Releasing slips for oil well tool

a technology for oil wells and tools, applied in the direction of fluid removal, sealing/packing, borehole/well accessories, etc., can solve the problems of slipping into the casing wall while holding down the tool, affecting and the slipping can be extremely difficult to release, so as to achieve the effect of improving the service life of the releasing slip

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

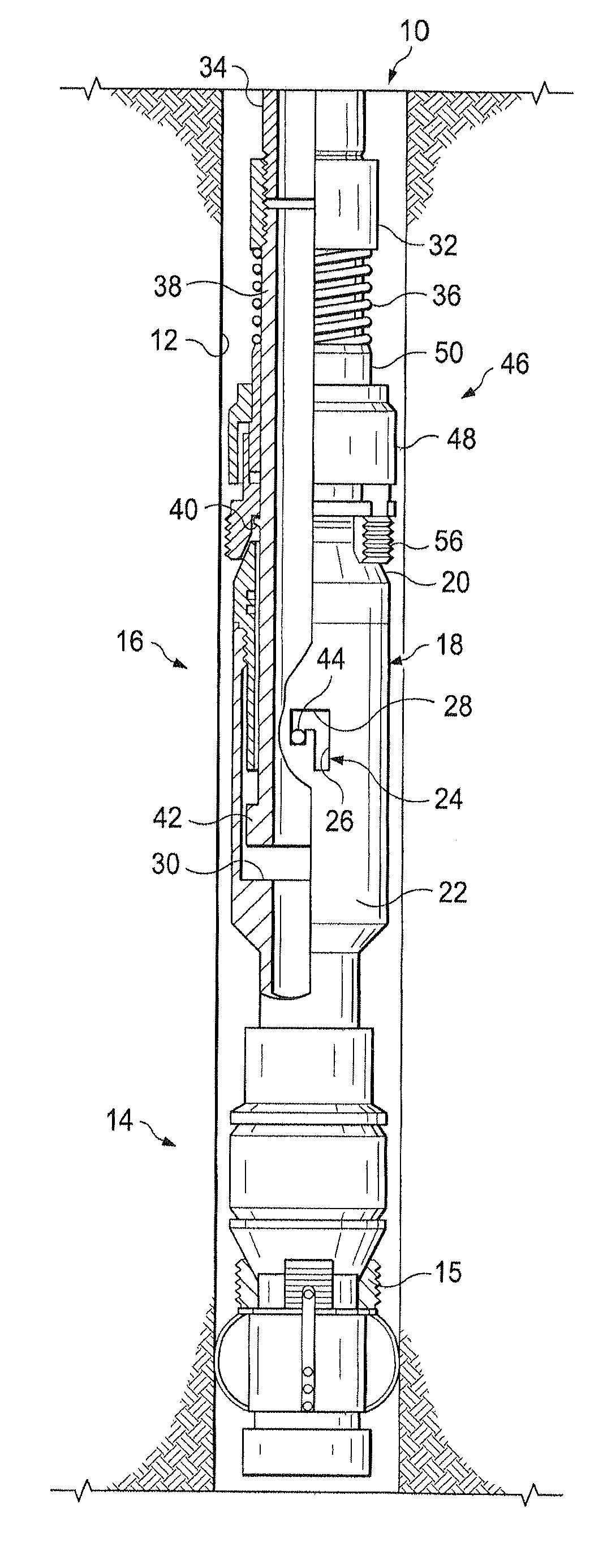

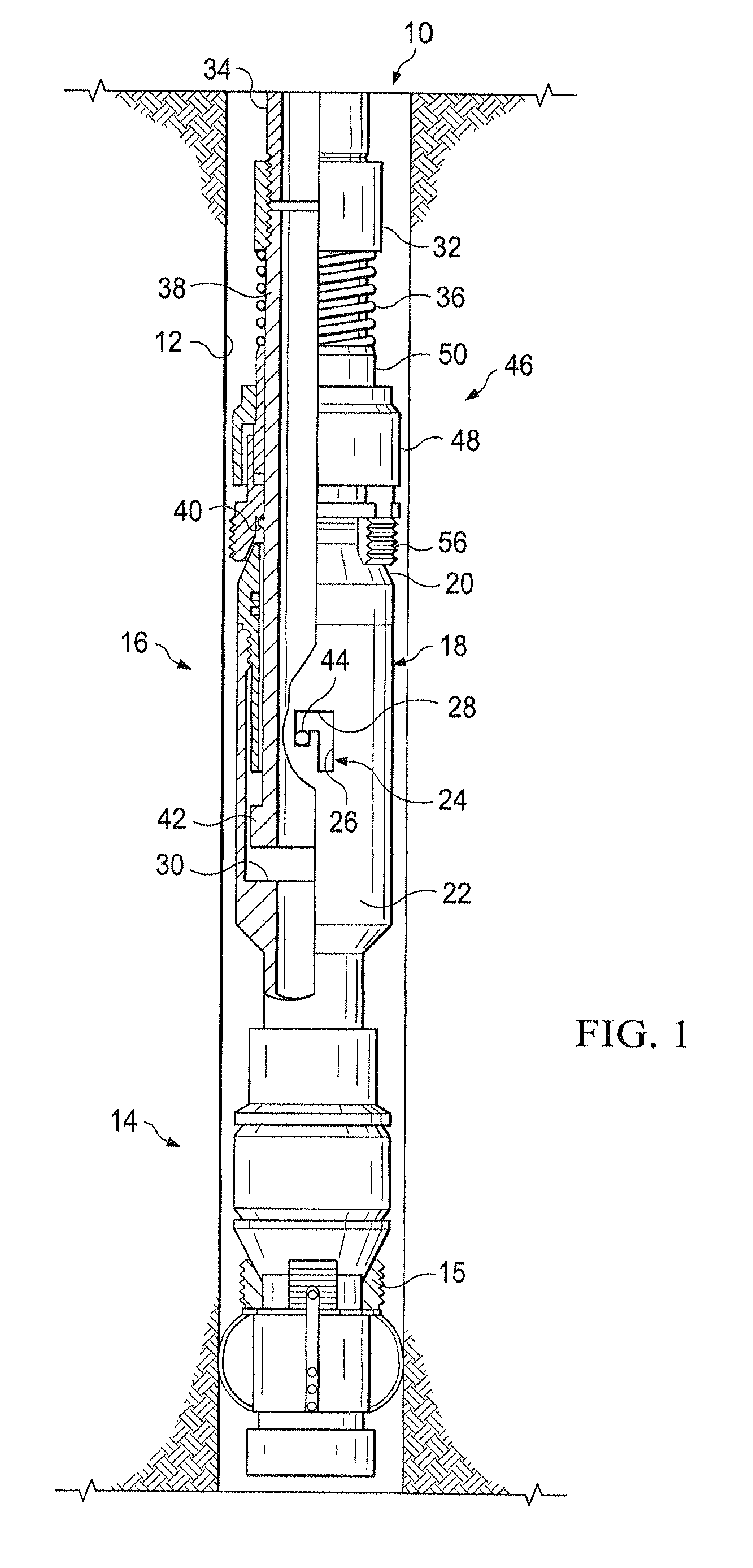

