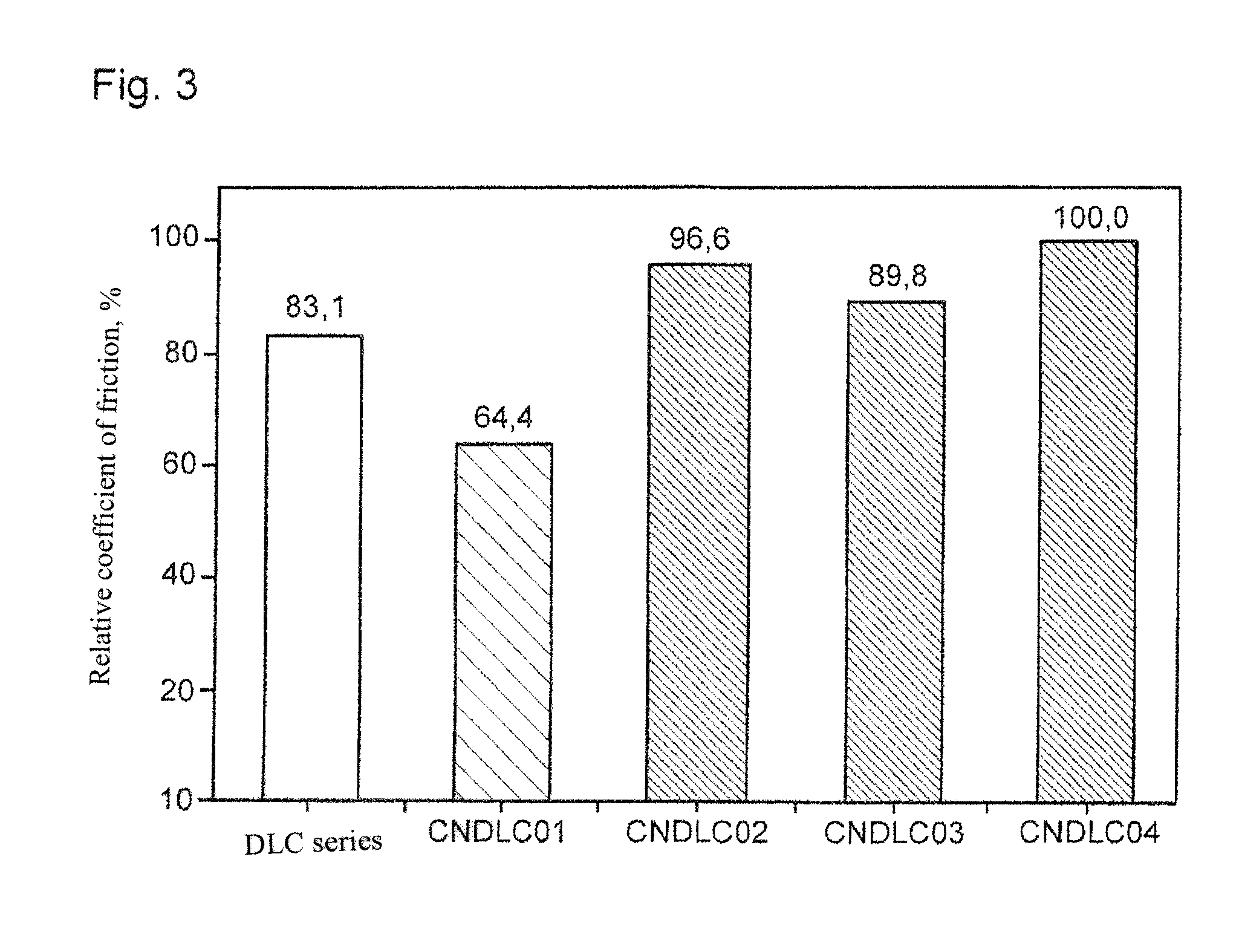

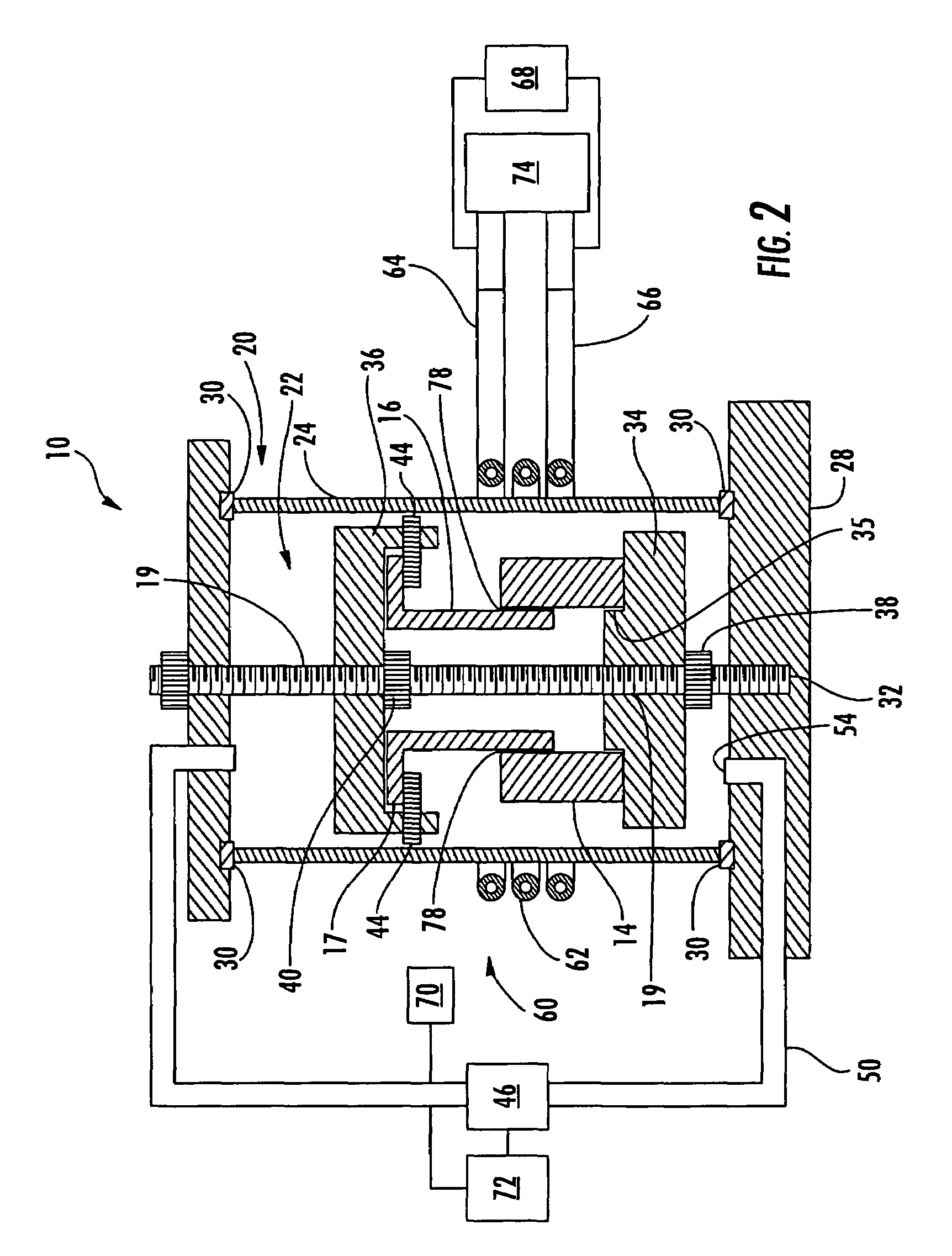

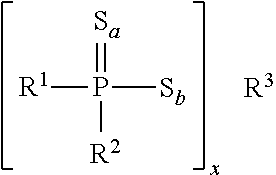

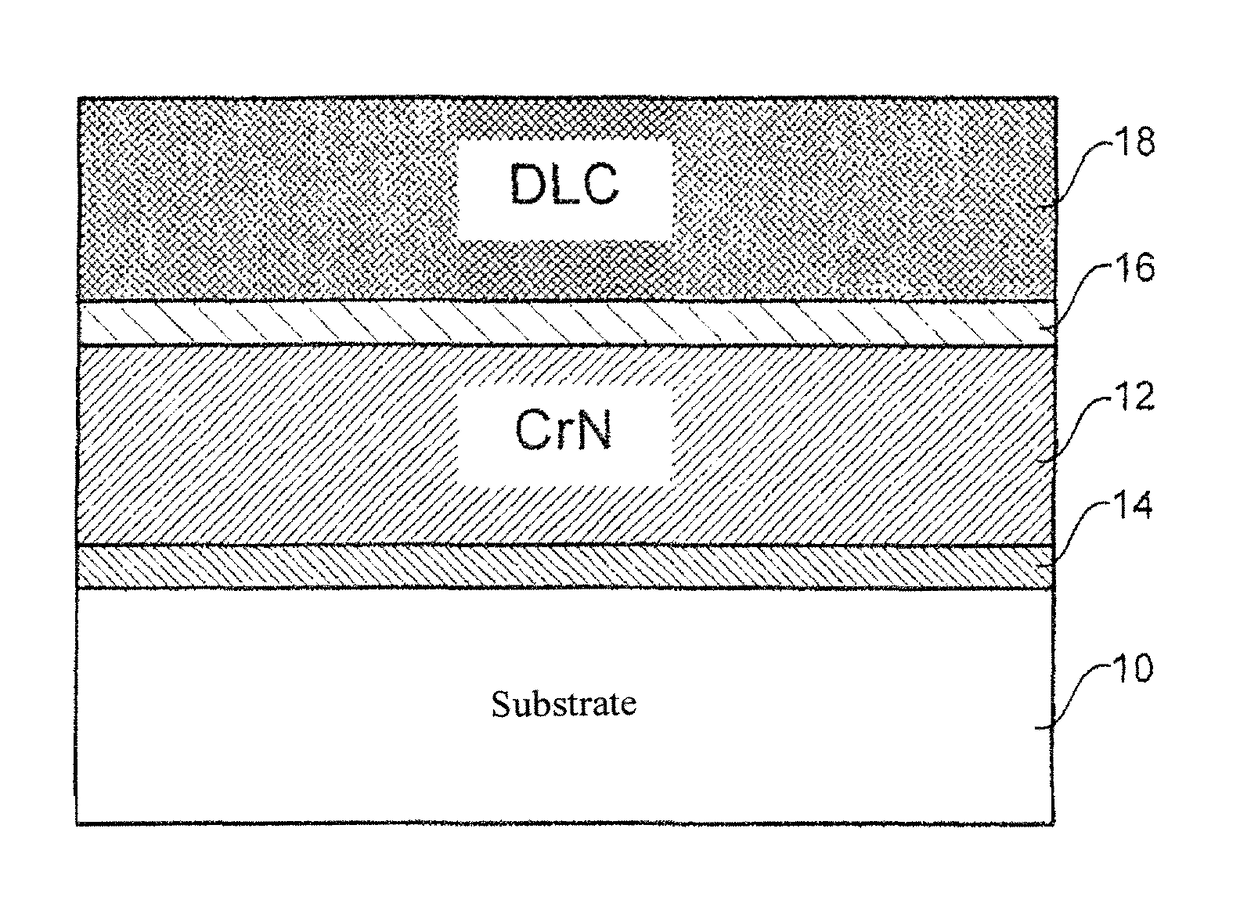

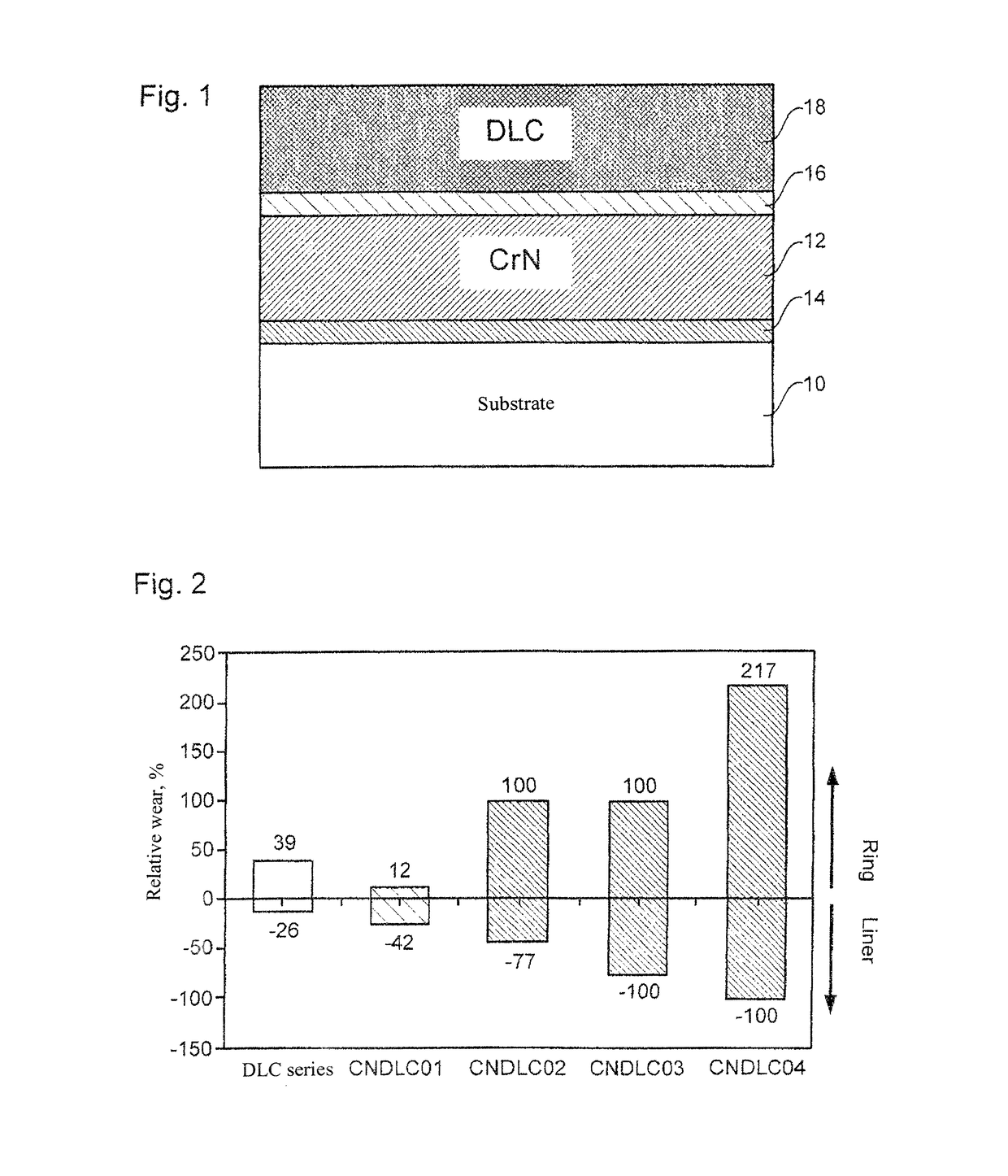

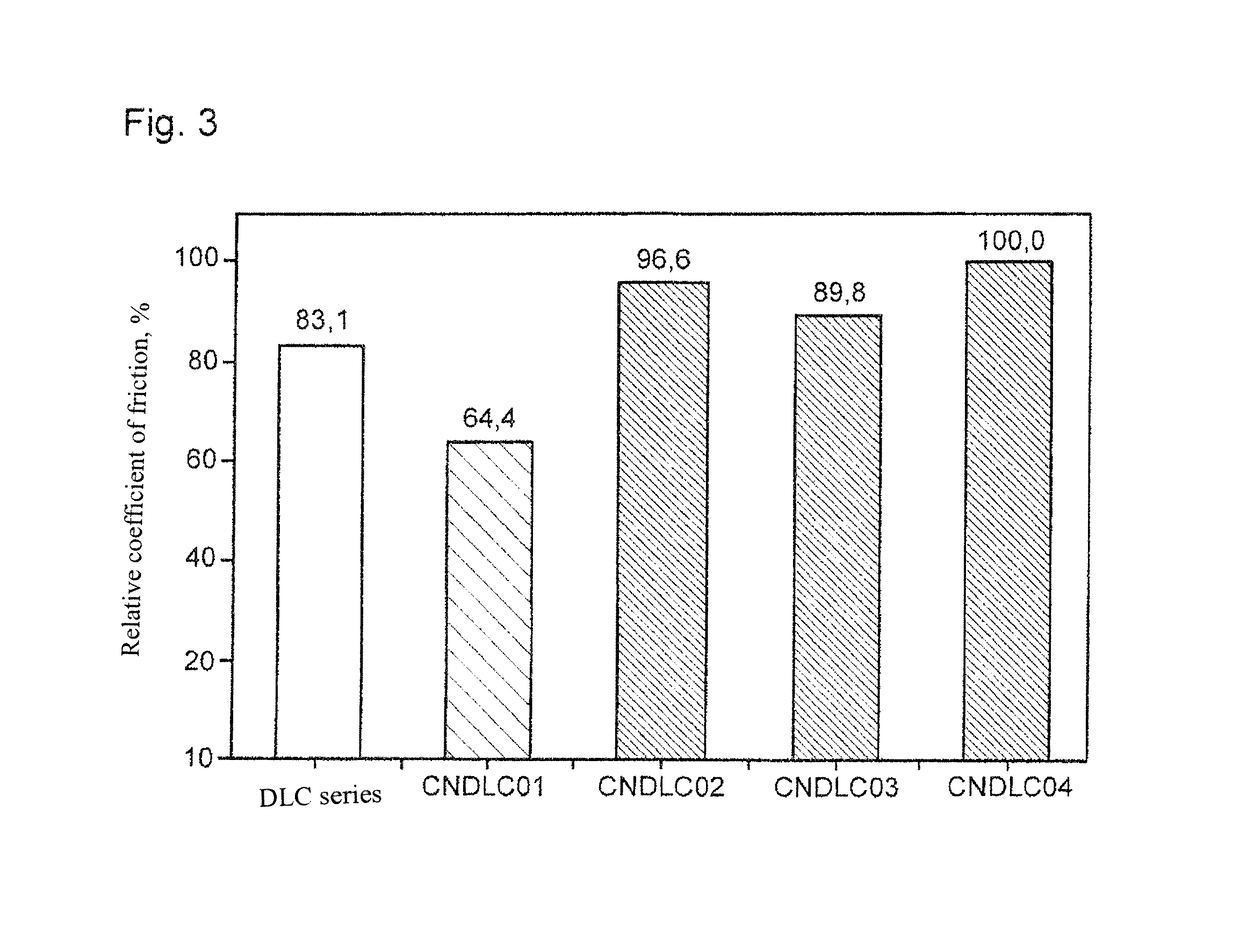

Sliding element, in particular piston ring, and combination of a sliding element with a mating running element

ActiveUS20130042845A1Improve featuresReduction factorPiston ringsBraking action transmissionPiston ringMetal free

The invention relates to a sliding element, in particular a piston ring, preferably made of cast iron or steel, comprising a coating having a CrN, an Me(CxNy), and a DLC layer extending from the inside to the outside, wherein the DLC layer is either metal-free or consists of a metal-containing substructure and a metal-free DLC top layer. The invention further relates to a combination of such a sliding element with an iron-based mating miming element.

