Aluminum alloy sheet for lithographic printing plate and method of producing the same

Inactive Publication Date: 2009-10-08

FUJIFILM CORP +1

View PDF3 Cites 8 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

[0008]The present invention has been achieved as a result of further experiments and studies based on the above findings. An object of the present invention is to provide an aluminum alloy sheet for a lithographic printing plate which allows pits to be more uni

Problems solved by technology

If the strength of the support is insufficient, the secured portion of the suppor

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Login to View More

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| Grain size | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

Login to View More

Abstract

An aluminum alloy sheet for a lithographic printing plate which allows pits to be more uniformly formed by an electrochemical surface-roughening treatment and exhibits more excellent adhesion to a photosensitive film and water retention properties, and a method of producing the same are disclosed. The aluminum alloy sheet includes 0.1 to 1.5% of Mg, more than 0.05% and 0.5% or less of Zn, 0.1 to 0.6% of Fe, 0.03 to 0.15% of Si, 0.0001 to 0.10% of Cu, and 0.0001 to 0.05% of Ti, with the balance being aluminum and impurities, the Mg content and the Zn content satisfying a relationship “4×Zn %−1.4%≦Mg %≦4×Zn %+0.6%”, and the amount of aluminum powder on the surface of the aluminum alloy sheet being 0.1 to 3.0 mg/m2. It is more effective when precipitates with a diameter (circle equivalent diameter) of 0.1 to 1.0 μm are dispersed on the surface of the sheet in a number of 10,000 to 100,000 per square millimeter (mm2).

