Sole Structure With Magnetic Cushion

a cushion and sole technology, applied in the field of sole structure with magnetic cushion, can solve the problems of insufficient buffering effect, unstable structure, and inability to provide enhanced jumping ability to users, so as to improve the buffering effect, increase the comfort of wearing shoes, and improve the effect of buffering

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

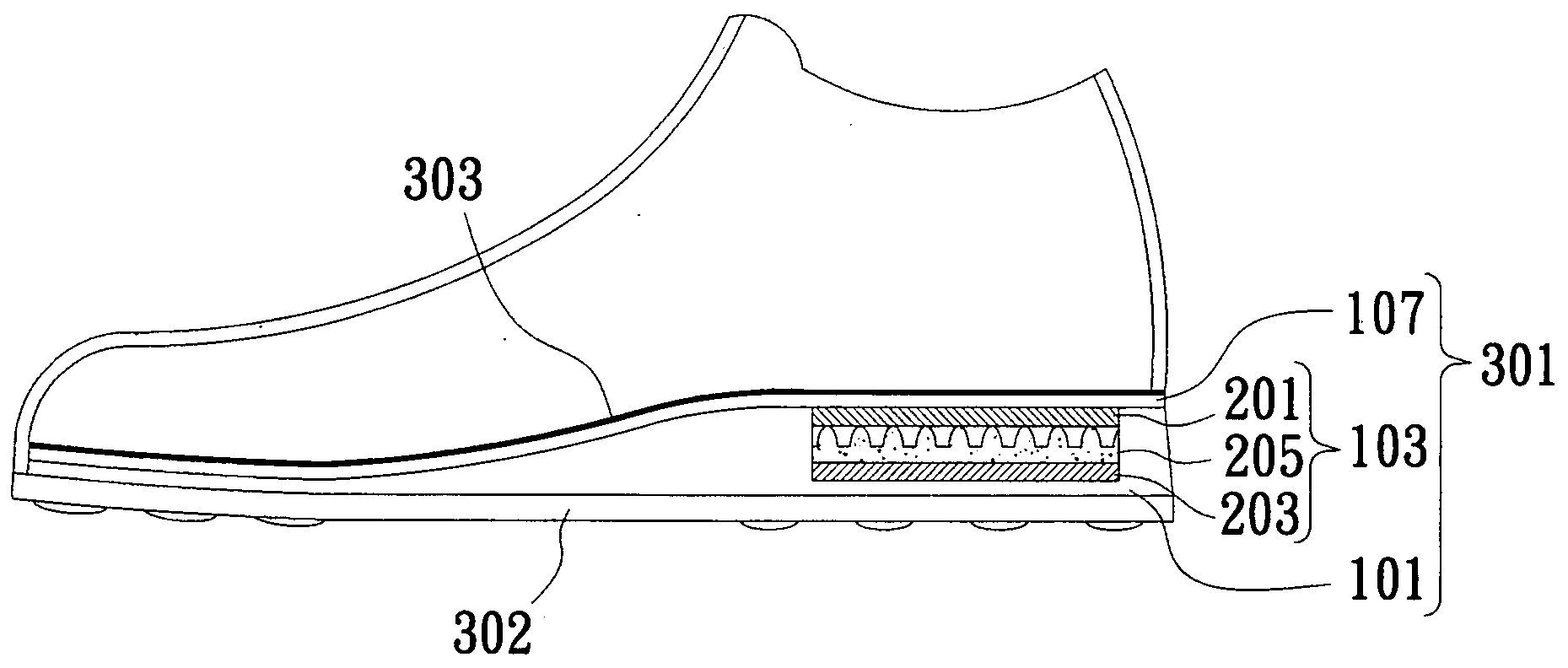

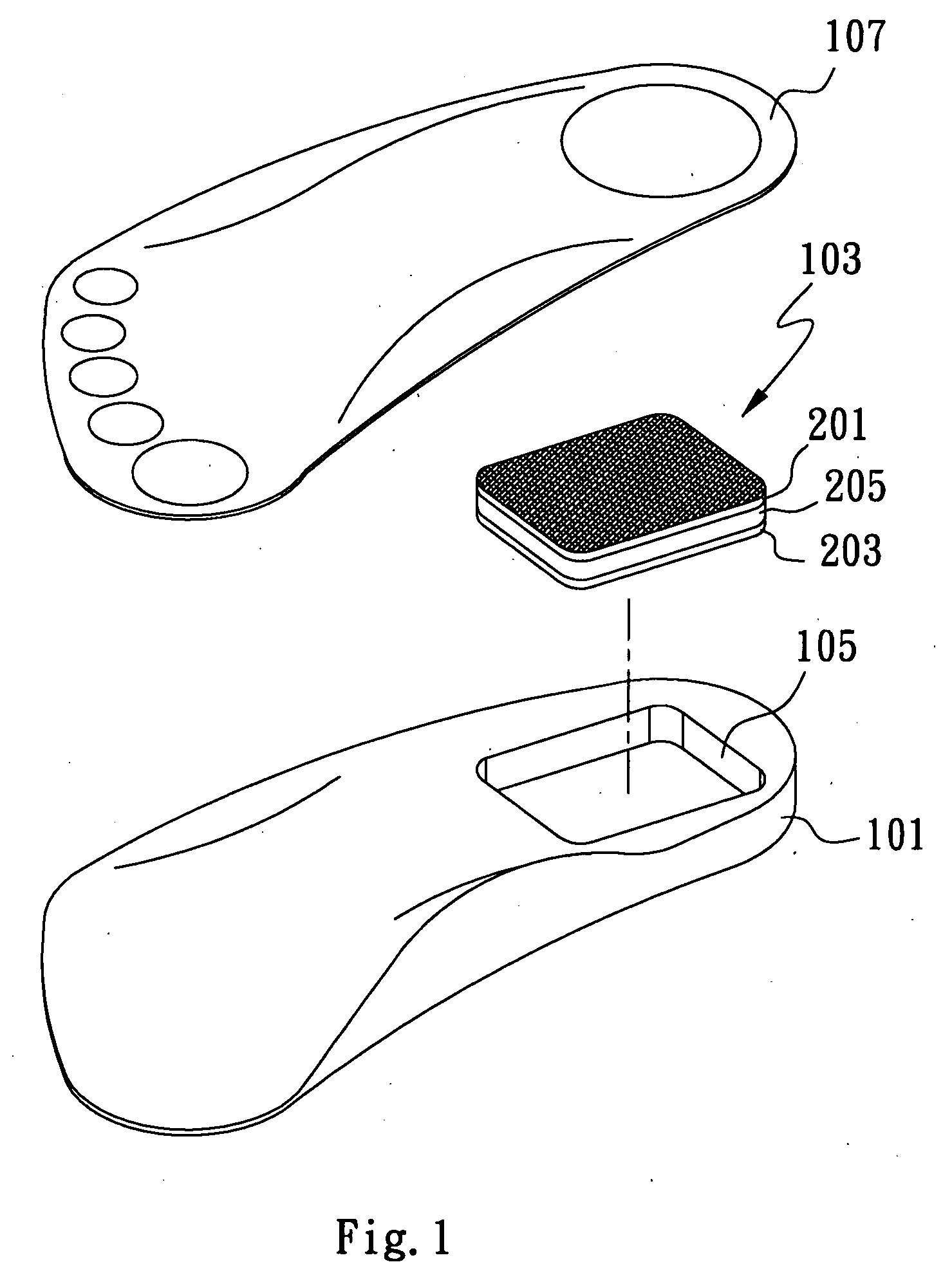

[0011]Please refer to FIGS. 1 and 3 at the same time. A sole structure with magnetic cushion according to the present invention is generally denoted by a reference numeral 301 and includes an outsole 302, a midsole main body 101, a magnetic cushion 103, a foam rubber layer 107, and an insole 303. As can be clearly seen from FIG. 1, the midsole main body 101 is formed at a heel portion thereof with an open-topped recess 105, in which the magnetic cushion 103 is positioned. The foam rubber layer 107 is located on a top of the midsole main body 101 to seal the magnetic cushion 103 in the recess 105 of the midsole main body 101.

