Cross-linked polyolefin material blend molded electrical transmission insulating products

a technology of cross-linked polyolefin and electrical transmission, which is applied in the field of polymer material blends, can solve the problems of typical hdpe material temperature limitation at/below 120° c, and achieve the effect of not weakening or losing structure and performan

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

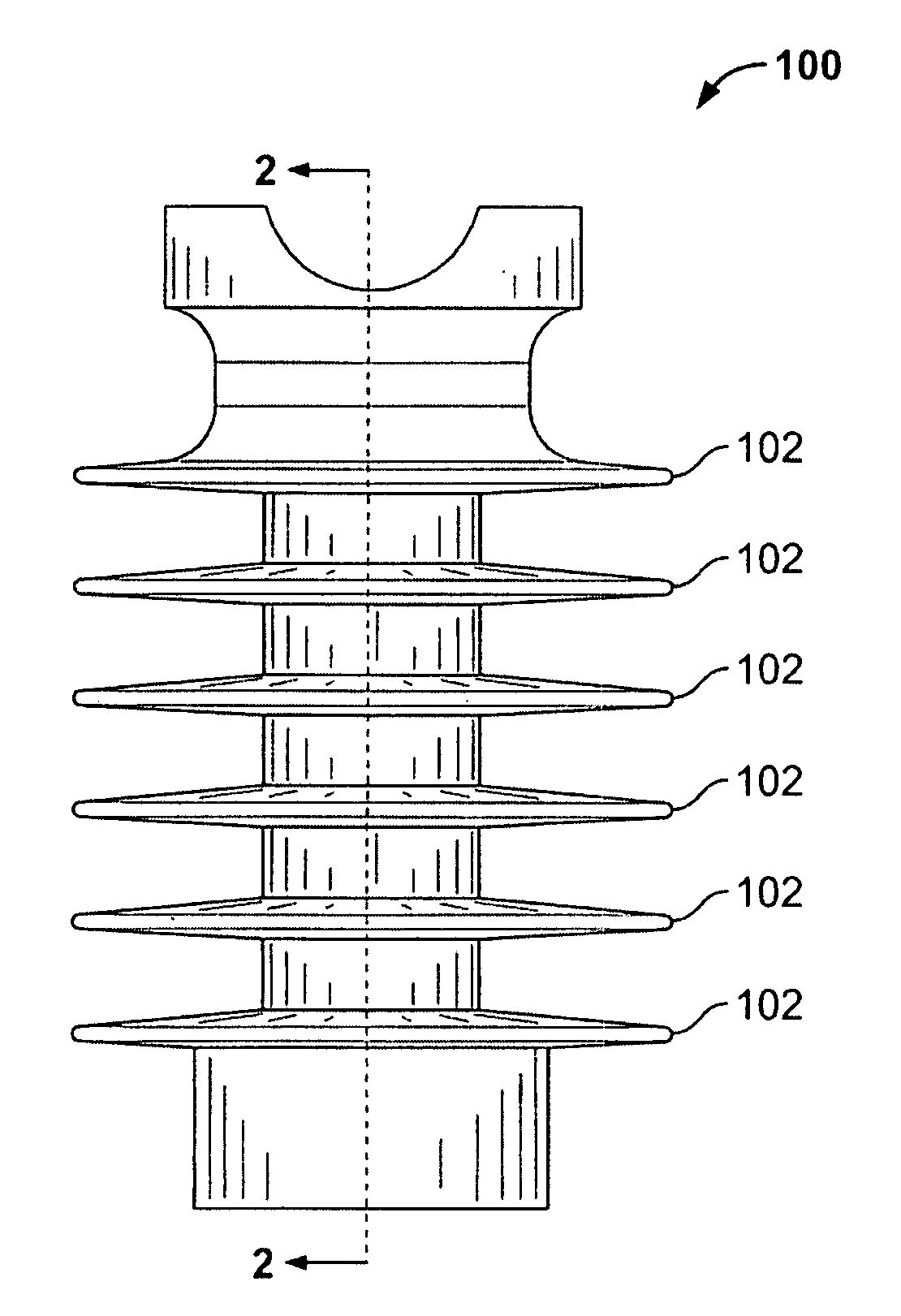

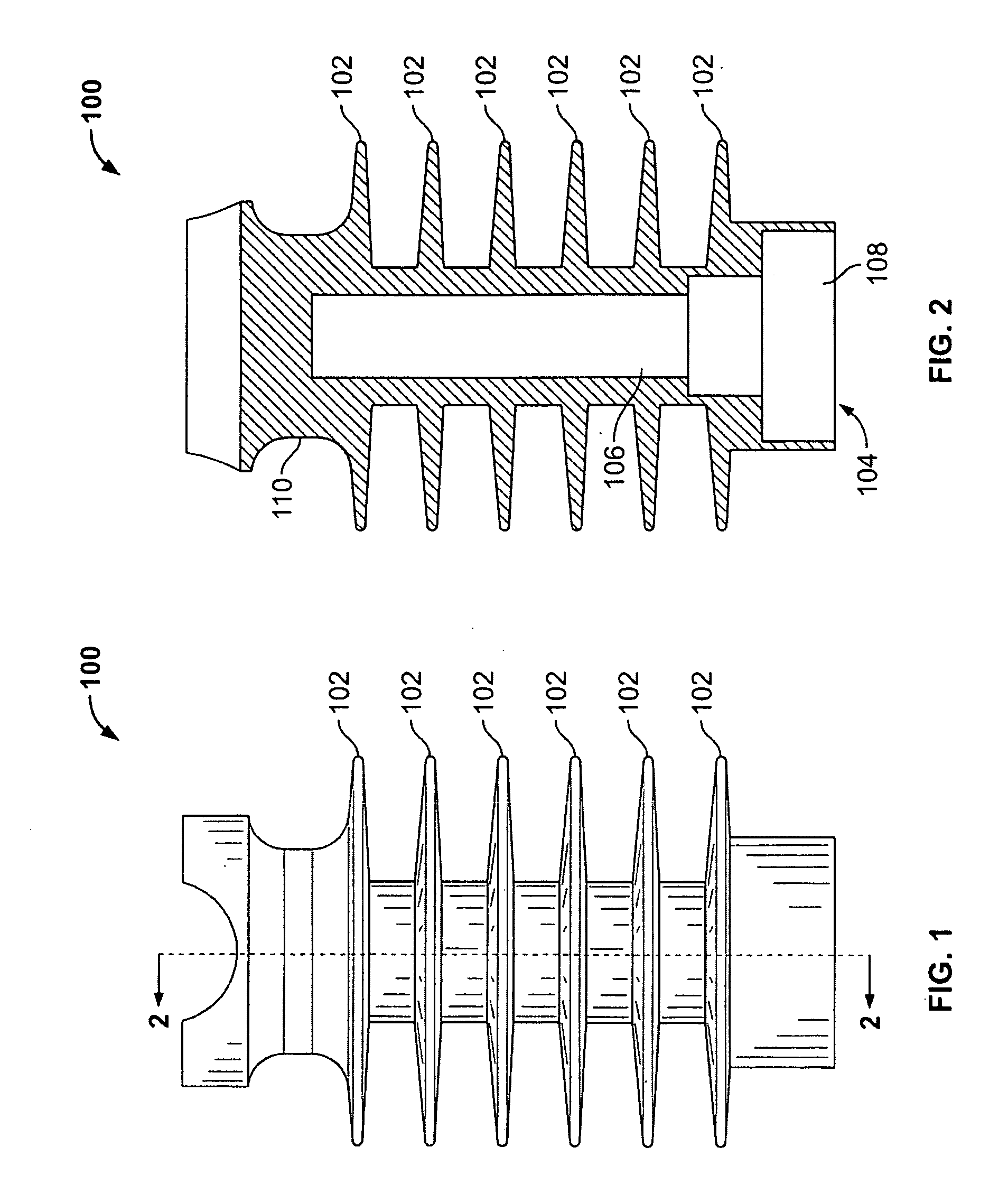

Image

Examples

Embodiment Construction

[0011]As will be further described herein, formulations of the current polymer material blends are generally comprised of four components:

[0012]1) Low density cross-linkable base resin;

[0013]2) High density resin;

[0014]3) Catalyst masterbatch; and

[0015]4) Color masterbatch.

[0016]In at least one preferred embodiment, a formulation for a polymer material blend includes at least one low density cross-linkable polymer base resin present in an amount at about 53% by weight of the total compound, at least one high density polymer resin present in an amount at about 37% by weight of the total compound, catalyst masterbatch present in an amount at about 5% by weight of the total compound, and color masterbatch present in an amount at about 5% by weight of the total compound.

[0017]The weight percentages of each component of the total compound can be varied by plus or minus 10% of the preferred weight percentage for each component. Accordingly, the at least one low density cross-linkable poly...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| temperatures | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com