Method of processing maraging steel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

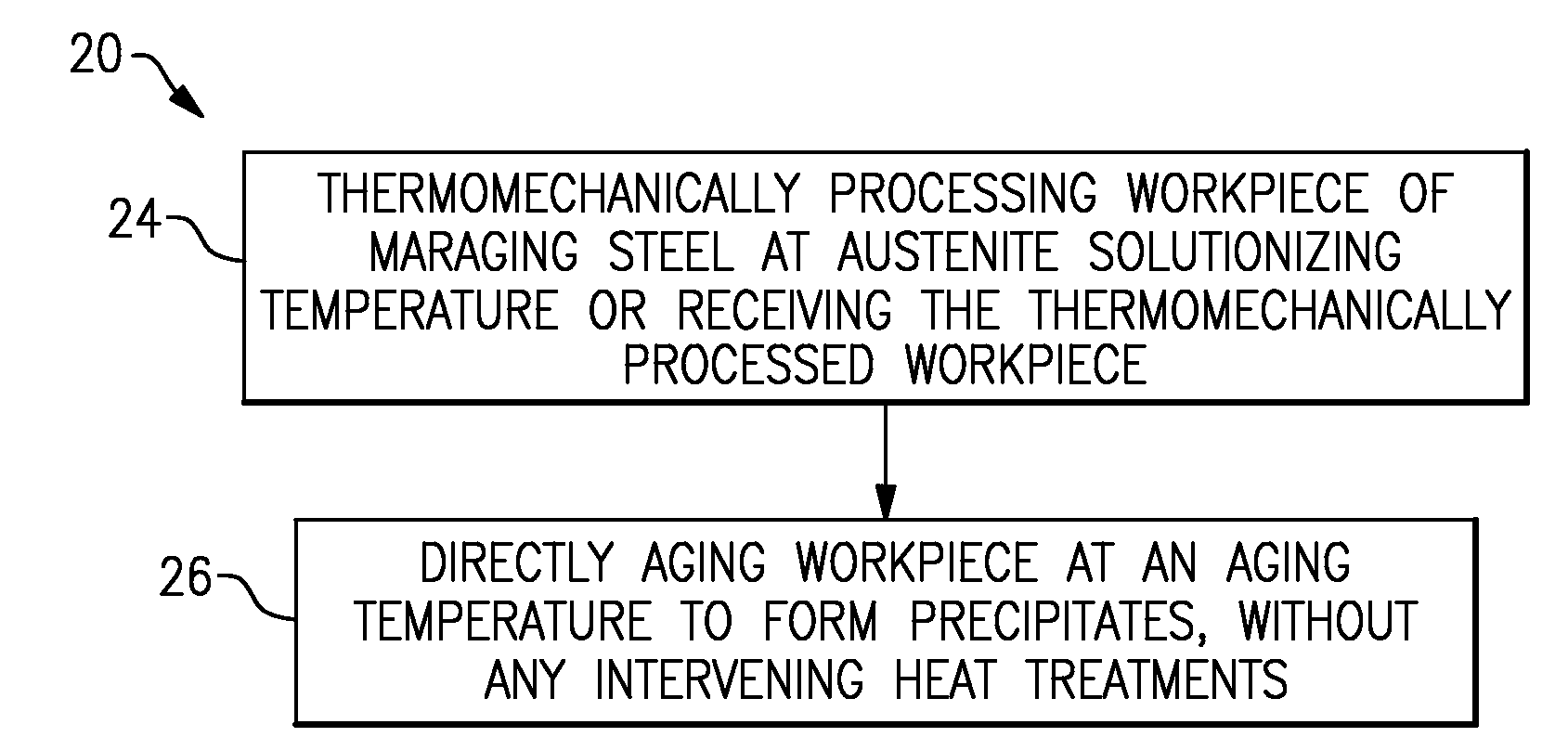

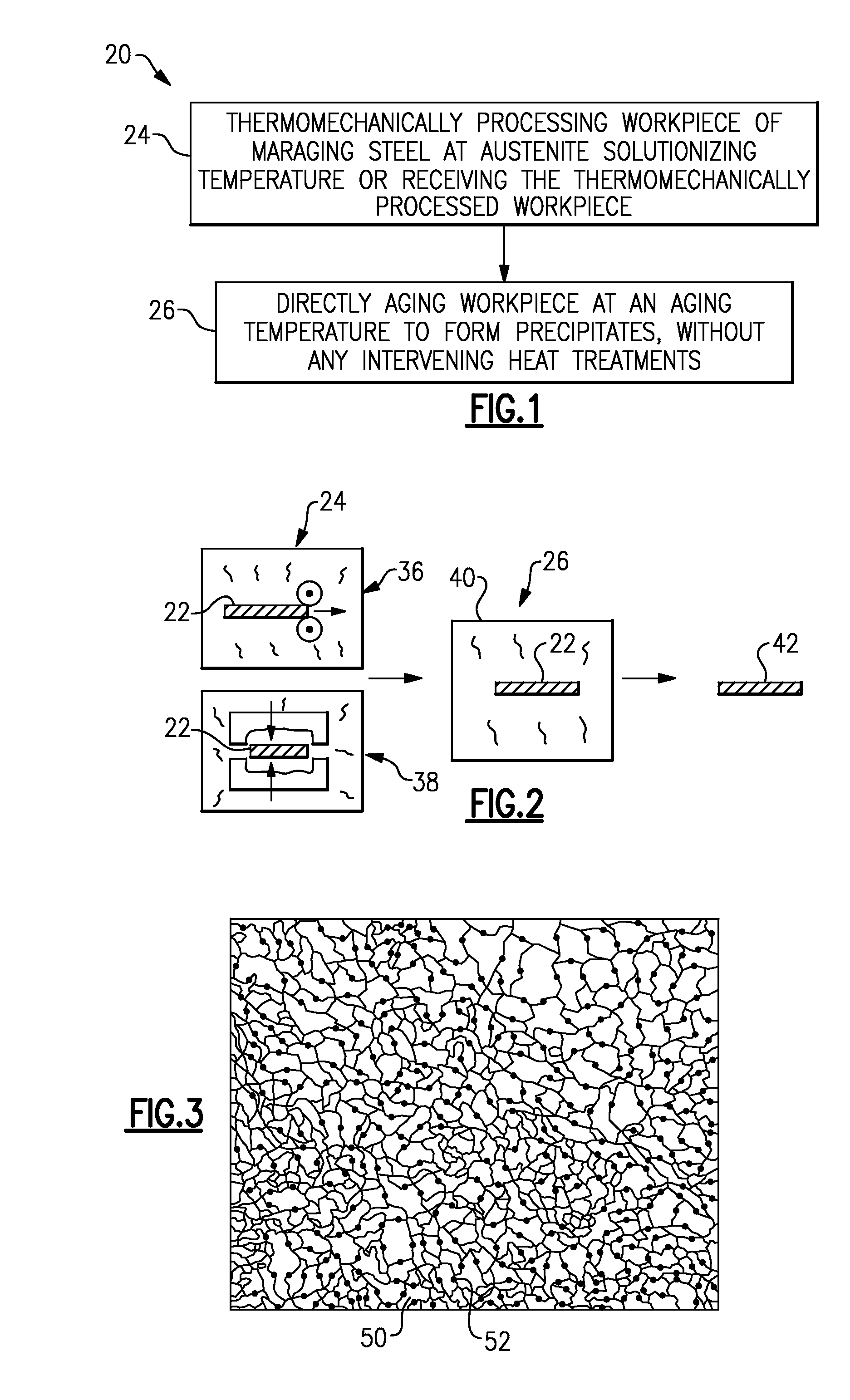

[0012]FIG. 1 illustrates an example method 20 of processing a workpiece of maraging steel 22 (see FIG. 2). The disclosed workpiece of maraging steel 22 may have any form, such as a sheet, ingot, or casting. As will be described, the method 20 may be used to economically process the workpiece of maraging steel 22 to provide improved properties.

[0013]The workpiece of maraging steel 22 is formed of a maraging steel alloy composition. For example, the maraging steel alloy composition includes 17 wt %-19 wt % of nickel, 8 wt %-12 wt % of cobalt, 3 wt %-5 wt % of molybdenum, 0.2 wt %-1.7 wt % of titanium, 0.05 wt %-0.15 wt % of aluminum, and a balance of iron. As can be appreciated, the composition may vary from the given example composition. In some examples, the given composition consists essentially of the given elements and impurities that do not affect the properties of the alloy or elements that are unmeasured or undetectable in the alloy. For example, the alloy generally does not i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com