Convection Barrier

a technology of convection barrier and seal, which is applied in the field of convection barrier, can solve the problems of unfavorable temperature rise of stored samples, inability to arrange robots in a 80° c. environment, and standard handling devices such as robots, which are not usually used properly, so as to improve the seal of the interior of the freezer, simplify the process of opening and closing the flap, and improve the friction coefficient of the material

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

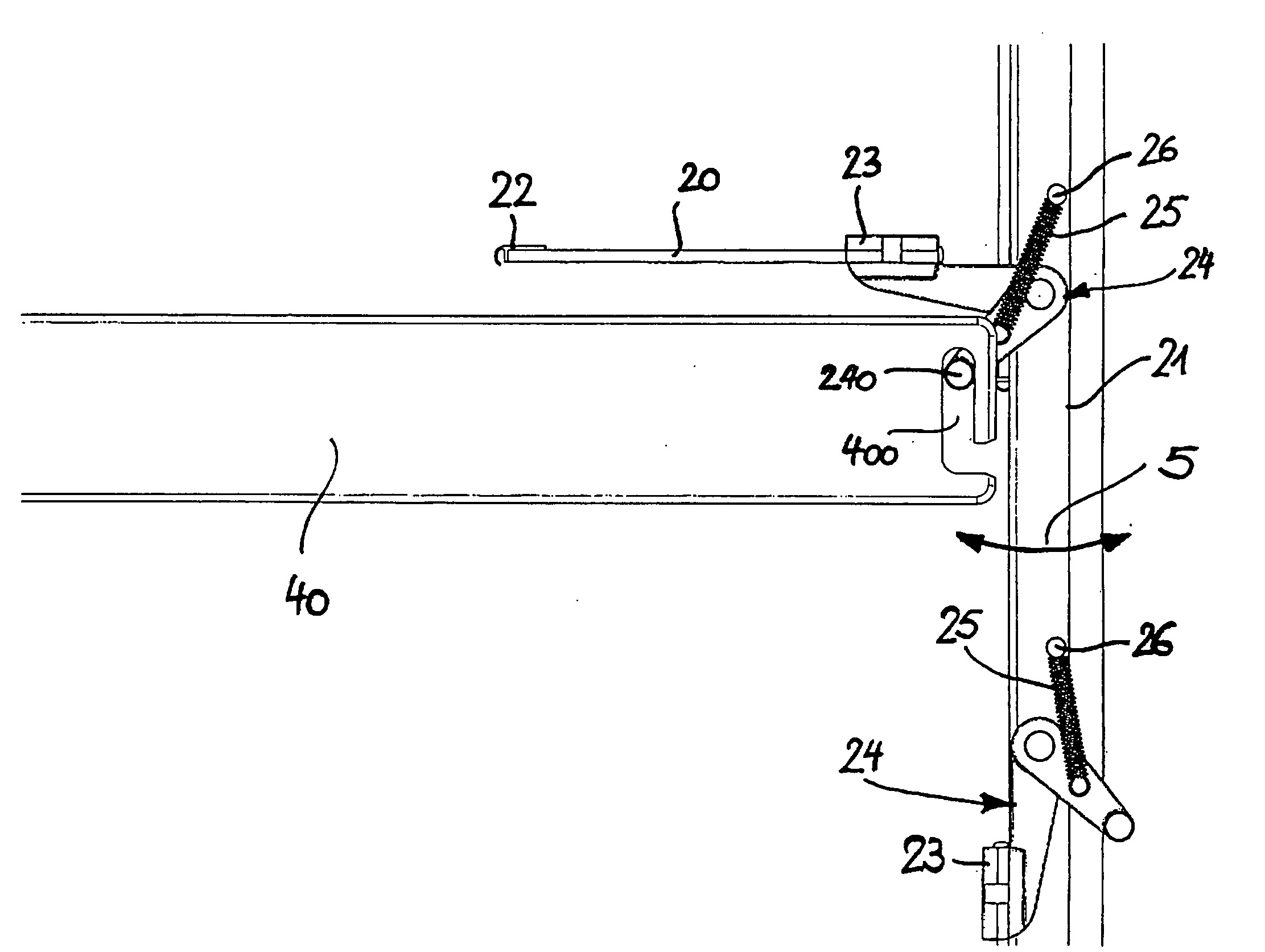

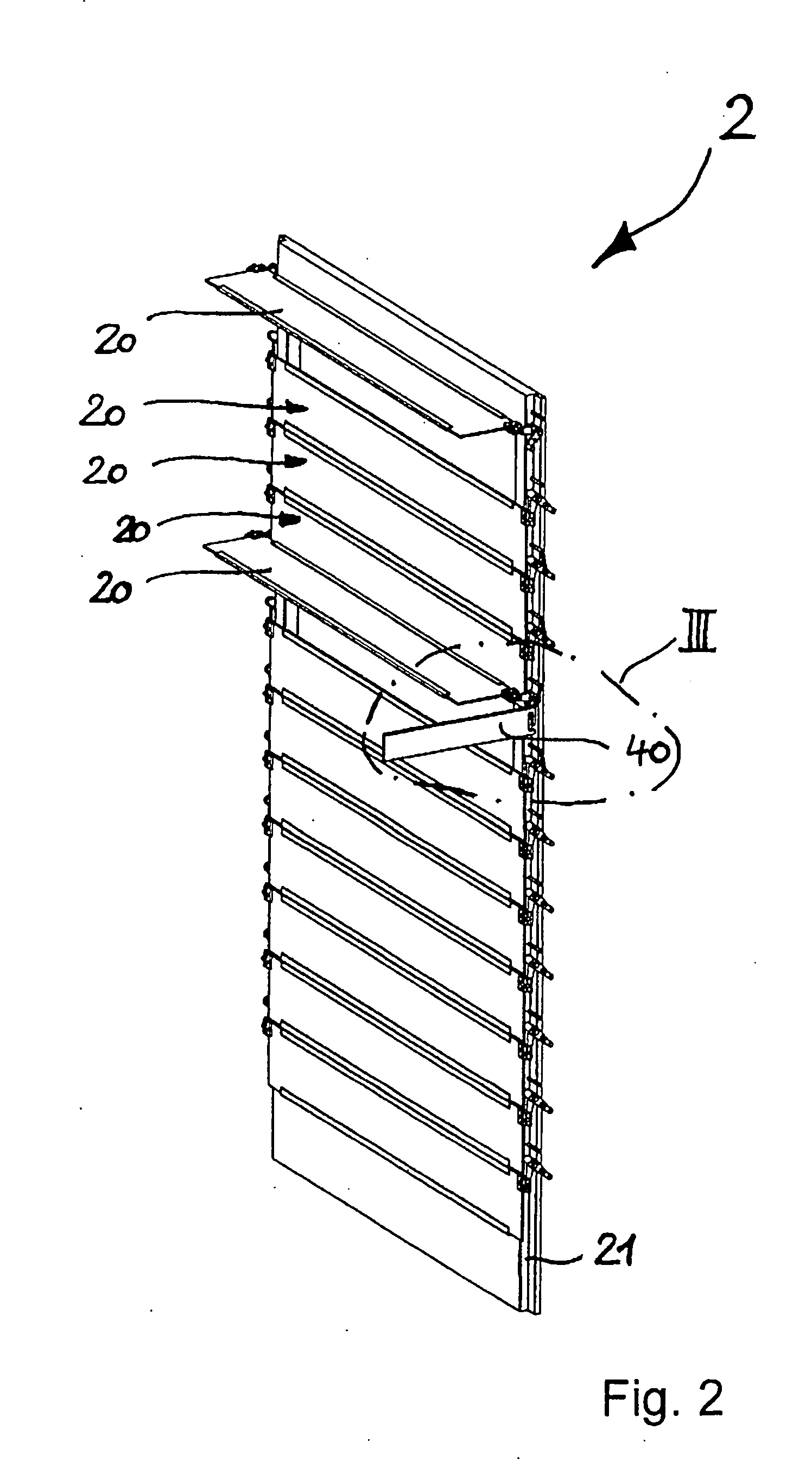

[0025]FIG. 1 shows a perspective view of an embodiment of a freezer 1 according to the invention with an embodiment of a convection barrier 2 according to the invention mounted thereto, with the door of the freezer not being shown in FIG. 1 for the sake of simplicity. Freezer 1 comprises a housing 10 having an opening 11 at the front side of freezer 1. A plurality of compartments are arranged in the interior 12 of freezer 1, in which drawers 3 carrying trays containing the stored samples can be arranged. Also shown schematically in FIG. 1 are parts of a robot 4 for automated access to the samples, in particular an actuator 40 for opening and closing the flaps of the convection barrier 2.