Description

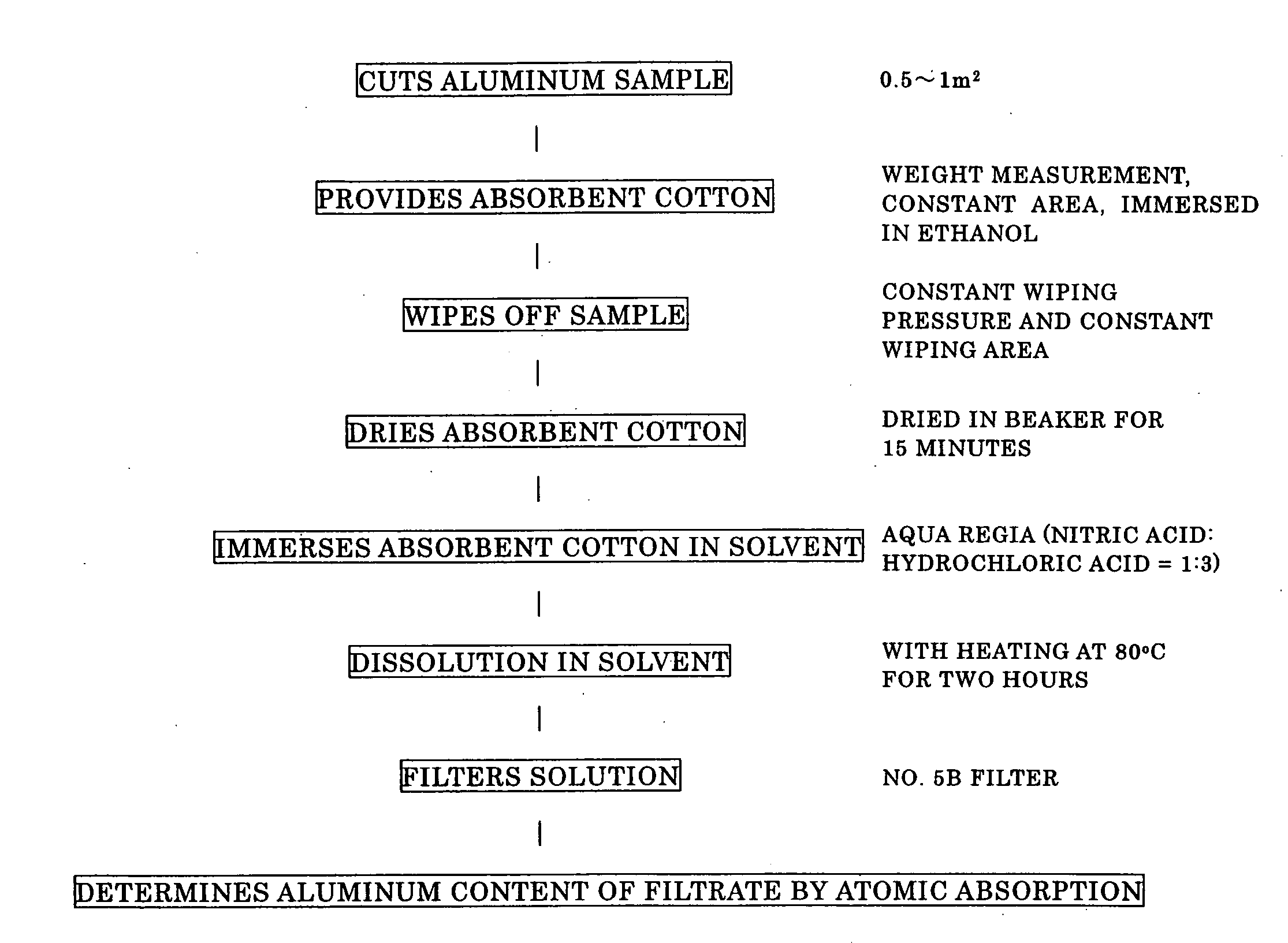

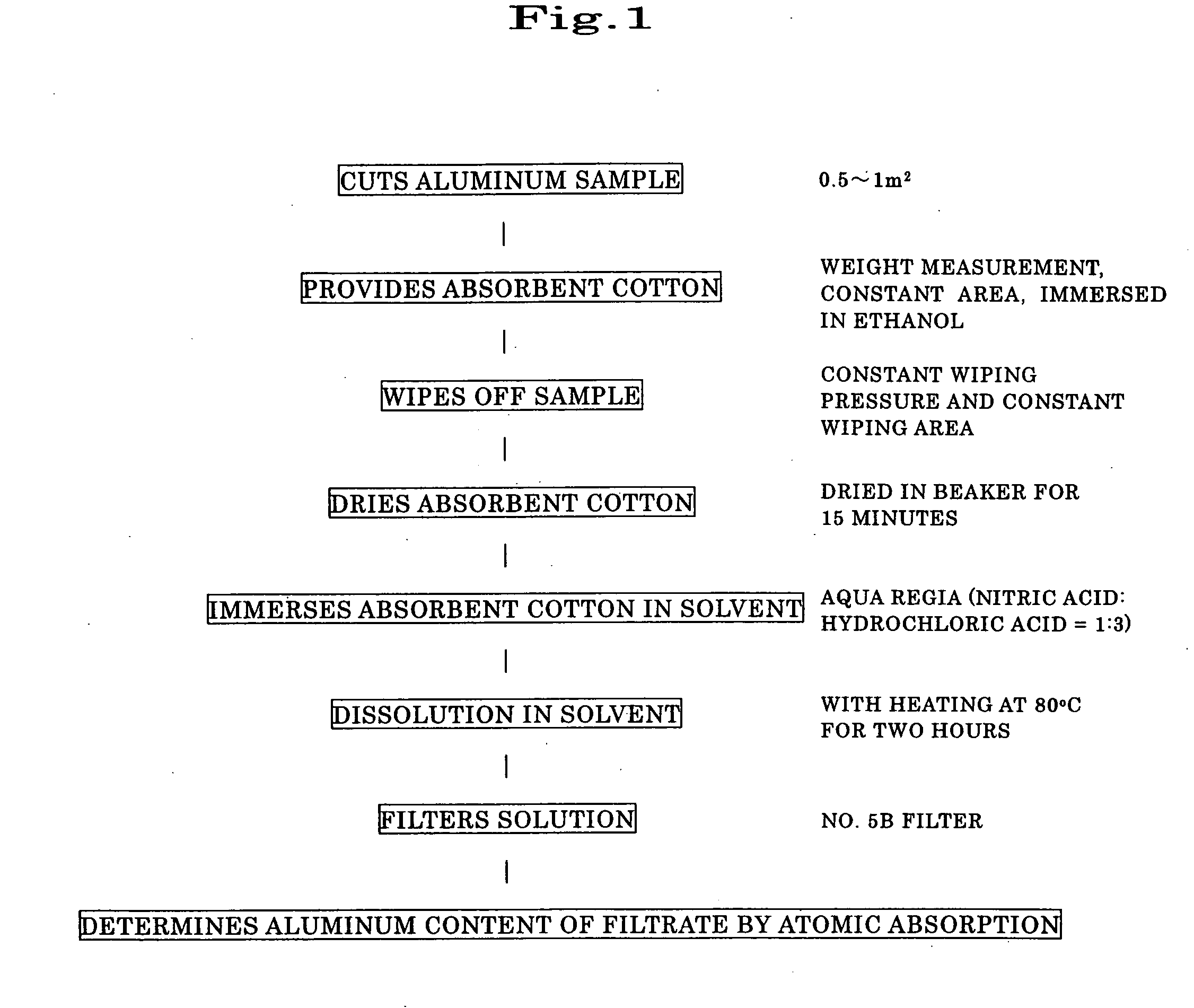

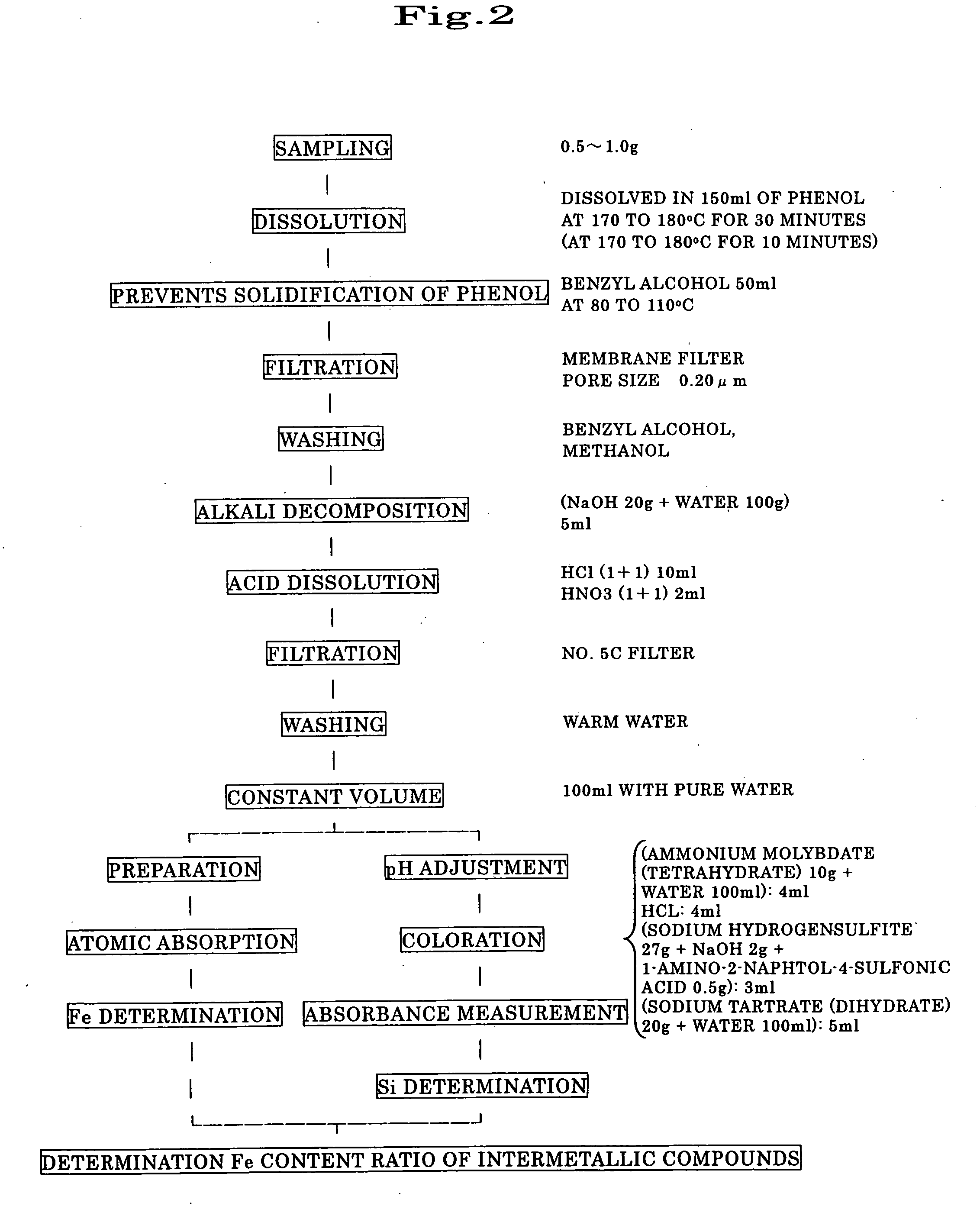

TECHNICAL FIELD[0001]The present invention relates to an aluminum alloy sheet for a lithographic printing plate. More particularly, the present invention relates to an aluminum alloy sheet for a lithographic printing plate which can be surface-roughened uniformly by an electrochemical etching treatment and exhibits excellent strength and thermal softening resistance, and a method of producing the same.BACKGROUND ART[0002]An aluminum alloy sheet is generally used as a support for a lithographic printing plate (including an offset printing plate). Such a support is surface-roughened from the viewpoint of improving adhesion to a photosensitive film and improving the water retention properties in a non-image area. As the surface roughening method, a mechanical surface roughening method such as ball graining, brush graining, or wire graining has been employed. In recent years, a method of roughening the surface of a support aluminum alloy sheet by an electrochemical etching treatment has...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C22C21/12C22C21/08C22F1/047C22C21/14C22C21/16C22C21/18

CPCB22F7/04B41N1/083B41N3/034C22F1/047C22C21/06C22C21/08C22C21/10C22C21/00

Inventor UESUGI, AKIOSAWADA, HIROKAZUOUGI, HIROSHIHIBINO, ATSUSHI

Owner FUJIFILM CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com