Owner:FEDERAL MOGUL BURSCHEID

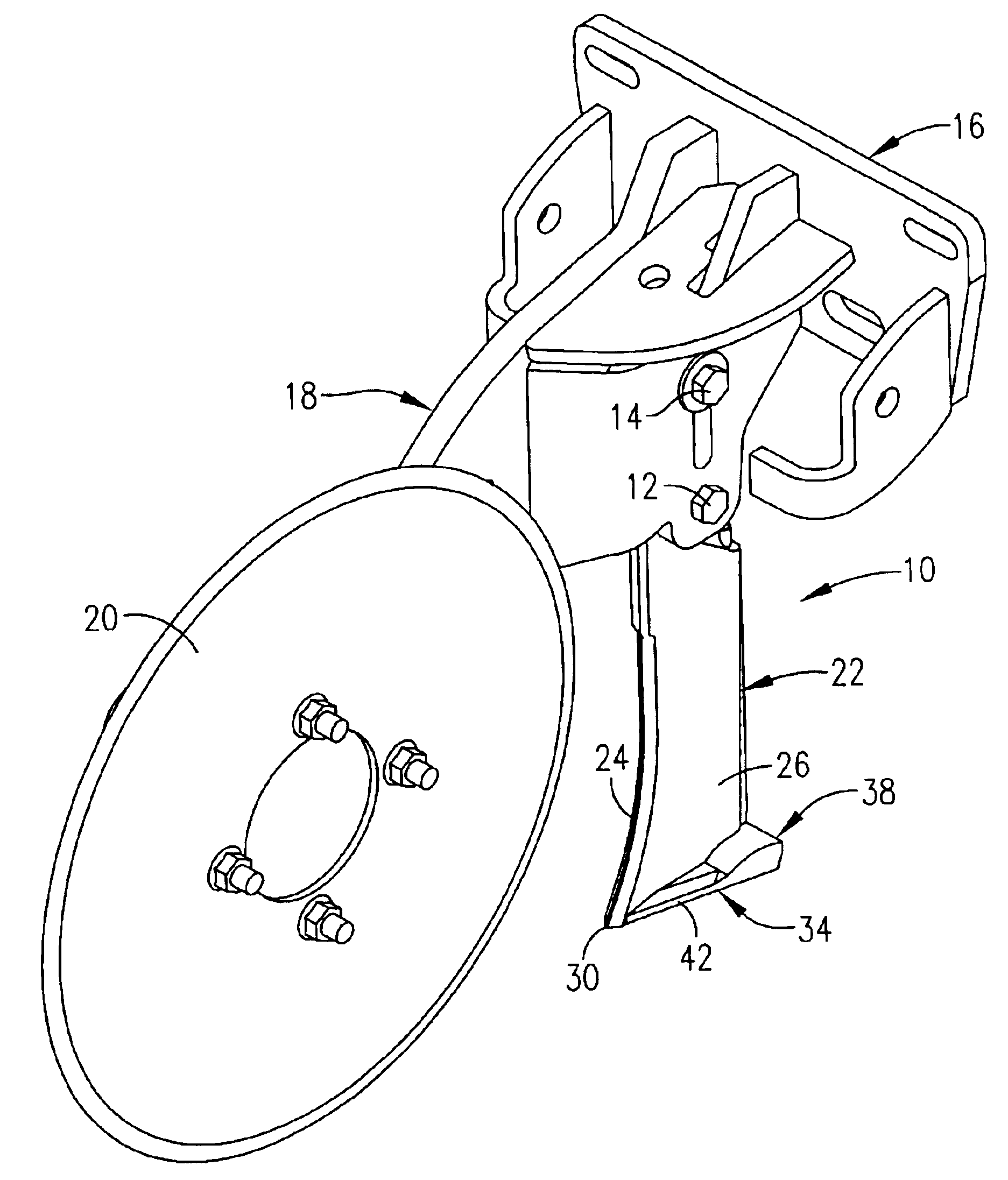

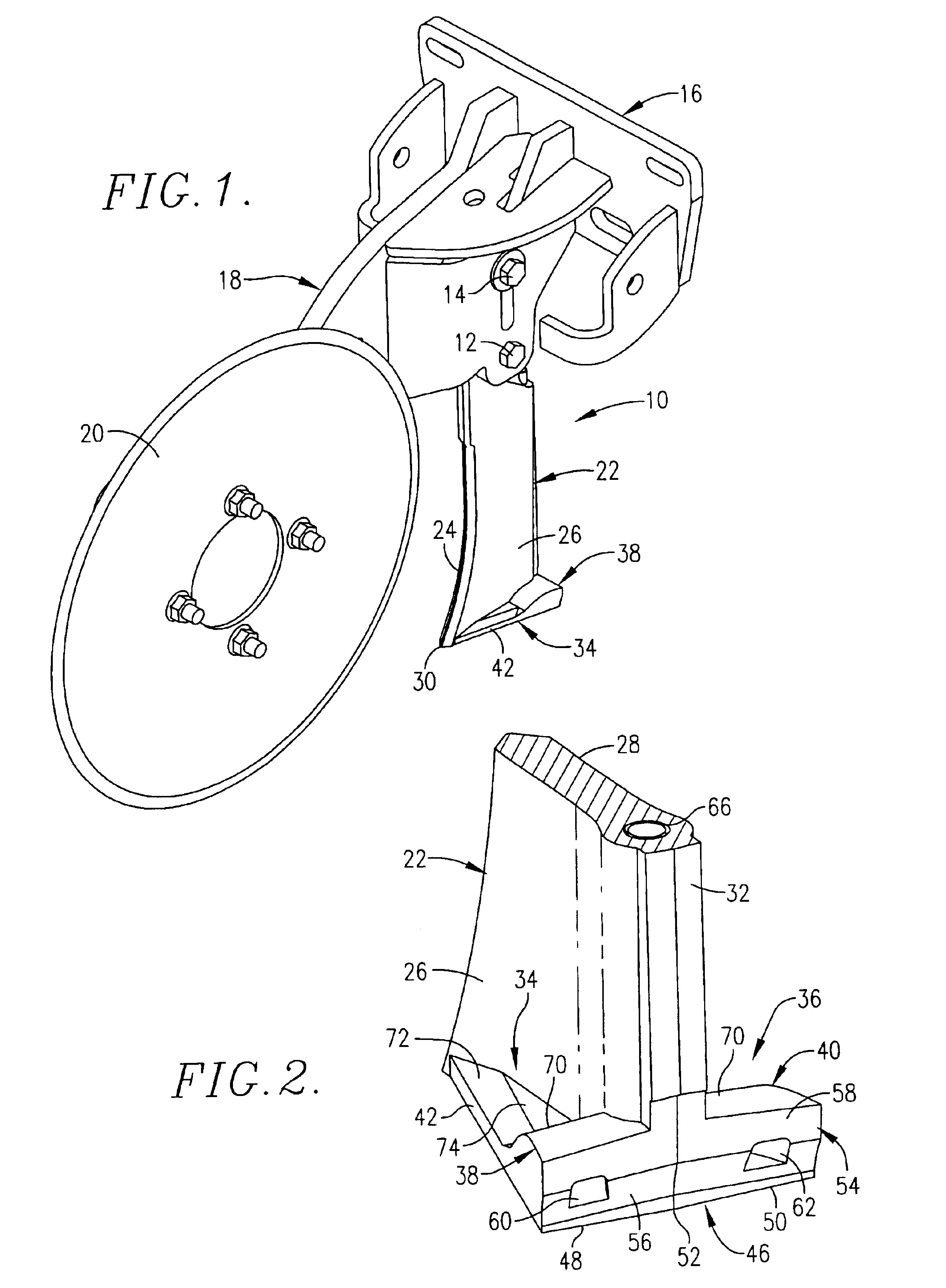

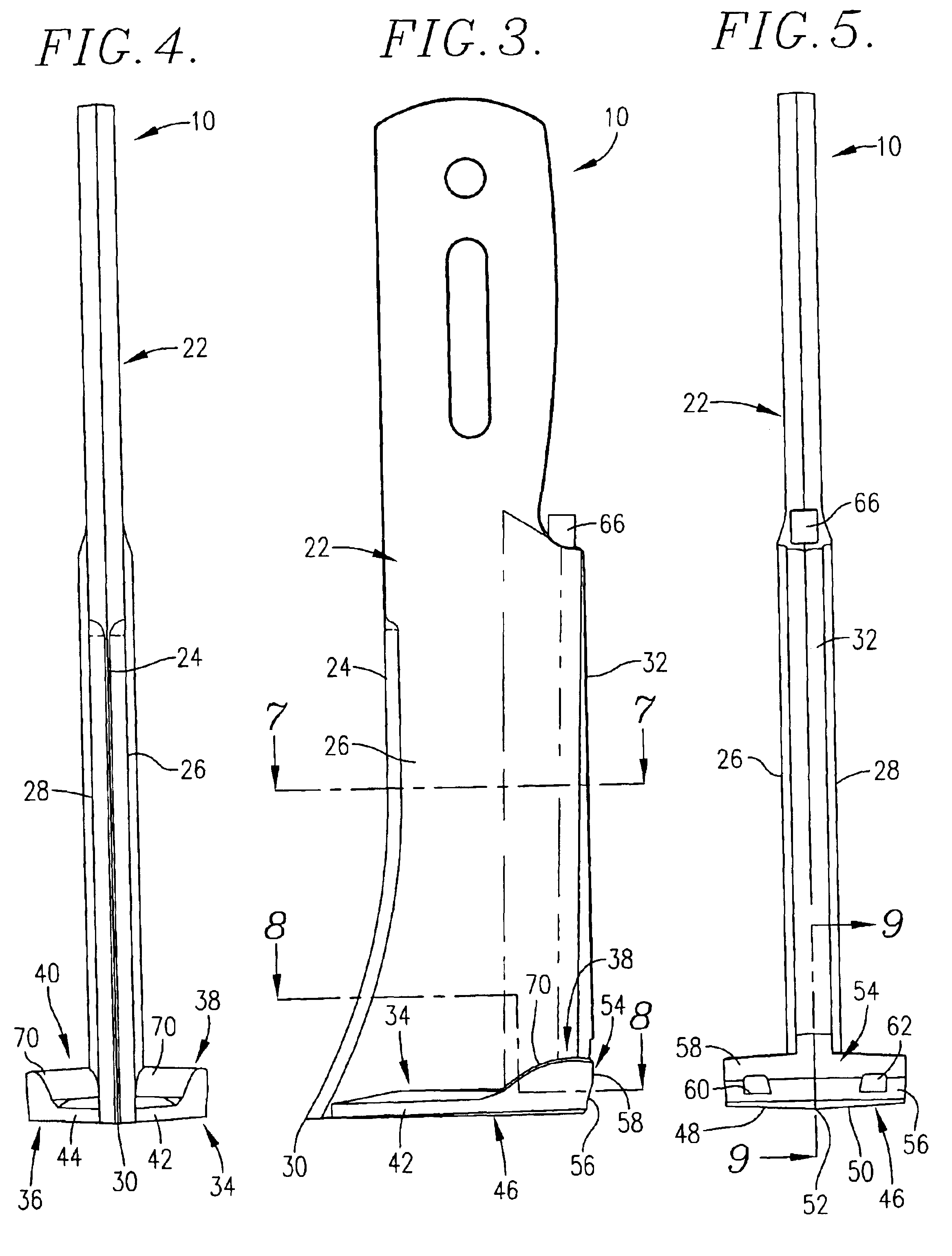

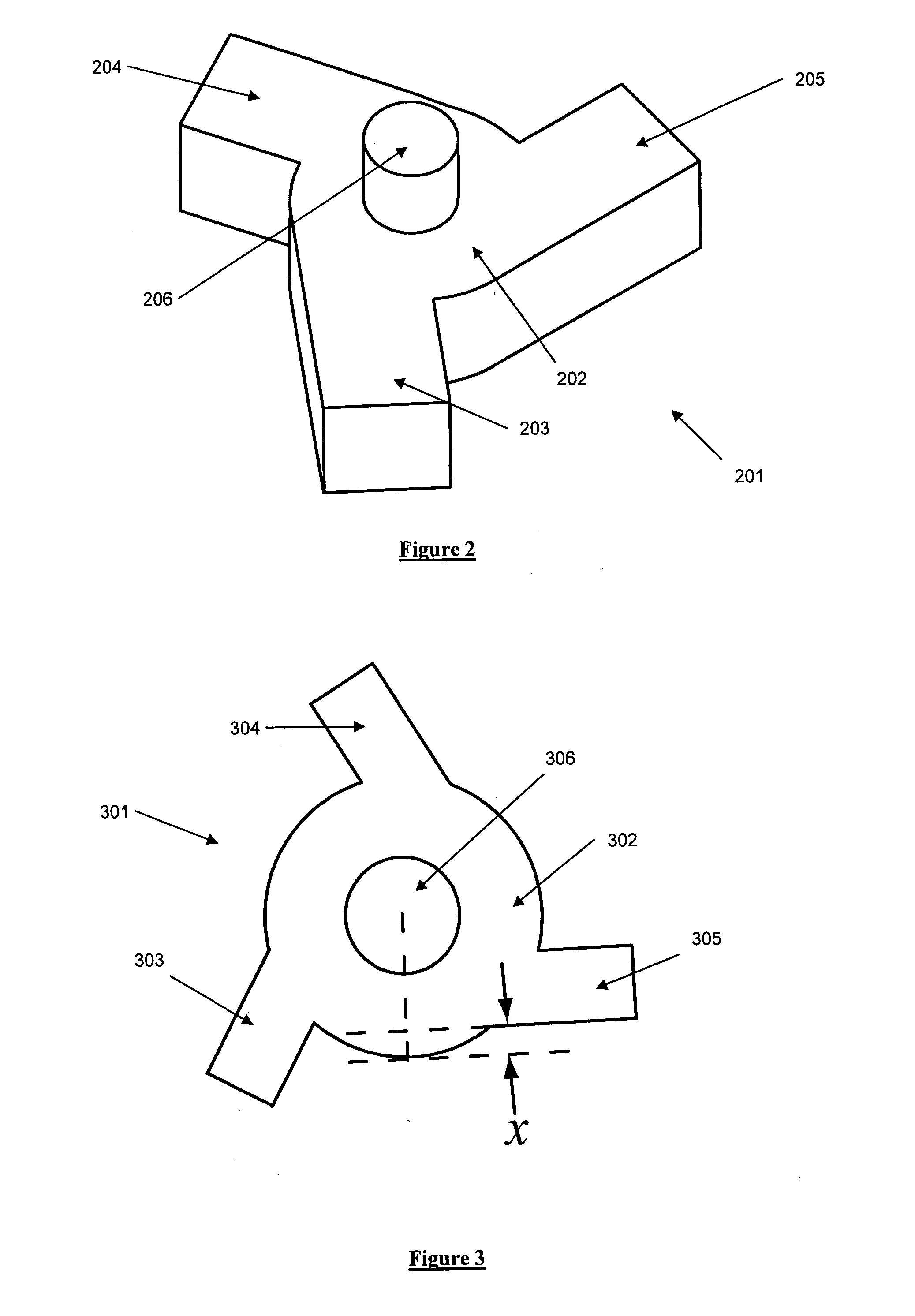

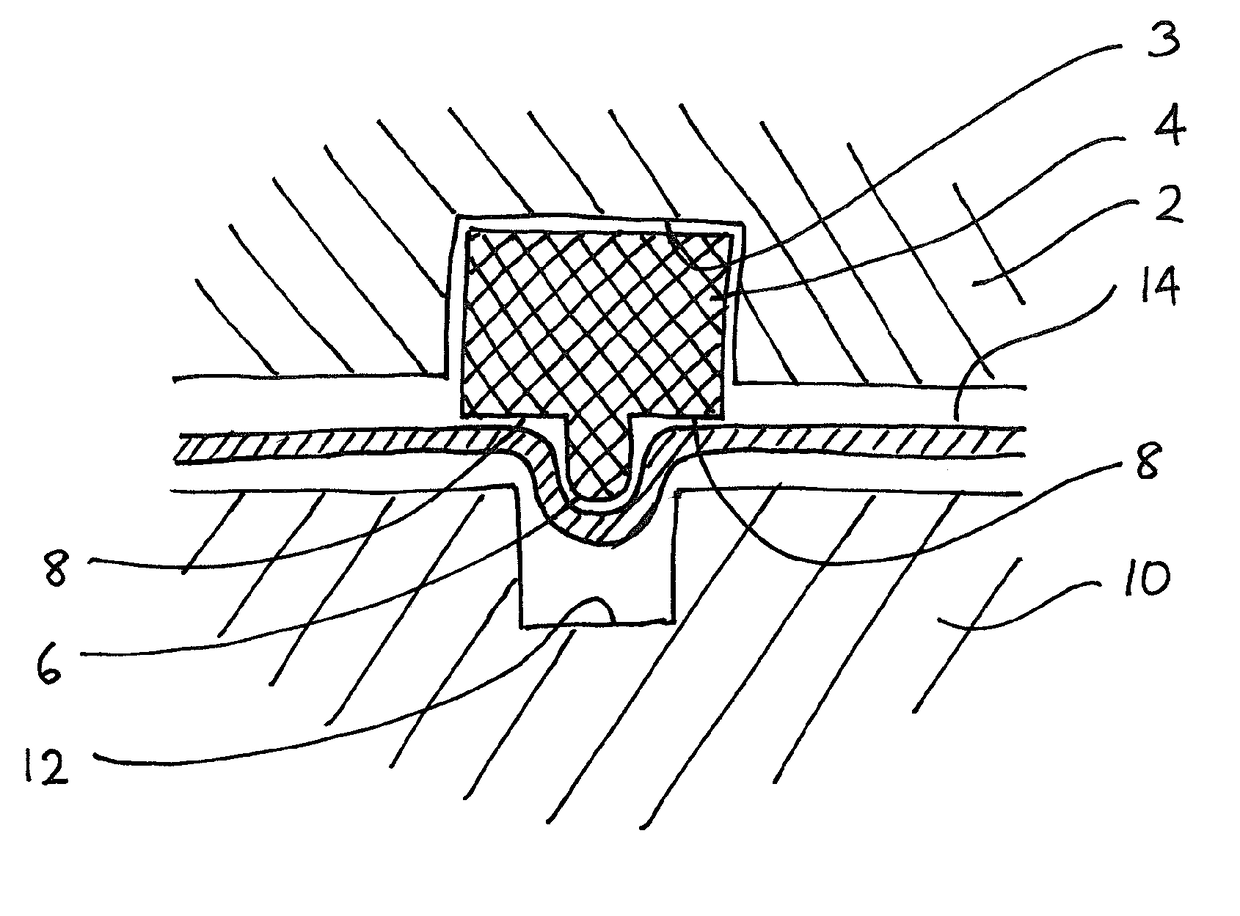

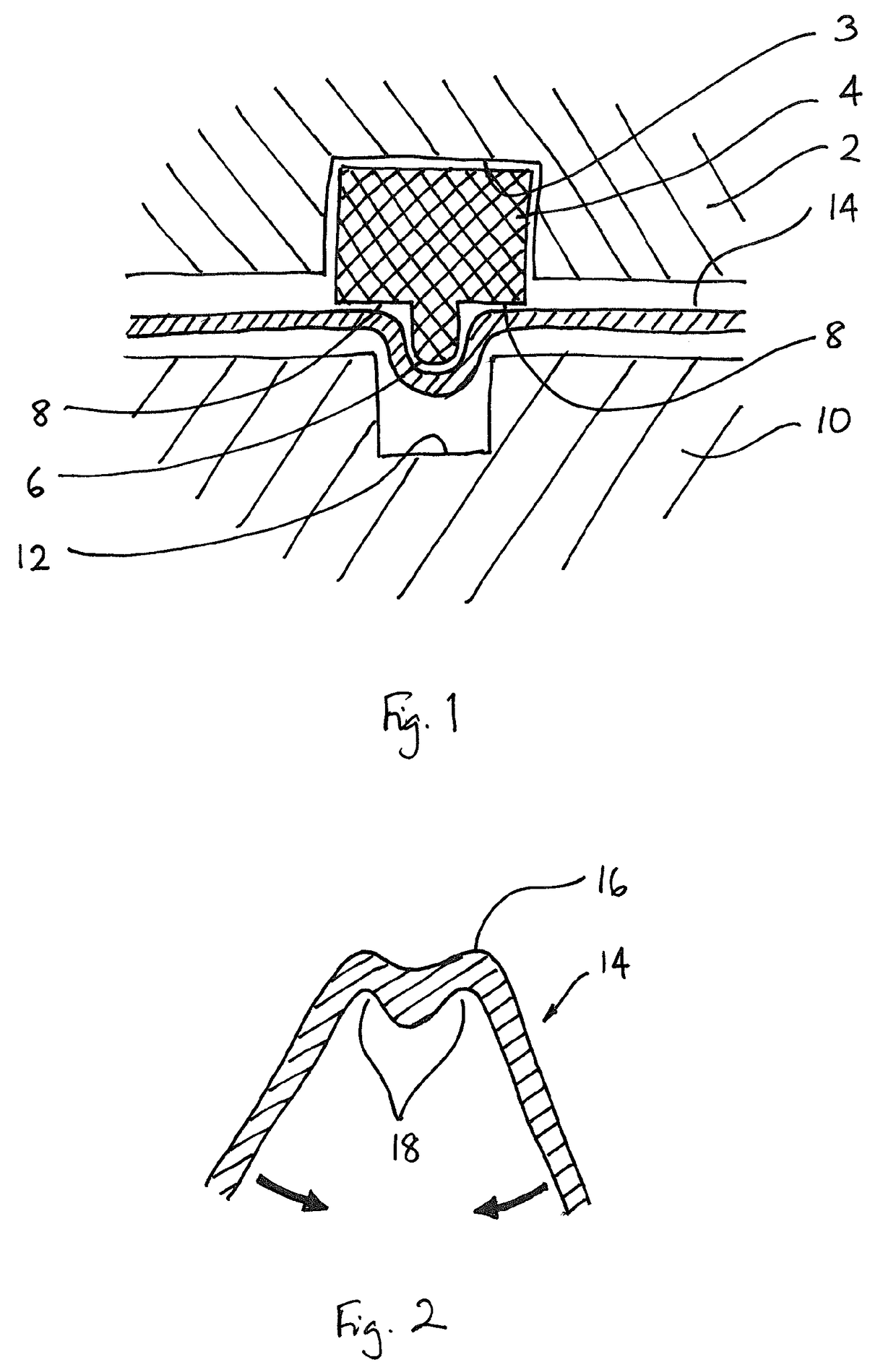

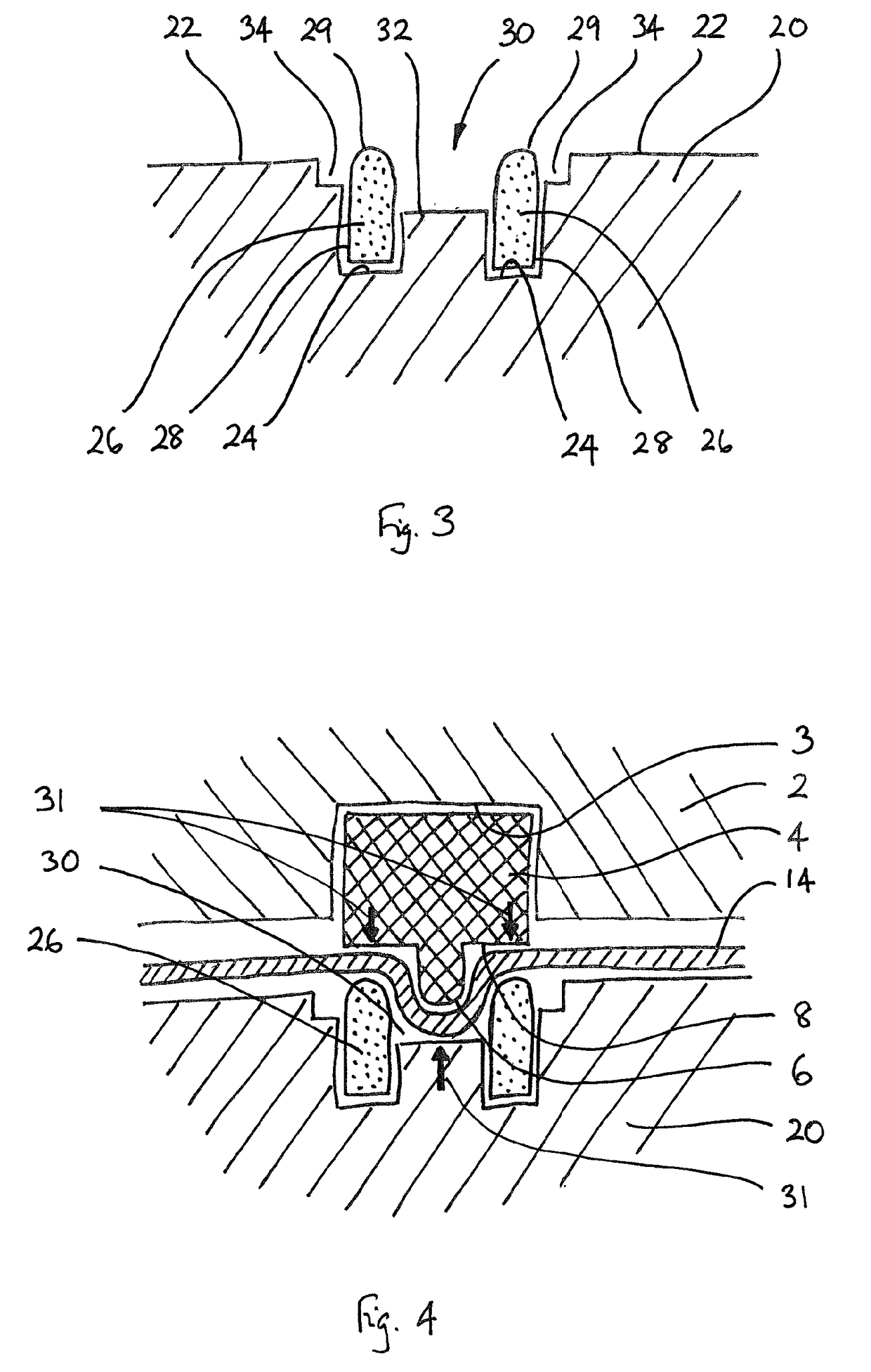

Subsoil fertilizer applicator

InactiveUS6860336B2Minimize opportunityOpportunities decreaseLiquid fertiliser distributionSoil-working equipmentsEngineeringMechanical engineering

A subsoil applicator has an upright shank provided with a leading soil-slicing edge and a pair of opposite sides. At the bottom of the shank, a pair of soil lifting wings are provided, presenting a pair of outermost wing edges that diverge rearwardly from the lowermost and forwardmost point of the shank to the rear extremity of the applicator. The wings are generally relatively thin and flat except for a thickened portion across their rear extremity making an upright, rearwardly facing rear wall. A pair of laterally spaced discharge outlets are located in the rear wall and communicate with an internal tubular passage within the shank for delivering substance down into the soil behind the wall as the applicator advances through the soil. The discharge outlets are located in undercut portions of the rear wall, while top, upwardly facing surfaces of the thickened portion are convexly curved to improve soil flow and provide extra protection against premature wear for the internal substance passageways.

Owner:GREAT PLAINS MFG INC

Process for improved combustion of fuel solids

InactiveUS20090241816A1Short reaction timeAvoid generatingCombustion using liquid and pulverulent fuelWaste based fuelNitrogen oxidesProcess engineering

The invention provides a combustion process using comminuted fuel solids from a steam-driven shear field, with controlled water content and optionally coated with a combustion catalyst. The method allows fuel solids to burn for energy production at low temperatures. The lower temperatures avoid emissions of nitrogen oxides, and the process also yields a clean, friable ash that has economic value.

