Stents with polymer-free coatings for delivering a therapeutic agent

a technology of stents and coatings, applied in the field of stents with polymer-free coatings for delivering a therapeutic agent, can solve the problems of coatings containing a coatings containing such a type of therapeutic agent without a polymer being generally ineffective in delivering the therapeutic agent, and presenting certain other limitations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

5.1 The Medical Device

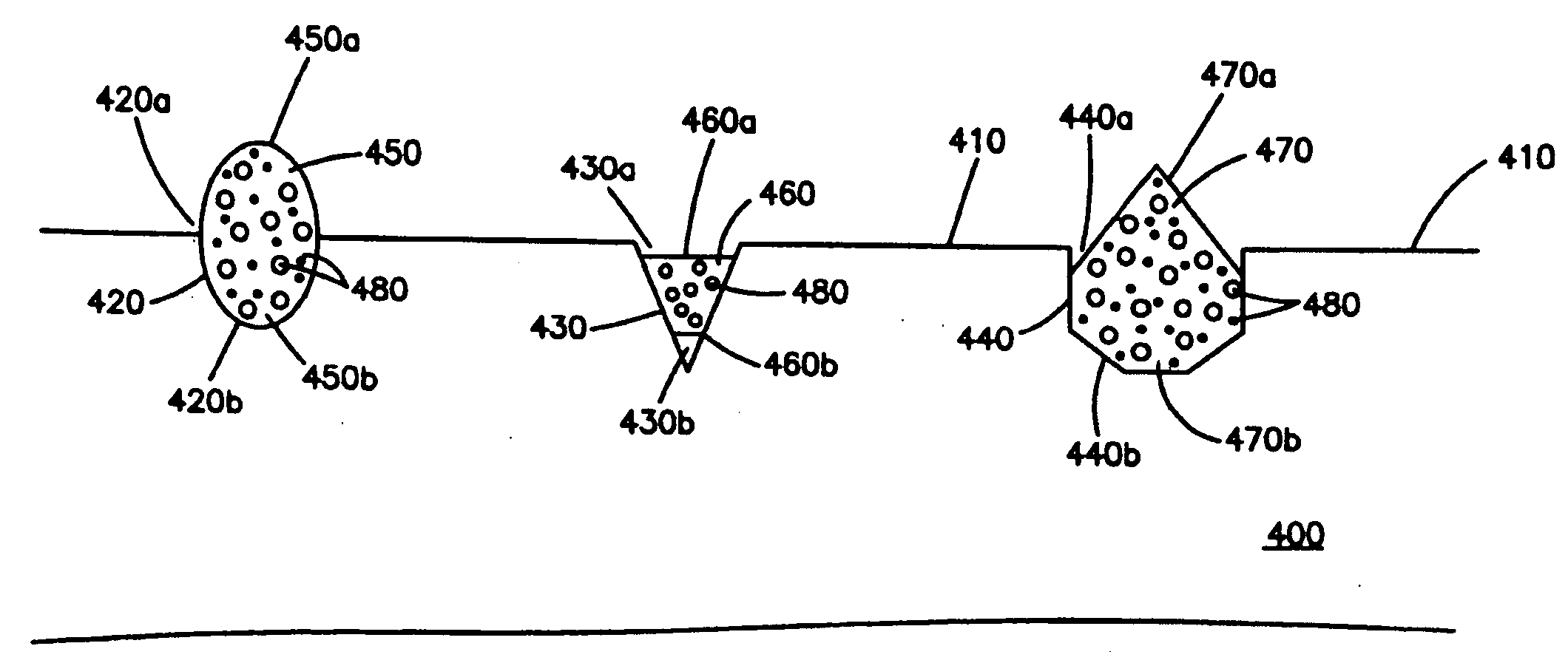

