Static electricity and dust removing apparatus

a technology of static electricity and dust removal apparatus, which is applied in the direction of carpet cleaners, cleaning machines, cleaning equipments, etc., can solve the problems of reducing the ion concentration of ions in the work environment, the inability to keep the dust removal dust-free, and so as to improve the quality of the processing of the matter to be processed and prevent the contamination of the work environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

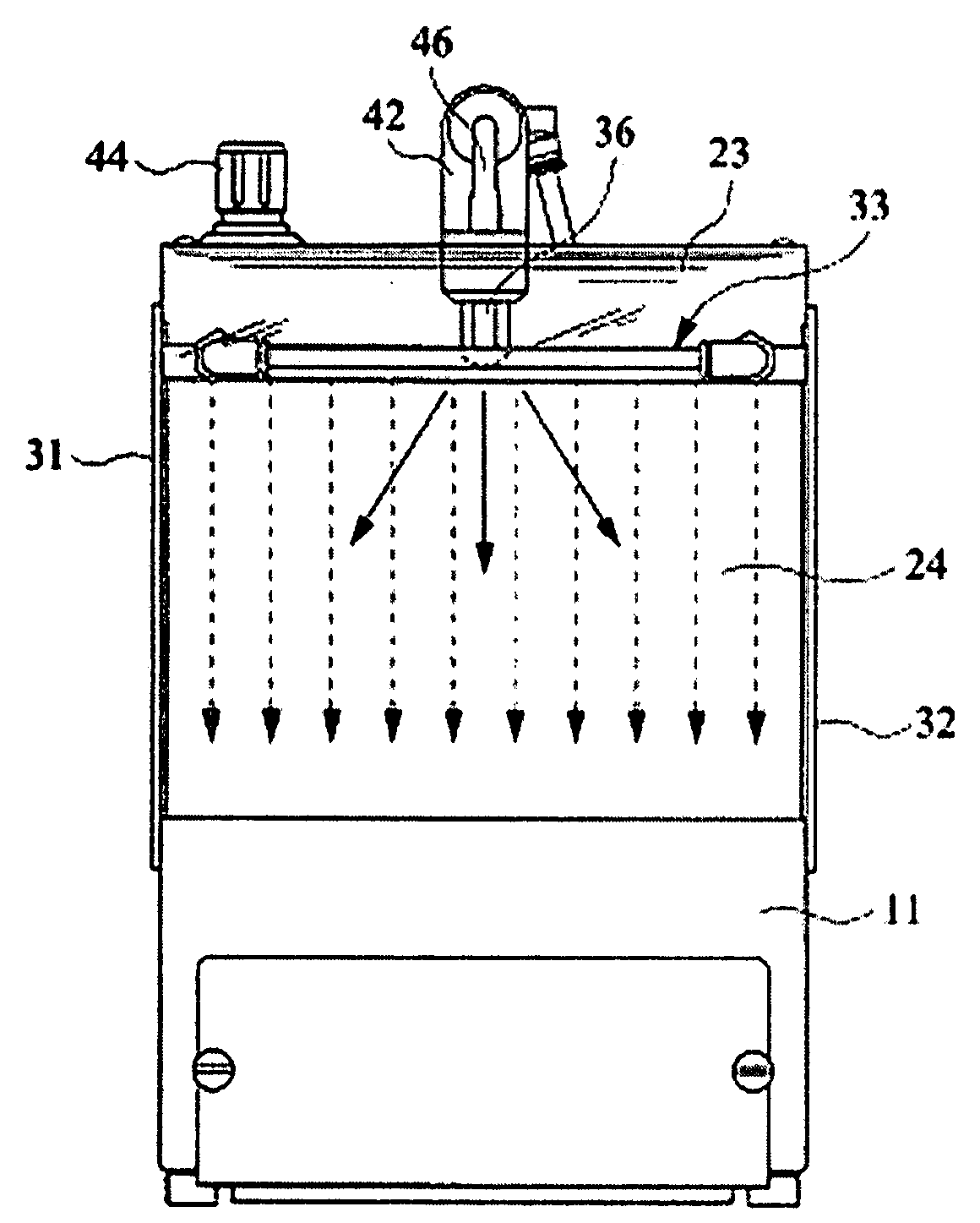