Owner:HYDROCOAL TECH

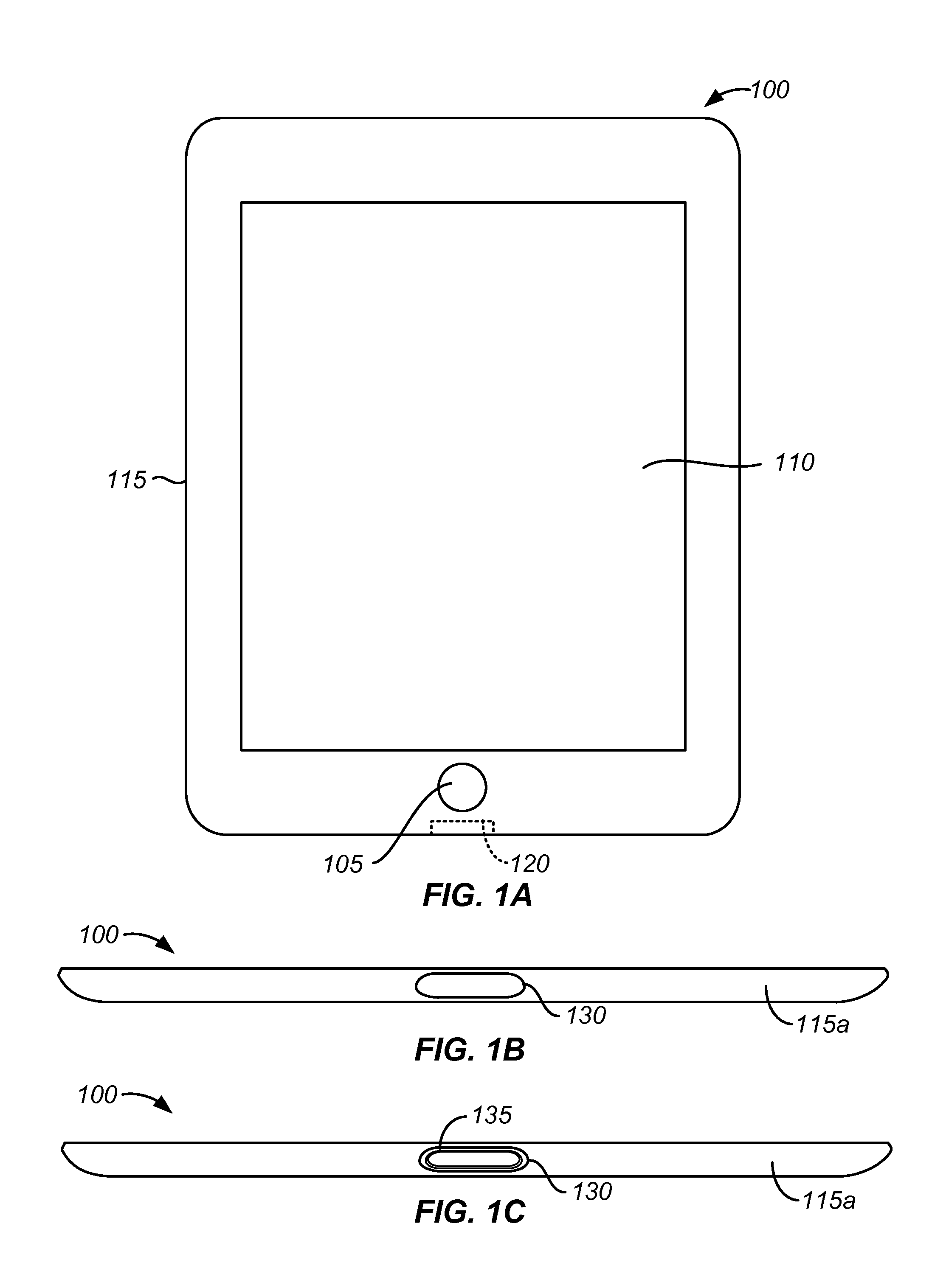

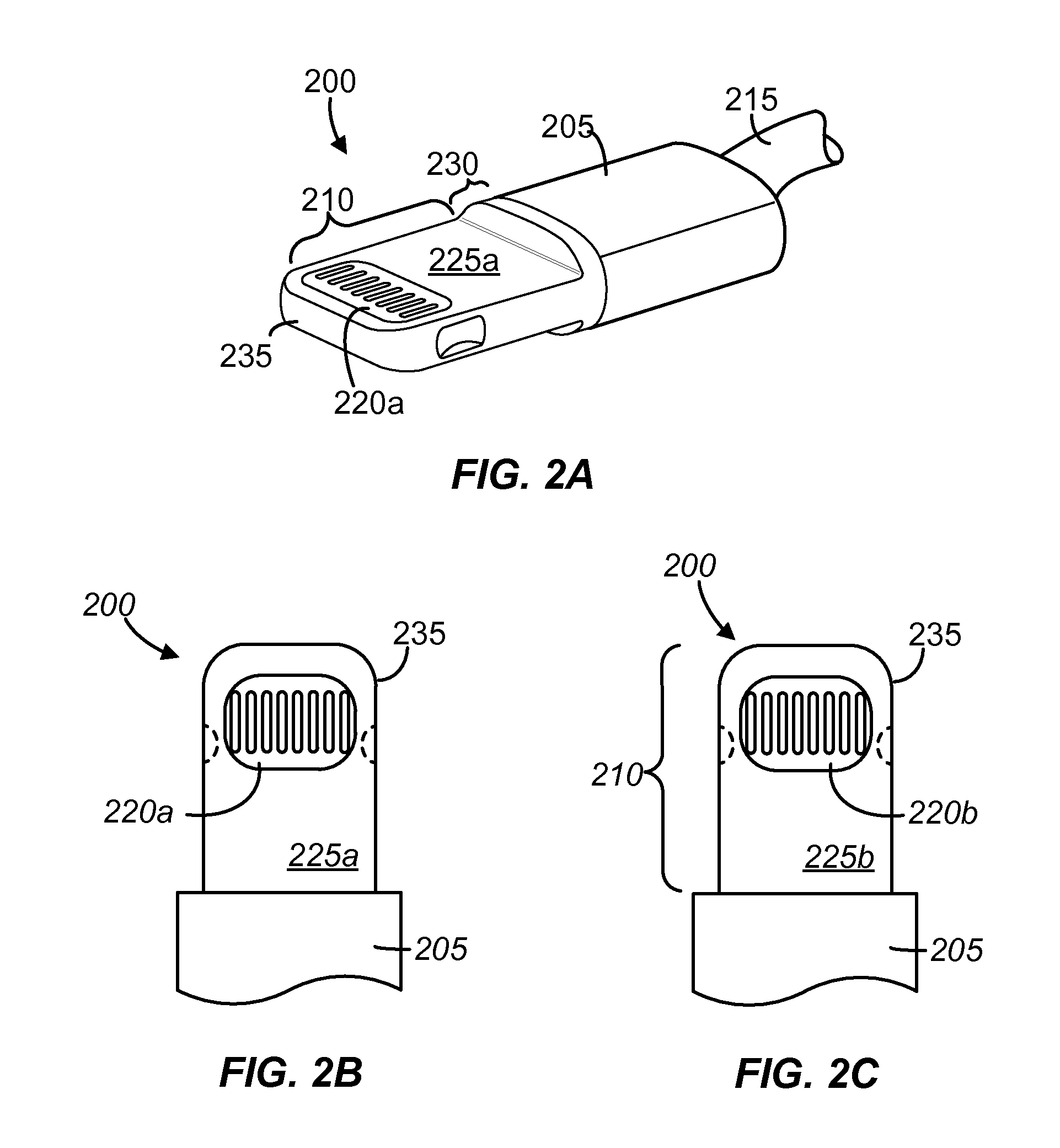

Connector bracket

InactiveUS8804355B2Avoid deformationReduce damage/breakageCable fittingsCircuit arrangements on conductive chasisEngineeringMechanical engineering

Brackets may be mated with or coupled to an opening of an electronic device enclosure or housing for receiving plug connectors to reinforce the receptacle connector and / or device housing and potentially reduce damage / breakage. For example, a bracket can have a front face with a curvature. A back face of the bracket can include a first opening that communicates with a cavity. The cavity can be defined at least in part by upper and lower opposing inner surfaces, the lower inner surface including a portion that extends parallel to a portion of the bracket front face. The bracket can also include a hollow protrusion extending from the bracket front face in a front direction. The hollow protrusion can include an opening that communicates with the opening of the back face and extends through the hollow protrusion. Methods for manufacturing the connector bracket are also provided.

Owner:APPLE INC

Process for preparing fuel solids for gasification

InactiveUS20090199479A1Short reaction timeAvoid generatingWaste based fuelLiquid carbonaceous fuelsParticulatesProcess engineering

The invention provides a process that comminutes fuel solids in a steam-driven shear field, with controlled water content and optionally a catalyst, with gasification of the free-standing or slurry particulate outputs. Unlike conventional gasification methods the invention requires no dioxygen to be present, and produces dry friable ash that has significant marketable value as a material in its own right.

Owner:TAYLOR DAVID WALKER

Form of coal particles

InactiveUS20090199459A1Short reaction timeAvoid generatingSolid fuelsWaste based fuelPorosityNitrogen oxides

The invention provides a micronized form of coal particles with improved characteristics for porosity, hydration and preservation of pristine surfaces. The coal of the invention can burn at low temperatures, avoiding emissions of nitrogen oxides, and also has improved properties for surfactant-free suspension in either water or oil media, as well as for liquefaction and gasification.

Owner:TAYLOR DAVID WALKER

Electrically motorized pump having a submersible sleeve bearing

InactiveUS7008196B2Improved mechanical propertyImprove frictional characteristicPump componentsBearing componentsEnergy lossPolymer chemistry

The electrically motorized pump has a low energy loss because it uses of the shaft and the sleeve made from synthetic resin composition obtained by uniformly dispersing fine powder of RBC or CRBC in a resin. The typical process for the production of a synthetic resin composition for making the sleeve bearing for the pump for use in water includes kneading with a resin the fine powder of RBC or CRBC at a temperature in the neighborhood of the melting point of the resin, and thereby uniformly dispersing the fine powder of RBC or CRBC in the resin. Fibers, such as glass fibers, may be blended with the fine powder of RBC or CRBC and the resin.

Owner:MINEBEA CO LTD

Ambiphilic coal body surfaces

InactiveUS20090202820A1Little wearRapid and uniform and fuel efficient gasificationWaste based fuelRecord information storageLiquid mediumNitrogen oxide

The invention provides compositions of matter comprising coal body surfaces having improved characteristics for hydration and preservation of pristine surfaces, and which are compatible with both hydrophilic and hydrophobic liquid media. The coal body surfaces of the invention facilitate burning at low temperatures, avoiding emissions of nitrogen oxides, and also have improved properties for surfactant-free suspension in either water or oil media, as well as for liquefaction and gasification.

