Wear Assembly For Excavating Equipment

a technology of excavating equipment and wear, which is applied in the direction of soil shifting machines/dredgers, machines/dredgers working methods, construction, etc., can solve the problems of inability of operators to see the ground, inability to effectively guide the cutterhead along a path best suited to the terrain, and considerable power is needed to drive the cutterhead. , to achieve the effect of reducing power consumption, minimizing drag, and minimizing the power needed to drive the equipmen

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

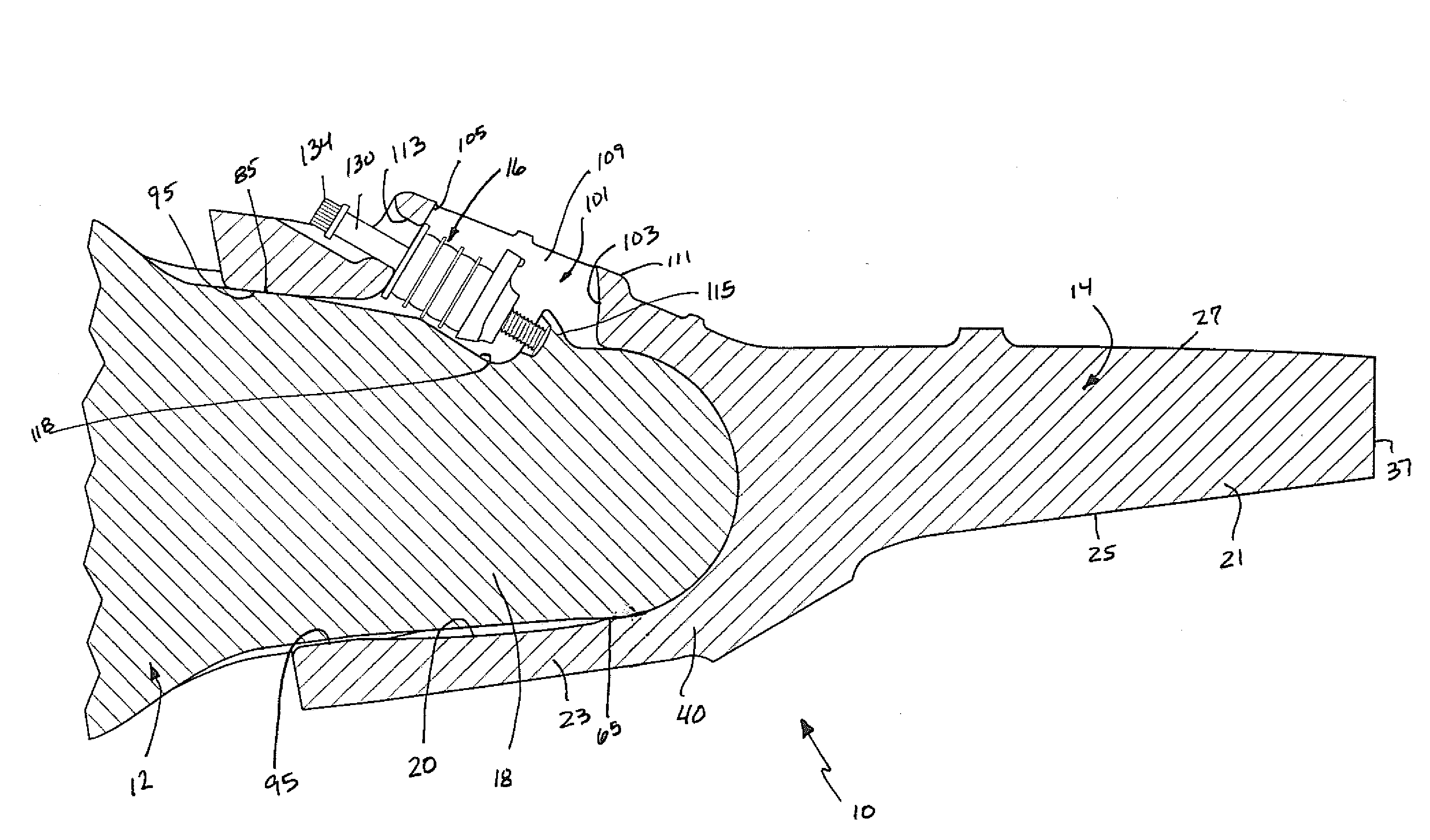

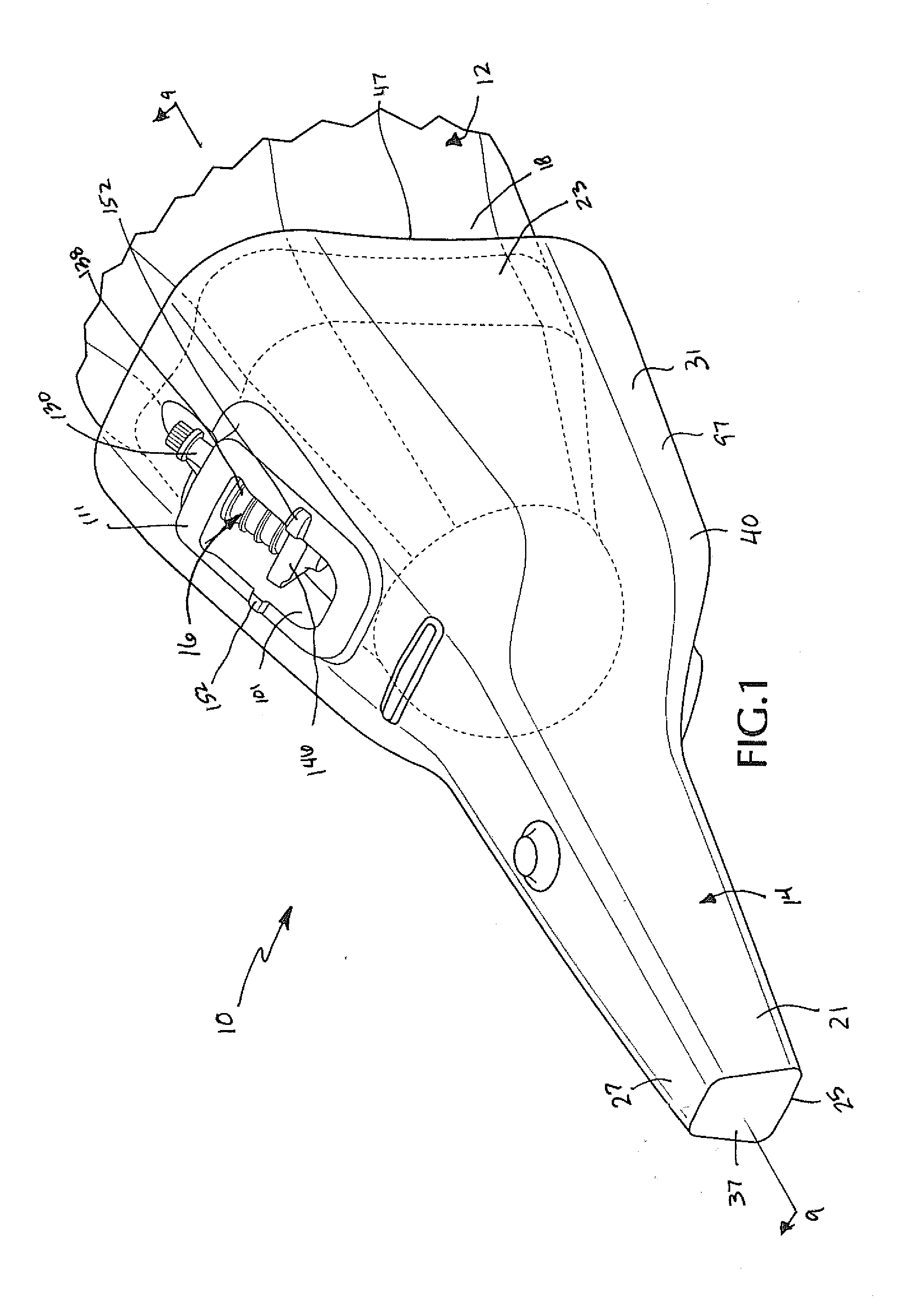

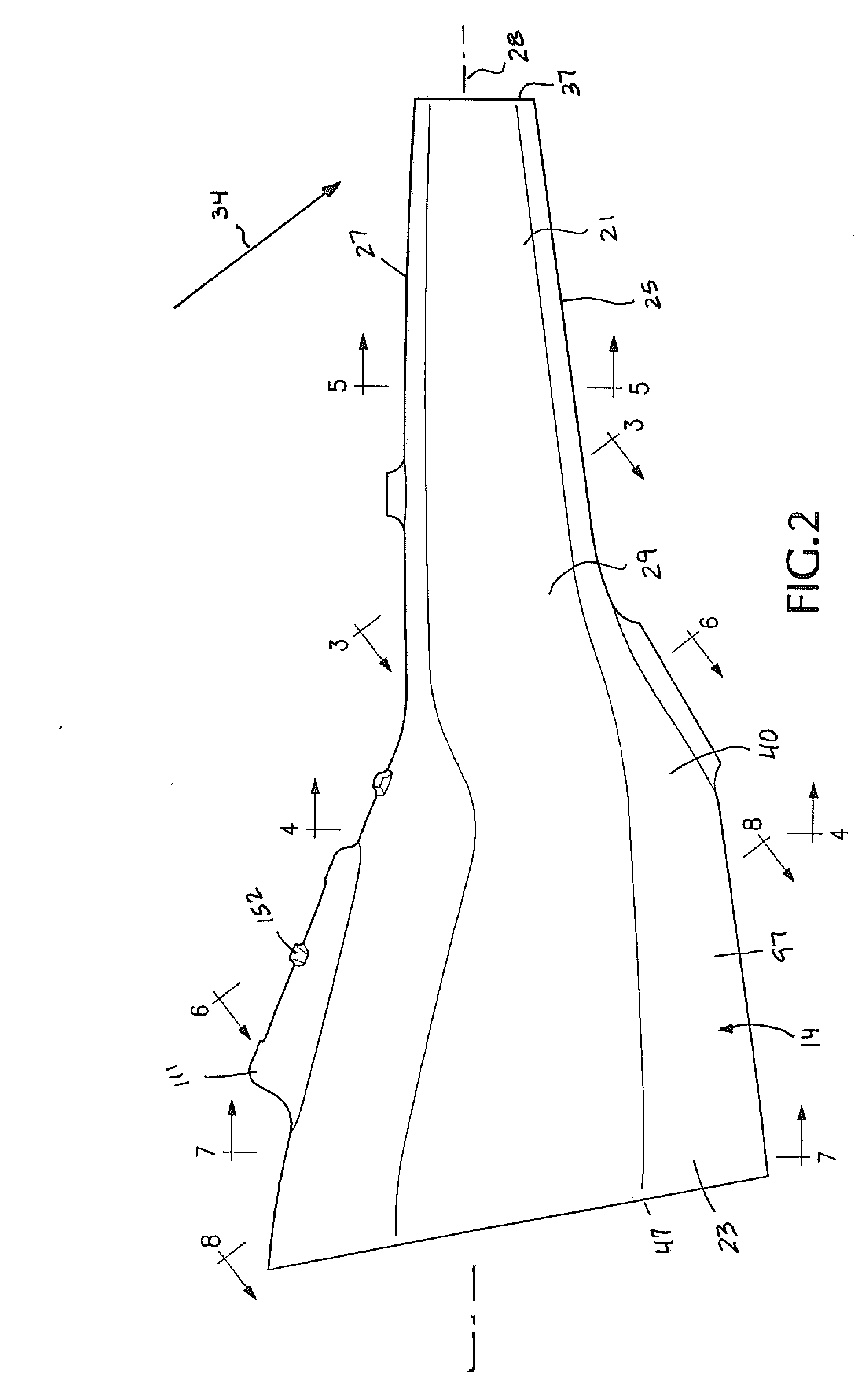

[0045]The present invention pertains to a wear assembly 10 for excavating equipment, and is particularly well suited for dredging operations. In this application, the invention is described in terms of a dredge tooth adapted for attachment to a dredge cutterhead. Nevertheless, the different aspects of the invention can be used in conjunction with other kinds of wear assemblies (e.g., shrouds) and for other kinds of excavating equipment (e.g., buckets).

[0046]The assembly is at times described in relative terms such as up, down, horizontal, vertical, front and rear; such terms are not considered essential and are provided simply to ease the description. The orientation of a wear member in an excavating operation, and particularly in a dredge operation, can change considerably. These relative terms should be understood with reference to the orientation of wear assembly 10 as illustrated in FIG. 1 unless otherwise stated.

[0047]Wear assembly 10 includes a base 12 secured to a dredge cutt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com