Sealed container and method of manufacturing

a technology of sealing container and manufacturing method, which is applied in the field of sealing containers, can solve the problems of reducing the shelf life of the product due to spoilage, slow venting process of the bag, and spoilage of the contents, so as to achieve effective evacuation, reduce the risk of failure of the sealing mechanism, and economic and effective

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022]The present invention is now illustrated in greater detail by way of the following detailed description which represents the best presently known mode of carrying out the invention. However, it should be understood that this description is not to be used to limit the present invention, but rather, is provided for the purpose of illustrating the general features of the invention.

[0023]The present invention relates to sealed containers. More specifically, the present invention relates to containers, such as plastic or synthetic, flexible bags wherein the containers can be compressed or evacuated to remove excess air or fluid content and may be sealed.

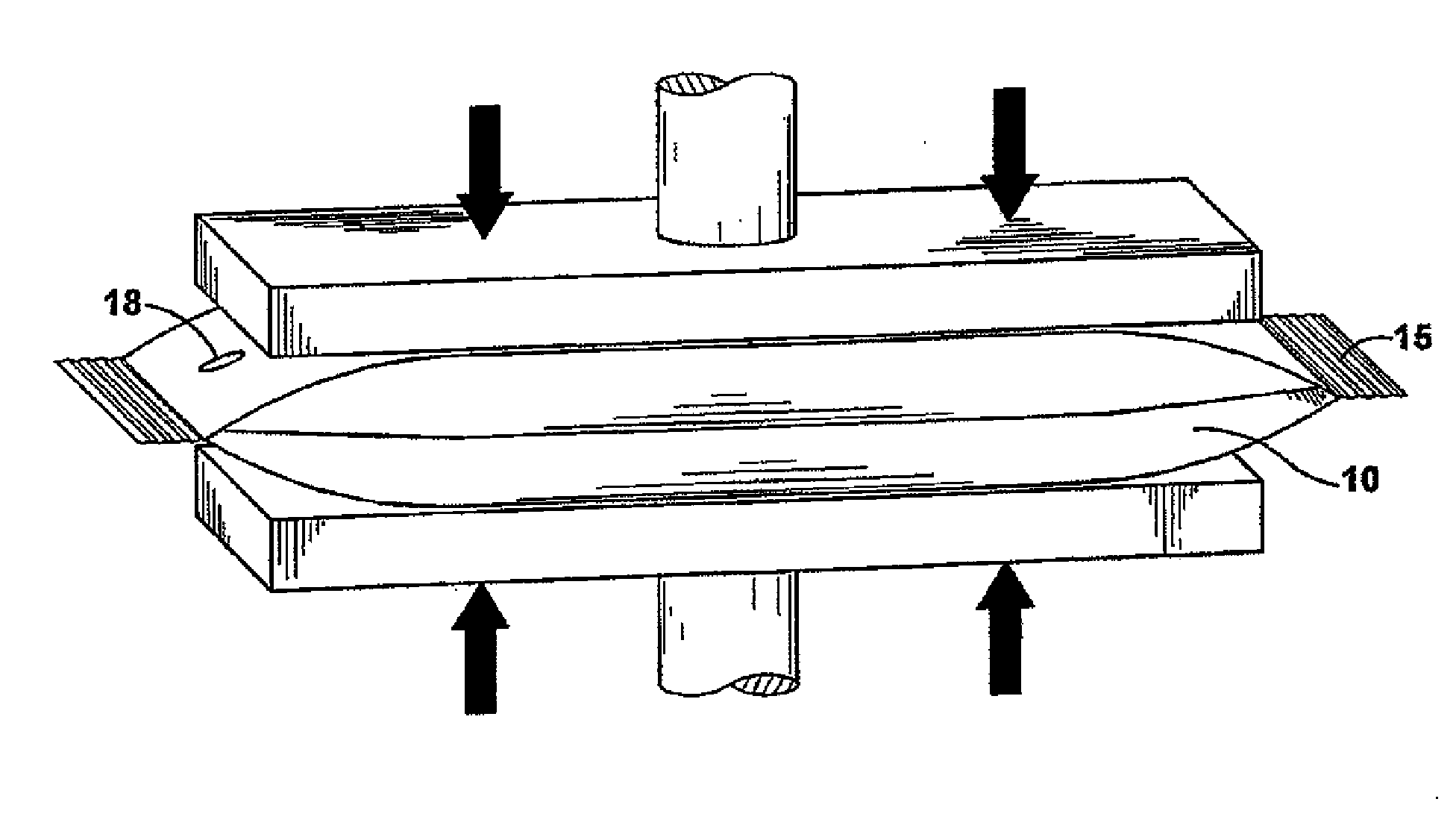

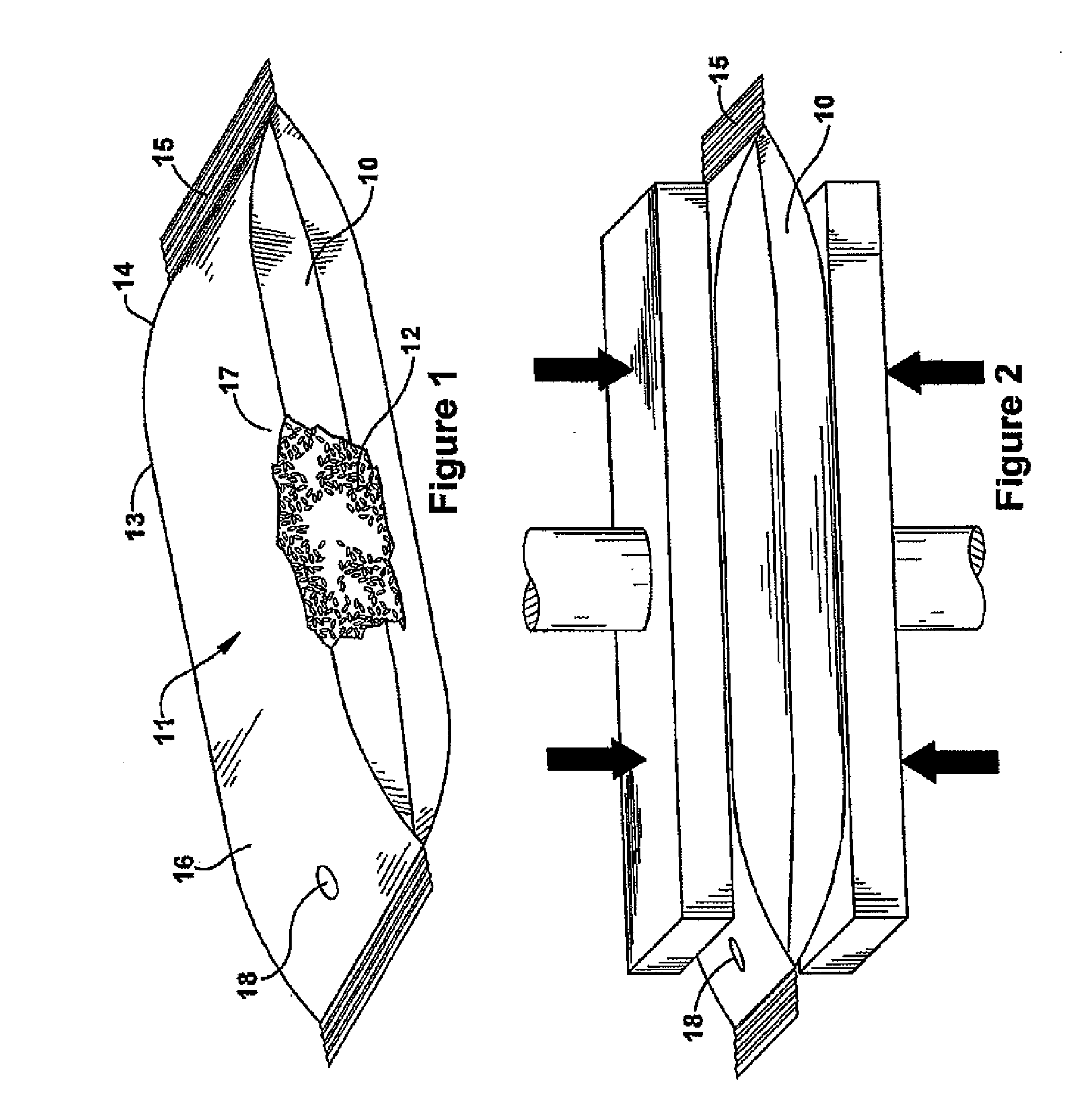

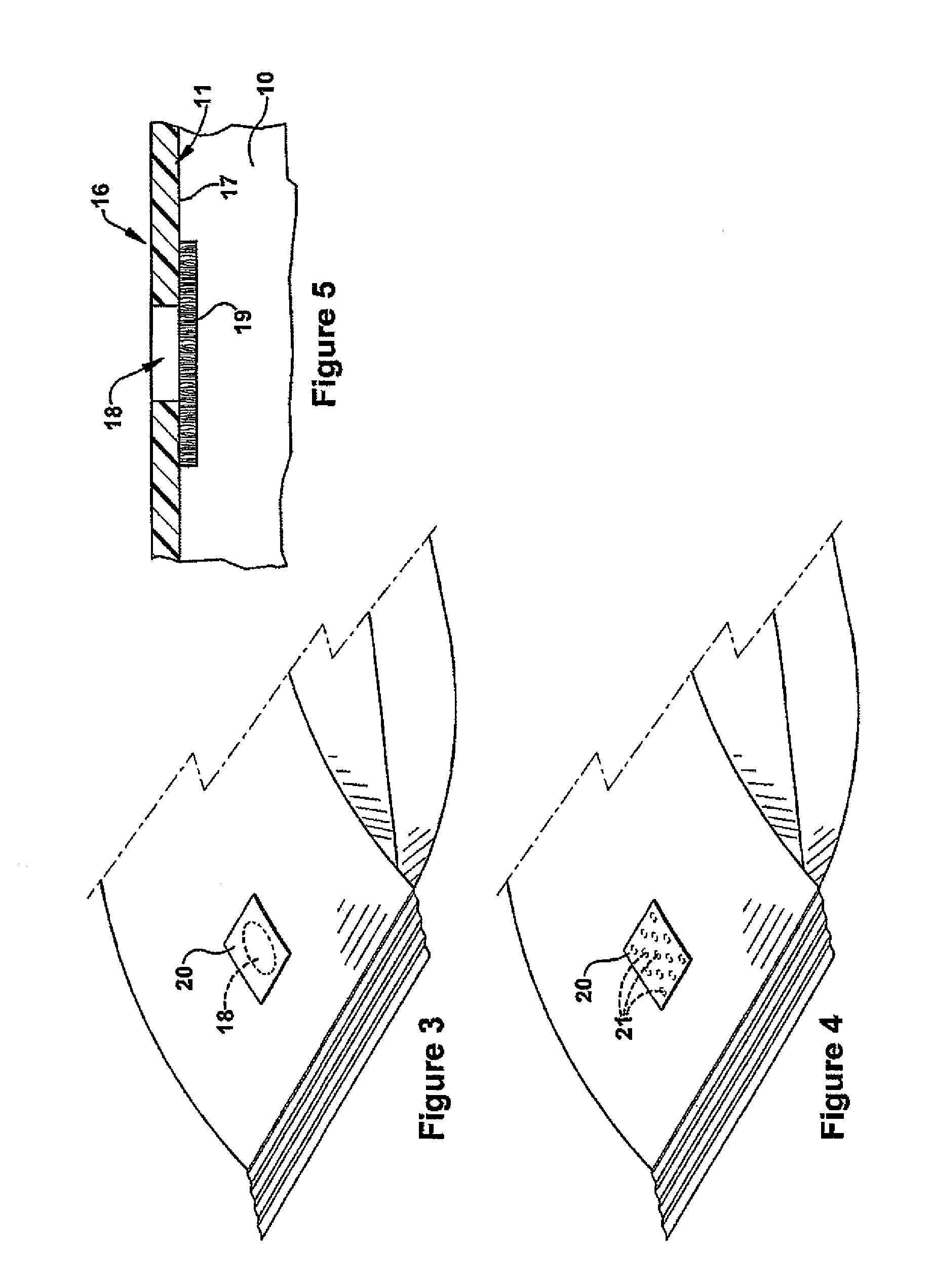

[0024]FIG. 1 shows pouch or container 10 lying on its side in an orientation suitable for stacking on a retail shelf for example. FIG. 1 shows that container 10 includes a main body 11 for holding material 12, the main body 11 forming an interior region or a pouch 13 and terminating at a principal or top opening 14 sealed with a clo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| temperatures | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com