Integrated roller for a treadmill, method for making and a special-purpose extrusion tool

a technology of integrated rollers and treadmills, applied in the field of fitting parts of fitness equipment, can solve the problems of increasing fit clearance, increasing material wastage, and requiring even more process steps, and achieves the effects of less tendency to deform, prolonged service life and low raw material consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

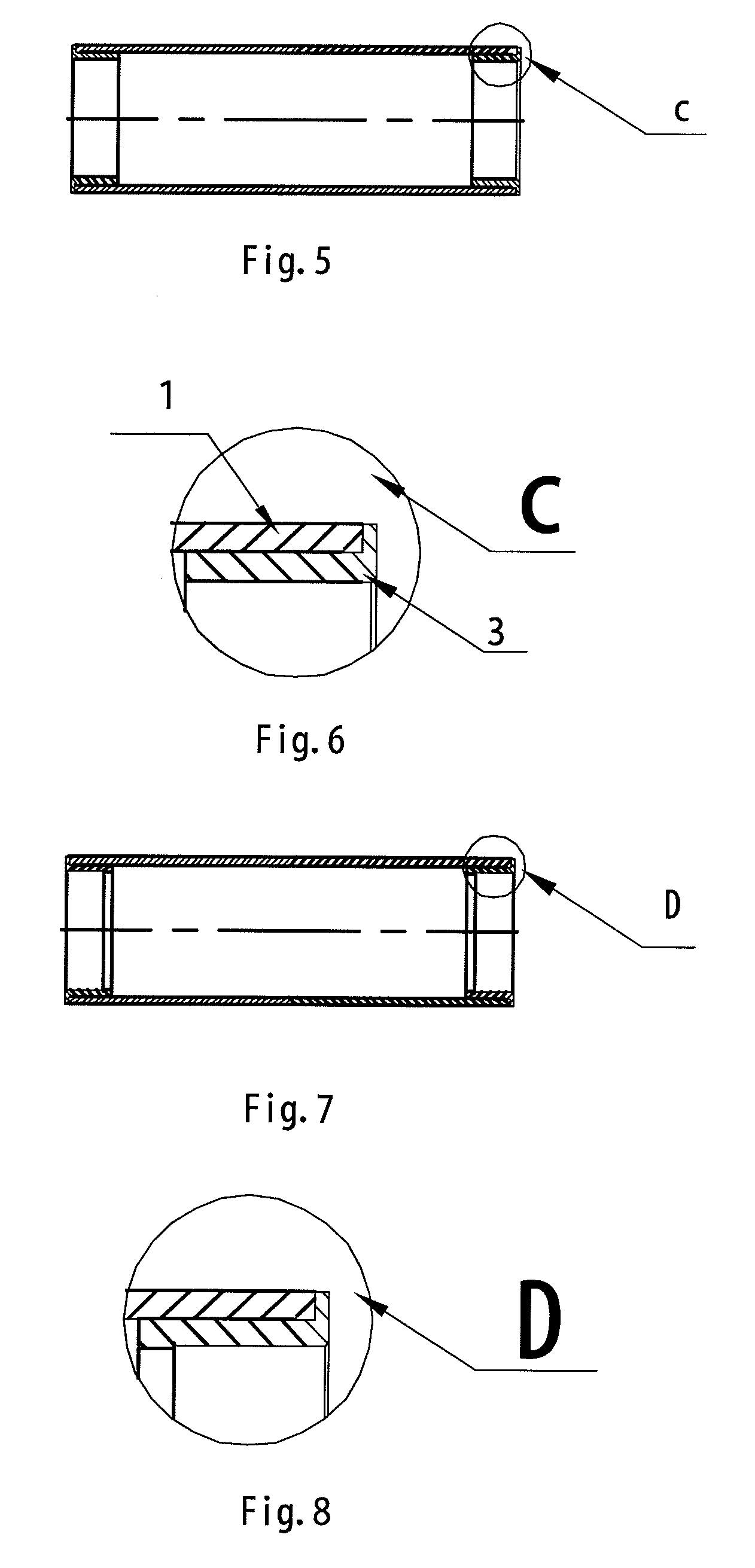

[0049]As shown in FIG. 13 to FIG. 16, this invention is an integrated structure with the outer end 41 and inner end 42 thereof integrated, the outer diameter surface of the said inner end 421 and the inner hole surface of the said outer end 411 form close fit, and the tip of the inner end 422 extends inward along the inner diameter direction for a distance to form a plateau 44 shape. The said ends clearance 43 is 0 mm.

[0050]As shown in FIG. 17 to FIG. 20, this invention is an integrated structure with the outer end 41 and inner end 42 thereof integrated, the outer diameter surface of the said inner end 421 and the inner hole surface of the said outer end 411 form clearance fit, and the tip of the inner end 422 extends inward along the inner diameter direction for a distance to form a plateau 44 shape. The said fit clearance is between 0 to 6 mm.

[0051]As shown in FIG. 21 to 22, when this invention is carried out, the outer end 41 and the inner end 42 are of integrated structure, then...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com