Method and Device for Processing Crankshaft and Burnishing Roller for Crankshaft

a technology of burnishing roller and crankshaft, which is applied in the direction of crankshafts, grinding machines, manufacturing tools, etc., can solve the problems of high manufacturing cost and complex structure of the burnishing apparatus disclosed in the patent document 1, and achieve the effect of improving the surface properties of the crankshaft shank which is free of fillets, improving the surface properties and simplifying the structure of the crankshaft machining apparatus

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

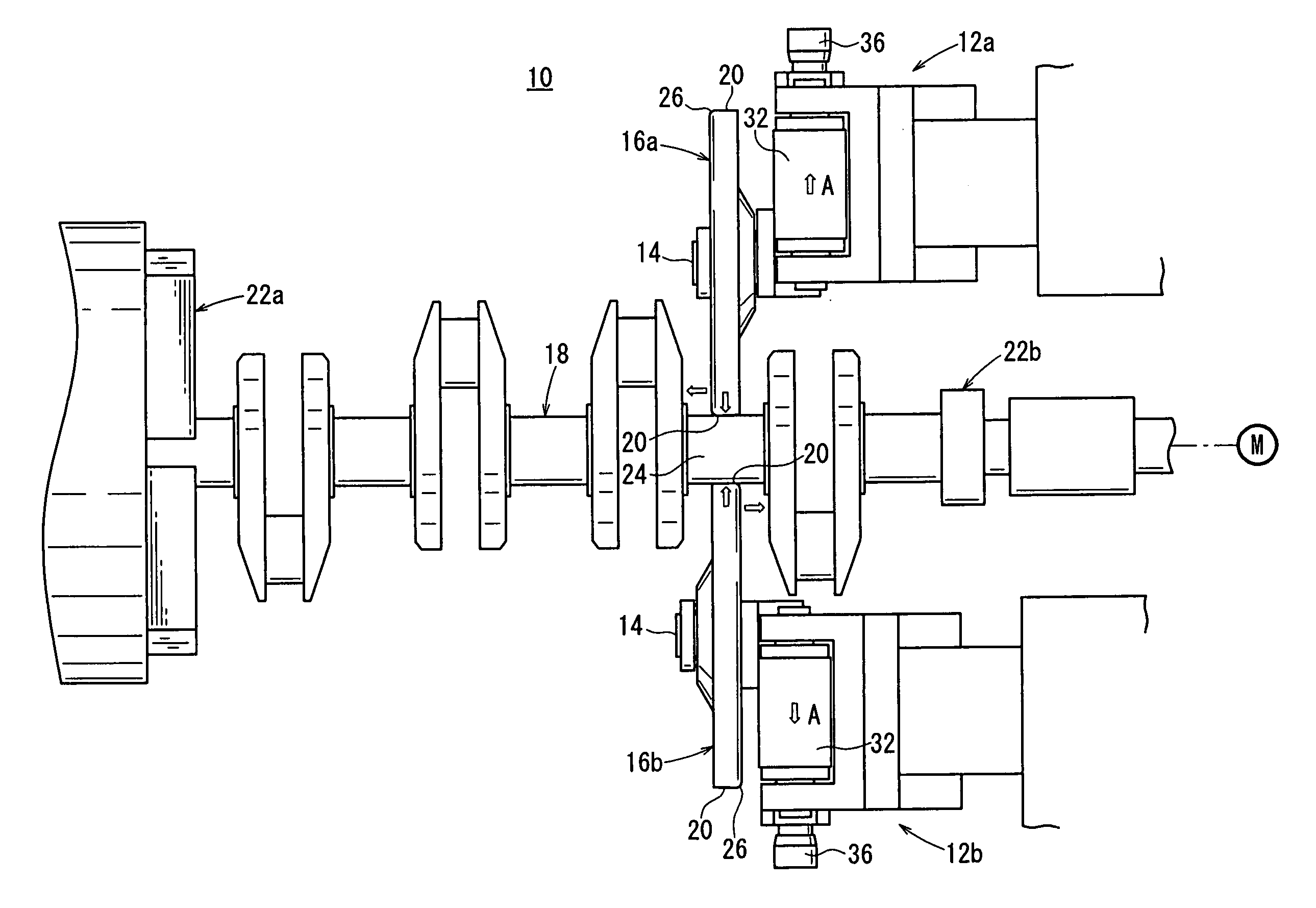

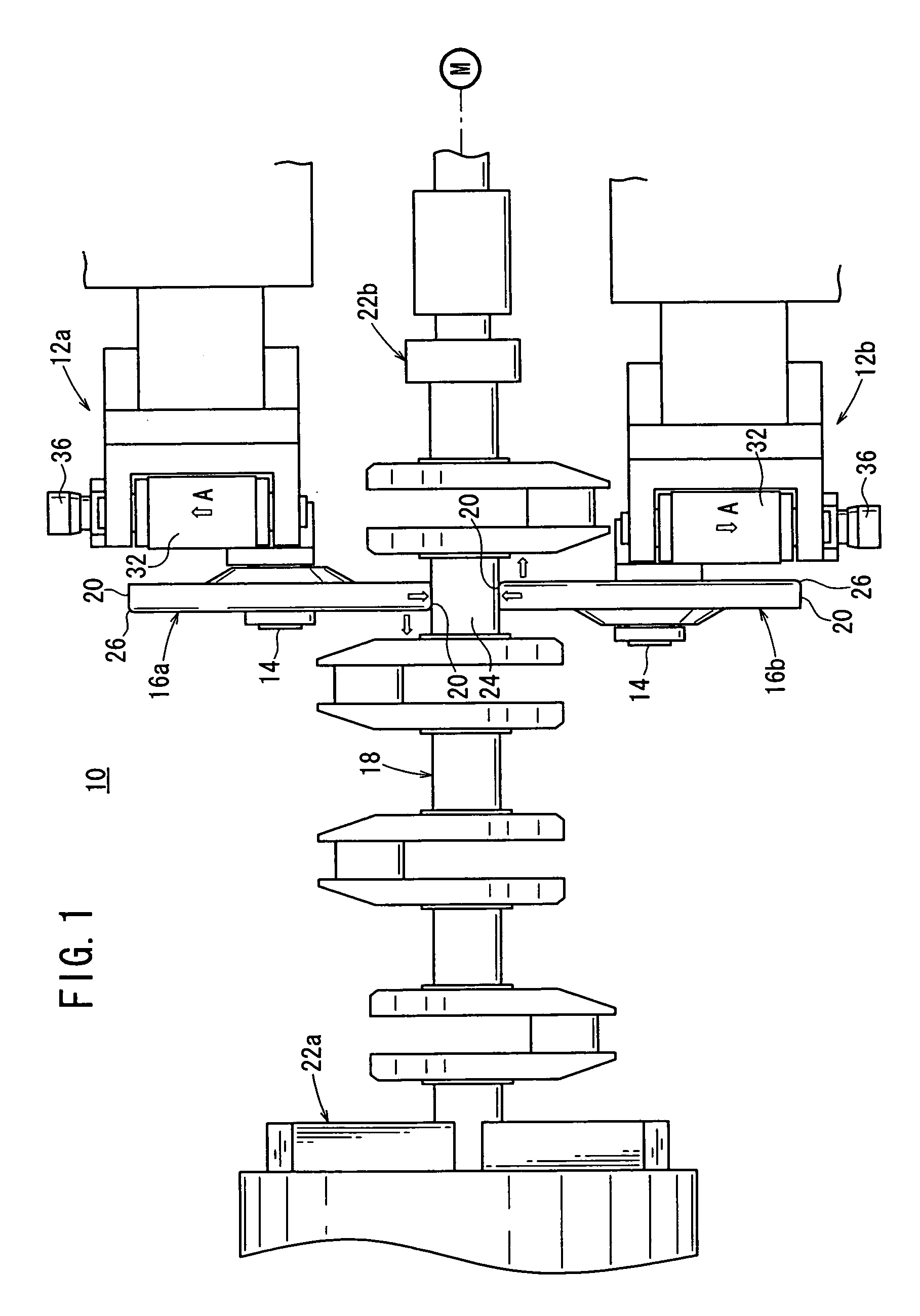

[0040]In FIG. 1, the reference character 10 represents a crankshaft machining apparatus according to an embodiment of the present invention.

