Thermoplastic container, in particular a bottle, having a partially prismatic triangular body

a triangular body, partially prismatic technology, applied in the direction of containers, rigid containers, packaging, etc., can solve the problems of reducing the cost of containers to a minimum, affecting the appearance of the container, and the edges of the container to break, so as to improve the appearance, simplify the shape of the mould cavity, and improve the effect of shap

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

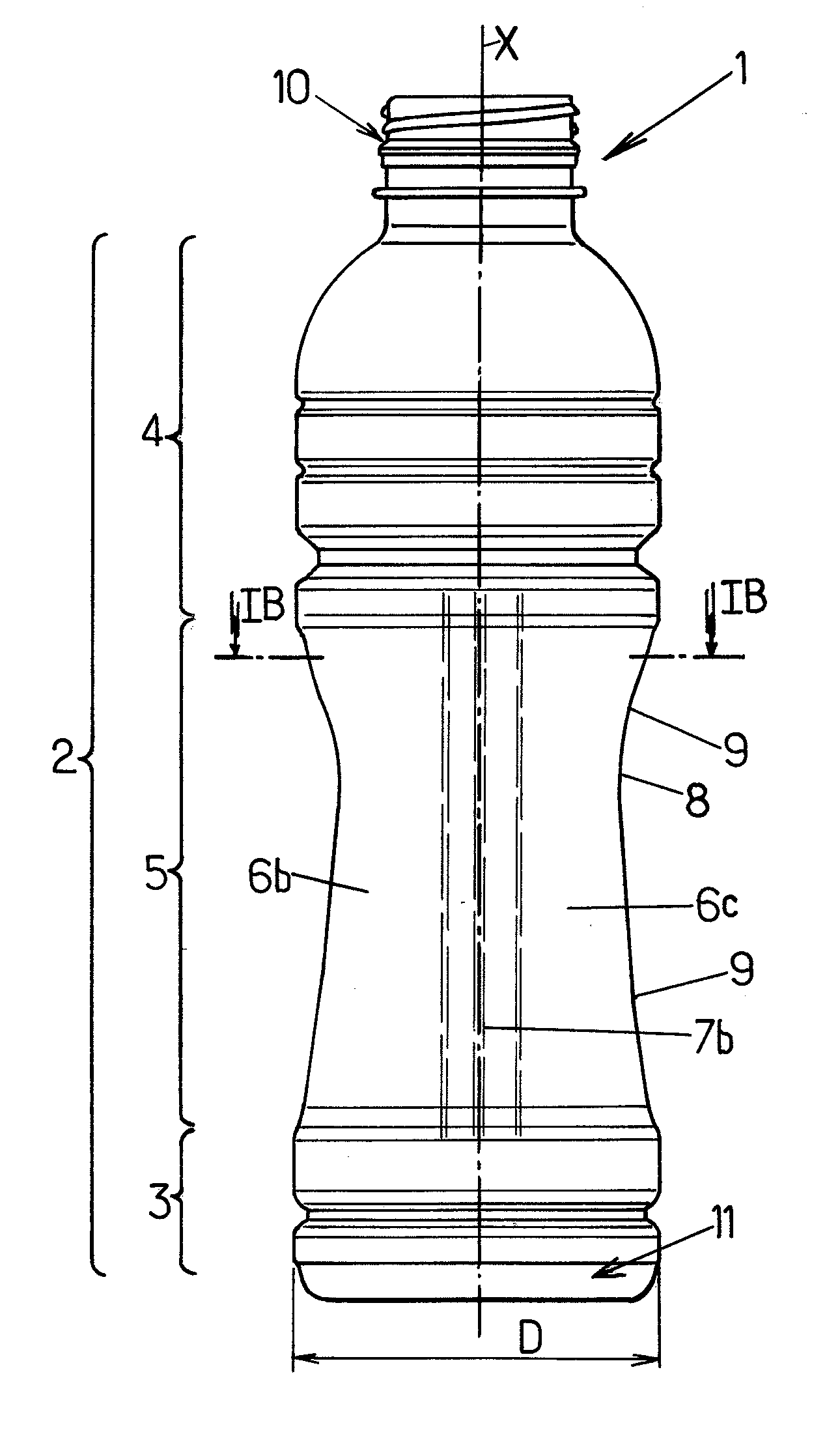

