Offset multiaxial or polyaxial screw, system and assembly

a multi-axial or poly-axial screw technology, applied in the field of screw, can solve the problem of difficult to get a “favorable angle” of the retainer relative to the screw head, and achieve the effect of extending the range of motion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

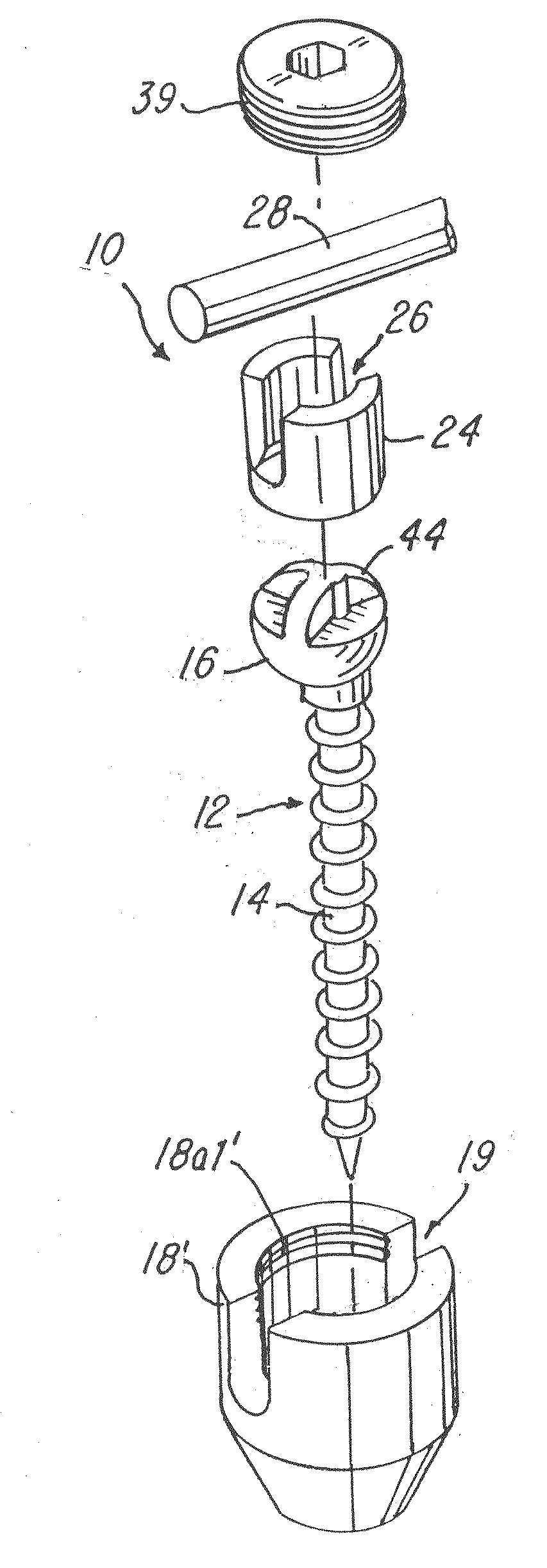

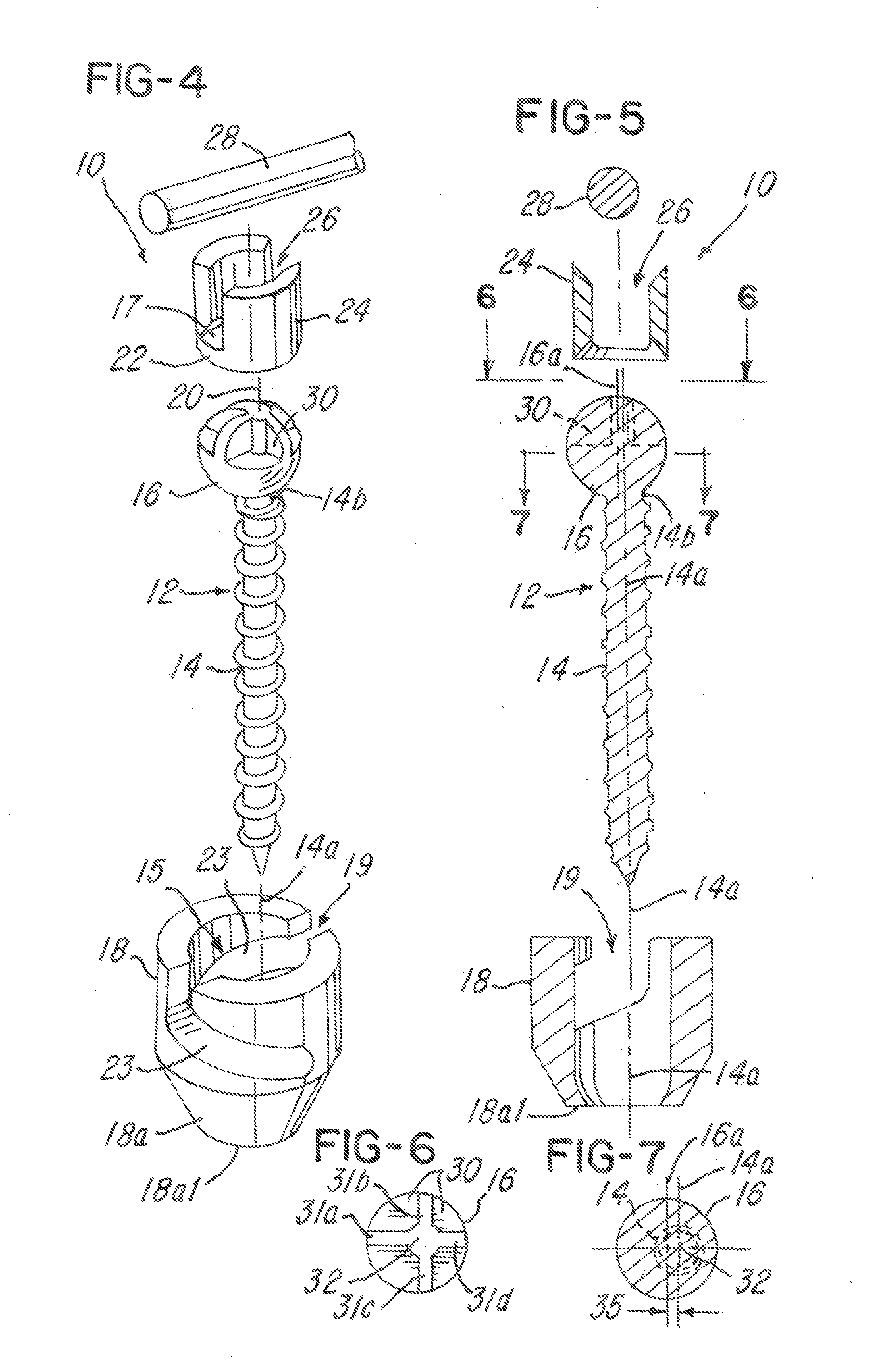

[0061]Referring now to the drawings in detail, wherein identical numerals indicate the same elements throughout the figures, FIGS. 4-35B depict various embodiments of a multi-axial screw and spinal fixation assembly 10. Spinal fixation assembly 10 includes a screw 12 having a threaded portion 14 and a screw head 16 that preferably has a rounded, arcuate, spherical or curved profile. Spinal fixation assembly 10 further includes a retainer 18, which preferably has a generally cylindrical configuration. In these illustrative embodiments, the retainer 18 is capless, but the retainer 18 could be non-capless, such as is illustrated in FIGS. 36 and 37 below. Although not shown, it will be appreciated that retainer 18 includes an aperture or bore 15 therethrough along a centerline axis 20 (FIG. 4). Accordingly, the bore 15 that receives a threaded portion 14 of the screw 12 until screw head 16 thereof is received adjacent a first end 18a of retainer 18. It will be understood that screw head...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com