One-piece drill bit for single-pass anchor bolting and single pass drilling apparatus

a drill bit and single-pass technology, applied in drilling machines and methods, cutting machines, mining structures, etc., can solve the problems of complex drill bits adapted to be extracted through casings, unsuitable hard ground conditions, and high cost of existing hard ground percussive anchor bolts that do not reuse drill bits, etc., to achieve less costly use and good wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

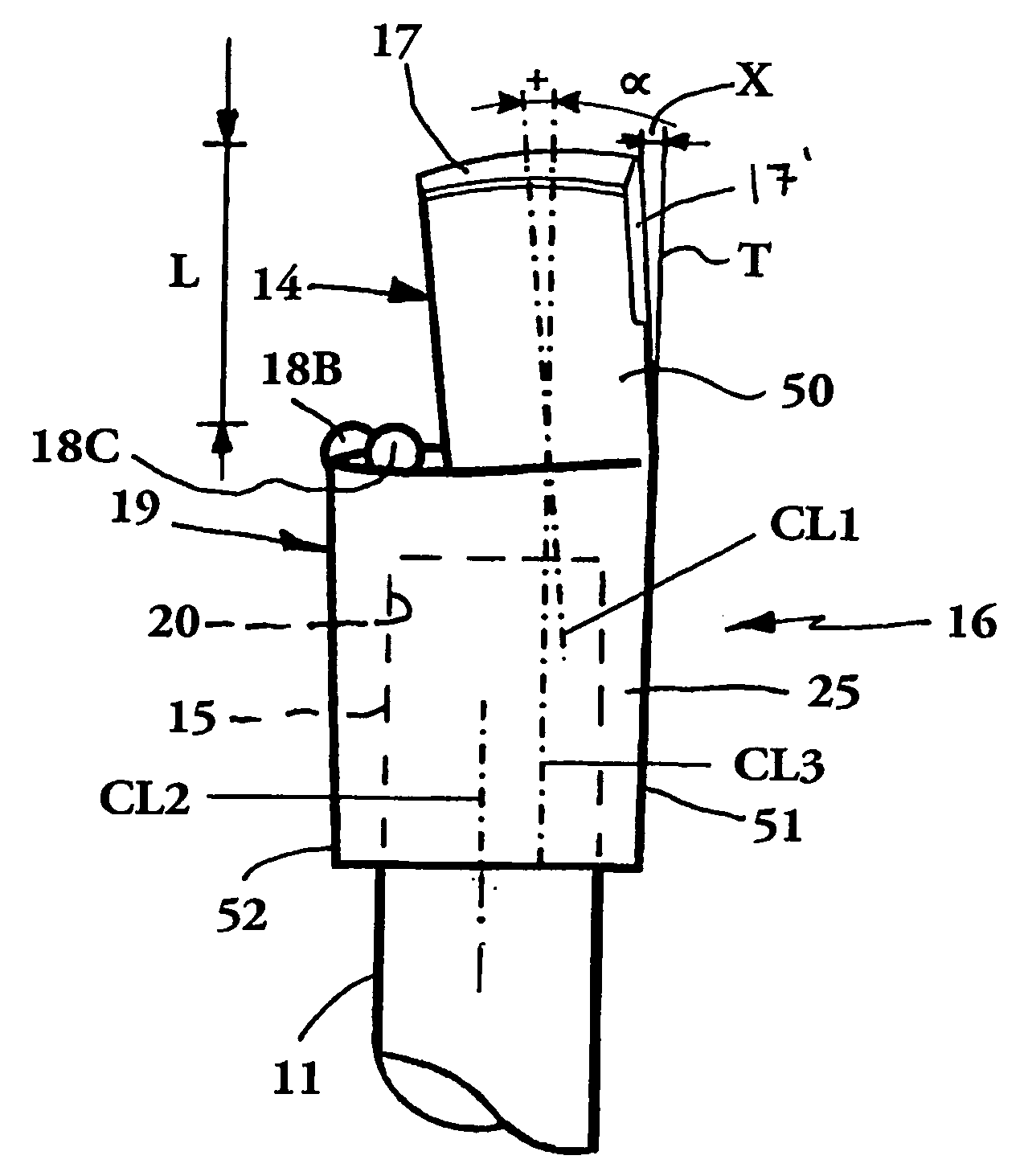