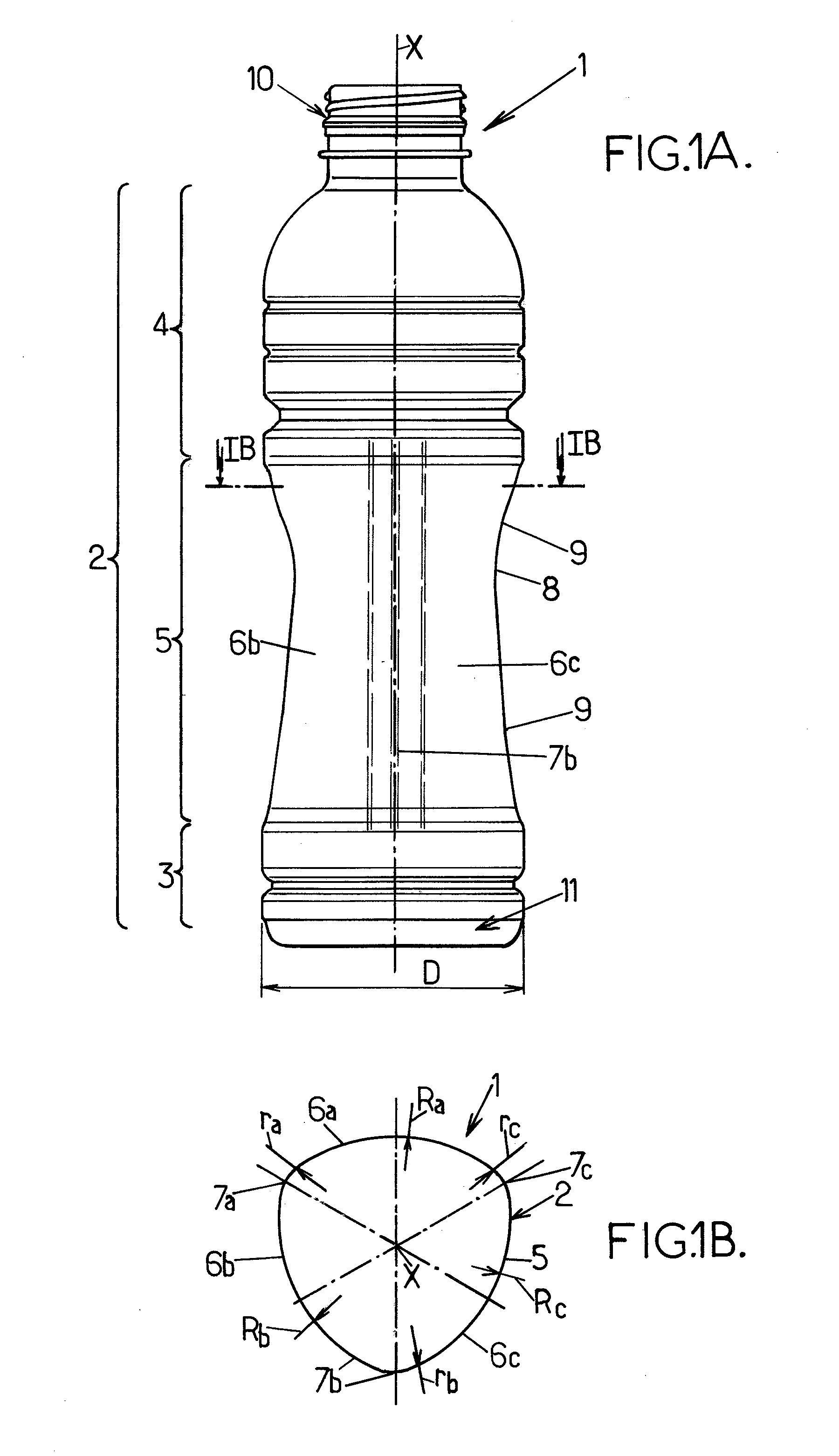

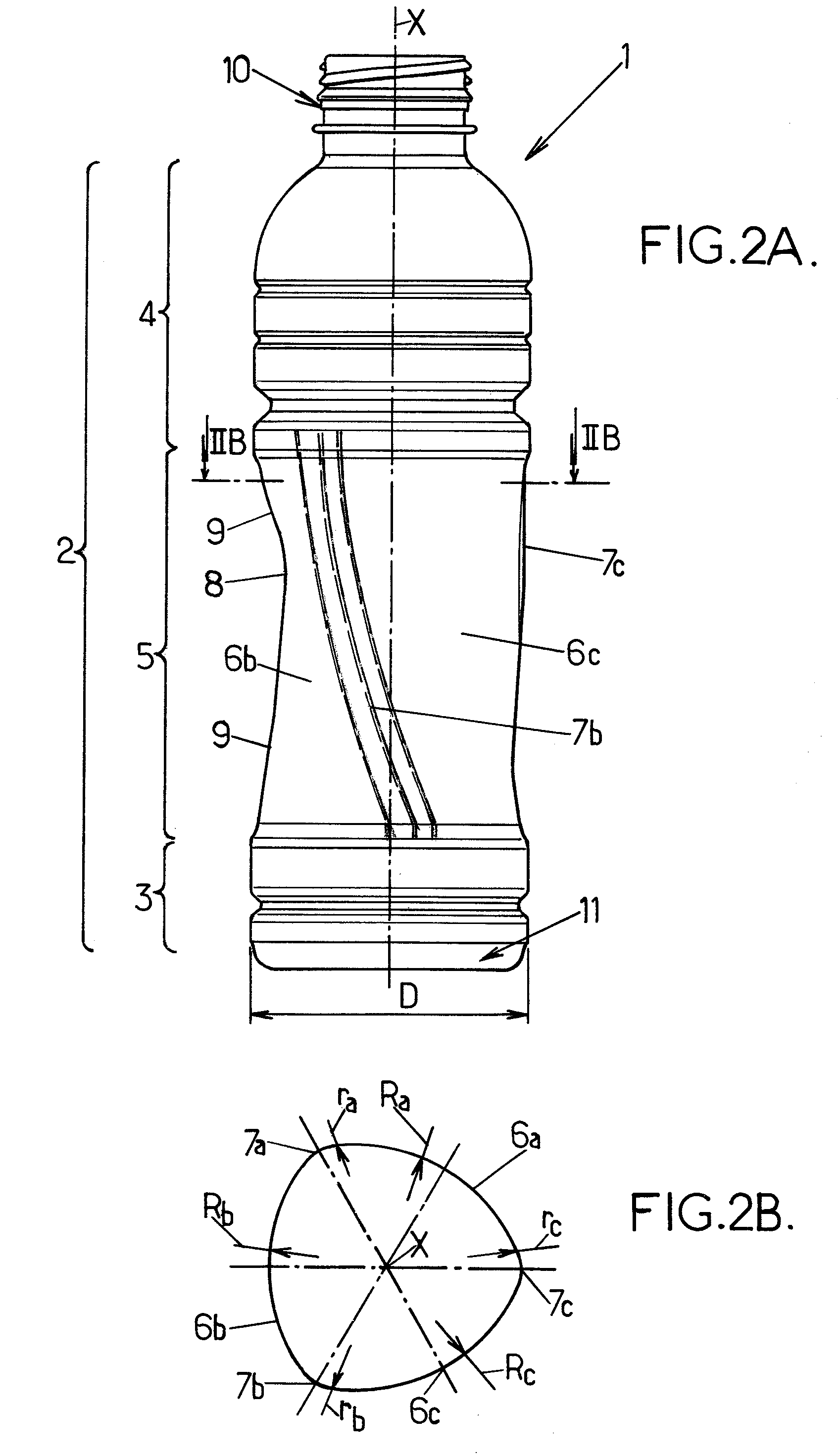

[0028]Reference will firstly be made to FIGS. 1A and 1B which show diagrammatically a container 1 such as a bottle made of thermoplastic material such as PET, which after filling and sealing is able to withstand without any substantial deformation to an internal pressure lower than atmospheric pressure.

[0029]The container 1 comprises a neck 10, a base or bottom 11 and a body 2 which extends between said neck and said base and has:[0030]a substantially cylindrical lower part 3,[0031]a substantially cylindrical upper part 4, and[0032]an intermediate part 5 which has (see FIG. 1B) an approximately prismatic triangular and curvilinear general shape, i.e. it has a cross section which is generally substantially triangular and curvilinear in shape inscribed within the respective contours of said lower part 3 and upper part 4, this intermediate part 5 comprising three main faces 6a, 6b, 6c joined by three edges 7a, 7b, 7c.

[0033]In the following, reference will be made to the axis X of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com