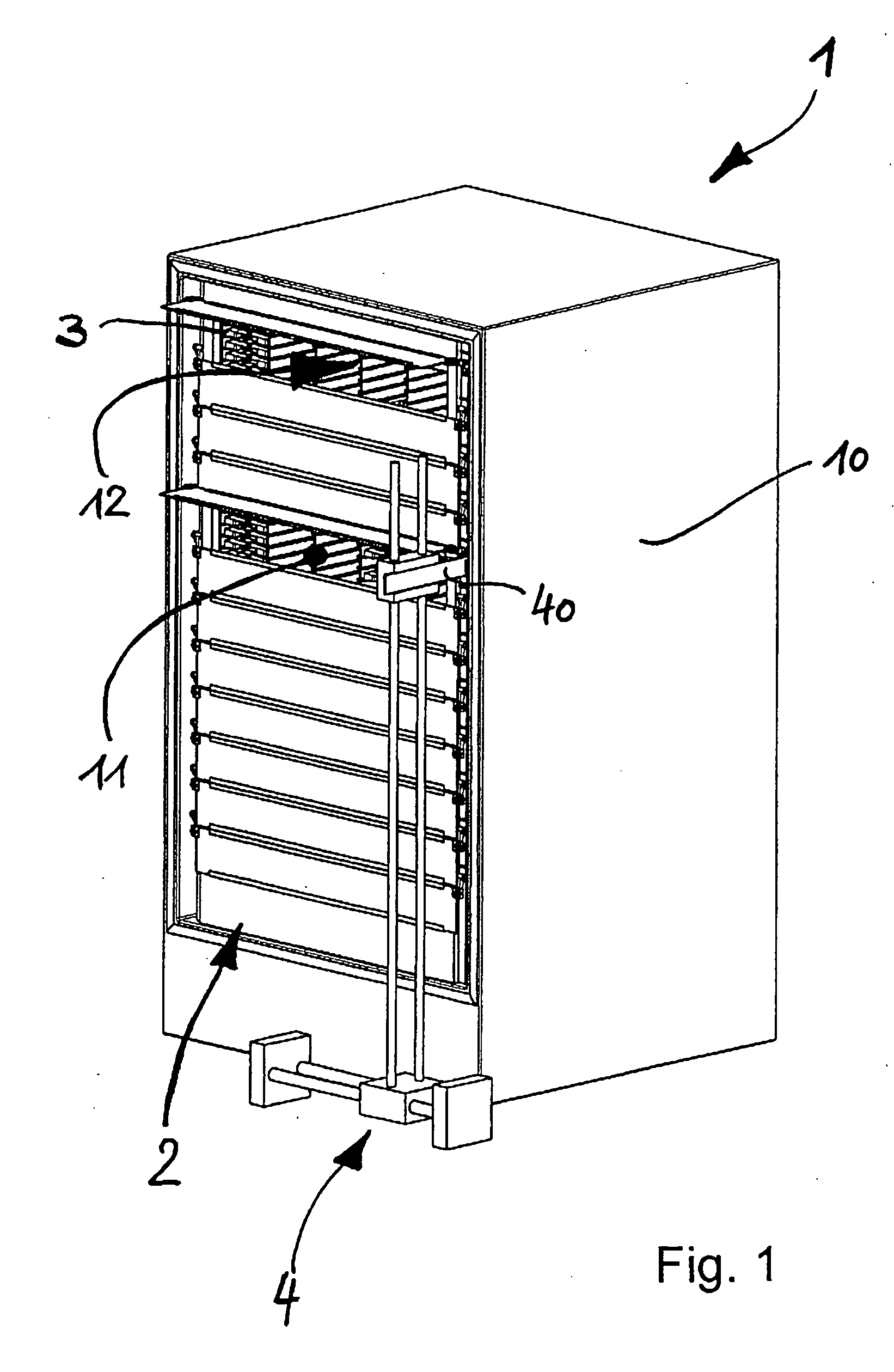

[0026]The embodiment of the convection barrier 2 according to the invention shown in FIG. 1 mounted to freezer 1 is shown in FIG. 2 prior to being mounted to freezer 1. Convection barrier 2 comprises a plurality of individual flaps 20 mounted to an outer frame 21, with flaps 20 being adjacently and a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com