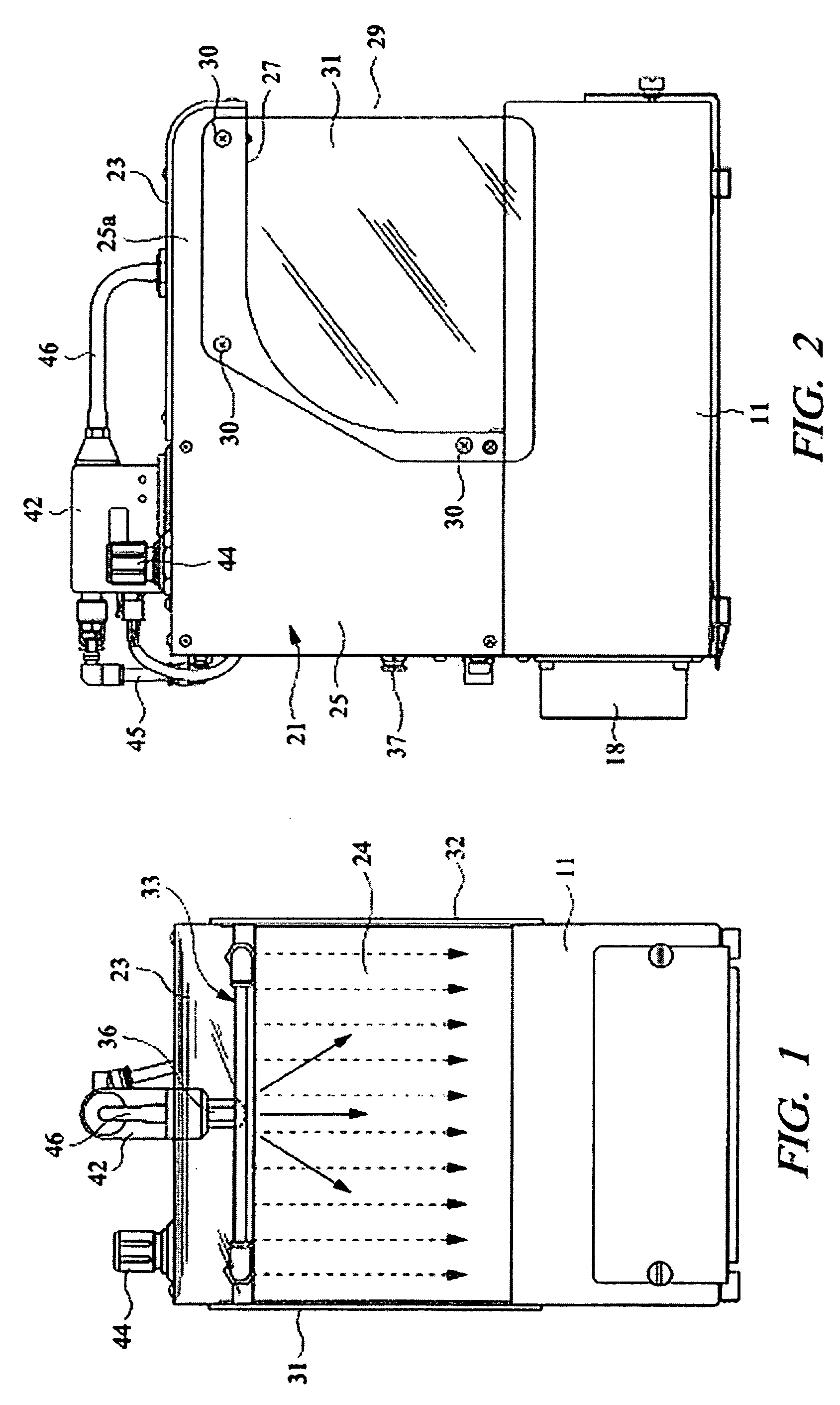

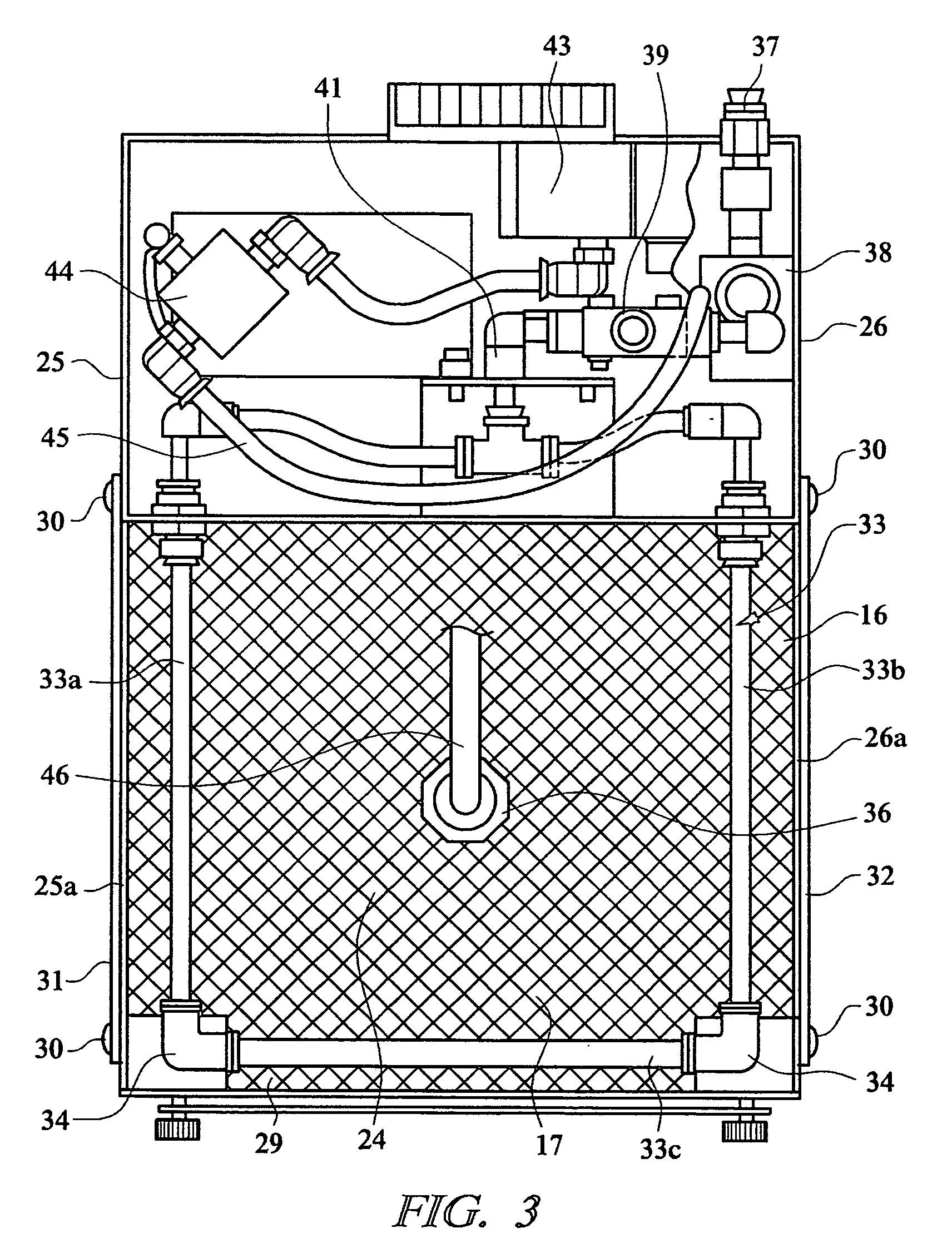

[0031]An embodiment of the present invention will be detailed below based on the drawings. This static electricity and dust removing apparatus has a base box 11 formed by combining plate materials. As shown in FIG. 4, in this base box 11, there is incorporated a blower, that is, an air blower 15 which has a motor 12, a fan 13 driven for rotation by the motor, and a case 14 accommodating these components. Inside the base box, a space for forming a flow of air, that is, an airflow path is formed. On a front end side of the base box 11, an airflow inlet port 16 is formed so that air vertically flows into the base box. An expanded metal 17 having many vents is attached to the airflow inlet port 16, whereby matters to be processed are prevented from entering from the airflow inlet port 16 into the base box 11. When the air blower 15 is driven, as shown by arrows in FIG. 4, air flows into the base box 11 from many vents of the expanded metal 17 provided to the airflow inlet port 16 and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com