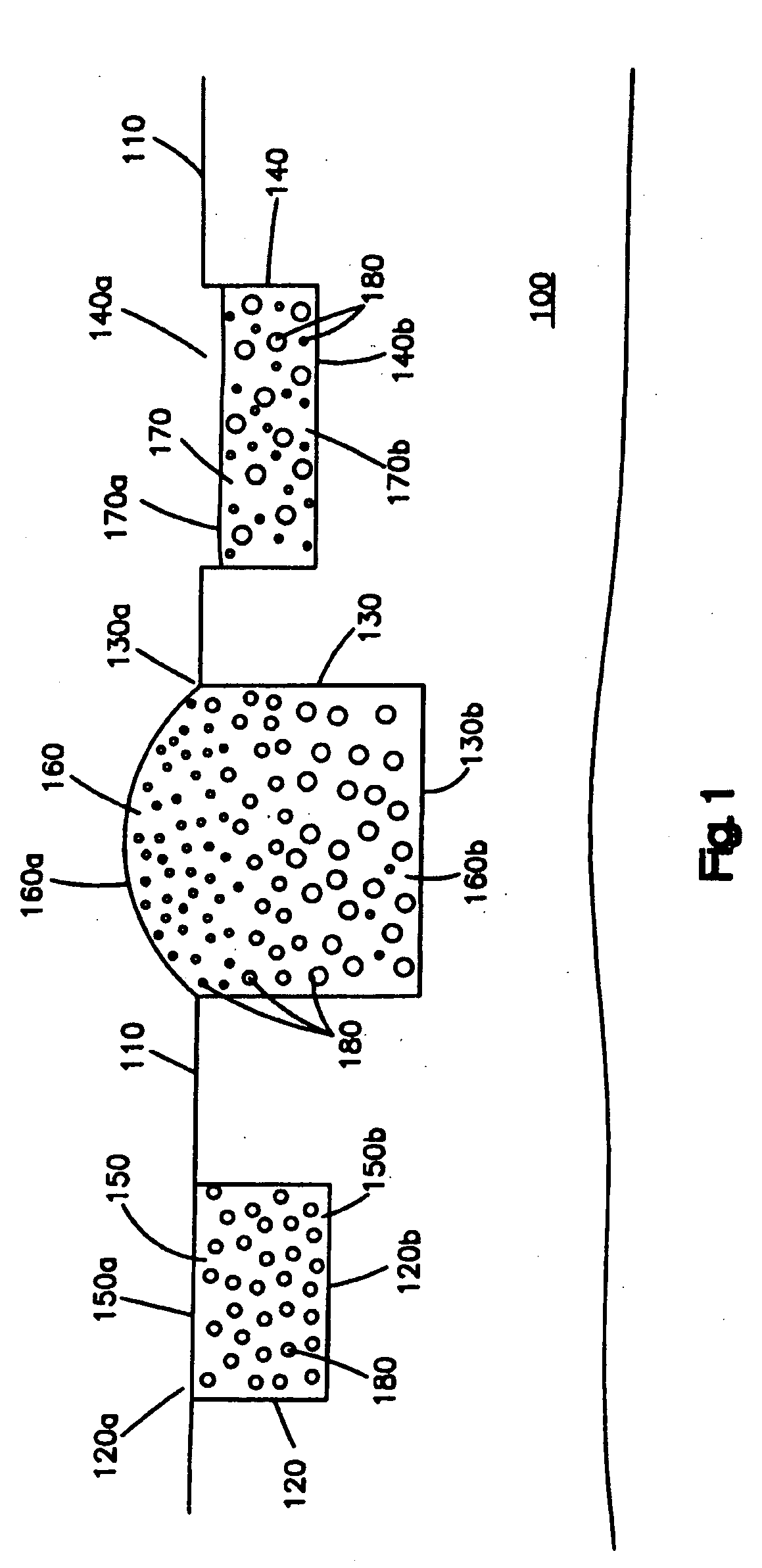

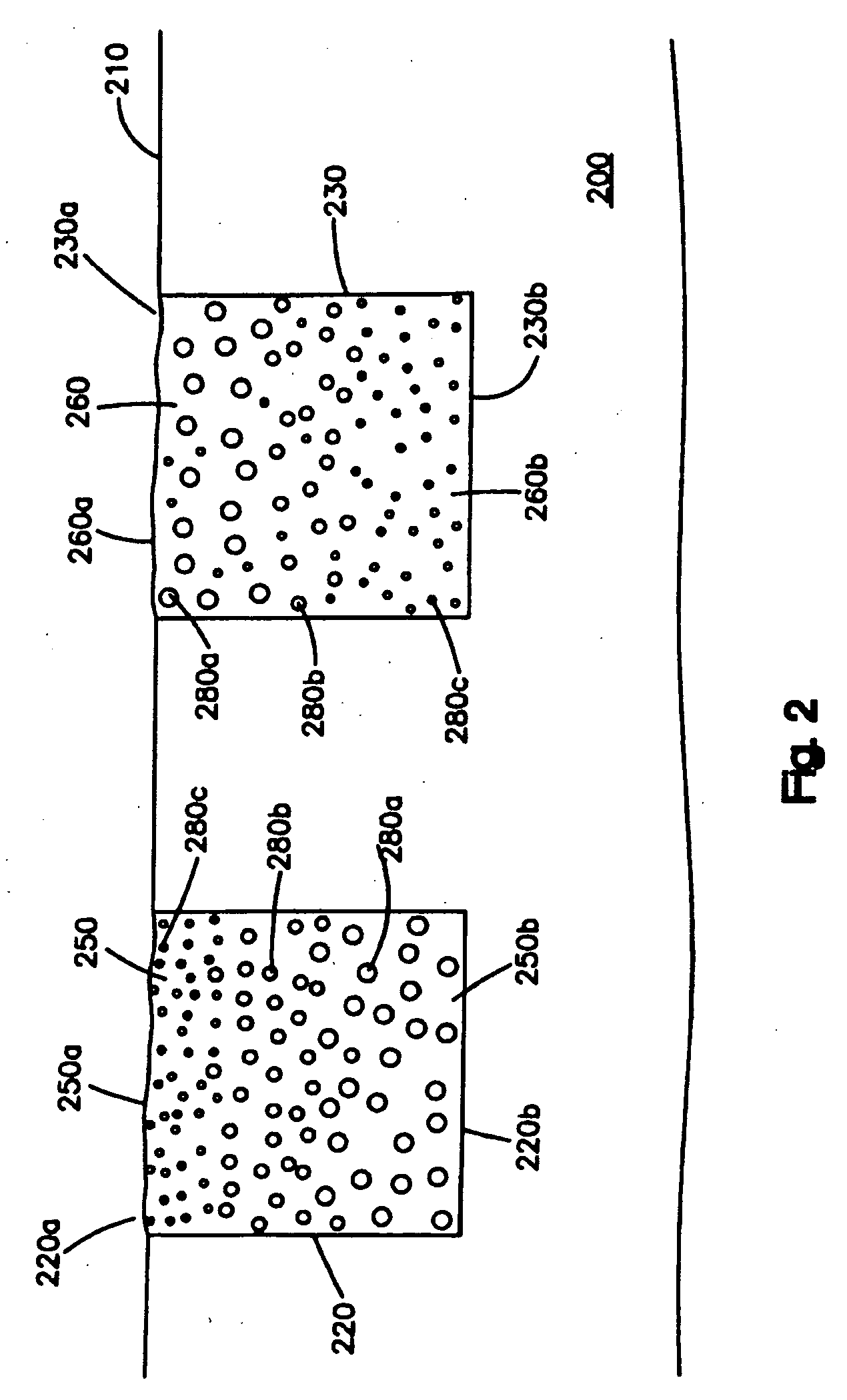

[0027]The medical devices described herein generally include a substrate having at least one surface. For instance, in the case where the medical device is an intravascular stent, the substrate is the stent sidewall structure and the surface is the abluminal surface of the stent. A cavity is disposed in the substrate and a pellet comprising a non-polymeric material having a plurality of pores therein is disposed in the cavity. A therapeutic agent is disposed in at least some of the pores for delivery to a patient.

[0028]FIG. 1 shows one embodiment of the medical device, which can be a stent. The medical device comprises a substrate 100 having a surface 110. In this embodiment, the surface 110 is free of any coating, i.e., is not covered by a coating. In other embodiments, a coating may be disposed on at least a portion of the surface 110. As shown in the figure, there are three cavities 120, 130 and 140 disposed in the substrate 100. Each cavity comprises two op...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com