Thin film membranes with additives for forward and pressure retarded osmosis

a technology of composite membranes and additives, applied in the direction of membranes, reverse osmosis, coatings, etc., can solve the problems of reducing membrane efficiency and reducing membrane efficiency for fo and pro processes, and achieve the effect of increasing the pressure in the draw solution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

)

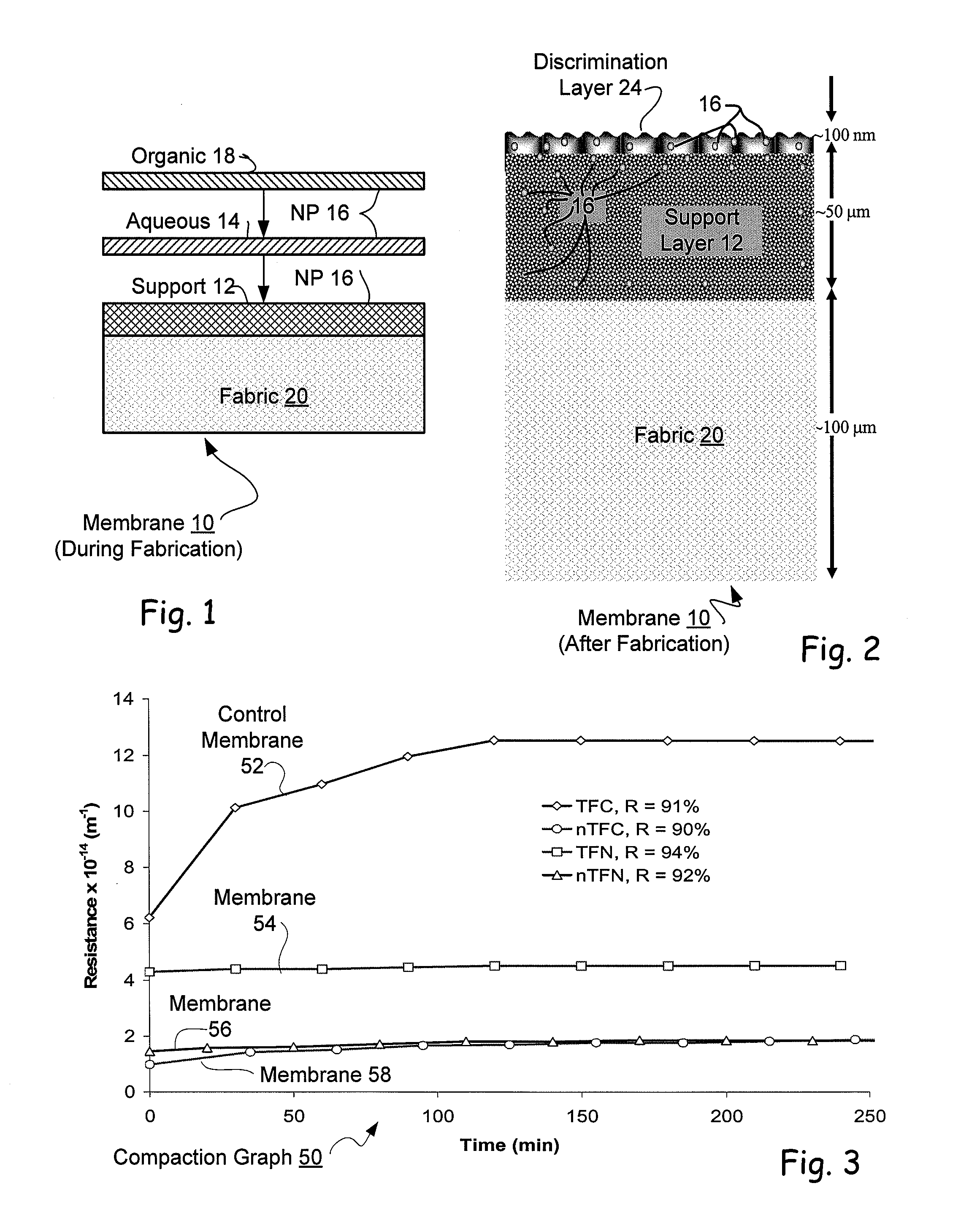

[0019]Referring now to FIG. 1, an exploded view of membrane 10 illustrating the fabrication process is shown in which membrane 10 may include organic phase layer 18, aqueous phase layer 14, porous support membrane 12 and fabric layer 20. One or more types of nanoparticles 16, or other additives as discussed below in greater detail, may be included in aqueous or organic phases 14, 18 before contact there between for interfacial polymerization so that nanoparticles 16 are dispersed in discrimination layer 24 as shown in FIG. 2. Nanoparticles / additives 16 may also be dispersed in support layer 12 and fabric 20.

