Polyethylene backboard training device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

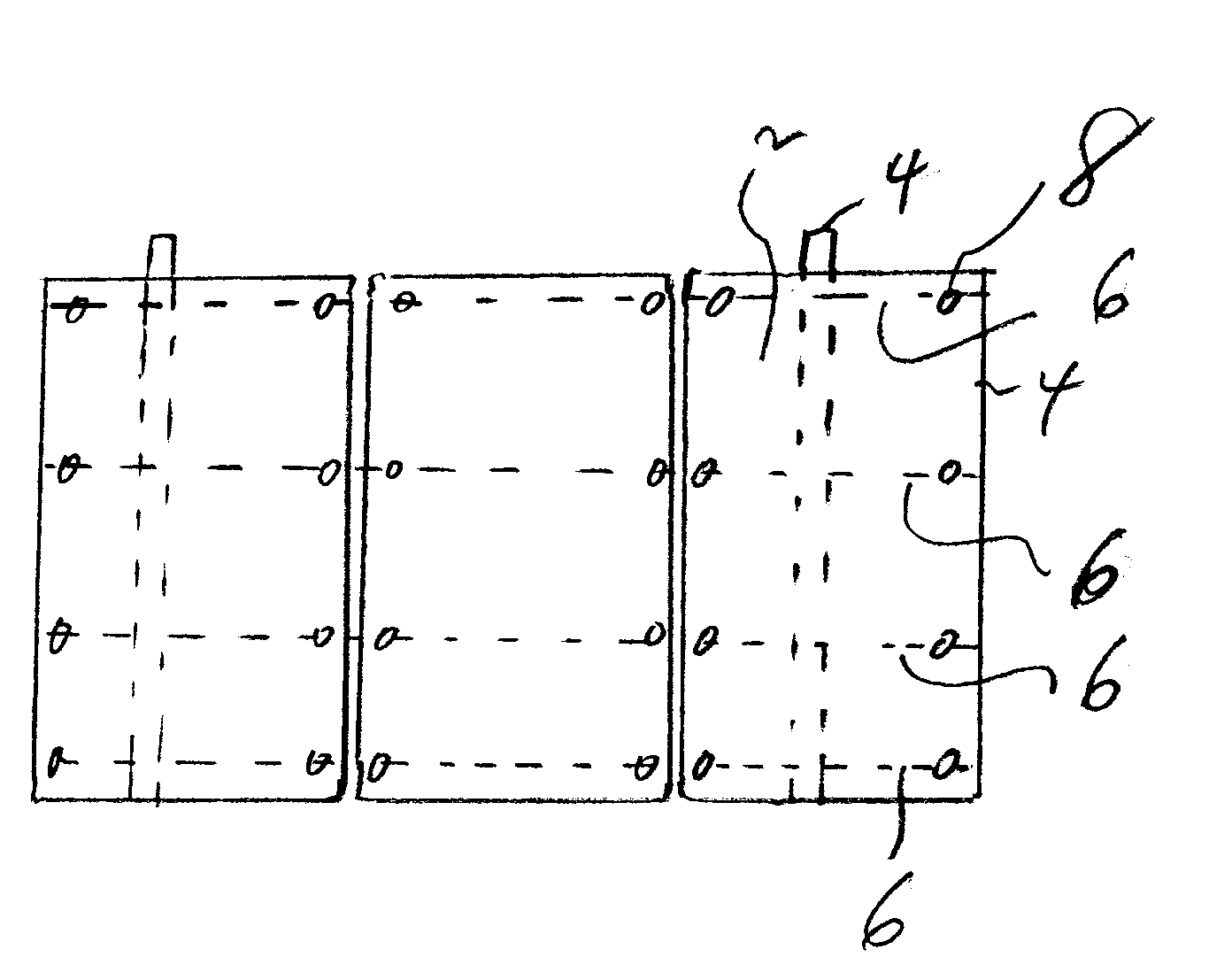

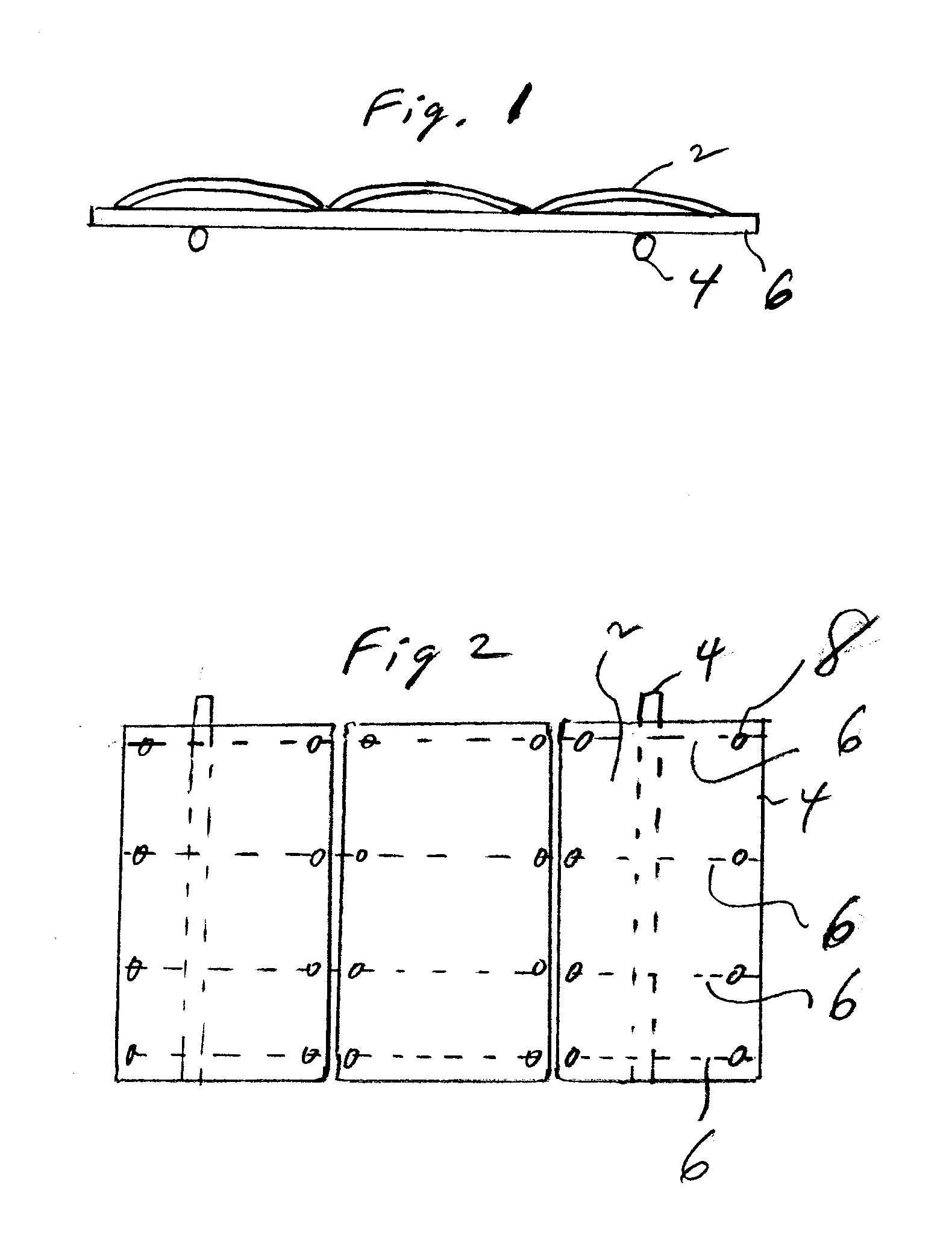

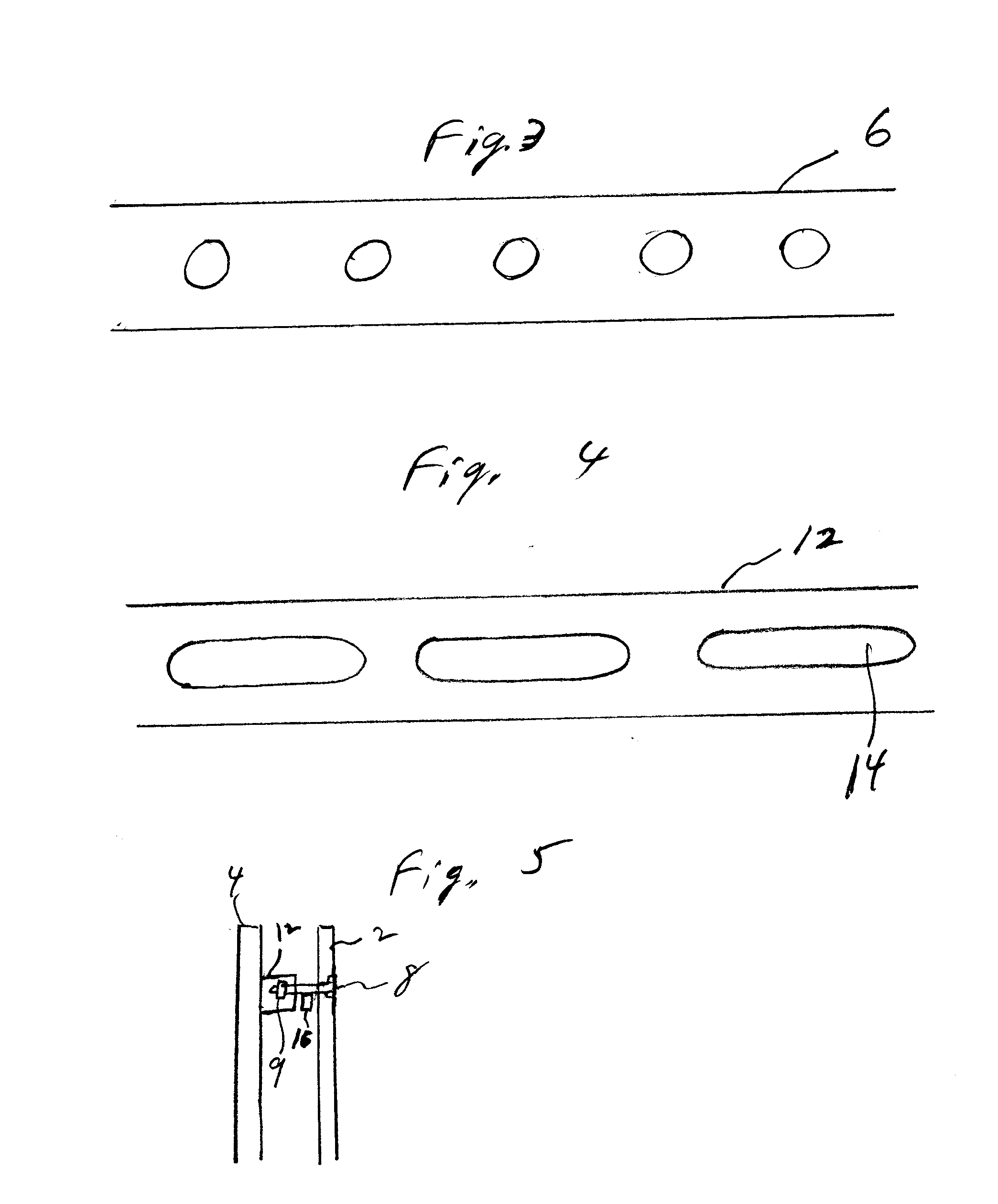

[0037]The invention will now be explained with reference to the attached Figs., without being limited thereto. The backboard training device comprises at least two HDPE panels mounted to a rigid support by a movable mount. The HDPE panels are highly flexible, resist puncture, cracking and weathering. However, the HDPE panels have a high coefficient of expansion, which results in severe buckling of the panels if they are not movably mounted to the rigid support. The HDPE panels have a high coefficient of expansion, for example greater than 0.00005 in / in ° F. The HDPE panels are usually about 4 feet by 8 feet or 4 feet by 10 feet, but can be sized as desired. The panels are usually at least about 0.5 inches in thickness to provide sufficient rigidity to avoid deforming during use, but can be any thickness as desired. Usually, the multiple panels are aligned in a horizontal direction with the length facing upward, as shown in the accompanying Figs. The movable mount is constructed and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com