Thermal converter devices, systems and control methods

a technology of thermal converters and converters, applied in the direction of engines, mechanical equipment, machines/engines, etc., can solve the problems that diesel engines cannot use catalytic converters to eliminate some or all, and the current technology does not efficiently and accurately address the problems associated with diesel engine emissions, so as to reduce nitric oxide in the exhaust, efficiently reduce and/or eliminate harmful pollutants, the effect of efficient and accurate address

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

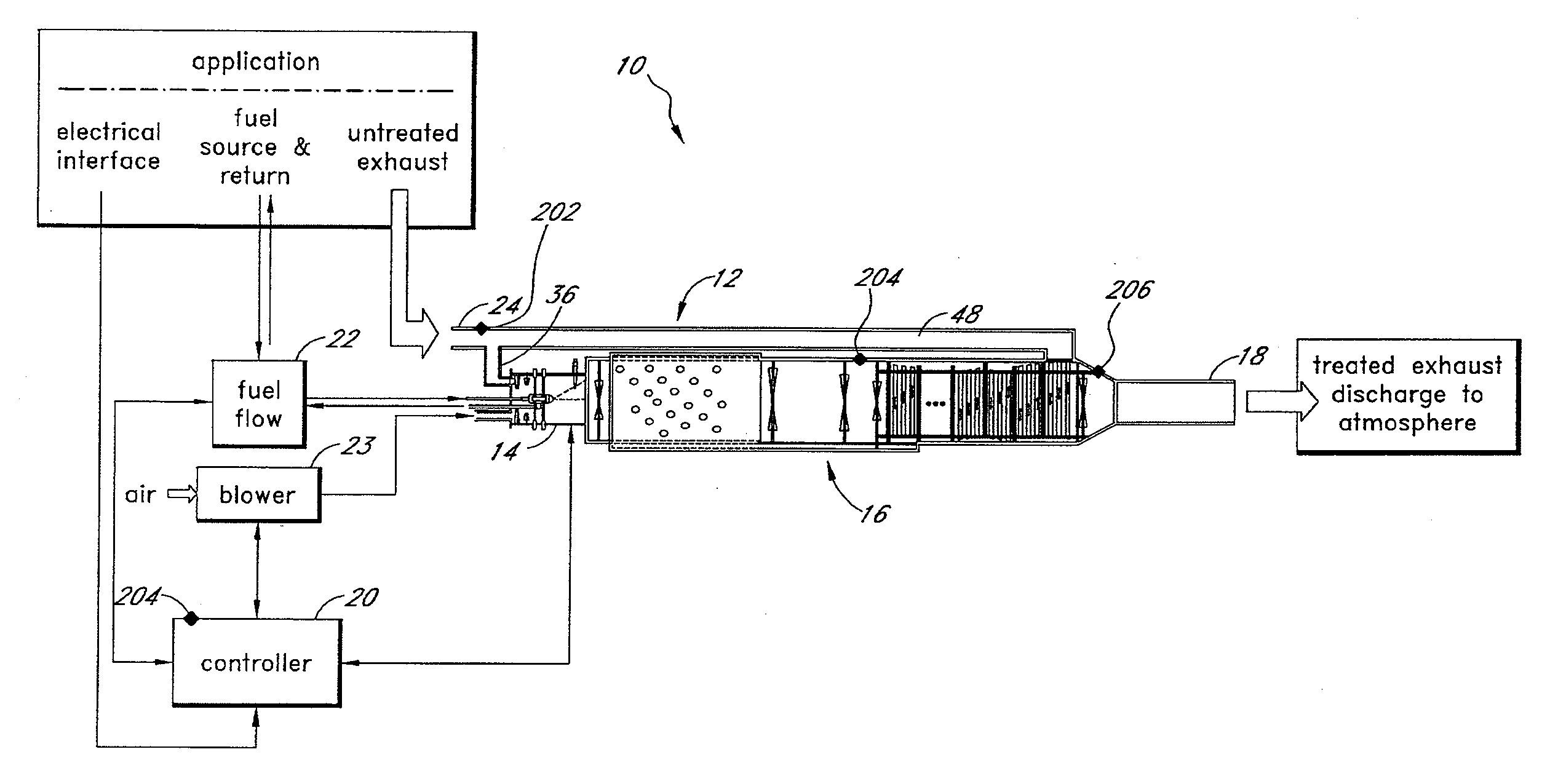

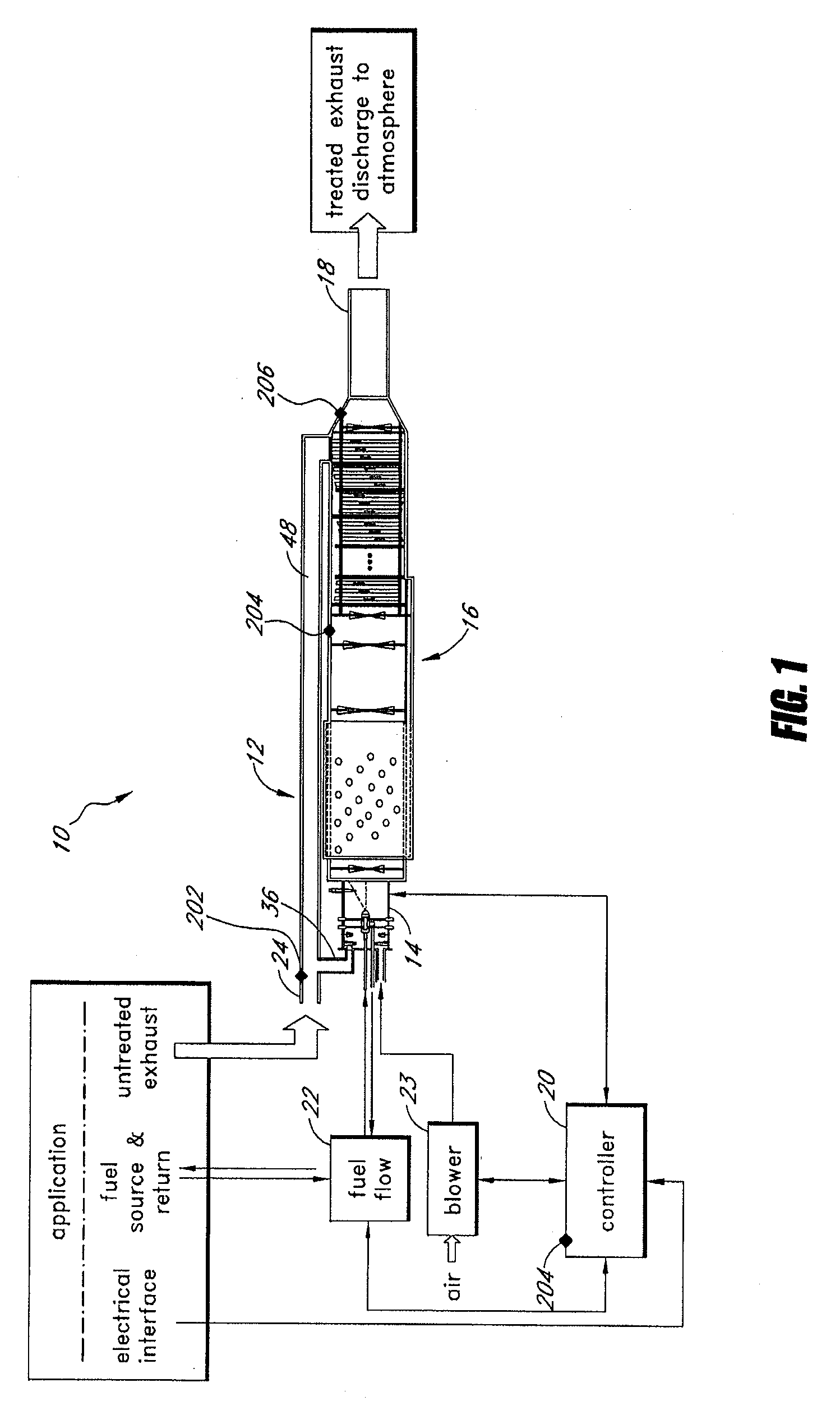

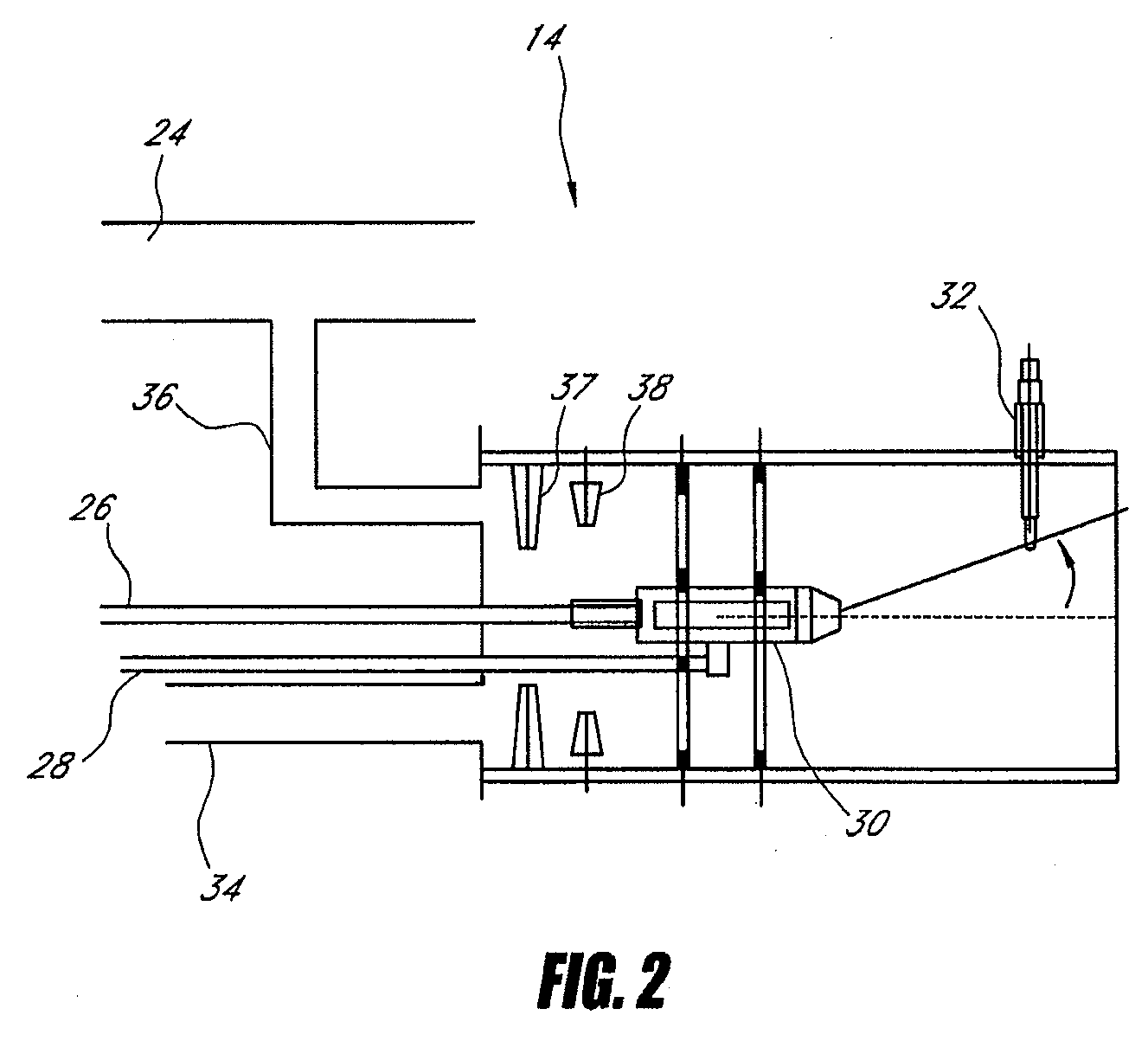

[0033]With reference to FIG. 1, an embodiment of a thermal converter system 10 can include a tube assembly 12. The tube assembly 12 can comprise an injector head 14, an assembly 16 of connected chambers and / or passageways, and an exhaust pipe 18. The tube assembly 12 can further comprise insulation material, an outer shell, and / or mounting hardware, which are not shown. In some embodiments, the tube assembly 12, or parts of the tube assembly 12, can comprise a right-circular long metal tube.

[0034]The system 10 can further include a thermal controller 20, fuel device 22, and air device 23, each of which can be in communication with and / or connected to the tube assembly 12. In some embodiments, the fuel device 22 can comprise a fuel flow rate controller. In some embodiments, the air device 23 can comprise an air blower or blowers. The system 10 described herein can be used, for example, to treat untreated exhaust gas which exits from an engine, and to reduce em...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com