Masonry structure

a masonry structure and masonry technology, applied in the field of masonry, can solve the problems of high installation time, high cost and high installation time of site-built masonry structures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

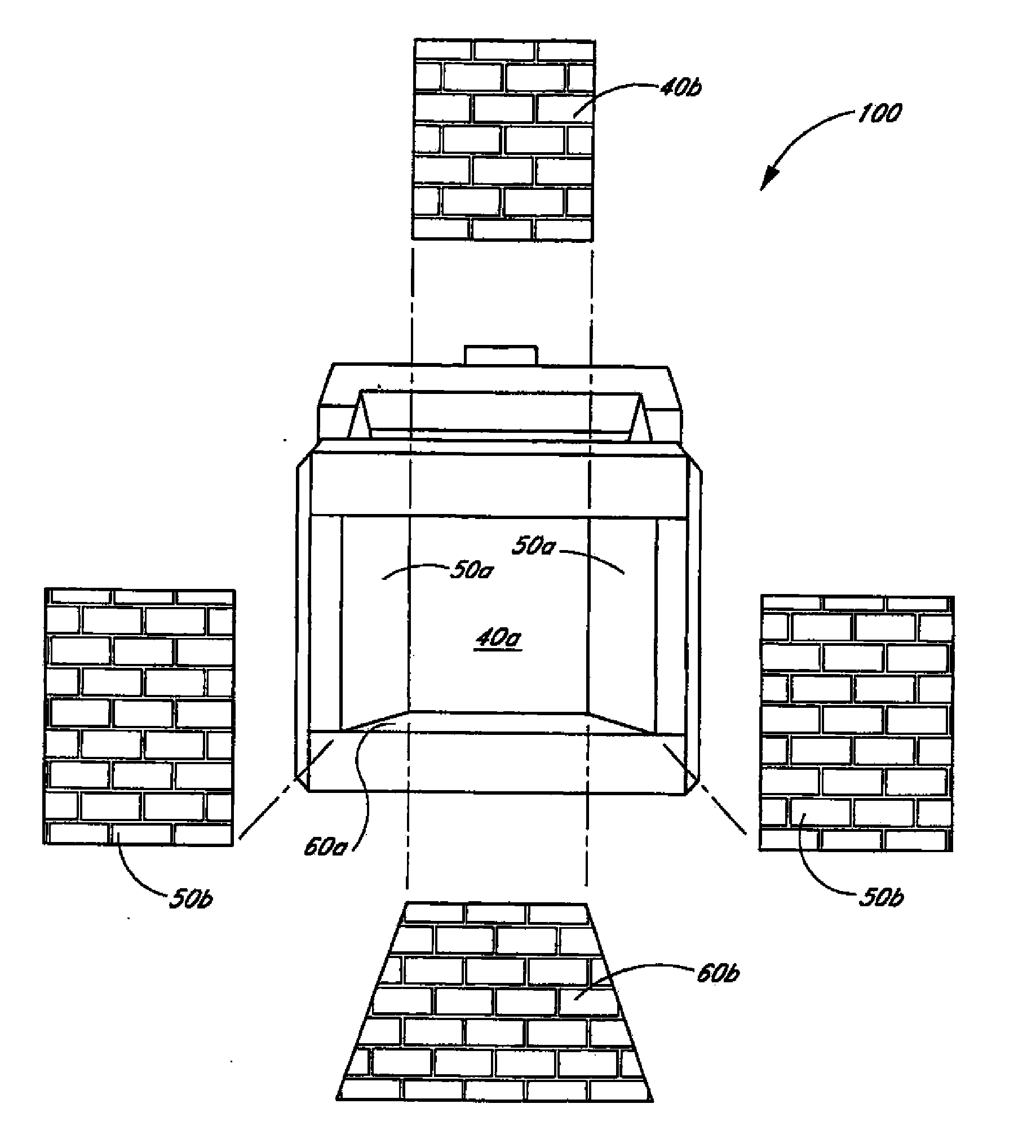

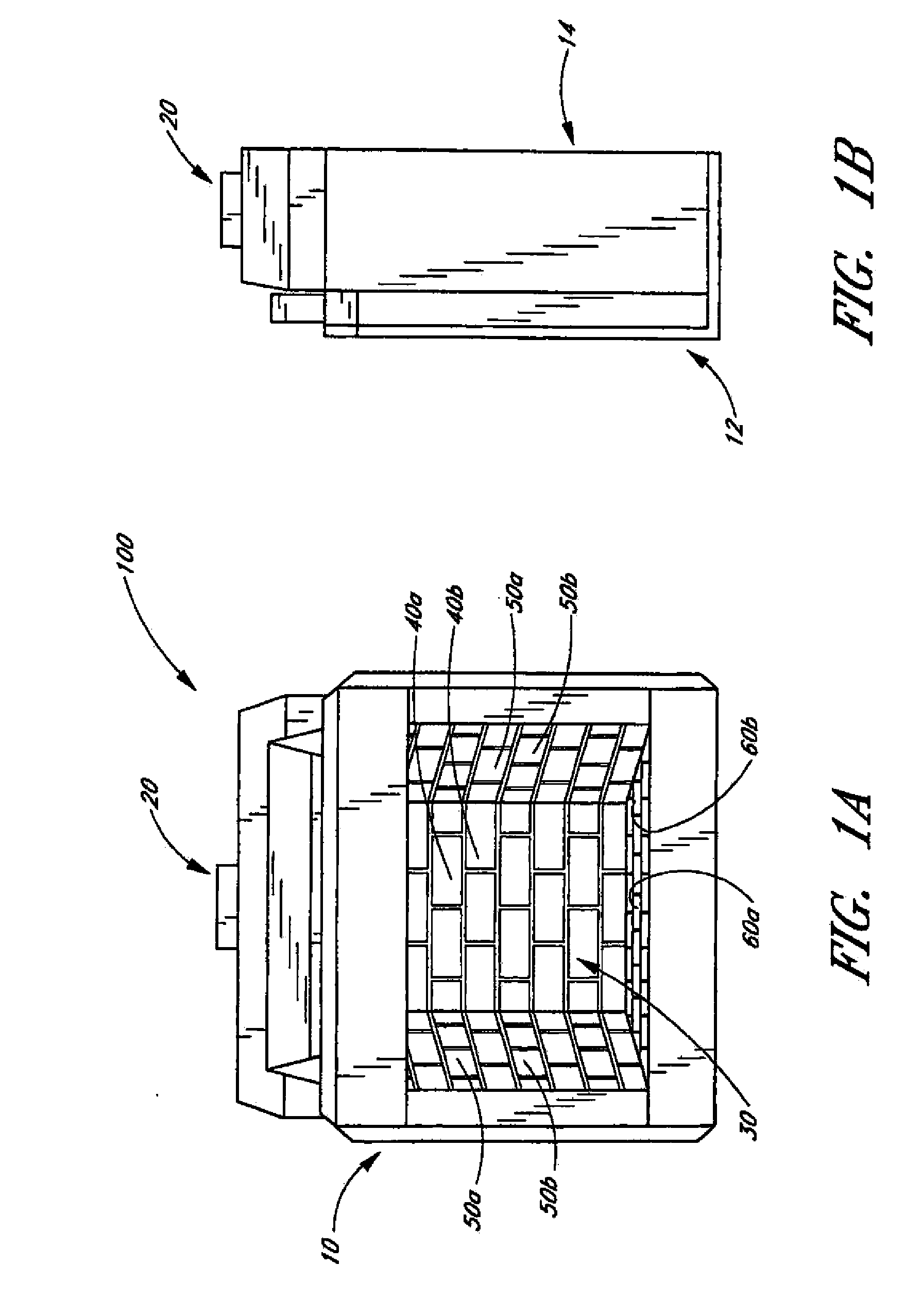

[0046]With reference to FIGS. 1A and 1B, a factory-built masonry fireplace 100 is illustrated therein. The fireplace 100 generally comprises a firebox 10 having a front end 12 and a rear end 14. The firebox 10 defines a cavity 30 and panels 40b, 50b, 60b are preferably disposed in the cavity 30. In the illustrated embodiment, the fireplace 100 has a chimney outlet 20, which is part of a chimney system (not shown). However, the furnace 100 can be vent free, thus not requiring a chimney system. The fireplace 100 can be adapted to burn various types of materials. For example, the fireplace 100 can be a wood and / or gas burning fireplace.

[0047]FIG. 2A illustrates the fireplace 100 of FIG. 1A with the panels 40b, 50b, 60b removed. The cavity 30 has a frame (not shown) with a rear area 40a, side areas 50a and a base area 60a. The frame can comprise at least one rail that defines the periphery of the cavity 30. The frame can optionally comprise a plurality of panels, such as a rear wall 40a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com