Owner:TAYLOR DAVID WALKER

Process for improved gasification of fuel solids

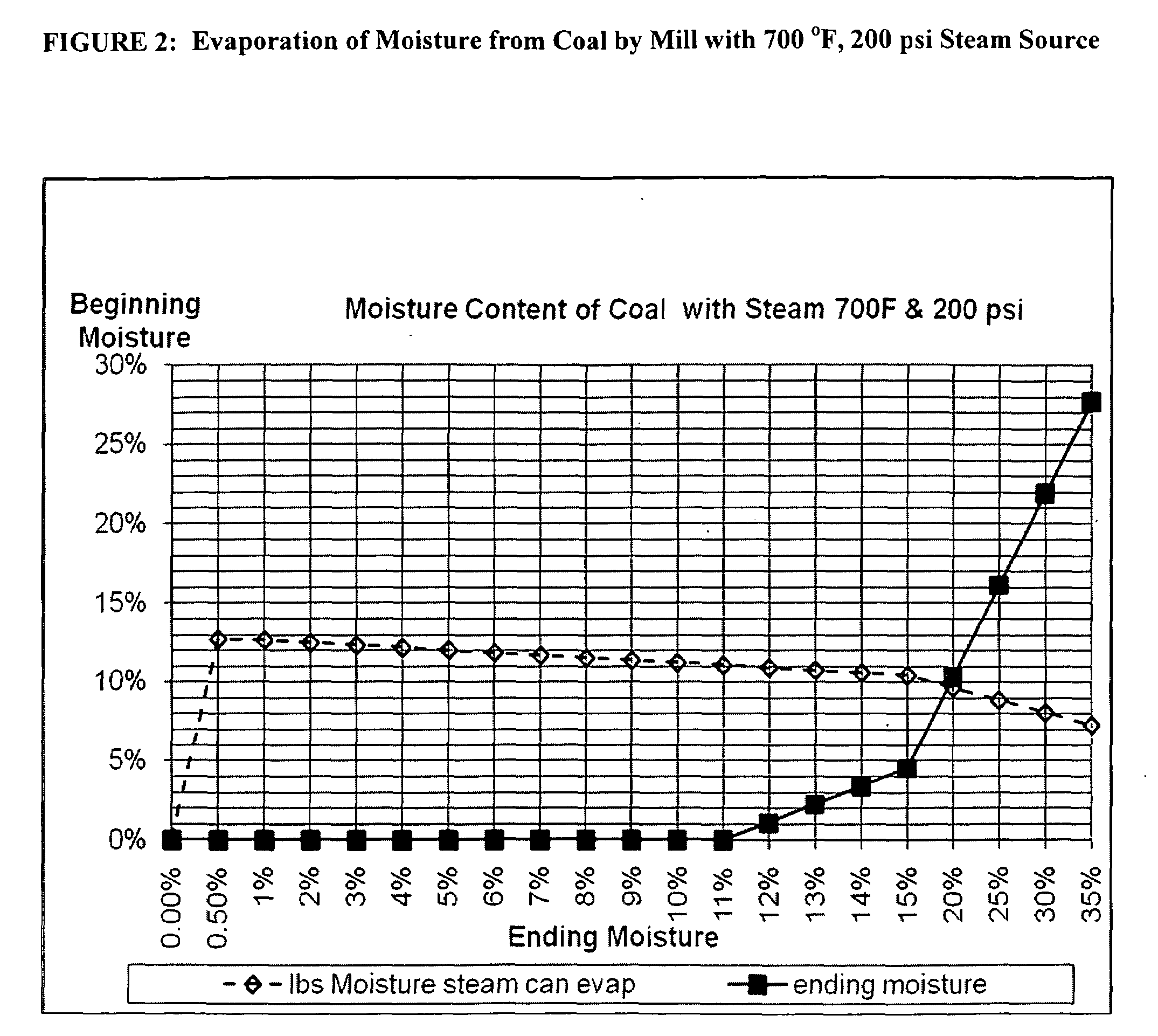

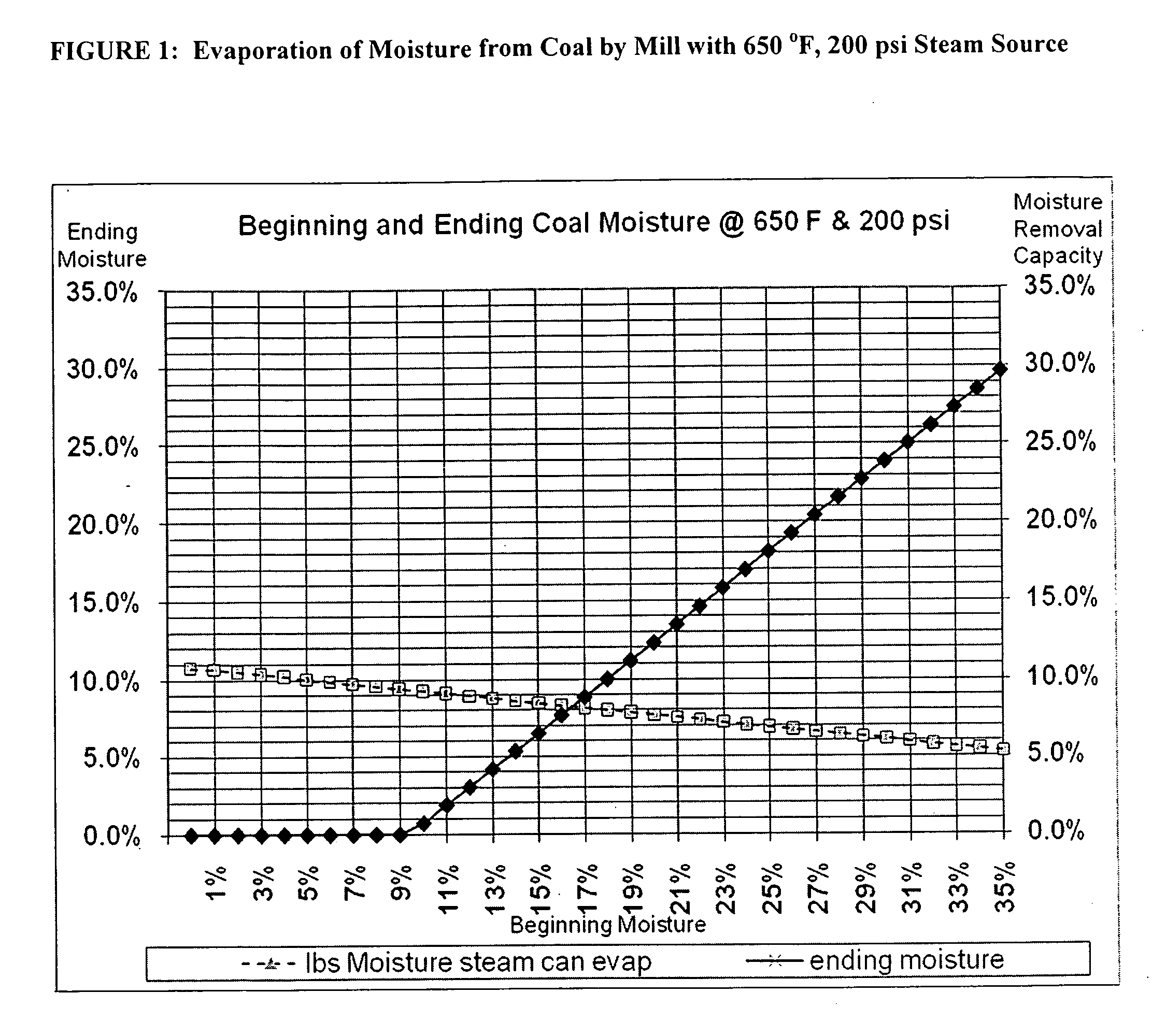

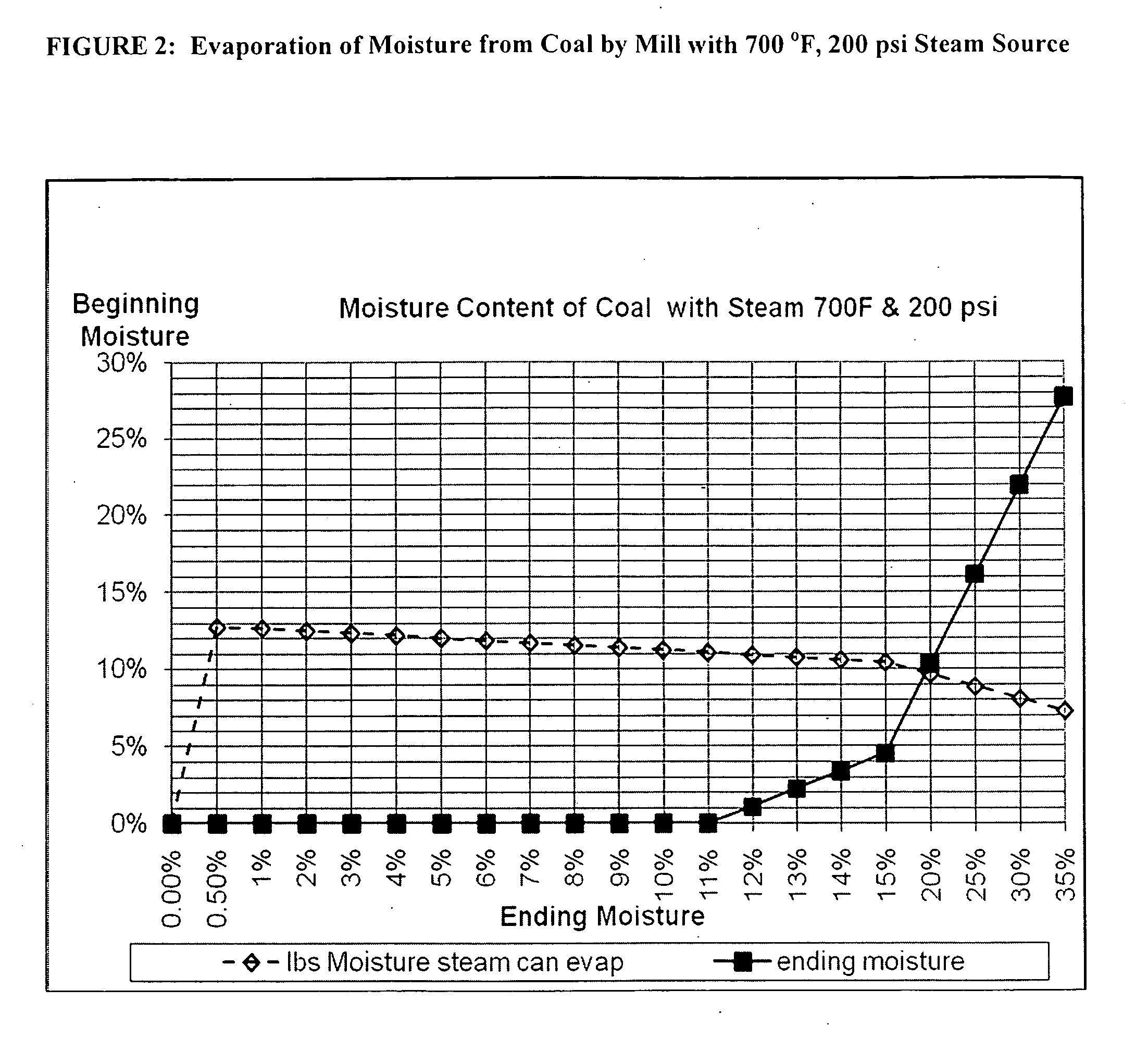

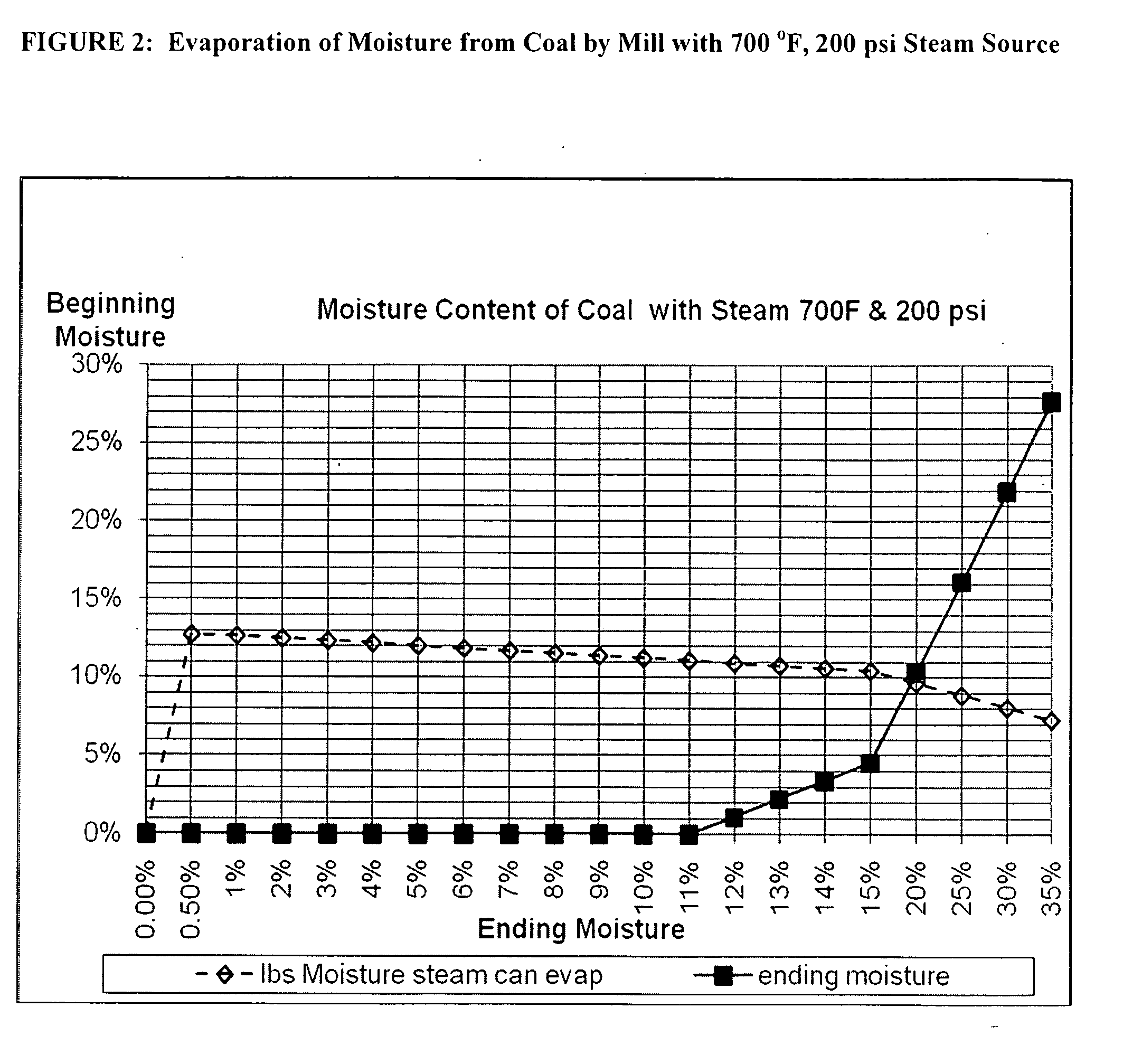

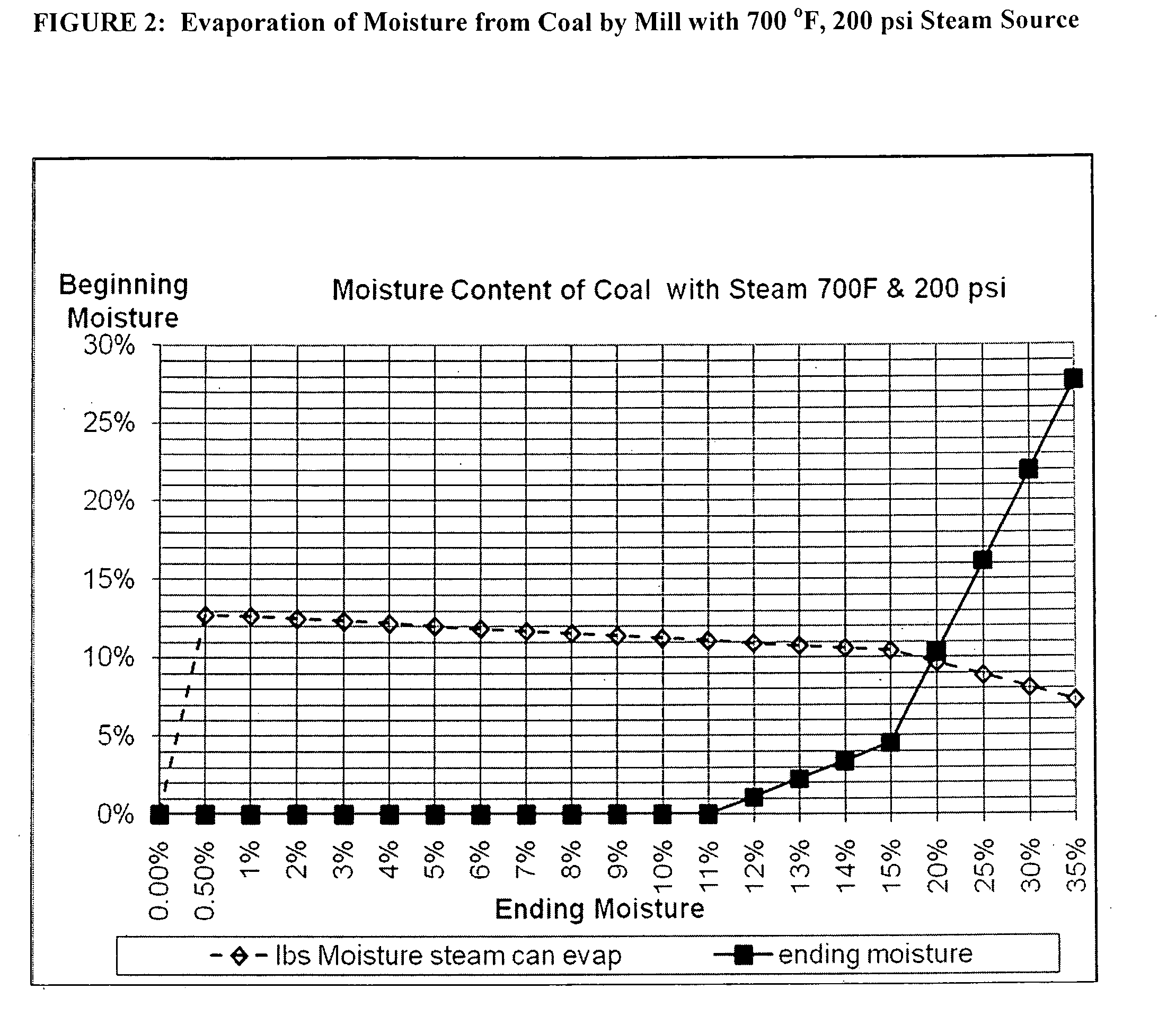

InactiveUS20090199478A1Short reaction timeAvoid generatingMultiple metal hydridesMuffle furnacesWater contentProcess engineering

The invention provides a process that comminutes fuel solids in a steam-driven shear field, with controlled water content and catalyst, with gasification of the particles entrained in the vented steam. Unlike conventional gasification methods the invention requires no dioxygen to be present, and produces dry friable ash that has significant marketable value as a material in its own right.

Owner:TAYLOR DAVID WALKER

Process for modifying fuel solids

InactiveUS20090199476A1Short reaction timeAvoid generatingHydrogenSolid waste disposalNitrogen oxidesCombustion

The invention provides a process for comminuting coal or other fuel solids in a shear field, and for optionally coating the solids with catalysts for combustion, liquefaction, and or gasification during the milling process. The process further provides for control of water content in the solids may be controlled before, during and after the milling in order to obtain micronized solids with fine hydration layers. The output fuel solids from the process can burn at low temperatures, avoiding emissions of nitrogen oxides, and they also have improved properties for surfactant-free suspension in either water or oil media, as well as for liquefaction and gasification.