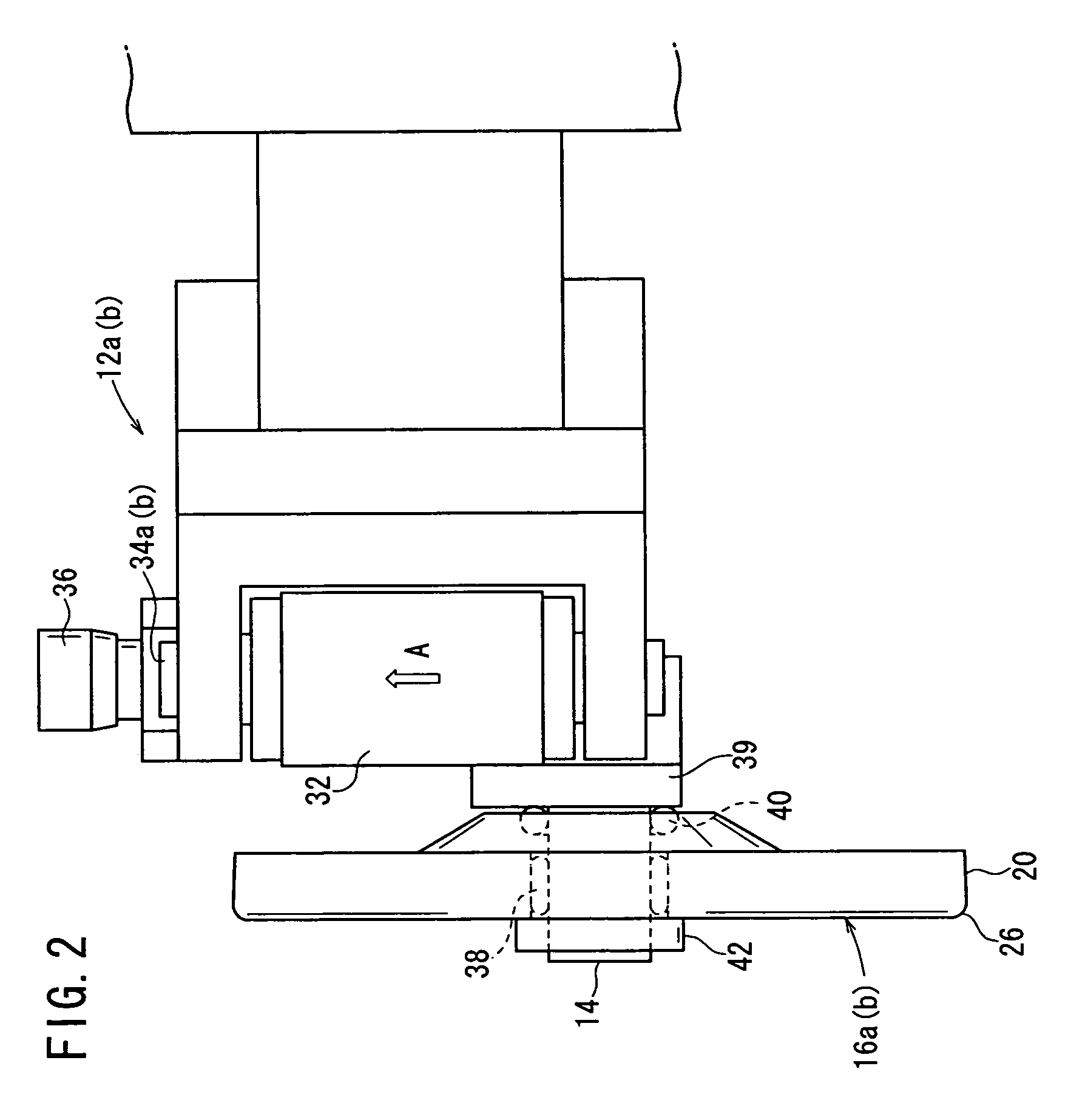

[0041]The crankshaft machining apparatus 10 is mounted on the turret (or rotary tool base) of a turret lathe (or a machining center) which is controlled by a numerical control system, not shown. The crankshaft machining apparatus 10 comprises first and second adapters 12a, 12b displaceable in the directions of three axes X, Y, Z which are perpendicular to each other, a pair of burnishing rollers 16a, 16b rotatably supported respectively on rotational shafts 14 of the first and second adapters 12a, 12b, and first and second holding mechanisms 22a, 22b for engaging respective both axial ends of a crankshaft 18 (hereinafter referred to as workpiece 18) and holding the workpiece 18 such that the workpiece 18 can be rotated about its own axis by a rotary drive source M.

[0042]The burnishing rollers 16a, 16b are disposed in mutually opposite relation t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle θ1 | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

| shape | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com