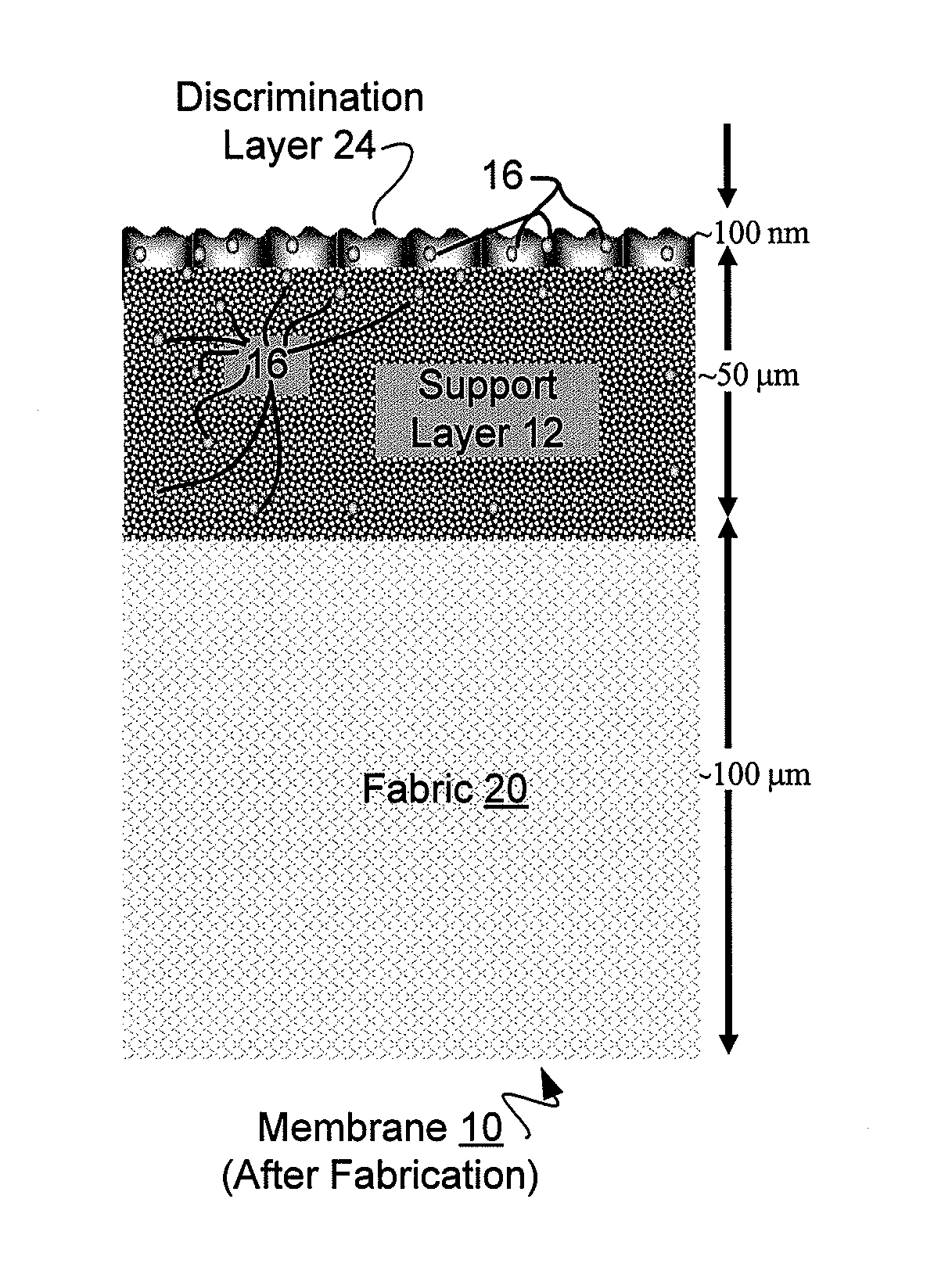

[0020]Referring now also to FIG. 2, a portion of membrane 10 is illustrated after fabrication including nanoparticles and / or other additives 16, in discrimination layer 24 as well as nanoparticles / additives 16 in support layer 12 which may be the same or different than those—if any—used in discrimination layer 24. In a conventional thin film composite or TFC membrane, made witho...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thick | aaaaa | aaaaa |

| thick | aaaaa | aaaaa |

| thick | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com