Owner:TAYLOR DAVID WALKER

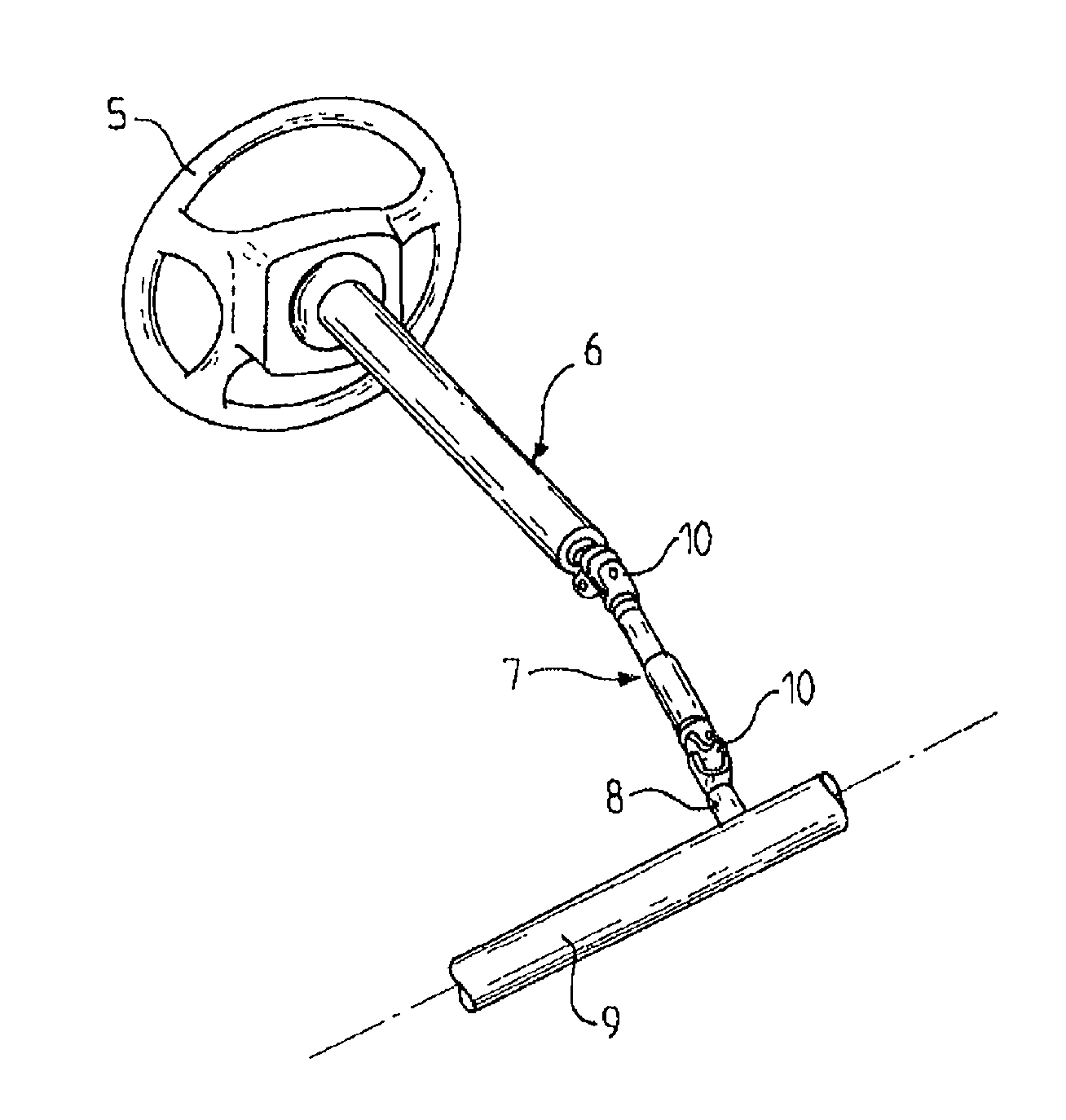

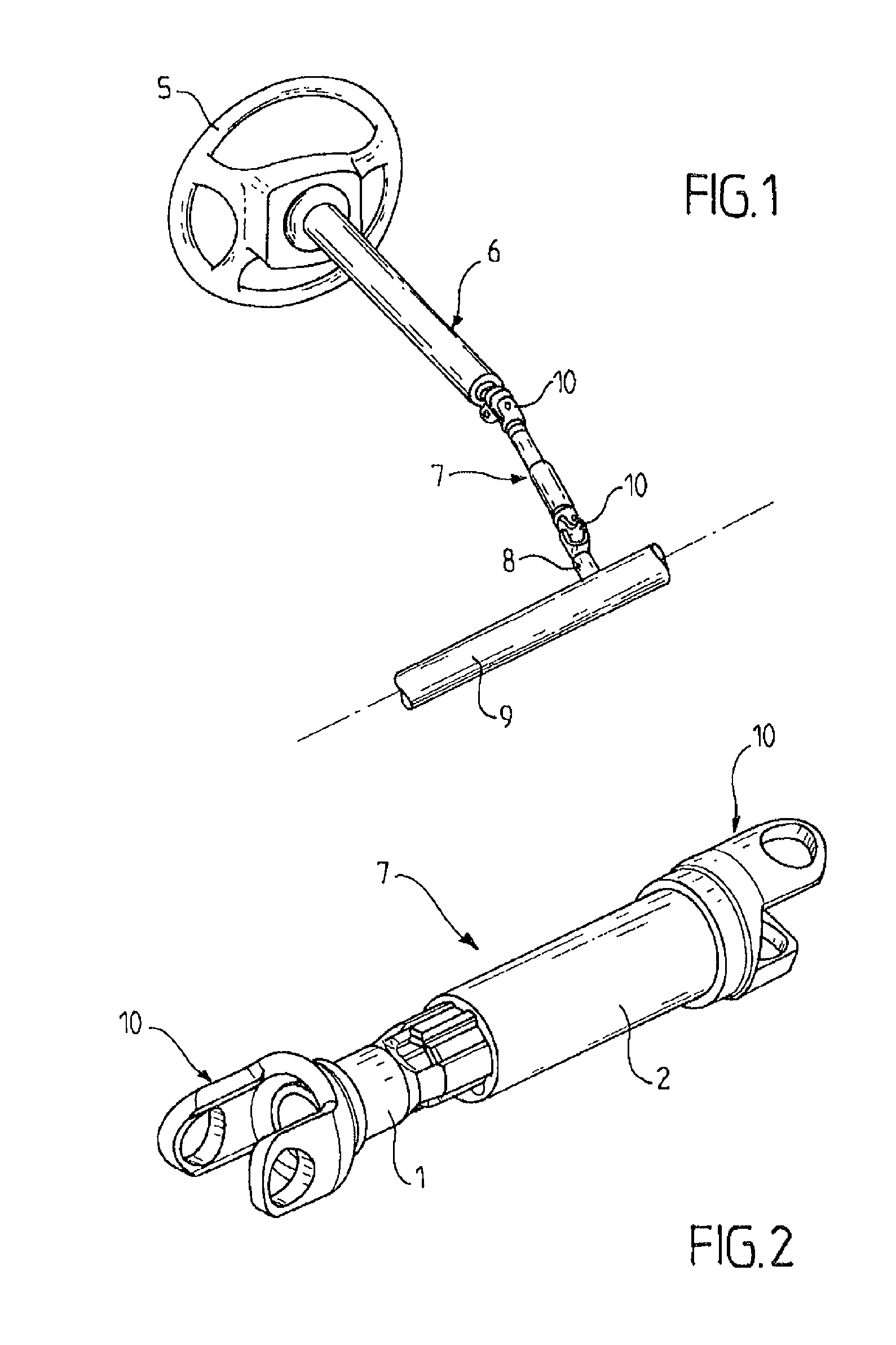

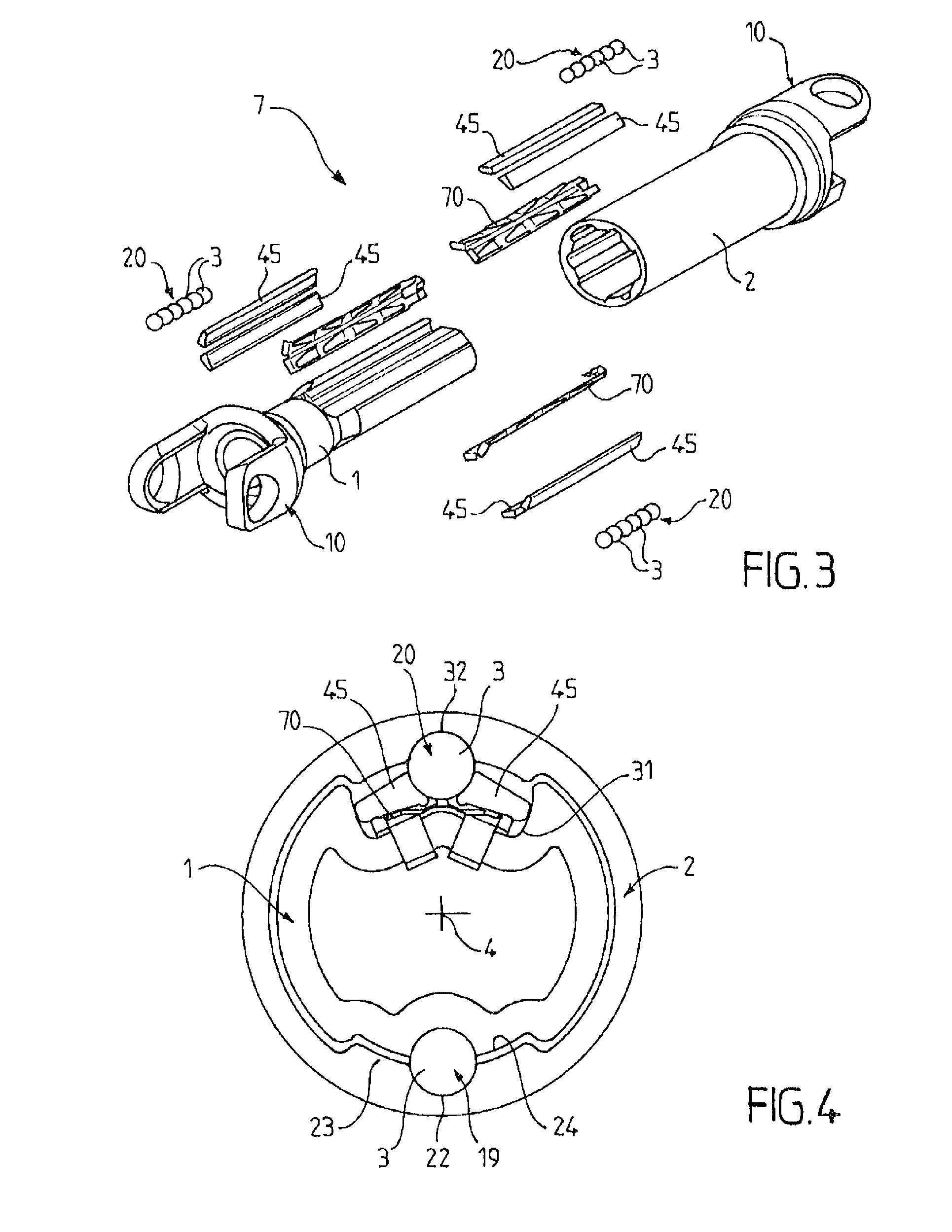

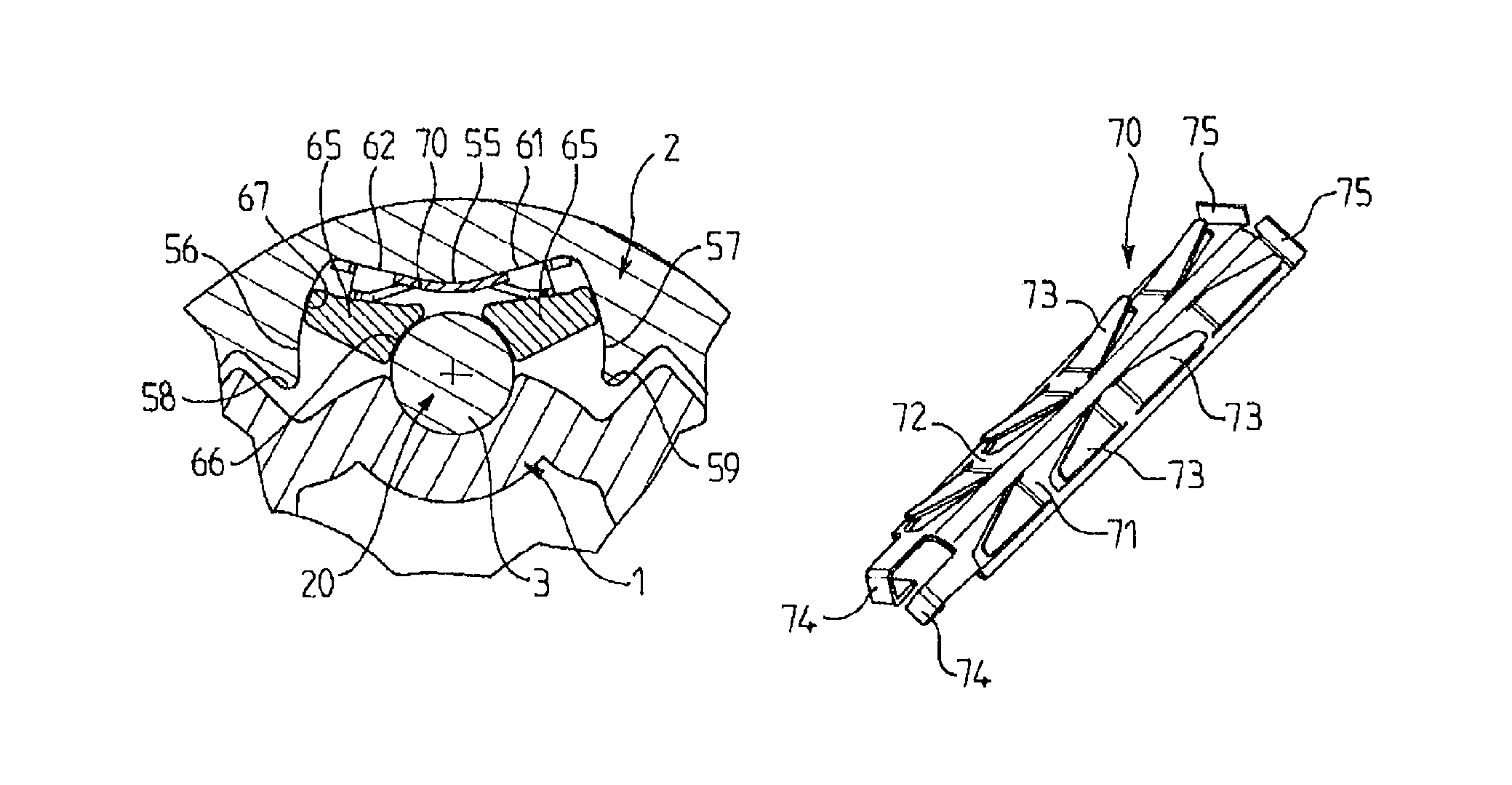

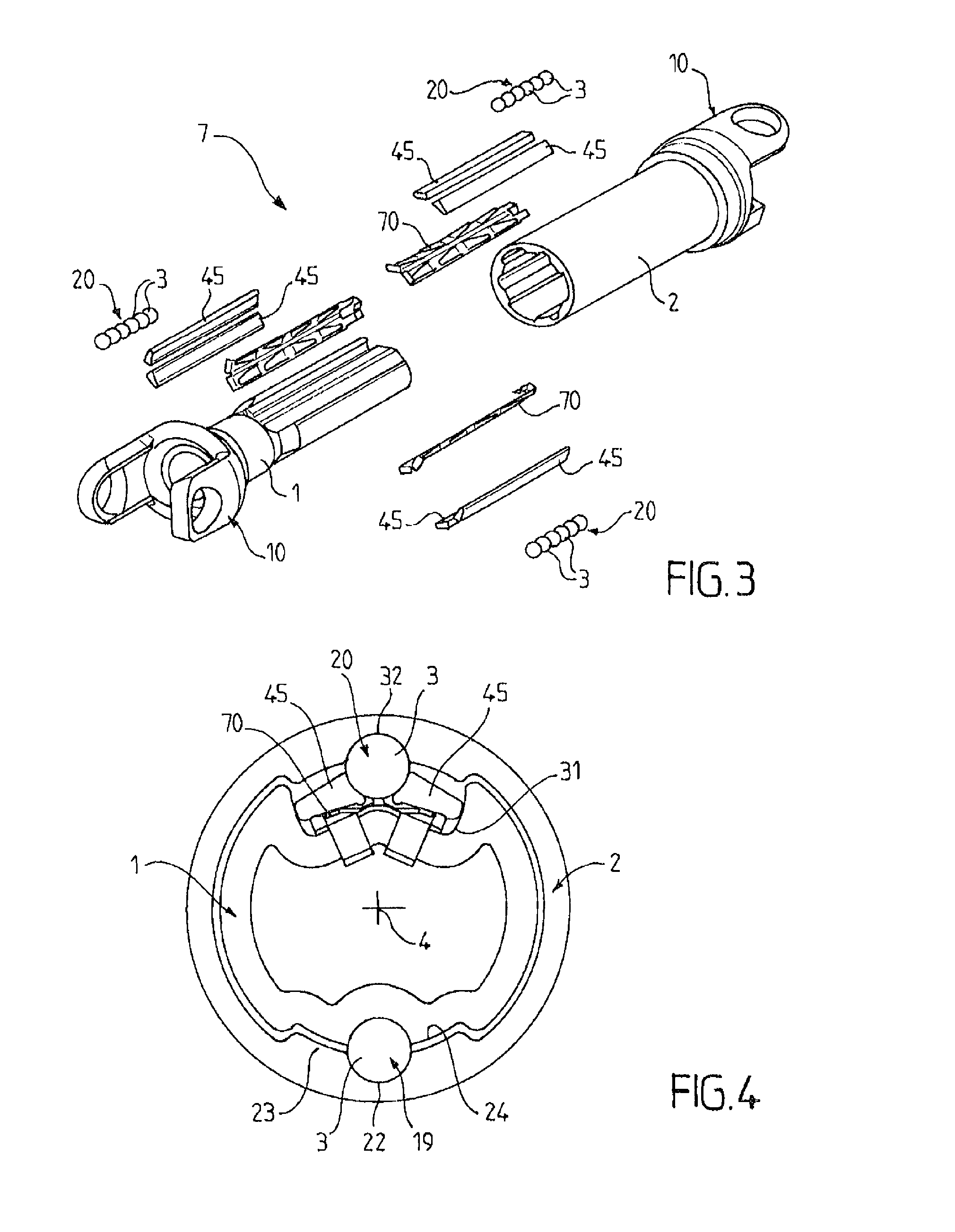

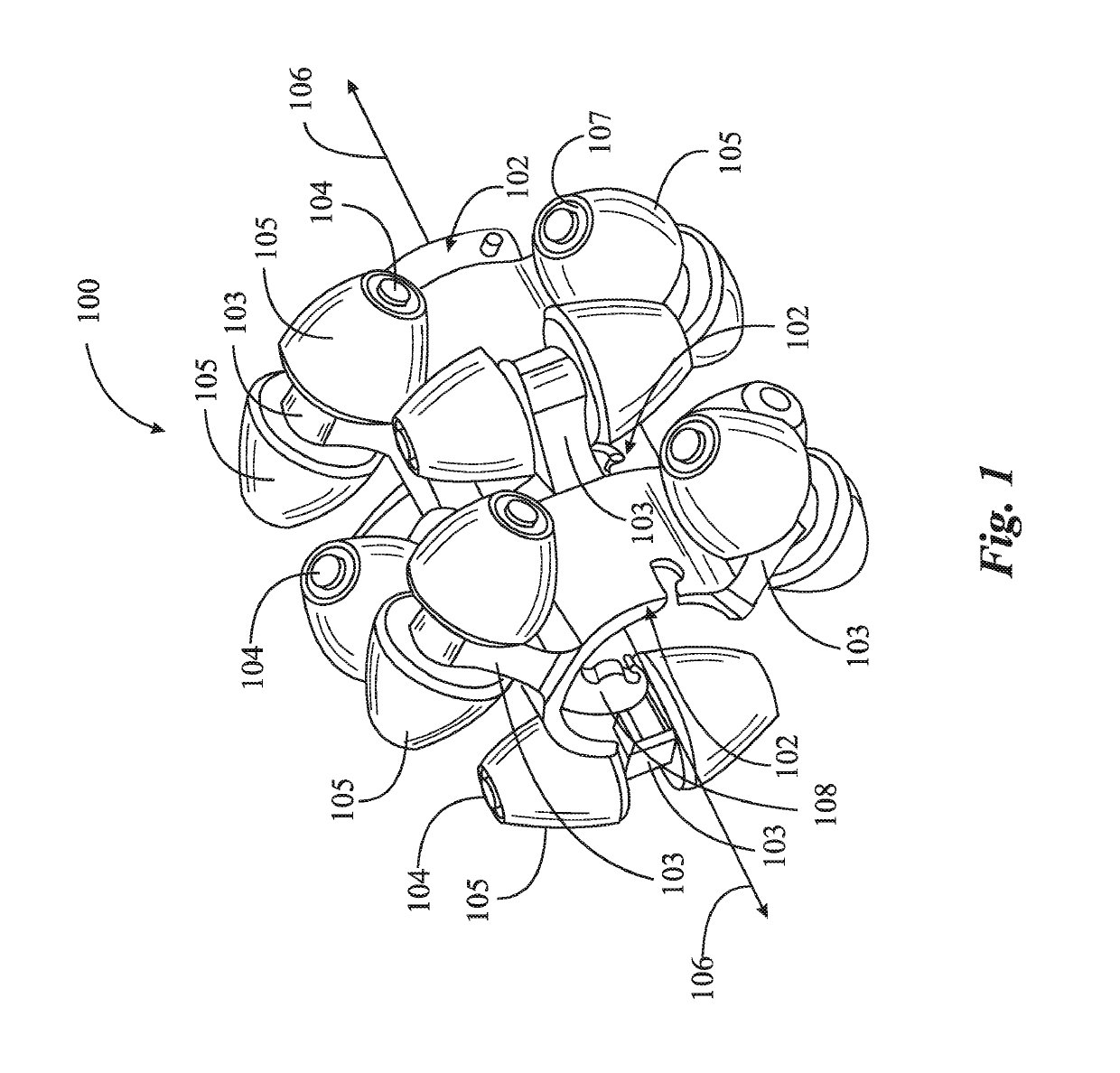

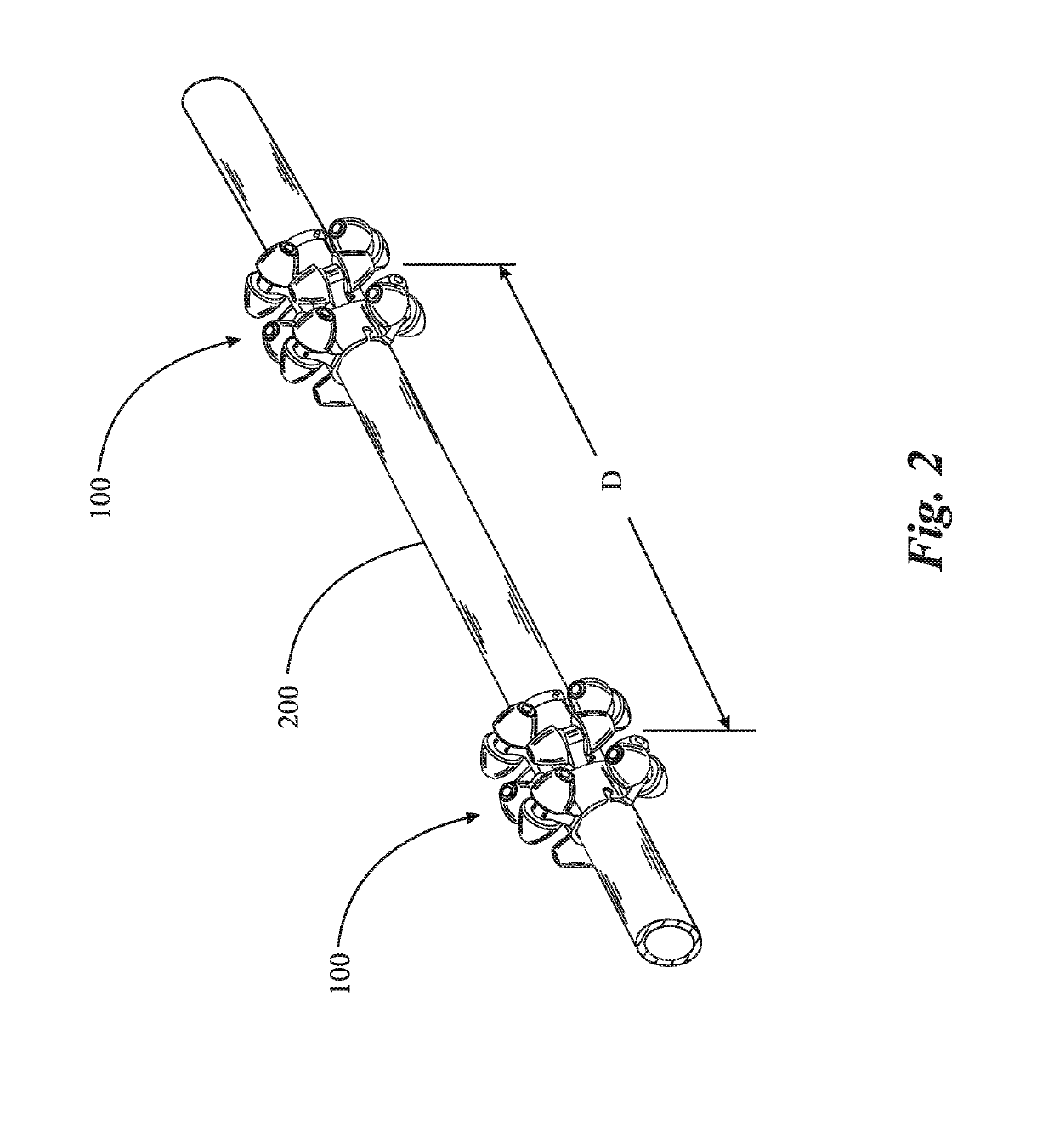

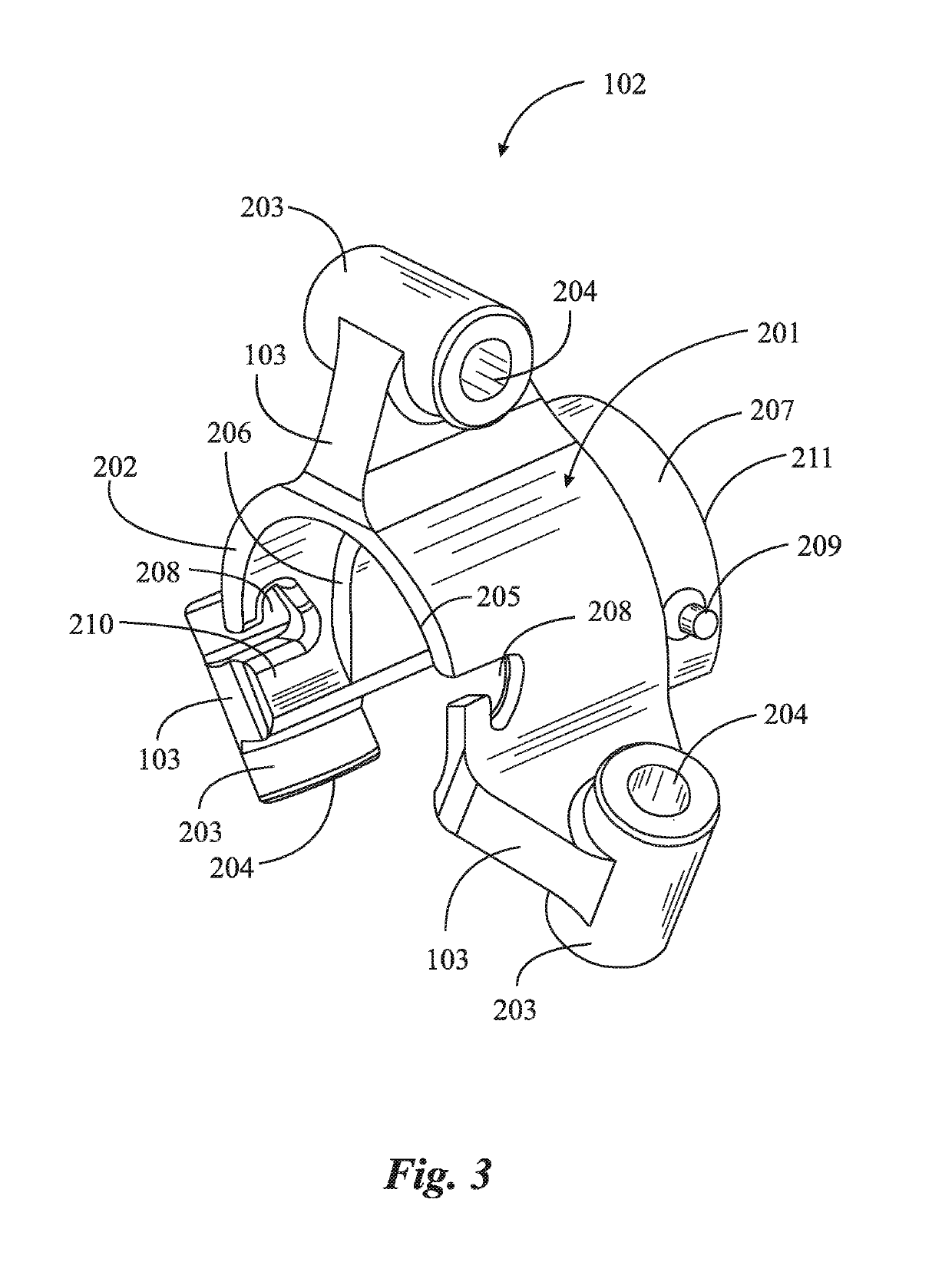

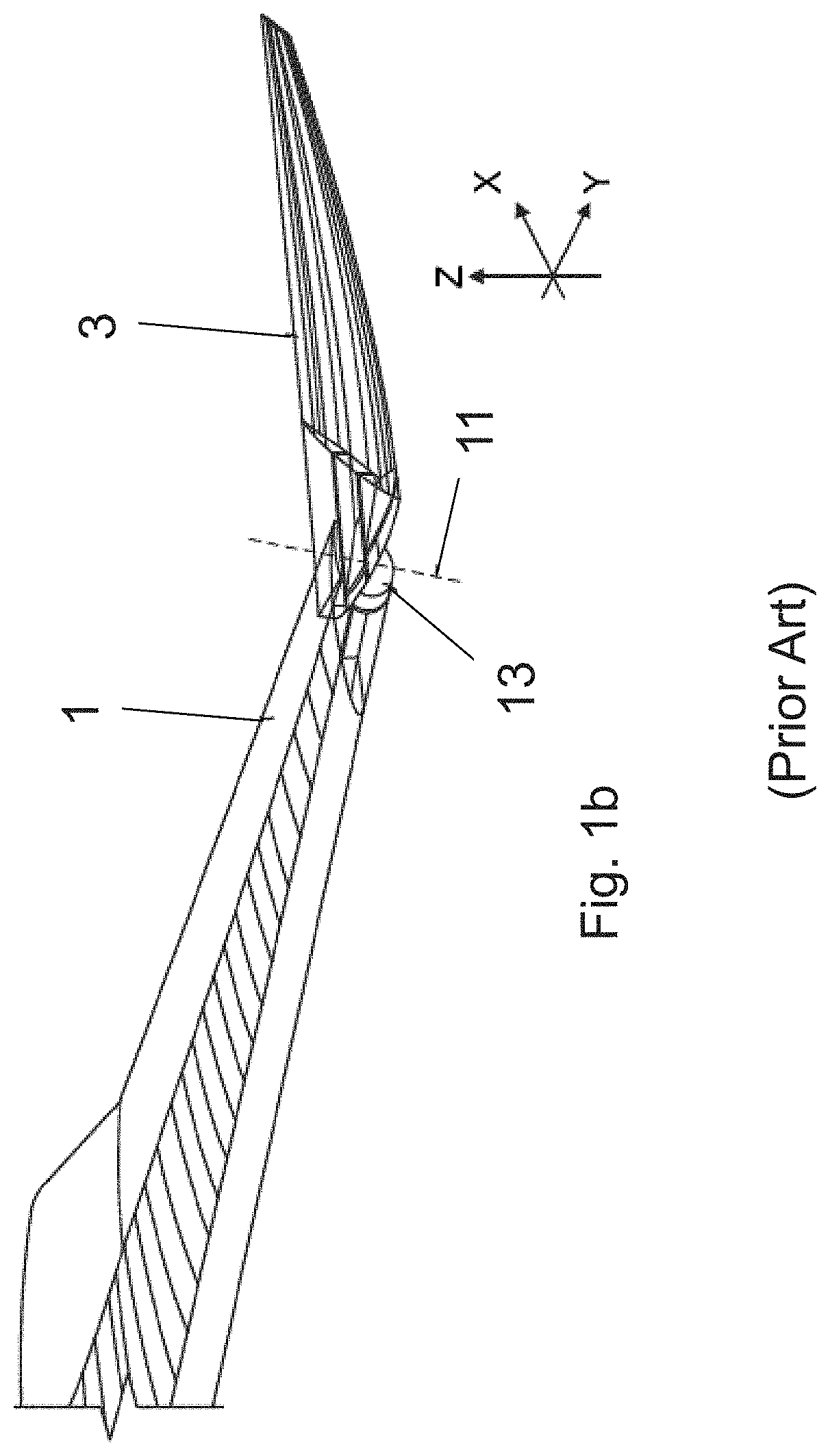

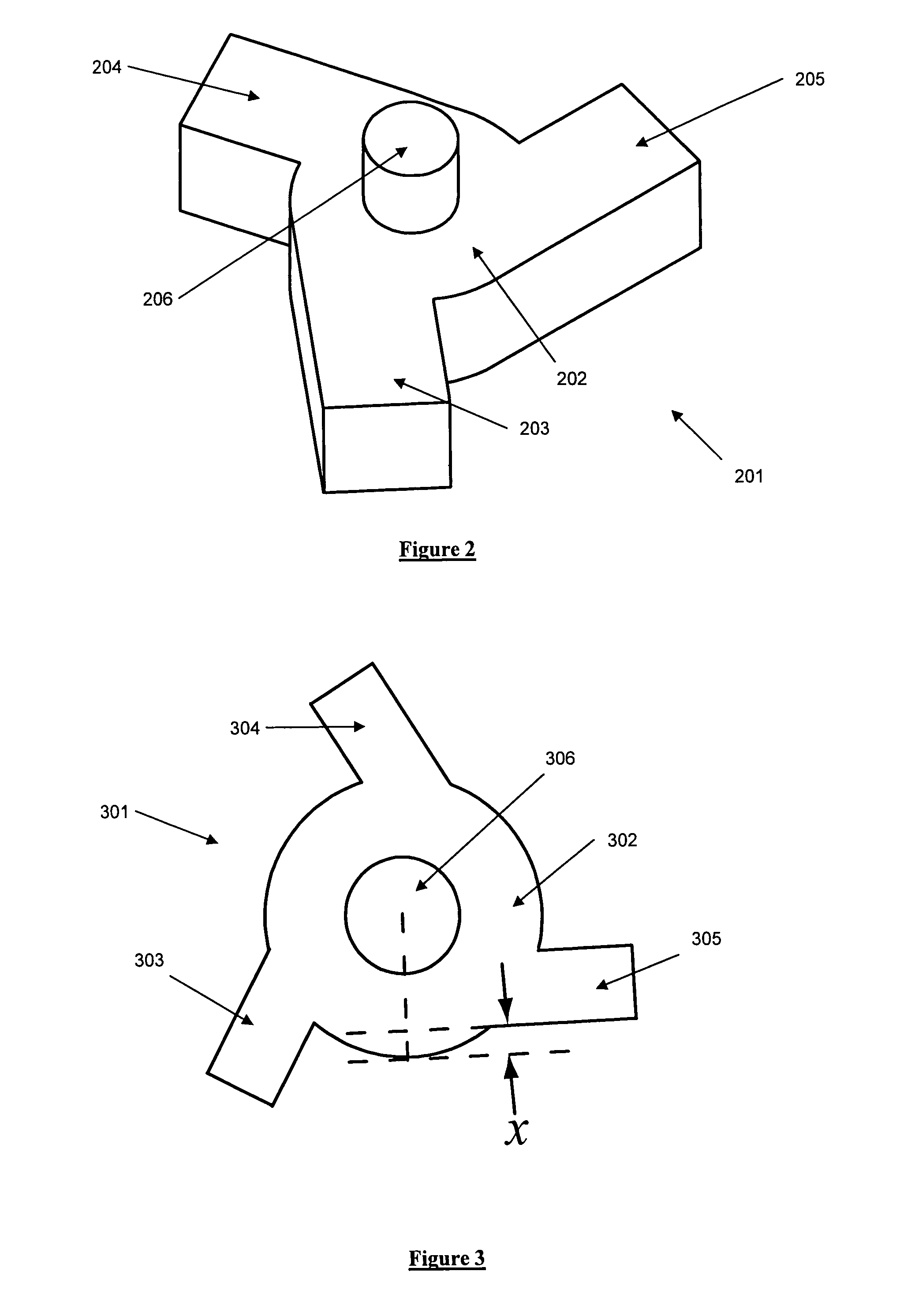

Ball-Type Coupling Device For Coupling Two Sliding Shafts With Pivoting Support

ActiveUS20130079165A1Reduce playImprove wear characteristicsYielding couplingLinear bearingsCouplingBall type

Device for coupling an inner shaft and an outer shaft which slide along their common axis with balls positioned between the two shafts. The balls rest directly in axial grooves of the outer shaft and on two rails positioned in axial grooves of the inner shaft. The two rails pivot about the balls, by pressing against flanks of mating curved profile of the axial groove, and are held in place by an elastic element which presses against the bottom of the axial groove.

Owner:ROBERT BOSCH AUTOMOTIVE STEERING VENDOME SAS

Brazed structural assembly and associated system and method for manufacture

InactiveUS7621437B2Improve fatigue resistanceImprove abilitiesFuselage framesEfficient propulsion technologiesFiberEngineering

A structural assembly and an associated system and method for manufacture are provided. The structural assembly includes an elongate member and a first connector member that is connected to an end of the elongate member by a braze joint. A second connector member can be connected to an end of the elongate member opposite the first connector by another braze joint. The elongate member is formed of a metal matrix composite material that includes a plurality of fibers of a reinforcement material disposed in a metal matrix. Each connector member is formed of a material that is dissimilar to the material of the elongate member. The braze joints can be formed by selectively heating the braze material, e.g., with an inductive coil that extends circumferentially around only a portion of the structural assembly.

Owner:THE BOEING CO

Ball-type coupling device for coupling two sliding shafts with pivoting support

ActiveUS8678939B2Reduce playImprove wear characteristicsYielding couplingRolling contact bearingsCouplingEngineering

Device for coupling an inner shaft and an outer shaft which slide along their common axis with balls positioned between the two shafts. The balls rest directly in axial grooves of the outer shaft and on two rails positioned in axial grooves of the inner shaft. The two rails pivot about the balls, by pressing against flanks of mating curved profile of the axial groove, and are held in place by an elastic element which presses against the bottom of the axial groove.

