Flexible material flooring miter device and system for flexible material flooring installation

a technology of flexible flooring and miter devices, which is applied in the field of flexible flooring installation, can solve the problems of failing to provide an improved system and method for installing flash coving and creating precision flash coving seams, and failing to aid installers in creating miter joints of flash coving at the intersection of walls, so as to reduce the likelihood of user injury, prevent utility knife slippage, and accurate cut of flexible flooring

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

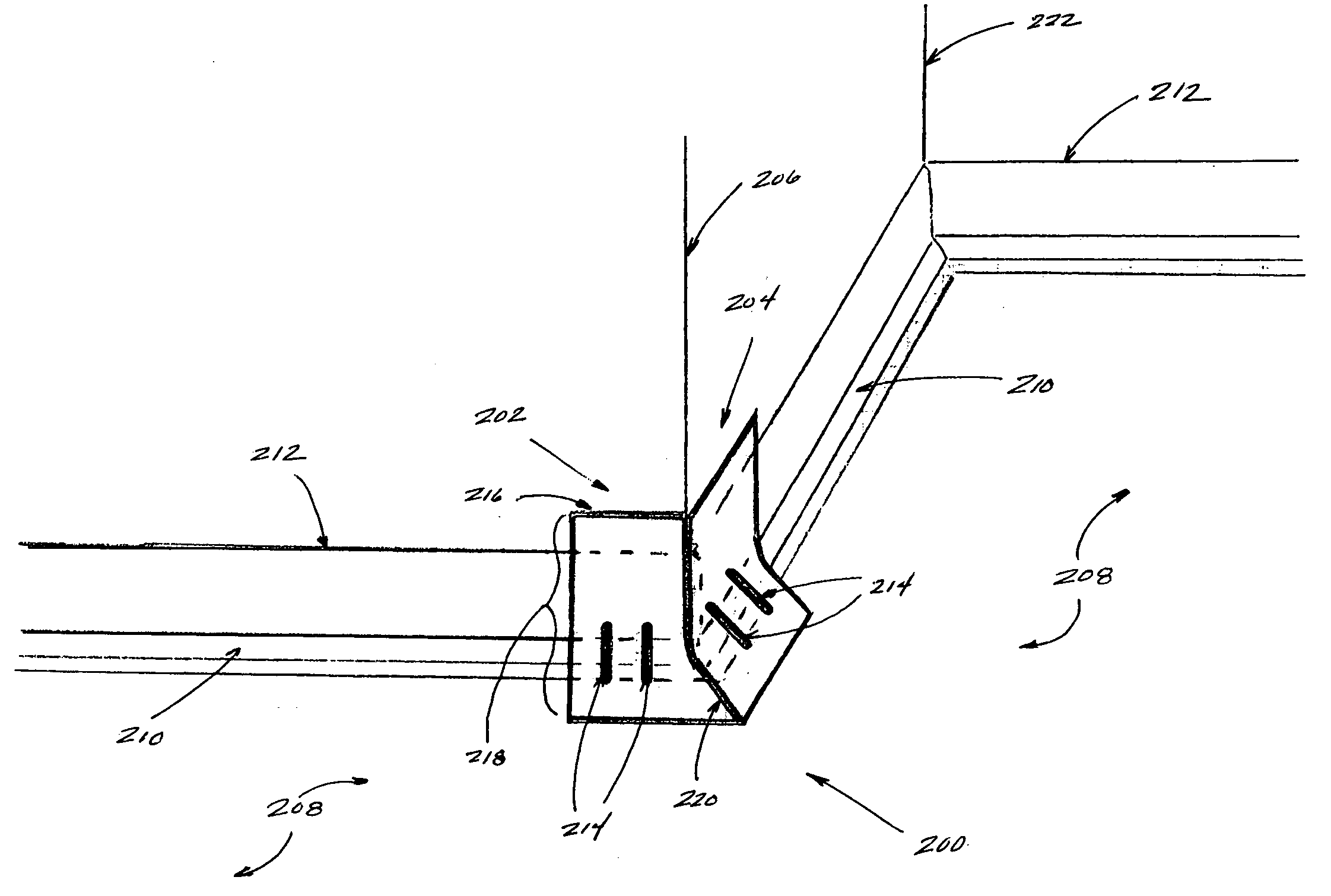

[0055]A detailed illustrative embodiment of the present invention is disclosed herein. However, techniques, systems and operating structures in accordance with the present invention may be embodied in a wide variety of forms and modes, some of which may be quite different from those in the disclosed embodiment. Consequently, the specific structural and functional details disclosed herein are merely representative, yet in that regard, they are deemed to afford the best embodiment for purposes of disclosure and to provide a basis for the claims herein which define the scope of the present invention. The following presents a detailed description of a preferred embodiment (as well as some alternative embodiments) of the present invention.

[0056]Moreover, well known methods, procedures, and substances for both carrying out the objectives of the present invention and illustrating the preferred embodiment are incorporated herein but have not been described in detail as not to unnecessarily ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com