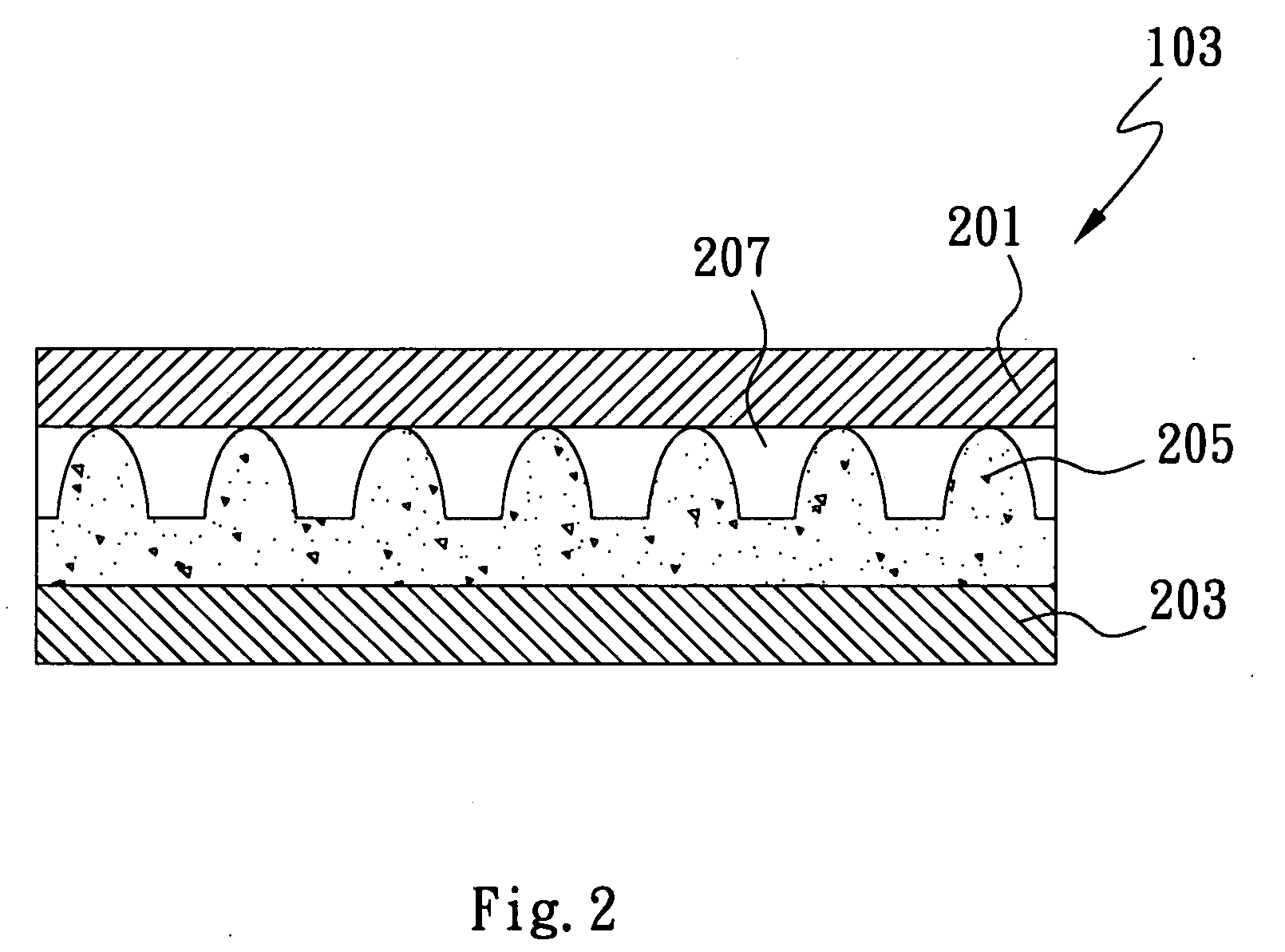

[0012]Referring to FIG. 2, which is a sectional view of the magnetic cushion 103. As shown, the magnetic cushion 103 is a laminated structure including three layers, namely, a first magnetic element 201, a foam rubber spacer 205, and a second magnetic element 203. The first magnetic element 201 and the second magnetic element 203 are arranged with their poles of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| area | aaaaa | aaaaa |

| area | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com