Owner:ROBERT BOSCH AUTOMOTIVE STEERING VENDOME SAS

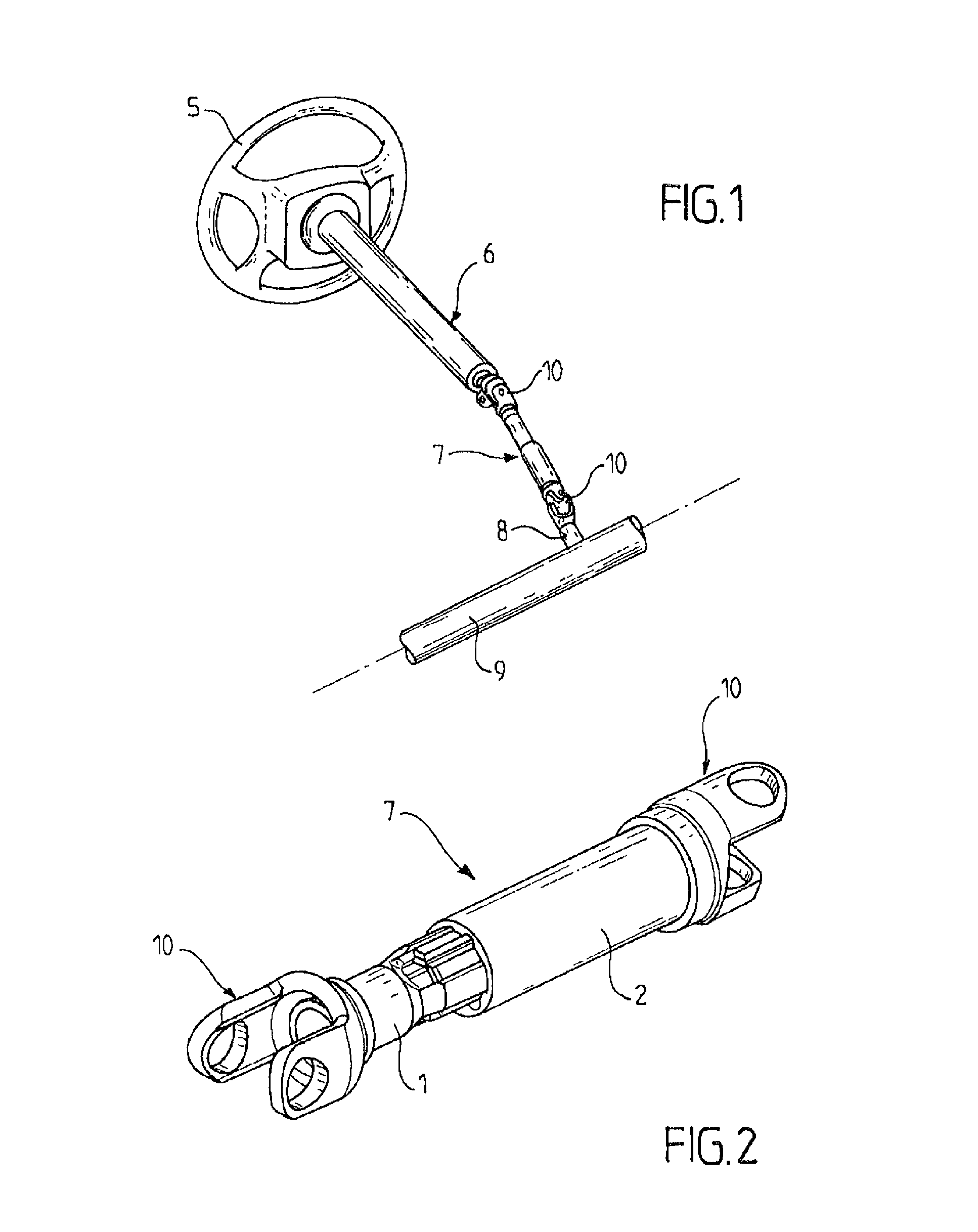

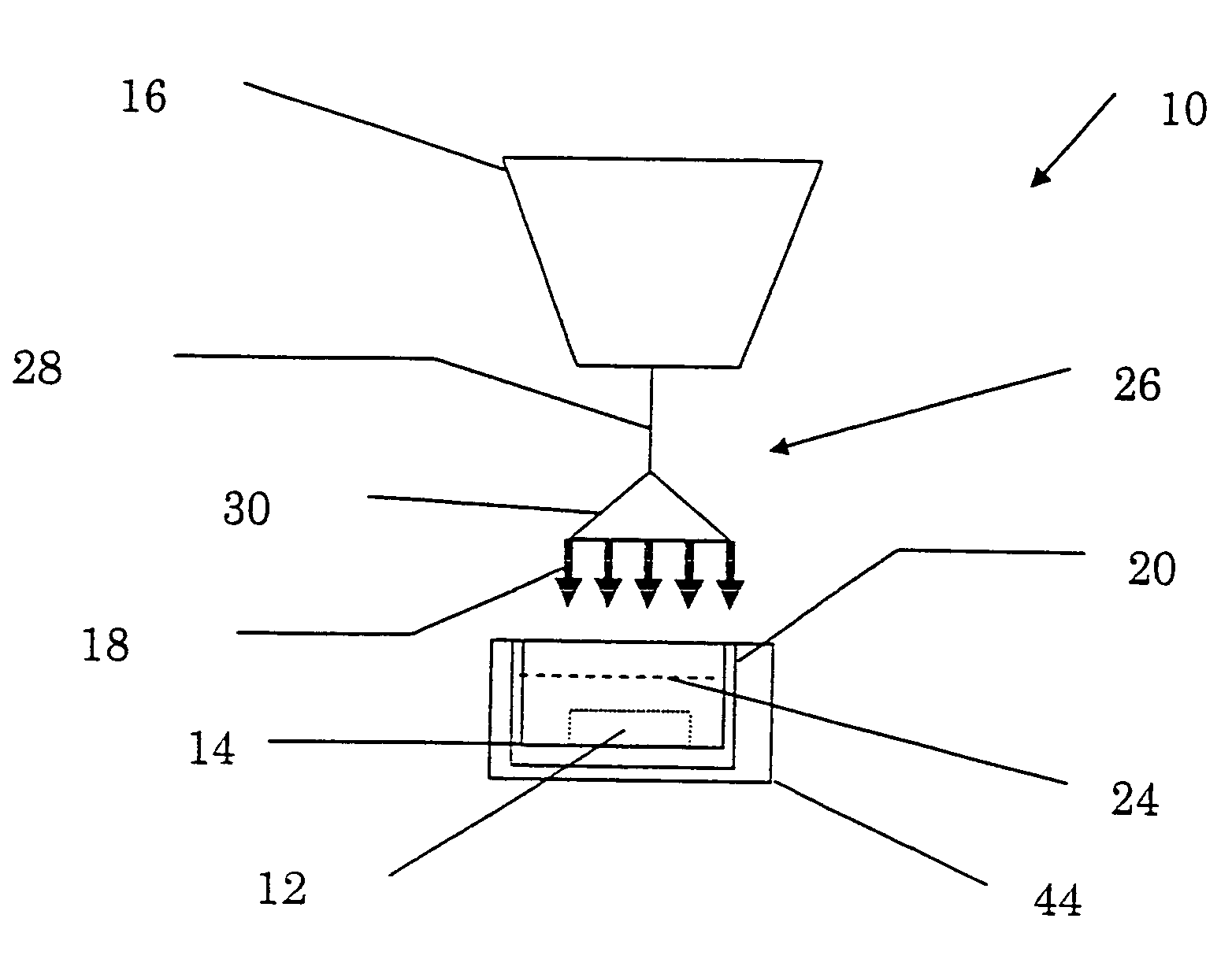

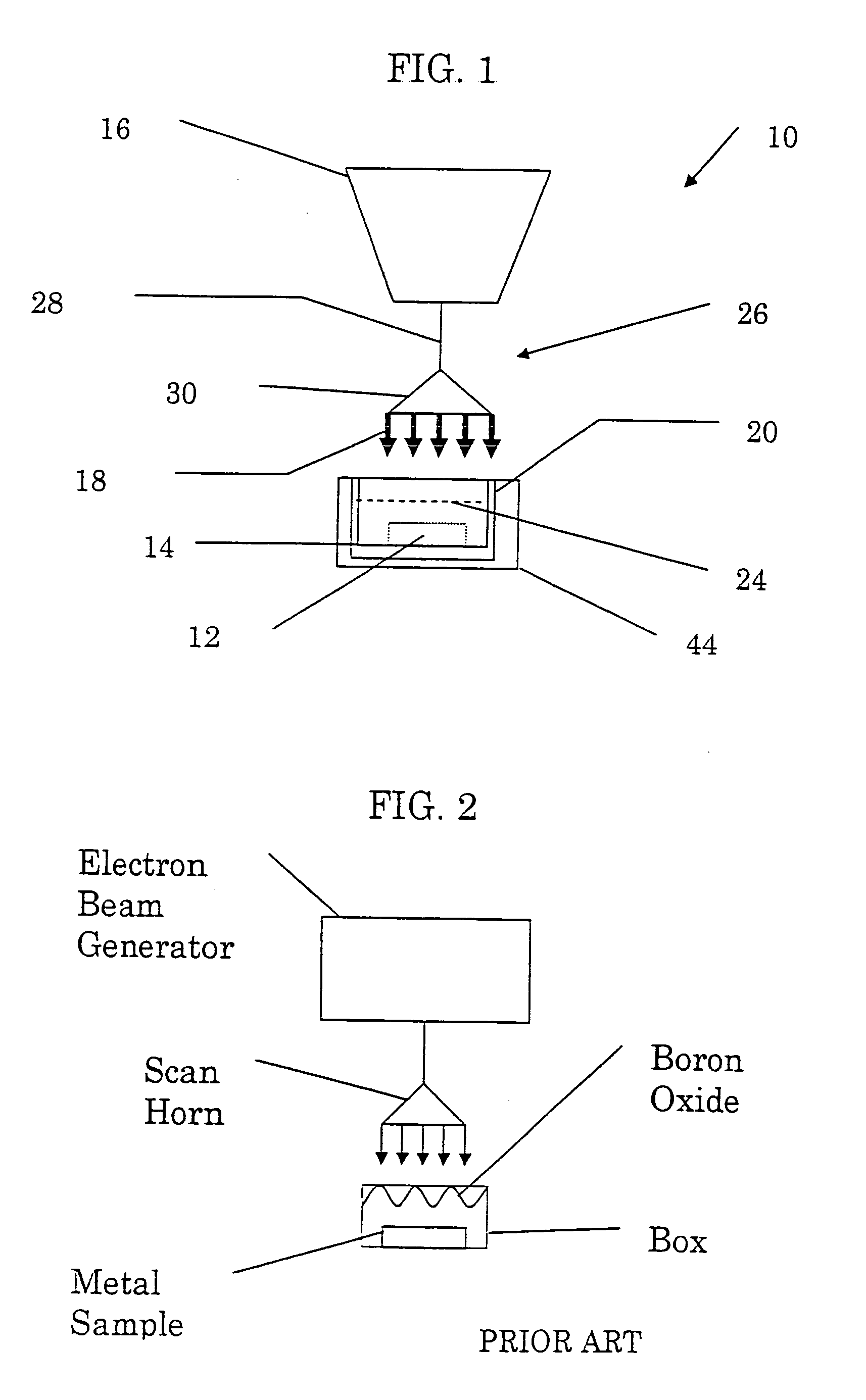

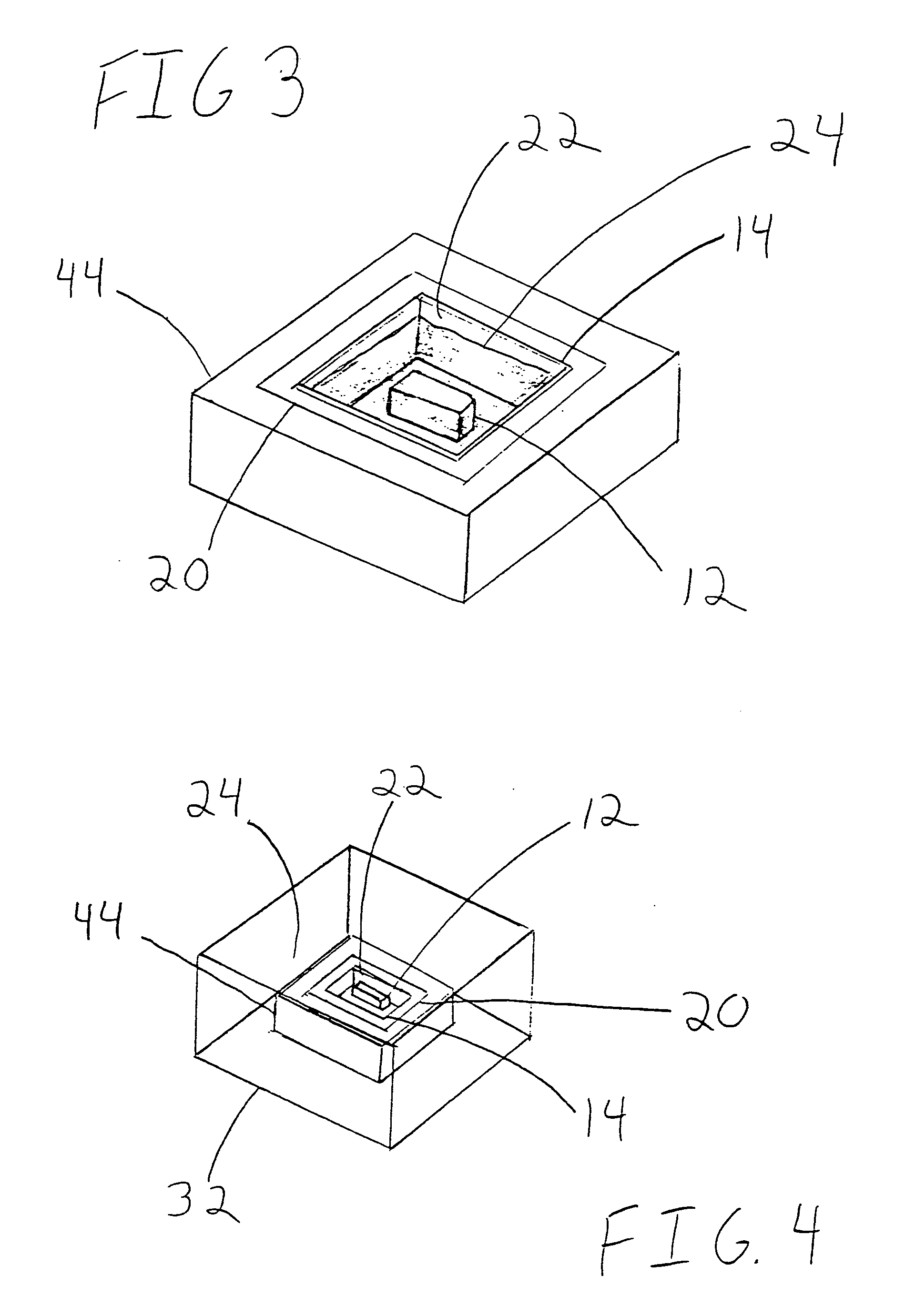

Apparatus and method using fractionated irradiation to harden metal

InactiveUS6933509B1Reduce porosityIncrease wear characteristicMagnetic materialsRadiation therapyEngineeringInstrumentation

The present invention provides an apparatus for hardening a metal article, comprising a holding device, an energy beam generator pointed at the holding device for directing energy beams at the holding device, and a cycling system supporting the holding device, wherein the cycling system varies the location of the holding device relative to the energy beam generator. The apparatus includes an energy beam delivery instrument system positioned between the energy beam generator and the holding device so that the energy an energy beam delivery instrument directs the energy beam to the holding device. Also, the apparatus includes an auxiliary heating device engaging the holding device, wherein the auxiliary heating device heats the metal article independently from the energy beam.

Owner:ALLASSO IND

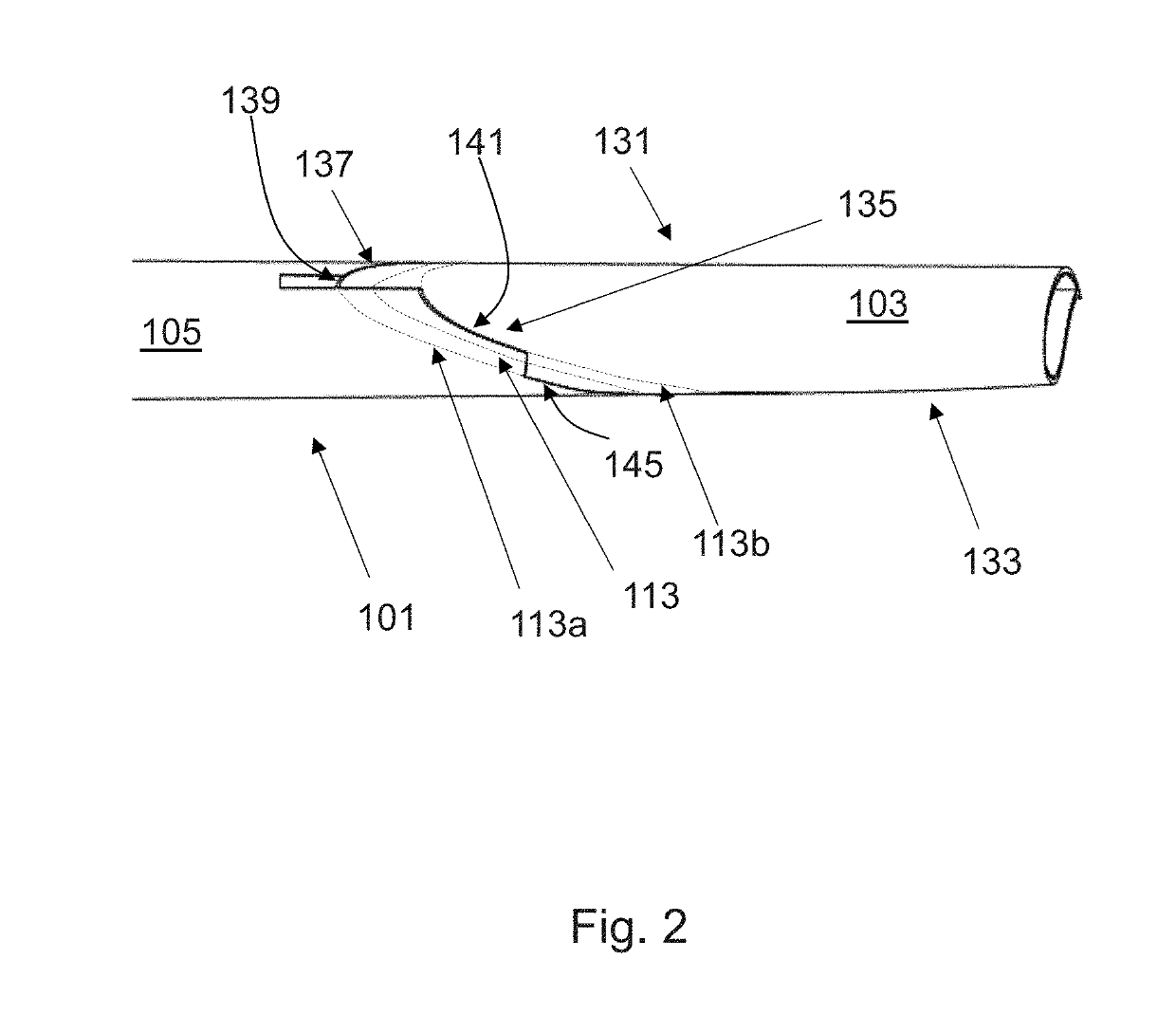

Hose carrier

Owner:MCDONALD DUSTIN

Process for Modifying Fuel Solids

InactiveUS20120227315A1Short reaction timeAvoid generatingWaste based fuelLiquid hydrocarbon mixture productionNitrogen oxidesCombustion

The invention provides a process for comminuting coal or other fuel solids in a shear field, and for optionally coating the solids with catalysts for combustion, liquefaction, and or gasification during the milling process. The process further provides for control of water content in the solids may be controlled before, during and after the milling in order to obtain micronized solids with fine hydration layers. The output fuel solids from the process can burn at low temperatures, avoiding emissions of nitrogen oxides, and they also have improved properties for surfactant-free suspension in either water or oil media, as well as for liquefaction and gasification.

Owner:HYDROCOAL TECH

Fluid Control

ActiveUS20100032596A1Weaken energyReduce erosionSoldering apparatusValve members for absorbing fluid energyFluid controlEngineering

A valve having a trim comprising a plurality of a vortex flowpaths, each flowpath comprising a central vortex chamber and having three tangential inlet passages is provided. As the fluid flows through the inlet passages and enters the vortex chamber the flows start to turn and impinge upon one another, i.e., the flow entering via inlet passage will impinge upon the flow entering via inlet, the flow entering inlet will impinge on the flow entering inlet and the flow entering inlet will impinge on the flow entering inlet. As the flow entering vortex chamber impinges on another fluid flow as opposed to a wall of the flowpath the vortex can be used to create a flowpath with reduced erosion. The flow from the inlets combine in a radial flow within the vortex chamber and exit via the outlet which is substantially axial to the vortex chamber.

