Antiskid latex glove and manufacturing method thereof

a technology of latex gloves and manufacturing methods, applied in gloves, clothing, garments, etc., can solve the problem that the anti-skid ability is not good enough to have an ideal protection effect, and achieve the effect of good anti-skid ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

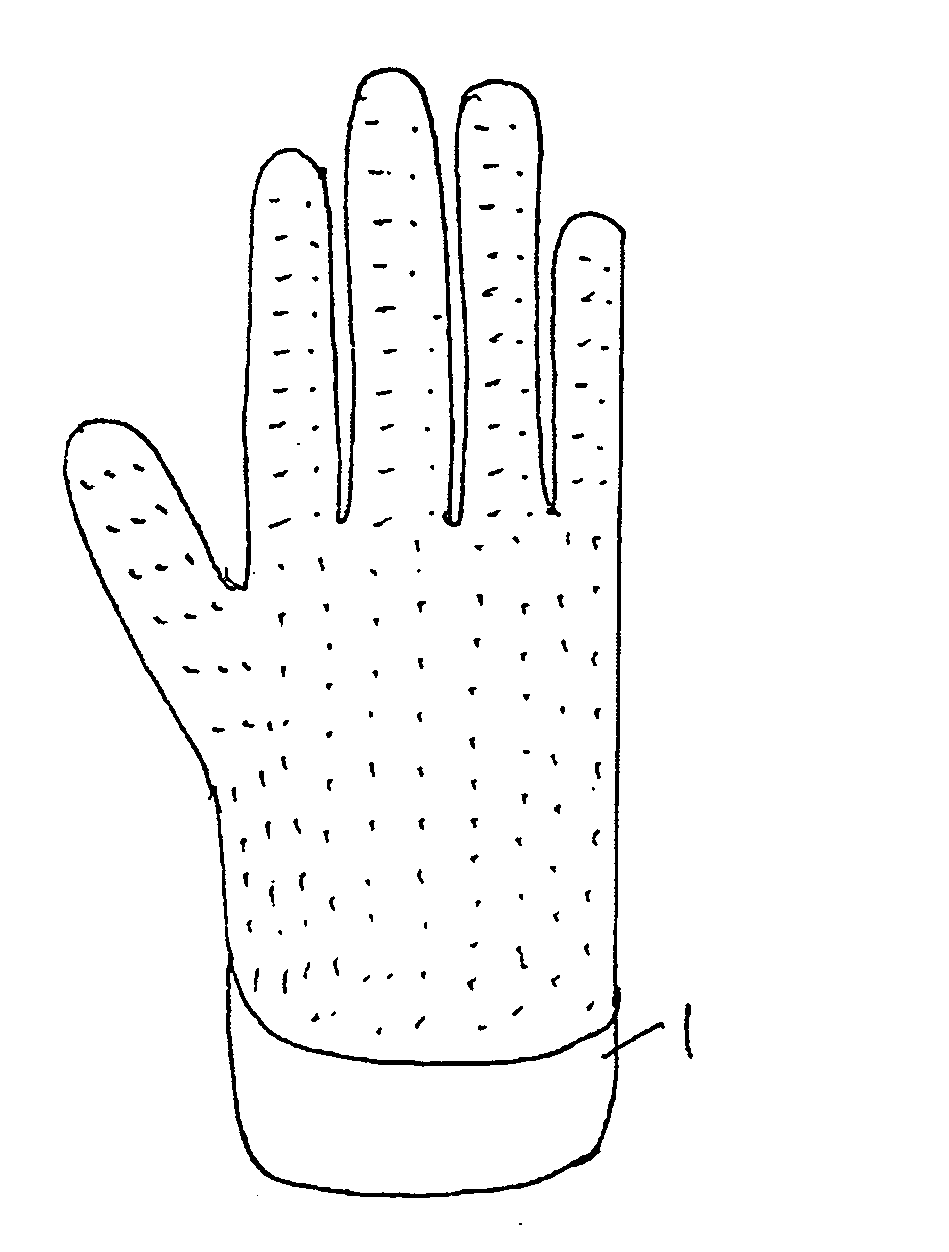

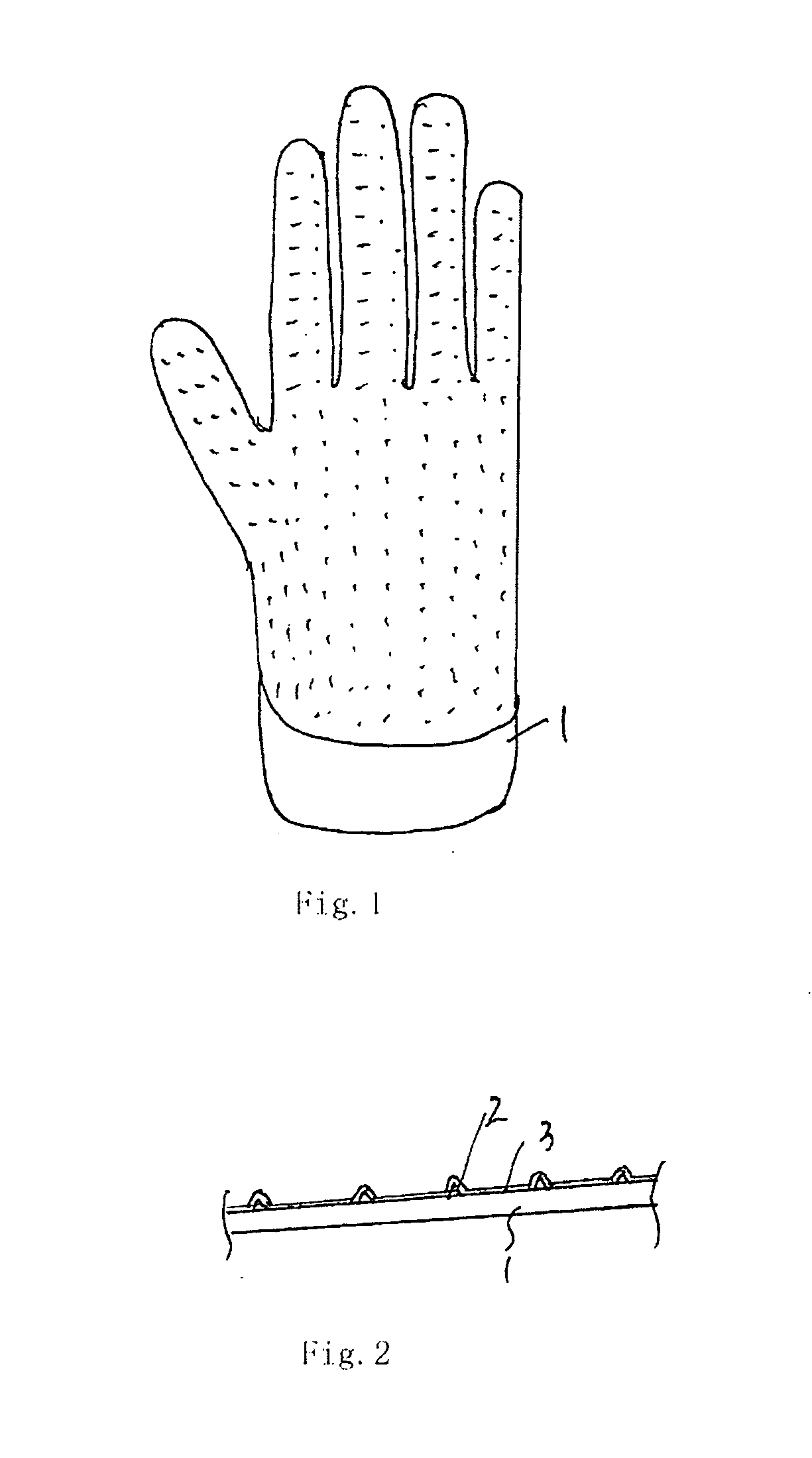

Image

Examples

Embodiment Construction

[0029]A method of manufacturing antiskid rubberized protective glove firstly comprises a step of providing dots made of PVC material on a glove base 1, that is to say, dotting directly on the glove base with PVC material so as to form dots thereon. During the dotting process, the dots are evenly or unevenly provided on a palm side of the glove base, and the dot is cone-shaped. Then drying, setting the dots and dipping the glove base with chemical latex material, such as NBR latex, natural latex, PU, PVC, and so on. And the product is obtained after regular process of drying, complementing sulfur, cleaning up, checking, packing, and so on. The product comprises glove base 1, a latex layer 3 coated on the glove base, and a PVC antiskid dot layer 4 provide between the glove base and the latex layer. The dot is cone-shaped for further increasing the antiskid ability.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com