Food processing machine

a technology of food processing machine and cover, which is applied in the direction of grain treatment, rotary stirring mixer, mixing, etc., can solve the problems of difficult dispensing of heavy hot liquid, inability of the cover to latch onto the container, etc., and achieve the effect of easy removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

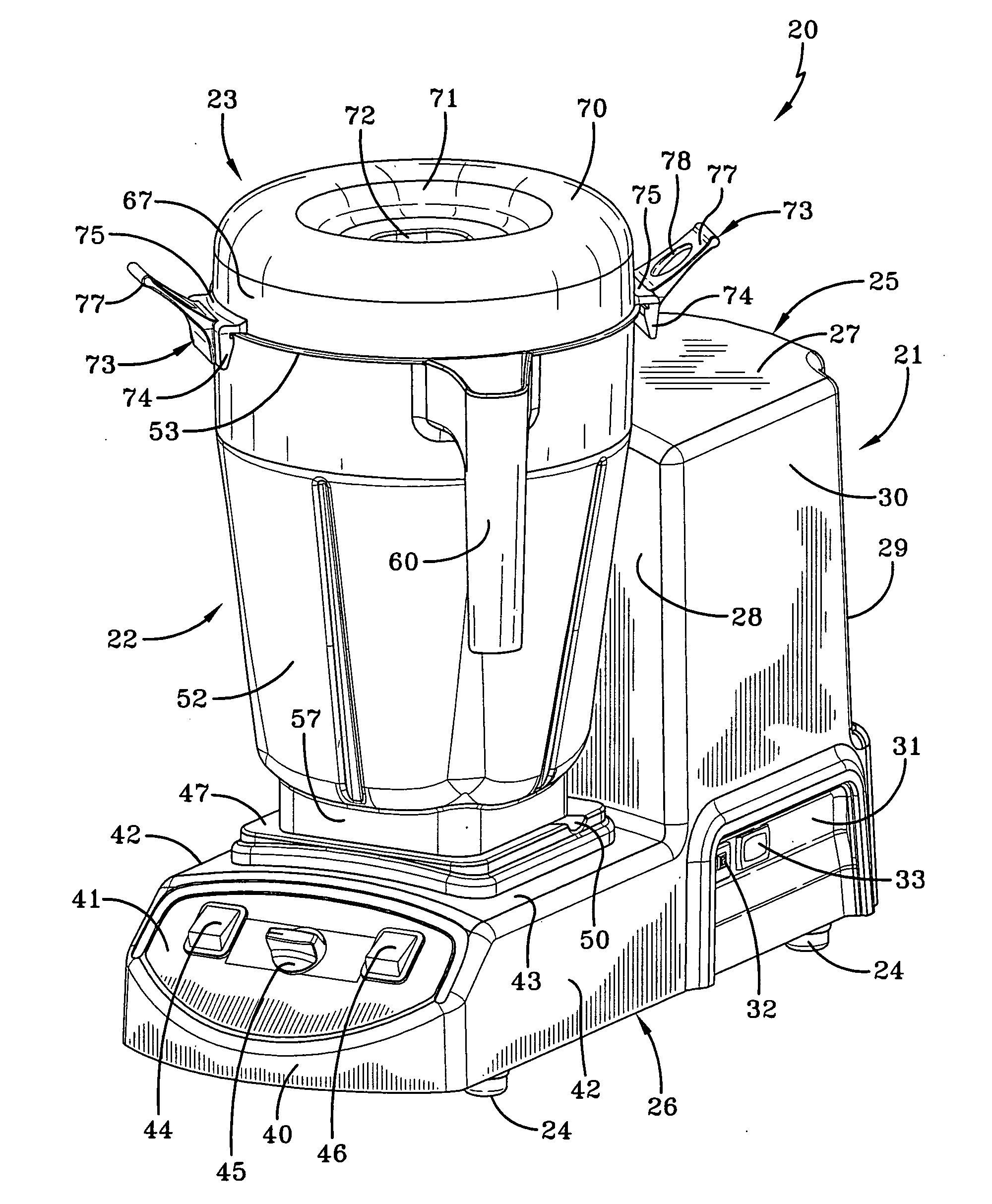

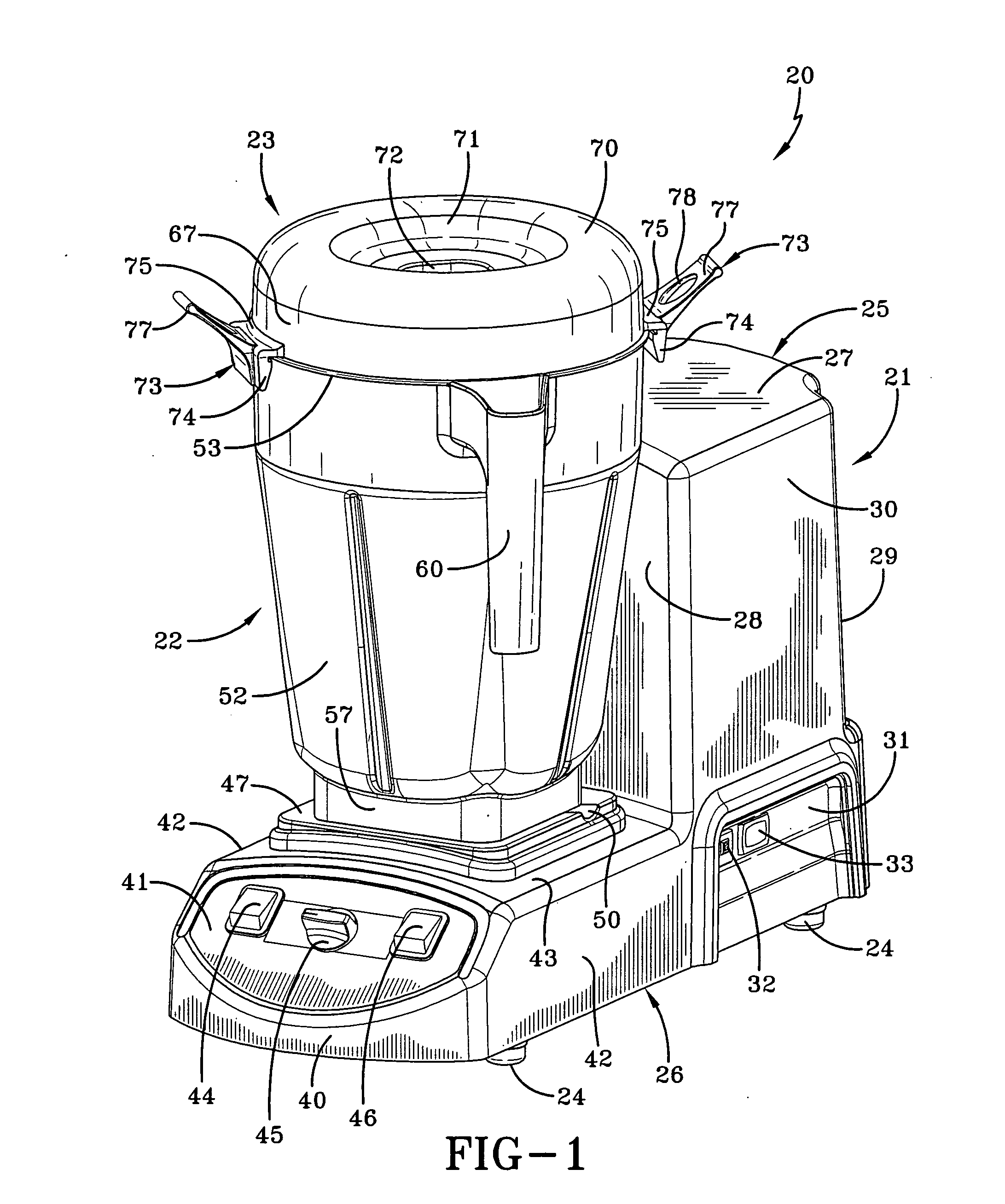

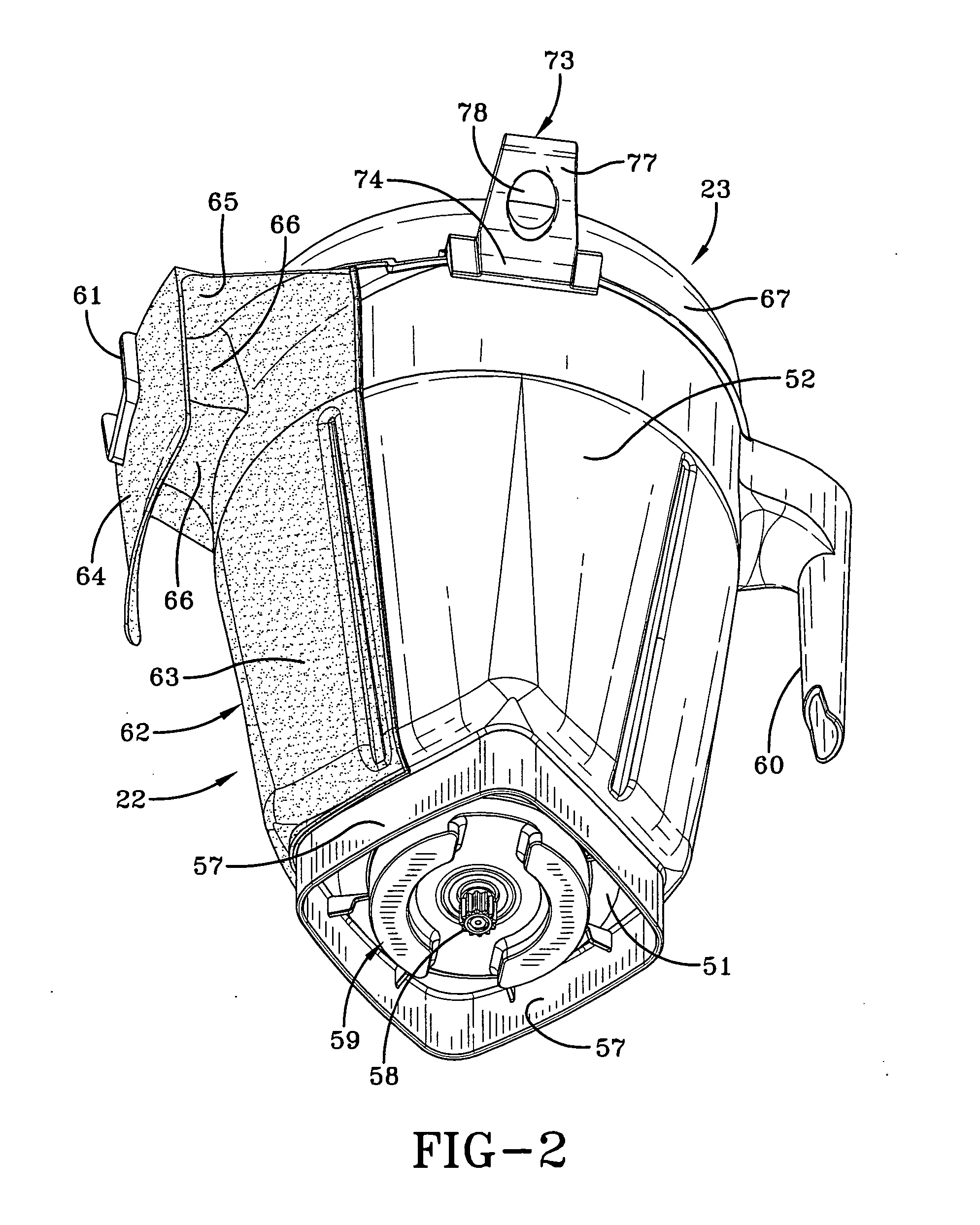

[0027]A food processing assembly is shown in FIG. 1 and is generally indicated by the numeral 20. Assembly 20 includes three basic component parts, a base member indicated generally by the numeral 21, a blender container indicated generally by the numeral 22, and a cover for the container 21 indicated generally by the numeral 23.

[0028]Base member 21 is provided with feet 24 and includes a motor housing portion generally indicated by the numeral 25 and a platform portion generally indicated by the numeral 26. Housing portion 25 includes a top wall 27, opposed front and rear walls, 28 and 29 respectively, and opposed side walls 30 which together with a bottom surface (not shown) house a motor. One of the side walls 30 is provided with a recess 31 which can receive any of several controls such as a circuit breaker 32, a master power switch 33 or the like. Because these controls are recessed, they are protected from accidental contact.

[0029]As shown in FIG. 10, the rear wall 29 of housi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com