Owner:IMI VISION LTD

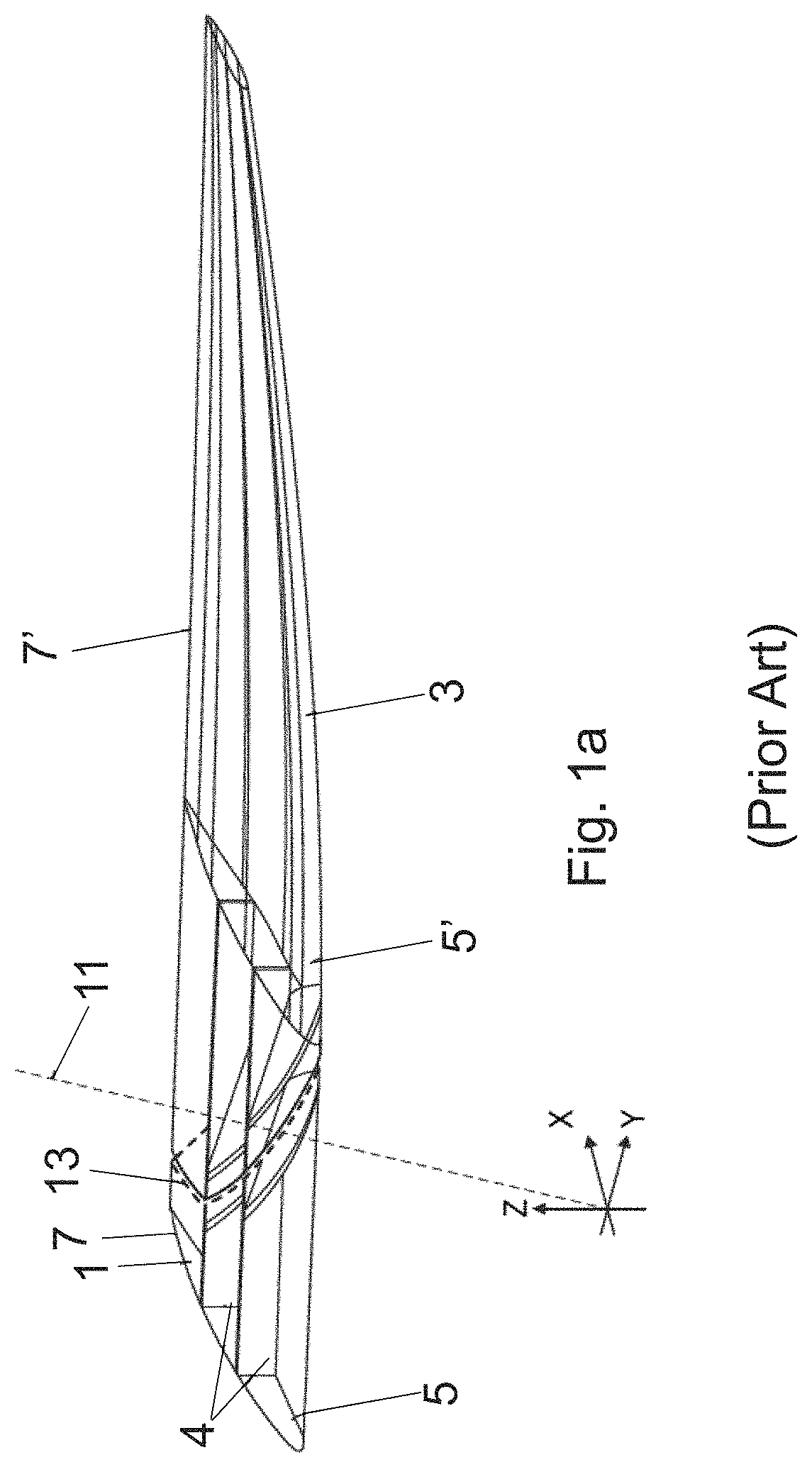

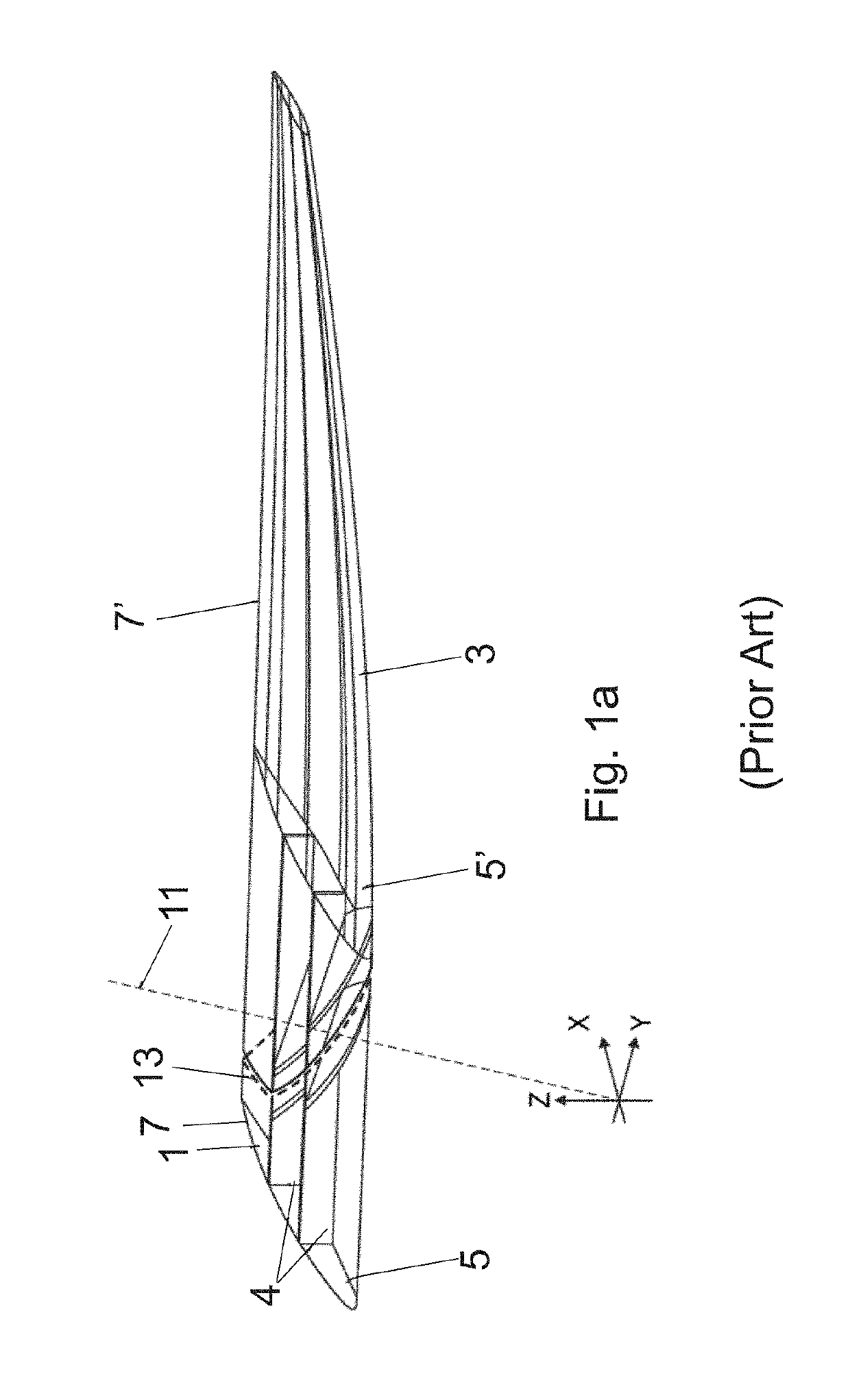

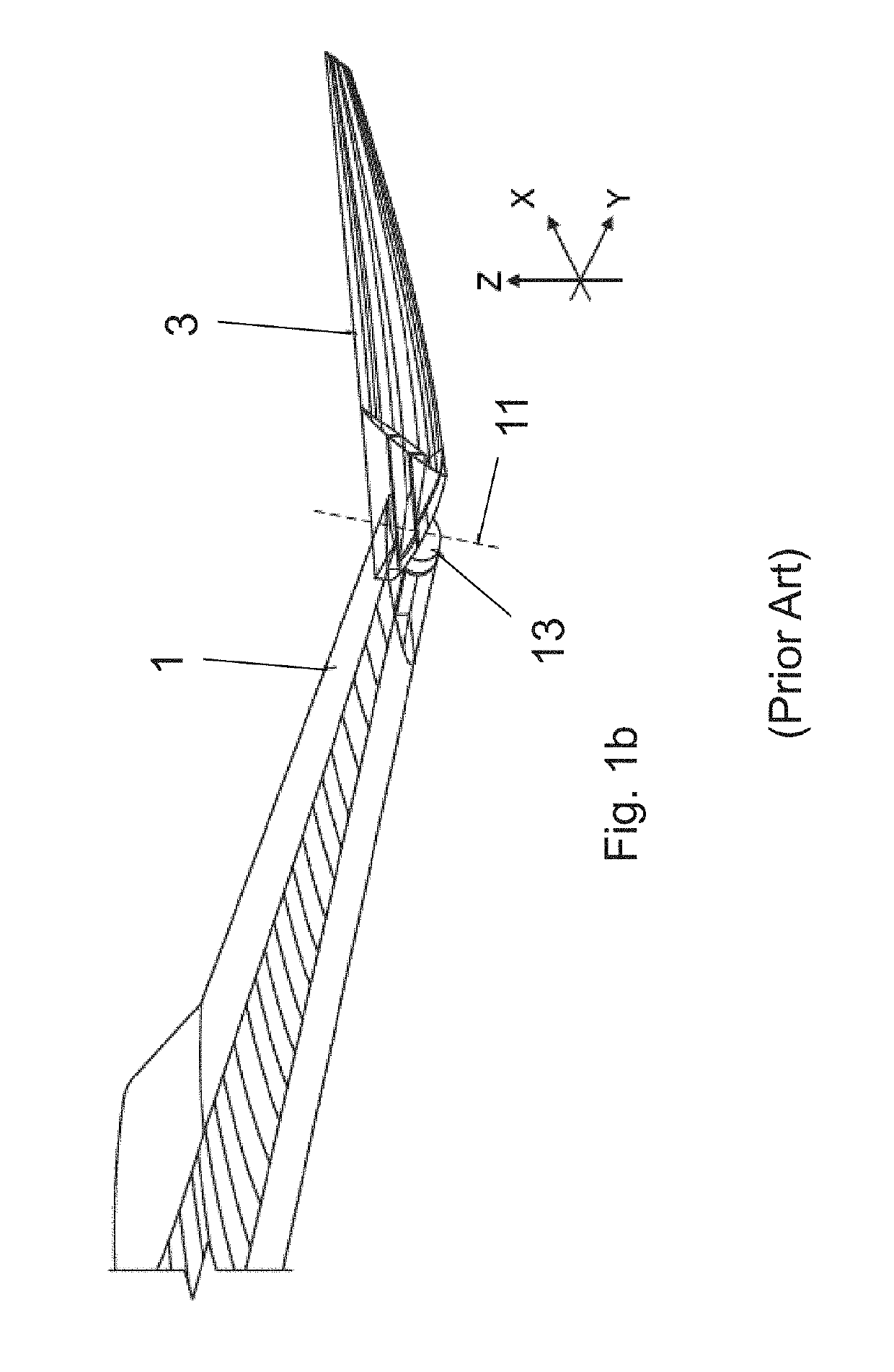

Moveable wing tip device, an outer end of a wing, and interface therebetween

ActiveUS11192630B2Improve aerodynamic performanceEasy to moveInfluencers by generating vorticesSpars/stringersStructural engineeringWingtip device

An aircraft having a wing, including a fixed wing with a wing tip device movably mounted at the outer end thereof is disclosed. The wing tip device is movable between: a flight configuration; and a ground configuration. The wing tip device and the fixed wing are separated along an oblique primary cut plane. The wing tip device and the fixed wing meet along an interfacing cut line. The wing tip device and fixed wing comprise a wing skin with a thickness, and end faces extending across the thickness of the wing skin provide interfacing surfaces corresponding to the interfacing cut line, wherein the interfacing surfaces are angled at a first orientation towards the front of the wing and a second, opposite, orientation towards the rear of the wing.

Owner:AIRBUS OPERATIONS LTD

High durability magnetorheological fluids

InactiveUS20120074348A1Reduce wearReduce frictionMagnetic paintsMagnetic liquidsOrganic baseMagnetorheological fluid

A magnetorheological fluid comprising a mixture of soft and hard iron particles, an organic based carrier fluid, and optional additives such as anti-friction, anti-wear, or surfactants unexpectedly have improved durability when used in devices for control vibration and / or noise, for example, shock absorbers, elastomeric mounts, dampers, and the like.

Owner:LORD CORP

Moveable wing tip device, an outer end of a wing, and interfacetherebetween

ActiveUS20190283859A1Easy to integrateImprove aerodynamic performanceSpars/stringersWing adjustmentsWingtip deviceFixed wing

An aircraft having a wing, including a fixed wing with a wing tip device movably mounted at the outer end thereof is disclosed. The wing tip device is movable between: a flight configuration; and a ground configuration. The wing tip device and the fixed wing are separated along an oblique primary cut plane. The wing tip device and the fixed wing meet along an interfacing cut line. The wing tip device and fixed wing comprise a wing skin with a thickness, and end faces extending across the thickness of the wing skin provide interfacing surfaces corresponding to the interfacing cut line, wherein the interfacing surfaces are angled at a first orientation towards the front of the wing and a second, opposite, orientation towards the rear of the wing.

Owner:AIRBUS OPERATIONS LTD

High durability magnetorheological fluids

InactiveUS8828263B2Reduce frictionReduce wearOther chemical processesMagnetic liquidsOrganic baseMagnetorheological fluid

A magnetorheological fluid comprising a mixture of soft and hard iron particles, an organic based carrier fluid, and optional additives such as anti-friction, anti-wear, or surfactants unexpectedly have improved durability when used in devices for control vibration and / or noise, for example, shock absorbers, elastomeric mounts, dampers, and the like.

Owner:LORD CORP

Sliding element, in particular piston ring, and combination of a sliding element with a mating running element

ActiveUS10131988B2Improve featuresReduction factorPiston ringsBraking action transmissionPiston ringHardness

A sliding element, such as a piston ring, for use in diesel or highly supercharged spark-ignition engines with iron-based mating running elements is provided. The sliding element includes a base material made of cast iron or steel and a coating. The coating includes a CrN layer, an Me(CxNy) layer, and a DLC layer extending from the inside to the outer side respectively. The DLC layer consists of a metal-containing substructure layer and a metal-free DLC top layer. The Me(CxNy) layer is crystalline and Me is tungsten (W), chromium (Cr), or Silicon (Si). The hardness of the metal-free DLC top layer is harder than the metal-containing substructure layer.

Owner:FEDERAL MOGUL BURSCHEID

Creasing Devices

ActiveUS20170190136A1Great freedomWithout risk of damageMechanical working/deformationBookbinding casesPaper sheetCoating

A creasing device is provided that includes a counter-rotating male drum and female drum. The male drum carries a conventional creasing ring with a central rib flanked by shoulders. The female drum comprises a central channel aligned with the creasing rib on the male drum; and a pair of projecting lateral ribs on each side of the central channel that are aligned with the shoulders on the male drum. The lateral ribs press a sheet of the card or paper stock against the shoulders of the creasing ring to better define the edges of the crease and to reduce the tendency of a printed coating on the stock to crack during subsequent folding. The pair of lateral ribs may be provided by a pair of inserts. Alternatively, both ribs and the central channel may be provided by a single insert.

Owner:TECH NI FOLD LTD

Fluid control

ActiveUS8146619B2Weaken energyReduce erosionSoldering apparatusValve members for absorbing fluid energyFluid controlEngineering

Owner:IMI VISION LTD

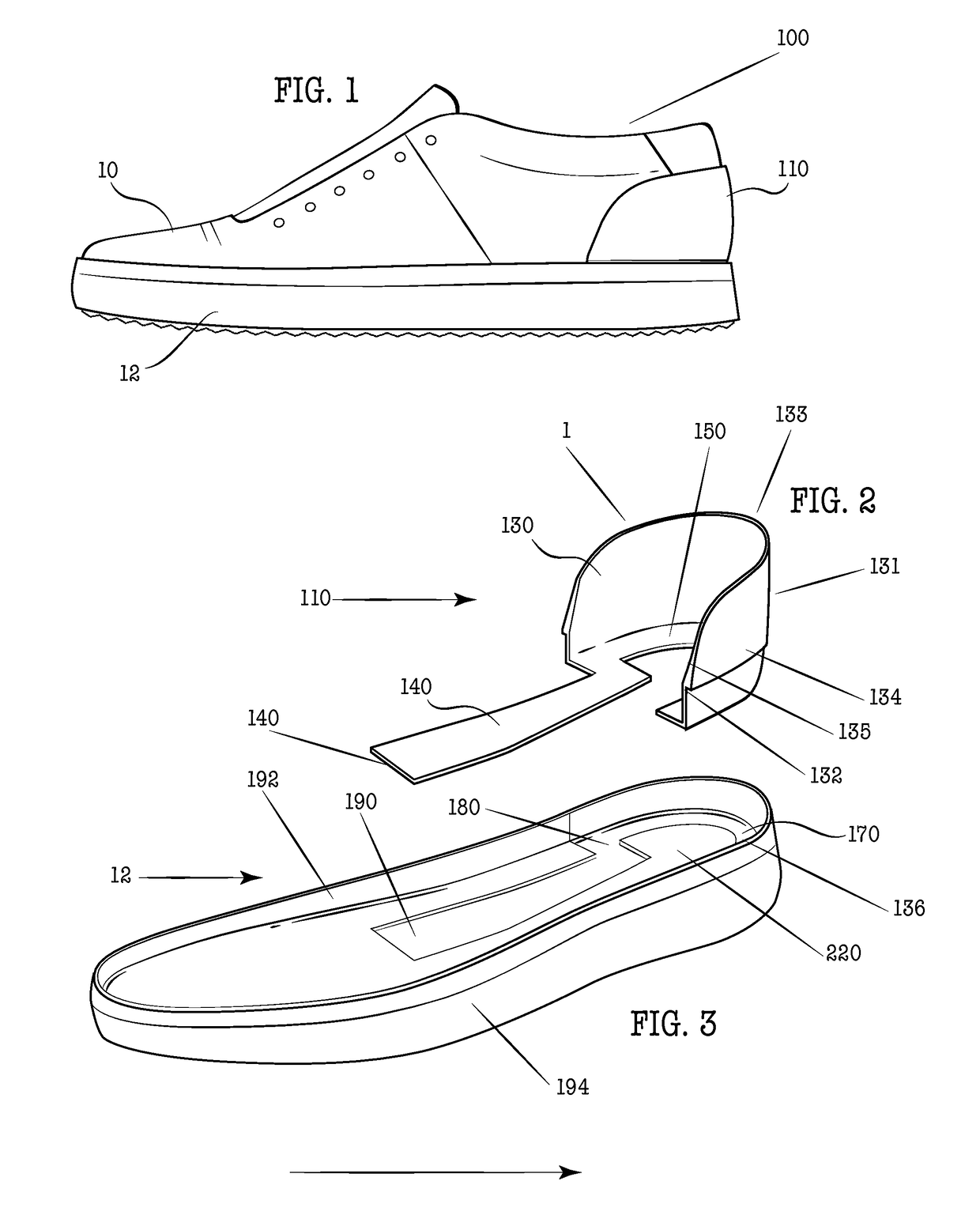

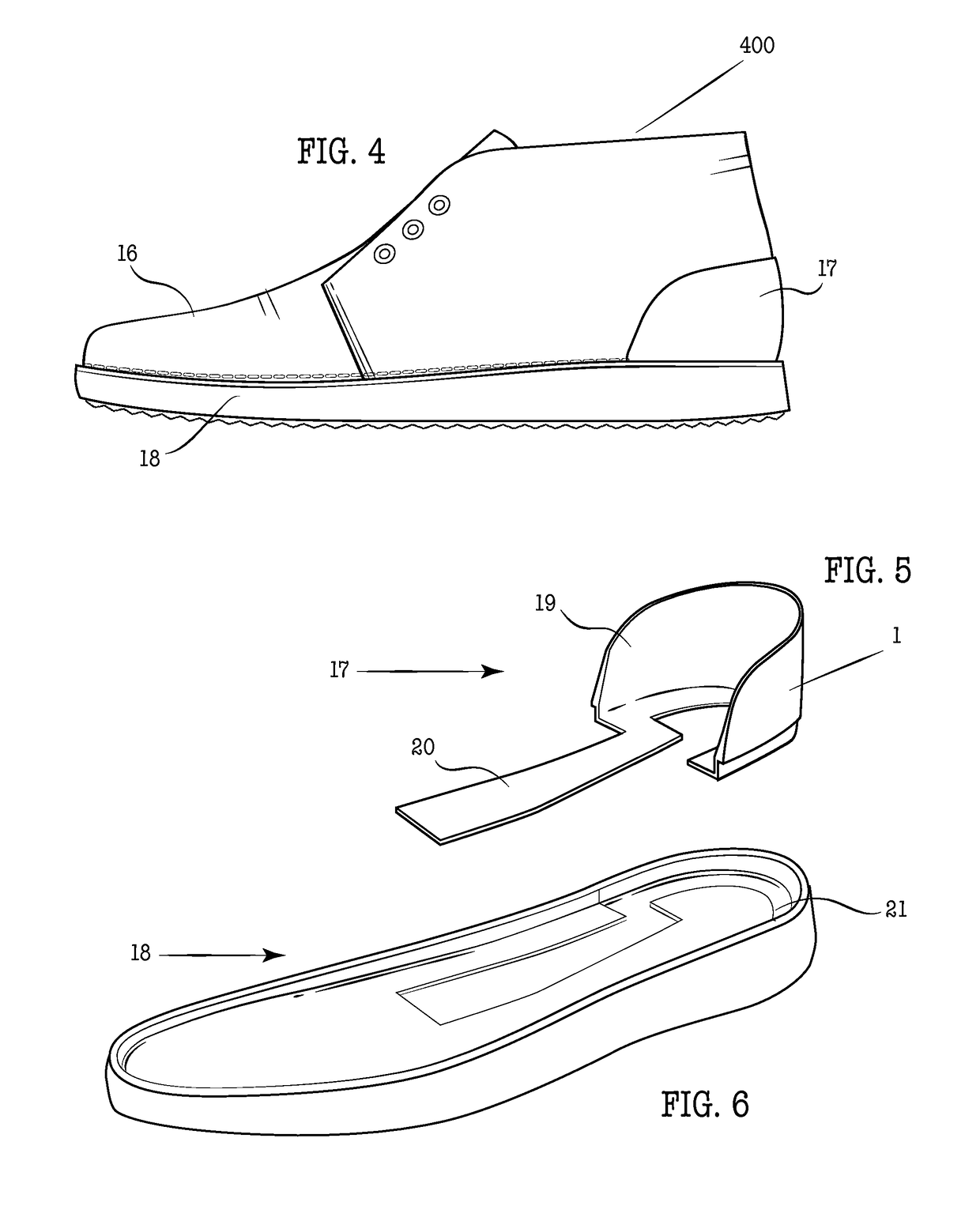

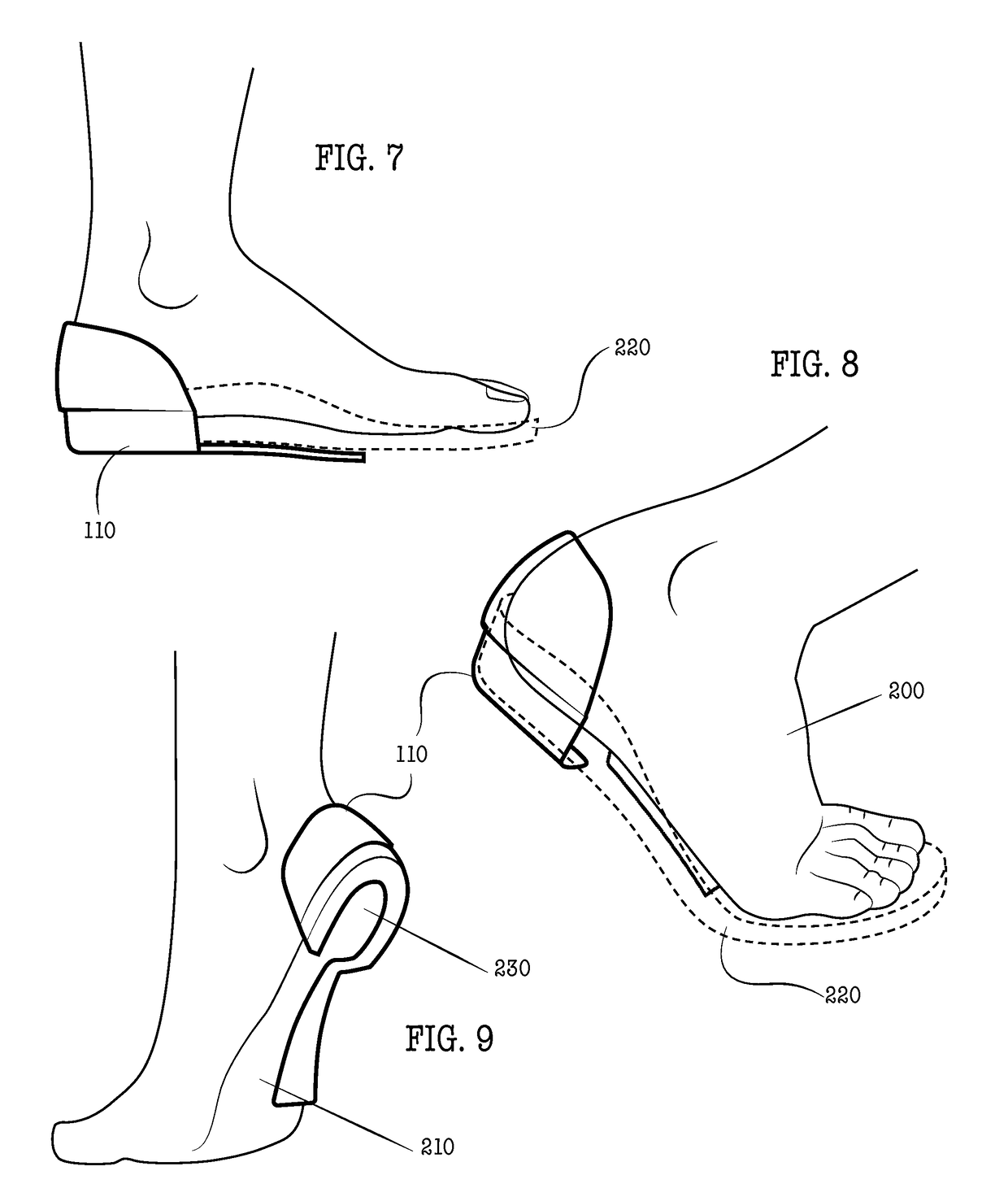

Integrated shoe support structure combining heel counter and shank

Embodiments are described for a semi-rigid apparatus for use in conjunction with the sole and upper of a shoe or sandal. The apparatus involves a heel stabilizer shank enclosing a portion of the heel, with a shank extension from the medial side, a lightweight support structure running along the bottom of the foot between the outsole and insole stiffening the heel and midfoot. Both elements are made from a single piece of material that can be injection molded, 3D printed, or the like. The purpose of this apparatus is to provide all day comfort, protect the heel from lateral shifting, and stiffen the heel and midfoot for less strain on the foot.