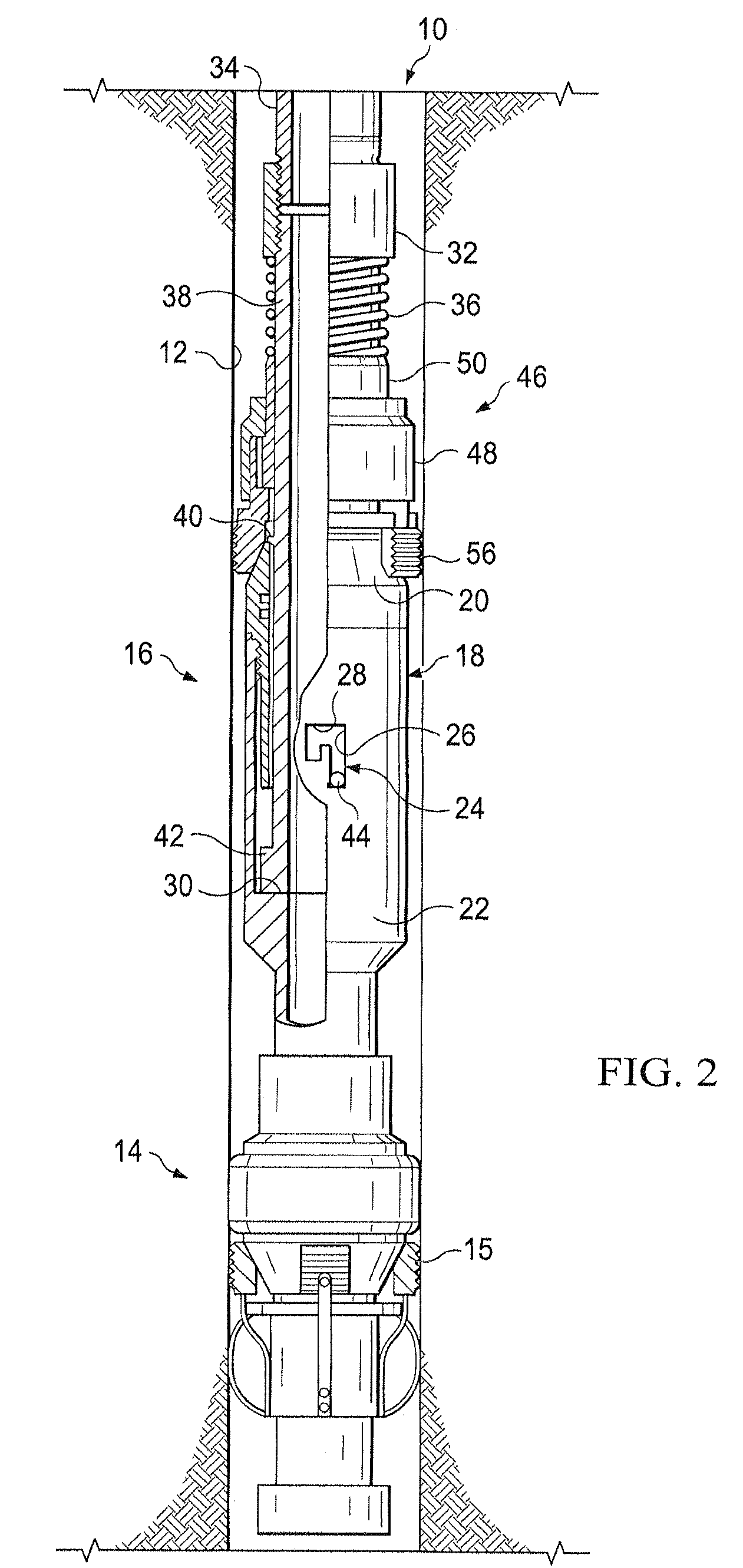

[0022]Referring first primarily to FIGS. 1 and 2, shown is well bore 10 having a wall 12. A packer 14 is shown lowered into well bore 10. Packer 14 includes an expansible element such as packer slips 15 for selectively engaging wall 12. A hold down tool 16 is connected to packer 14. Hold down tool 16 includes a cone assembly 18. Cone assembly 18 has an upwardly facing cone 20 and an outer casing 22. Outer casing 22 defines a j-slot 24 having a long vertical section 26 and a short horizontal section 28. Cone assembly 18 further defines an internal abutment 30.

[0023]A coupling member 32 is attached to an upper end of hold down tool 16. A tubing string 34 is connected to coupling member 32 for supporting hold down tool 16 and packer 14 within well bore 10.

[0024]A spring 36 is located above hold down tool 16. Spring 36 has an upper end in abutment with coupling member 32. A cylindrical mandrel 38 extends downwardly inside cone assembly 18. Mandrel 38 defines a protuberance 40 and has a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com