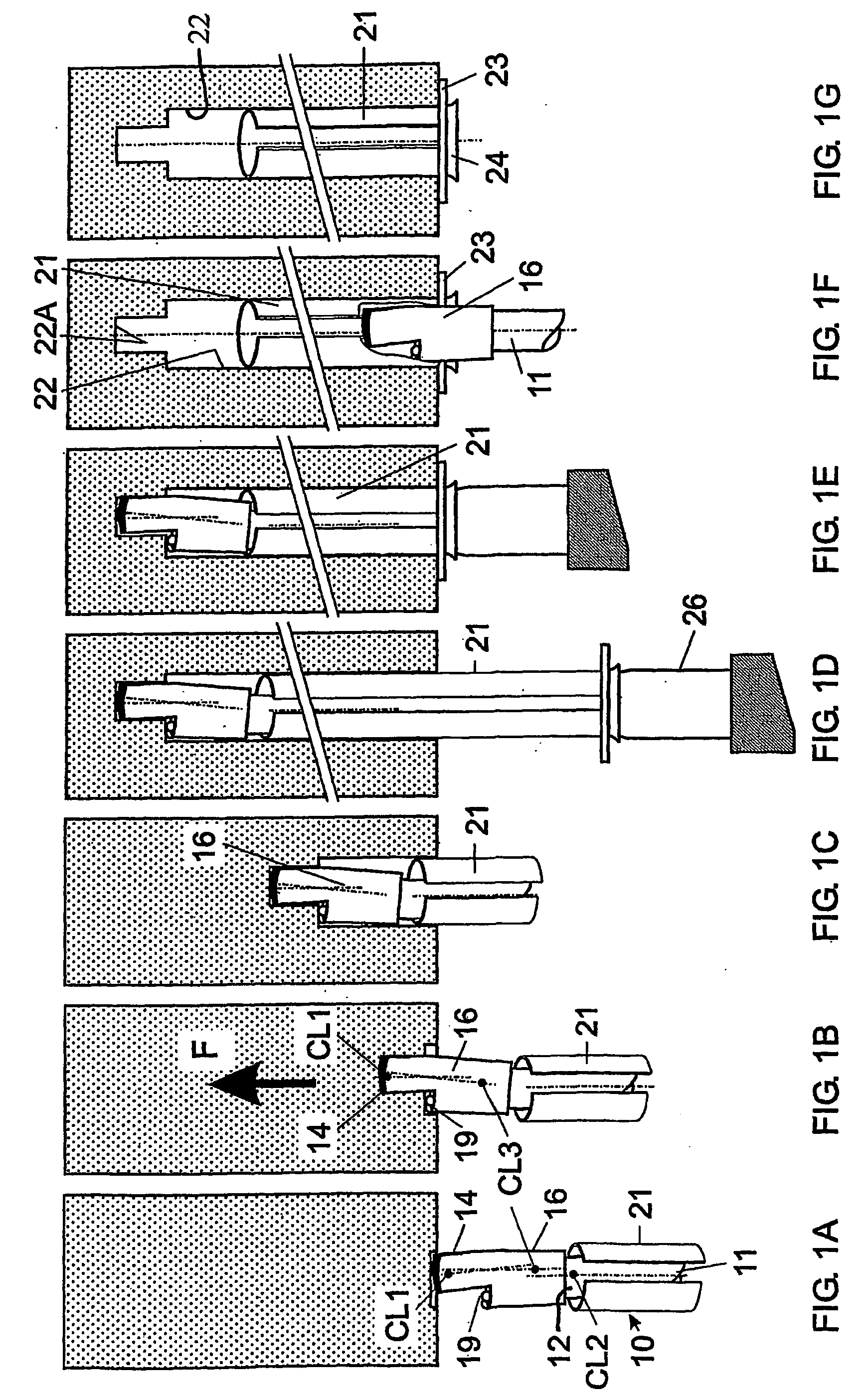

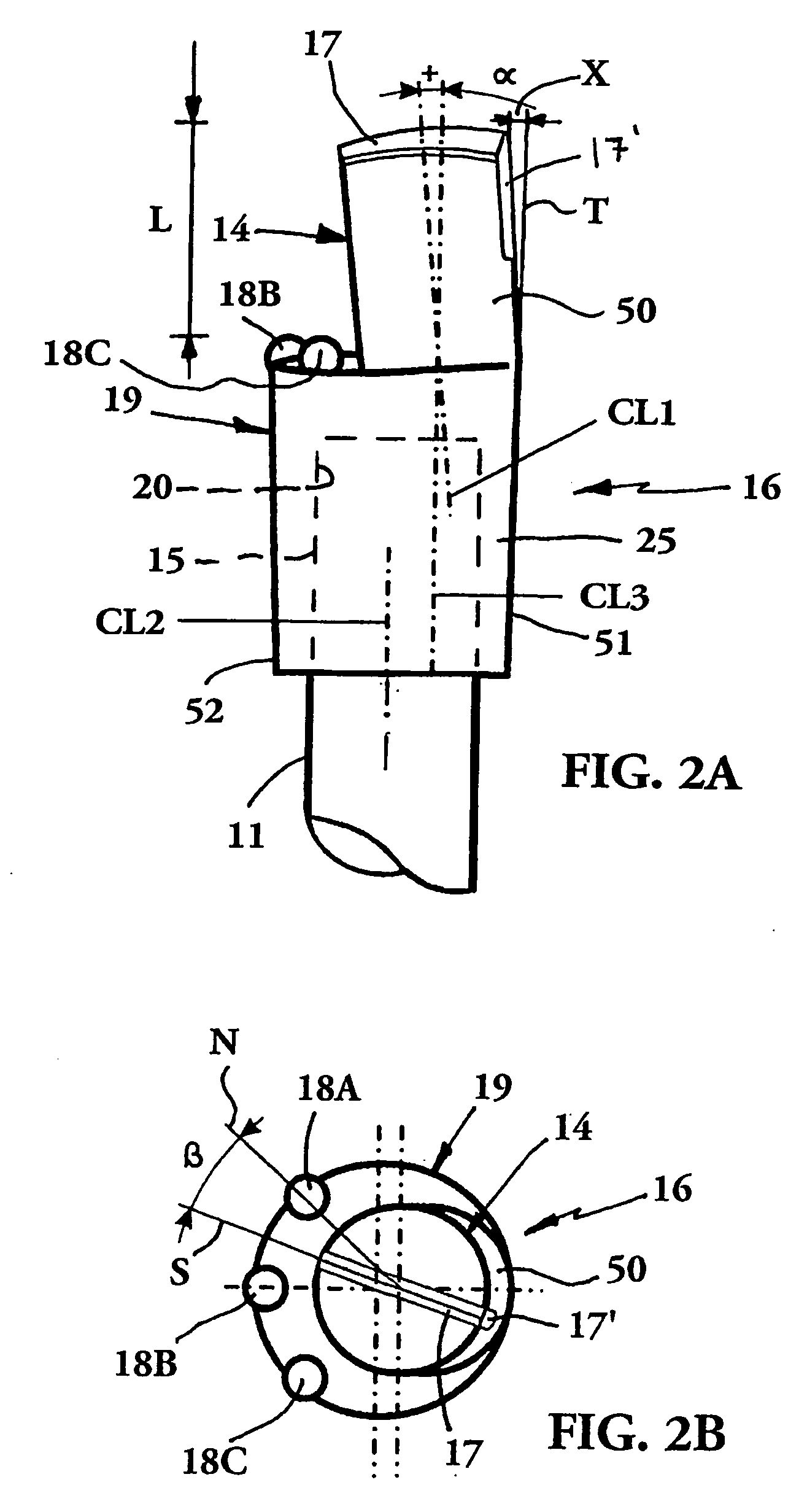

[0011]FIGS. 1A-1G show a single pass drilling apparatus 10 according to the present invention using a drill bit 16 according to the present invention and FIGS. 2A-3B more closely show the drill bit 16 according to the present invention. The single pass drilling apparatus 10 comprises several parts; e.g. an elongated drill steel 11 having a leading end 12 and a trailing end, not shown, reference being had to a drilling direction F. The leading end 12 has a connection portion comprising a thread 15, a taper or a bayonet connection, not shown. A one-piece drill bit 16 is provided having rock machining means 17 and 18A, 18B, 18C. The drill bit 16 is connectable to the drill steel via a connection portion 20 comprising a thread, a taper or a bayonet connection (not shown). The drill steel 11 and the drill bit constitute drilling means. The single pass drilling apparatus 10 further comprises an anchor bolt 21 adapted to at least partially enclose the drill steel 11. The anchor bolt 21 has...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com