Owner:CASCA DESIGNS INC

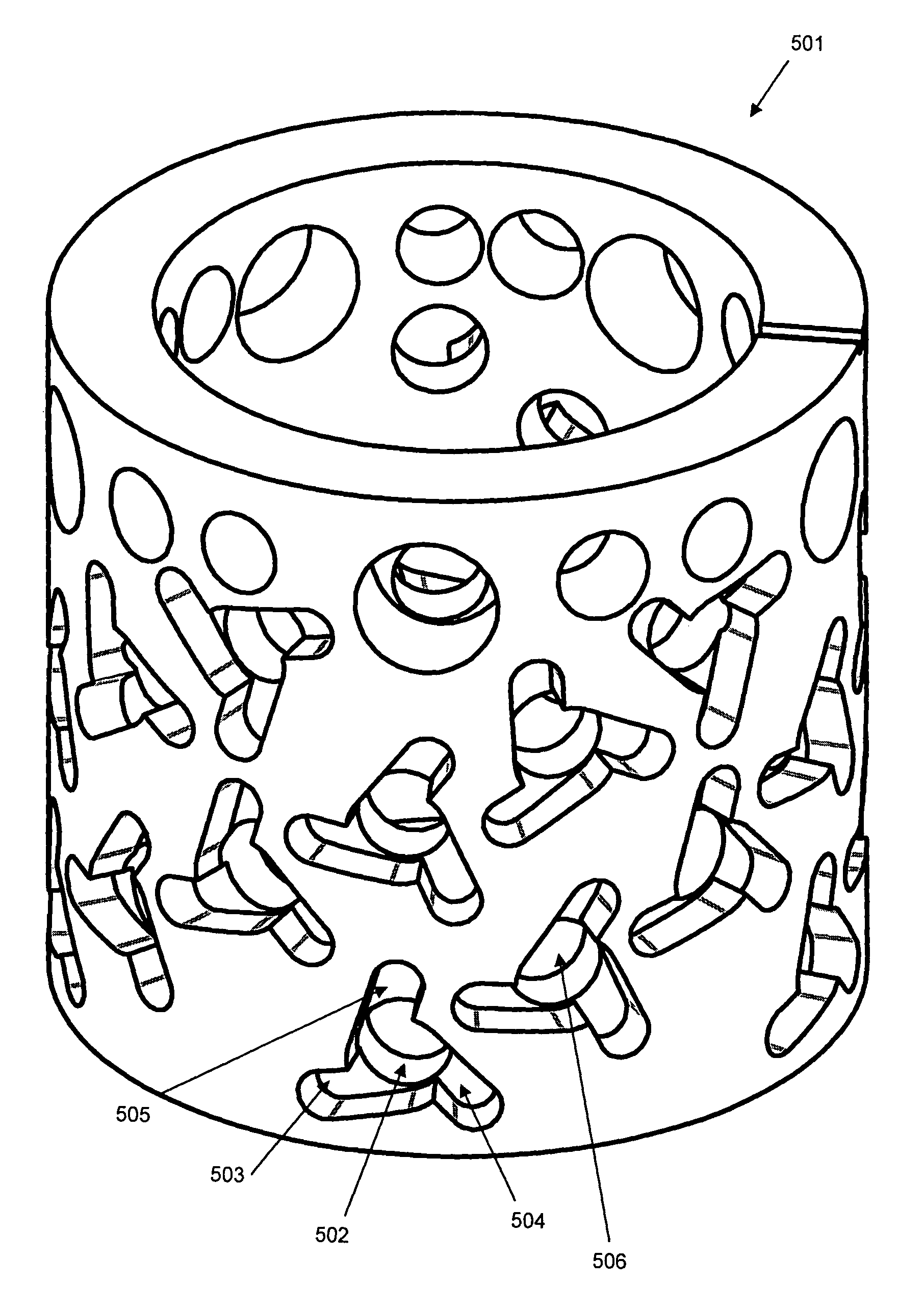

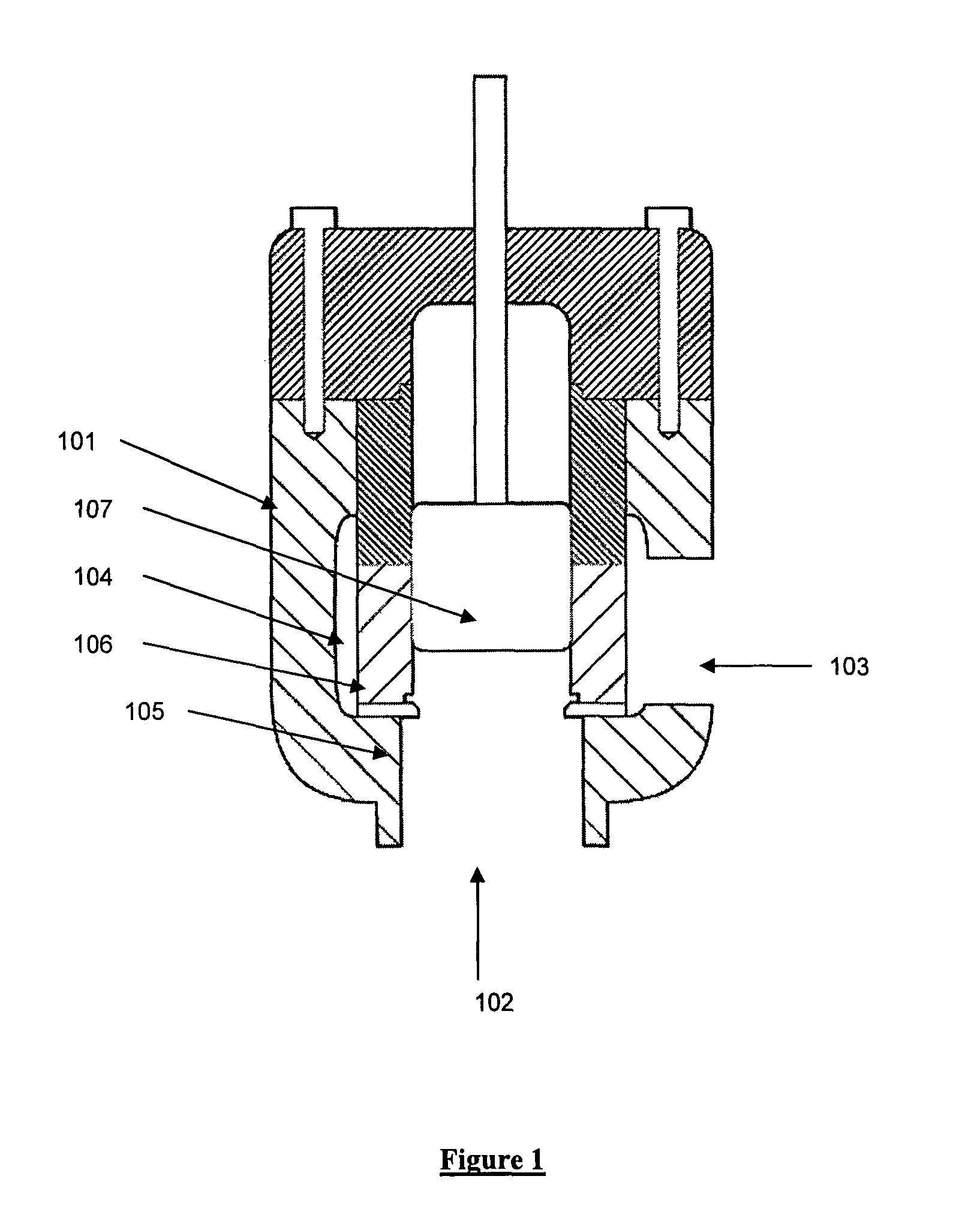

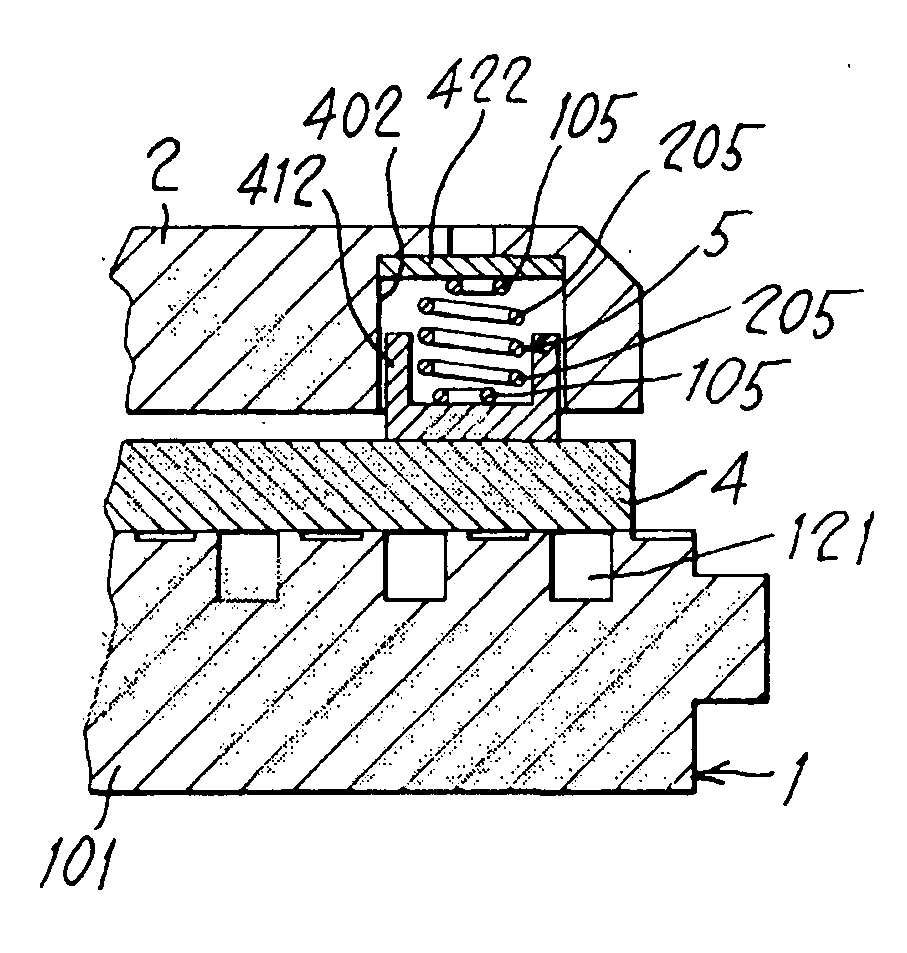

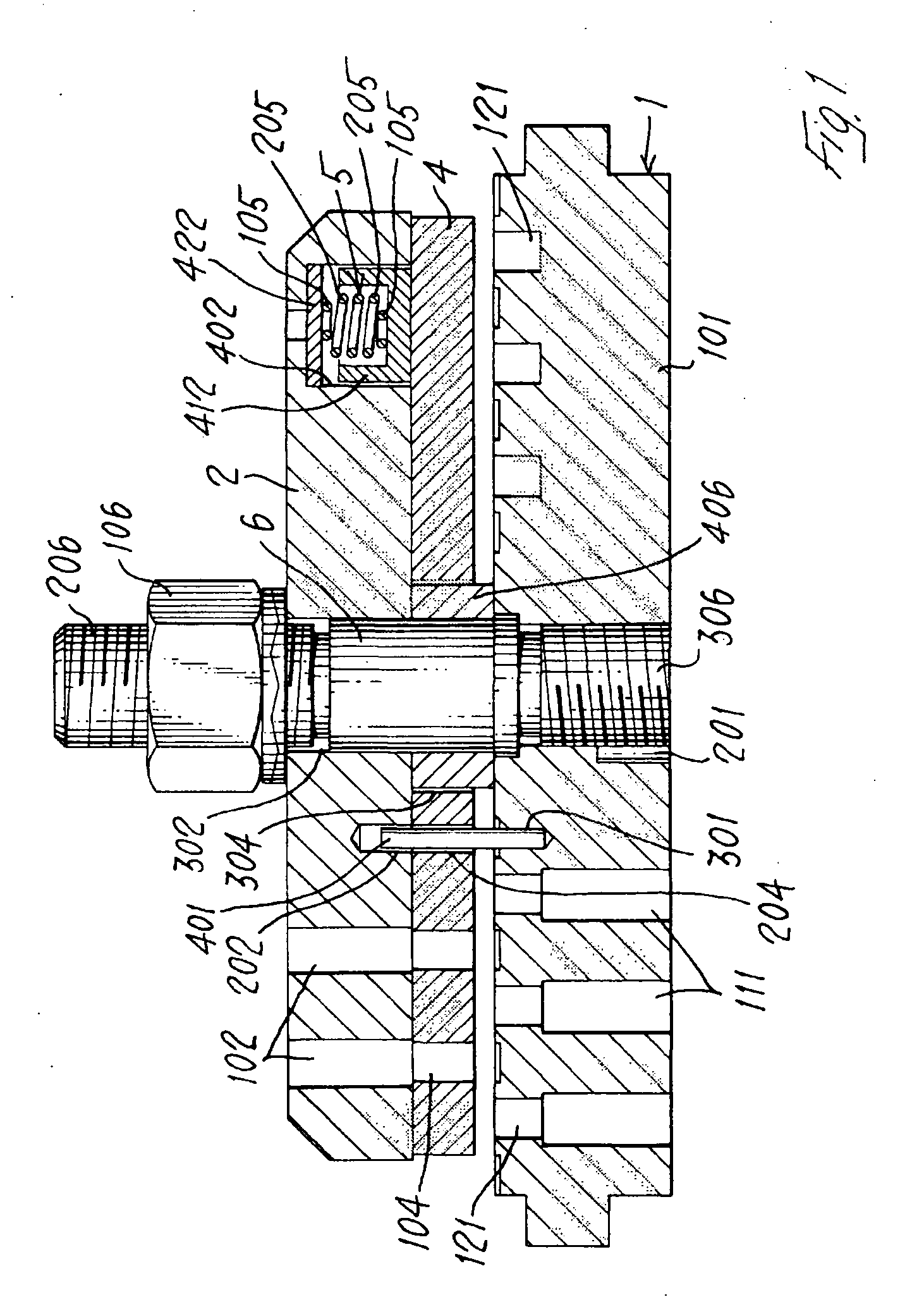

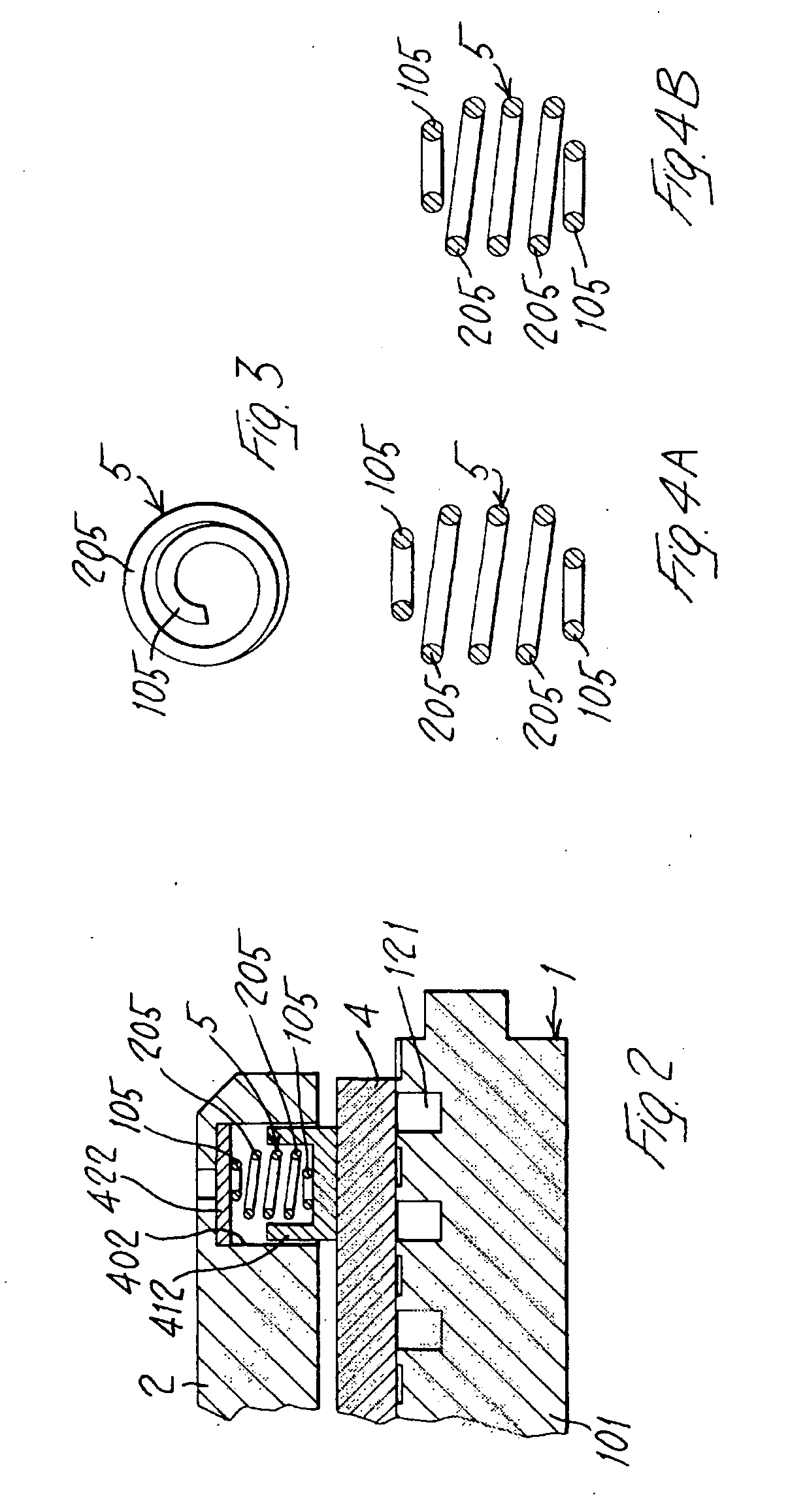

Valve, in particular for compressors

InactiveUS20090126807A1Small dimensionIncreased axial stabilityPositive displacement pump componentsCheck valvesEngineeringMechanical engineering

Valve, in particular for compressors, comprising a seat (1) provided with at least one flow way (111), an obturator member (4) able to obstruct said flow way (111) and movable with respect to said seat in a given direction, and means (5) for resiliently stressing said obturator (4), which are able to force said obturator (4) into a given position and are active in the direction of movement thereof; said resilient stressing means (5) comprise at least one cylindrical helical compression spring (5), characterized by the presence, between all the turns and along the entire working length of the spring (5), of inter-turn apertures.

Owner:DOTT ING MARIO COZZANI S R I

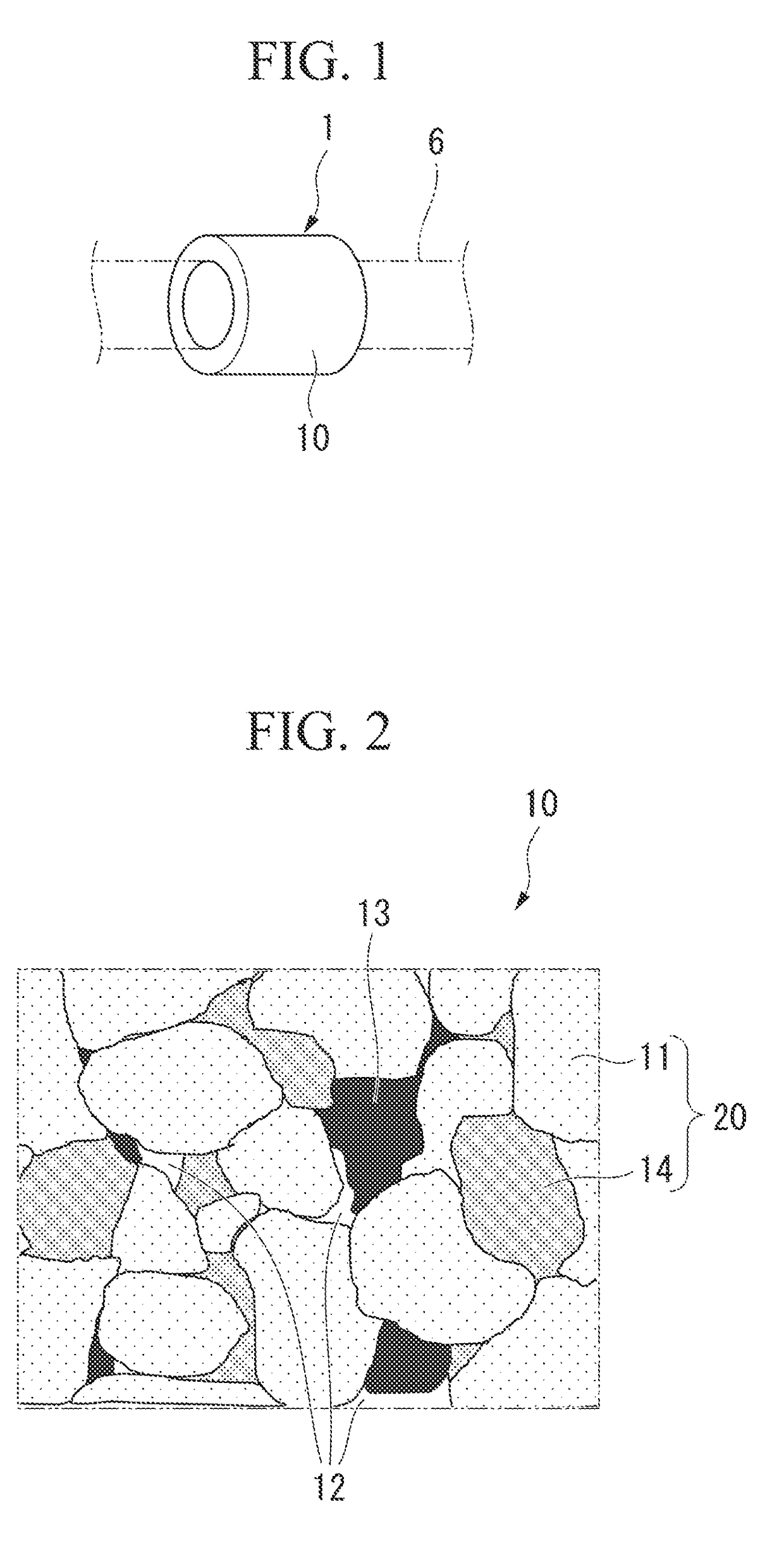

Cu-BASED SINTERED SLIDING MATERIAL, AND PRODUCTION METHOD THEREFOR

The Cu-based sintered sliding material has a composition including, by mass %, 7% to 35% of Ni, 1% to 10% of Sn, 0.9% to 3% of P, and 0.5% to 5% of C, with a remainder of Cu and inevitable impurities, wherein the Cu-based sintered sliding material includes a sintered body including: alloy grains that contain Sn and C and contain a Cu-Ni-based alloy as a main component; grain boundary phases that contain Ni and P as main components and are dispersedly distributed in grain boundaries of the alloy grains; and free graphite that intervenes at the grain boundaries of the alloy grains, the Cu-based sintered sliding material has a structure in which pores are dispersedly formed in the grain boundaries of the alloy grains, and an amount of C in a metal matrix including the alloy grains and the grain boundary phases is, by mass %, 0.02% to 0.20%.

Owner:DIAMET CORP

Composite material for low-wear mechanical components for force and motion transmission

PendingUS20210198454A1Easy to wearImprove wear characteristicsDialysis systemsRotary piston pumpsThermal dilatationMotion transfer

The invention relates to a composite material consisting of at least three constituents, a substrate material, a first fibrous reinforcing material and a second reinforcing material, wherein the first fibrous reinforcing material has a lower thermal expansion coefficient than the second reinforcing material and wherein the second reinforcing material has a lower electrical conductivity than the first reinforcing material, wherein the composite material is provided for use in building components of force and motion transmission, in particular those building components of force and motion transmission which come into contact with ultrapure water.

Owner:FRESENIUS MEDICAL CARE DEUTSCHLAND GMBH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com