Micropackaging method and devices

a technology of micro-packaging and components, applied in the direction of micro-structural devices, micro-structural technology, micro-structural device assembly, etc., can solve the problems of incompatibility between the ceramic in the packaging casing and the components inside, the process has inherent drawbacks, and the inability to make very thin walls of such ceramic materials, so as to simplify the manufacturing process and reduce costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

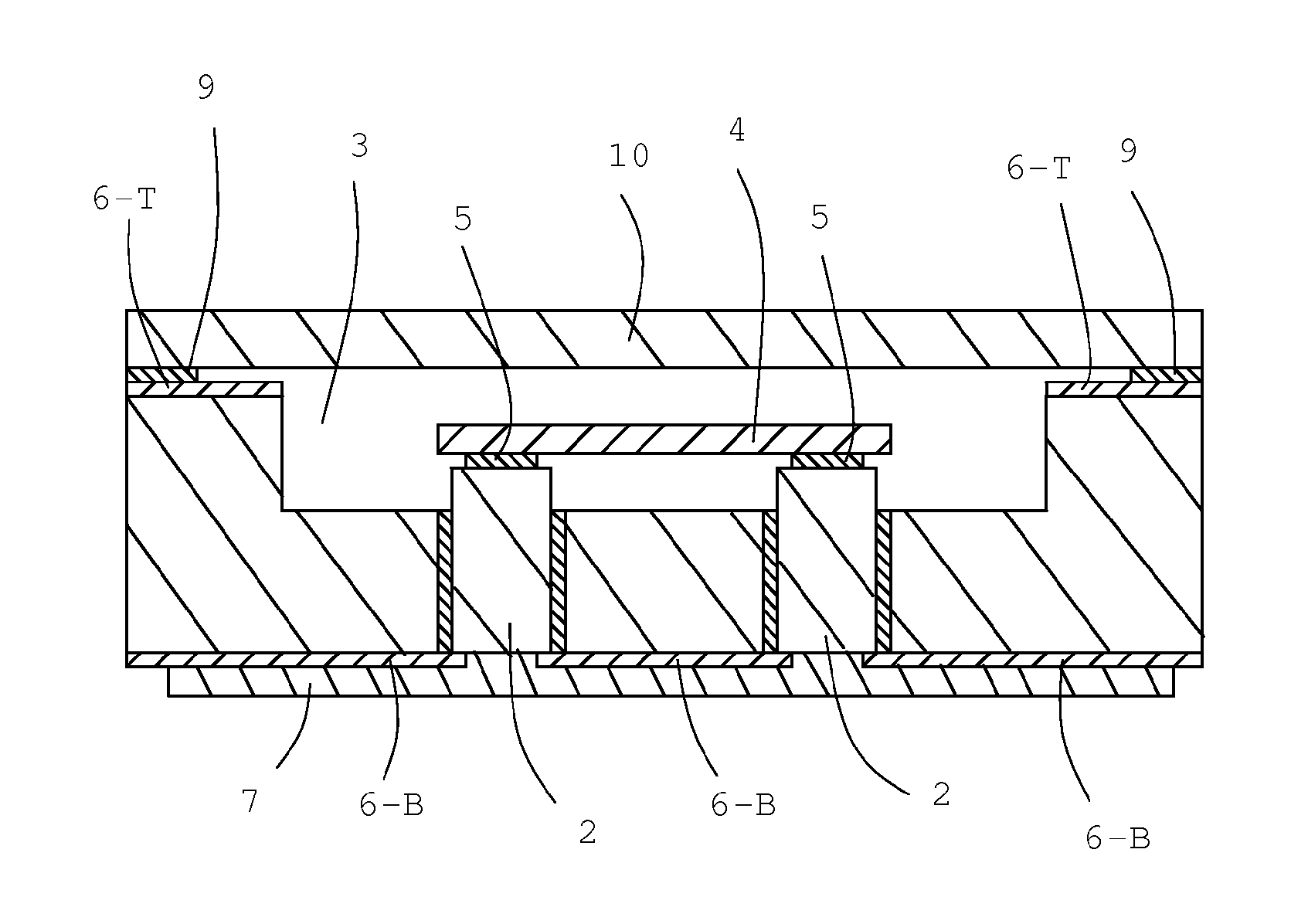

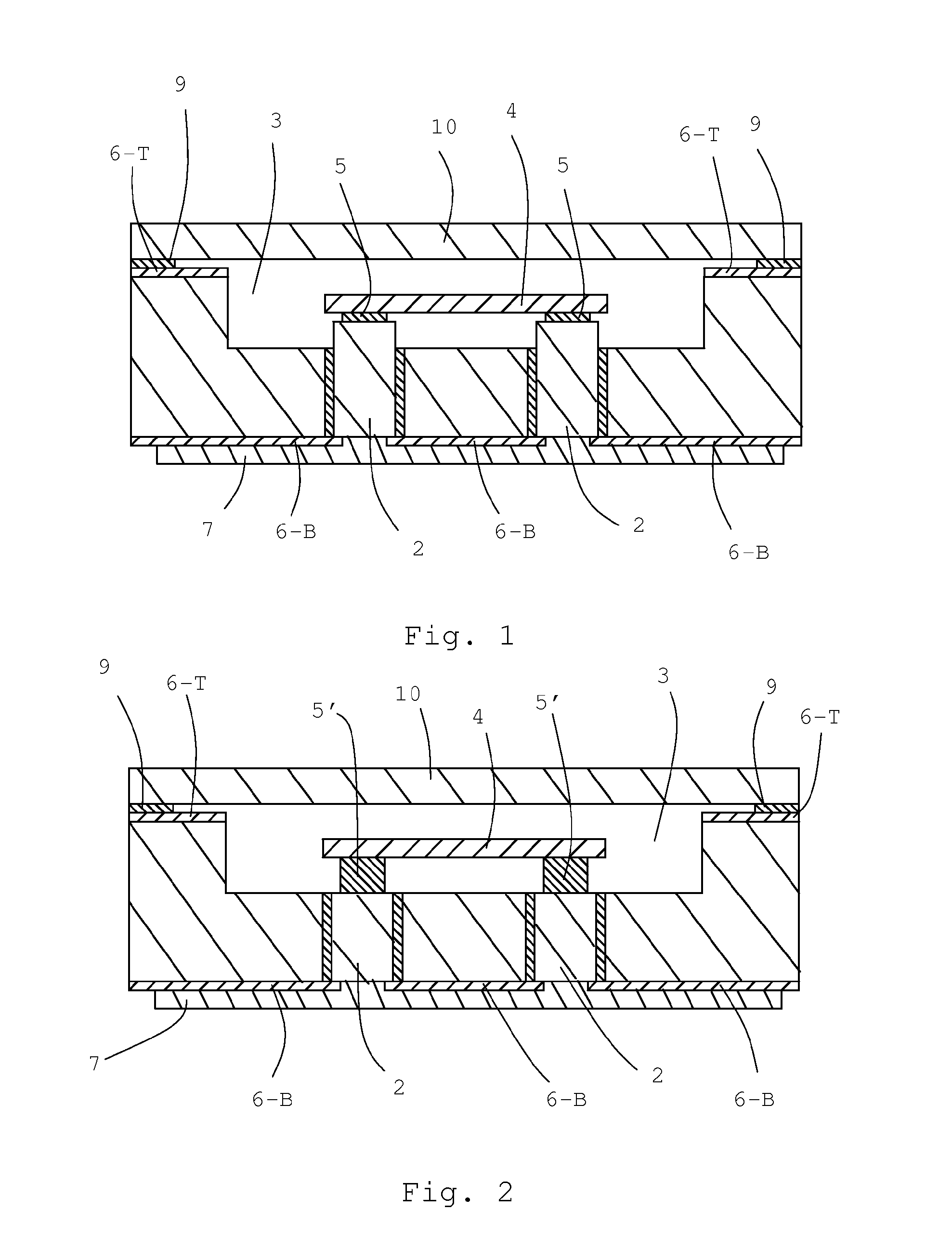

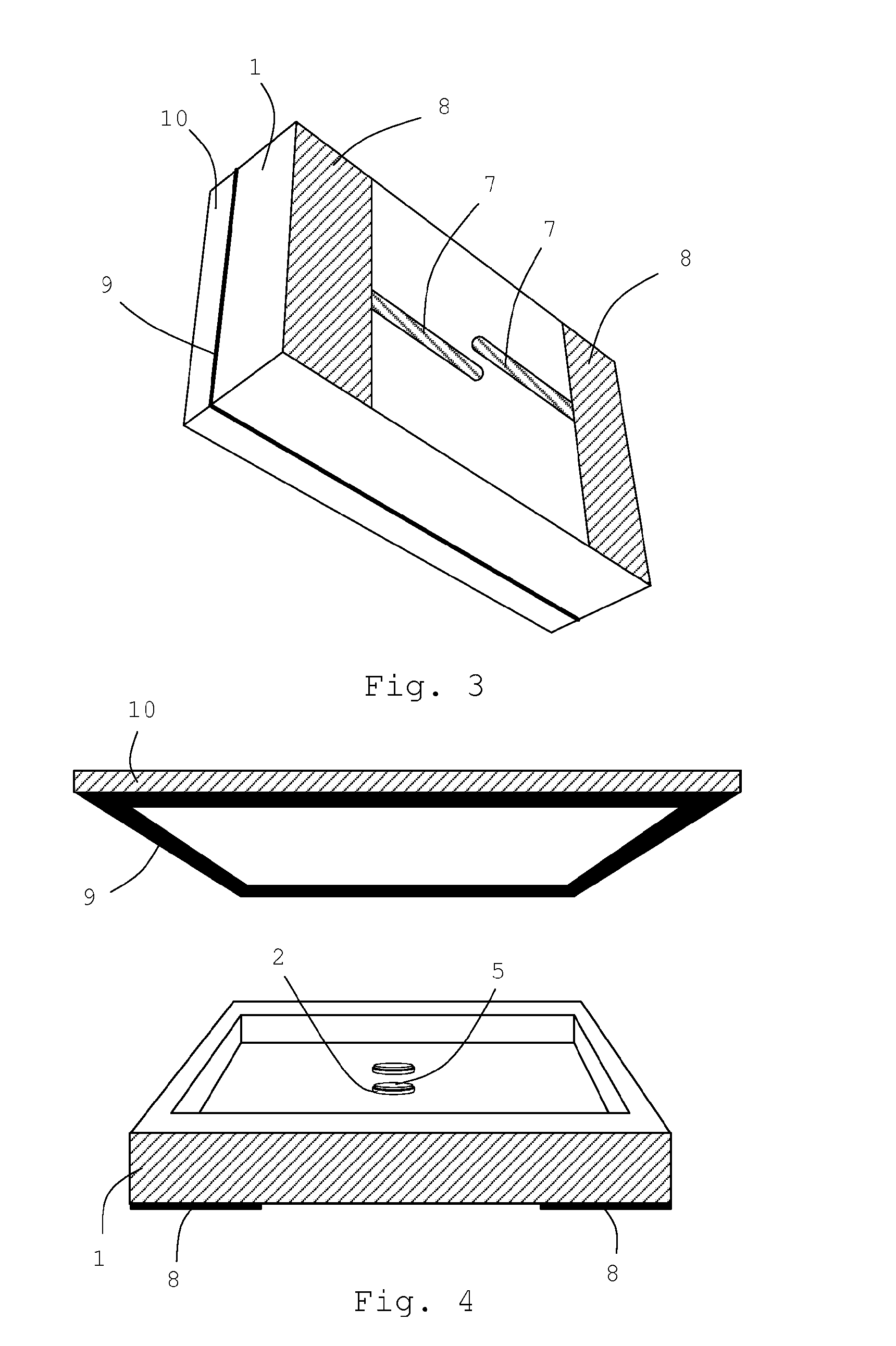

[0037]The invention is based on the use of electrical through connections (or “vias”), which enables connection of packaged micro-components to circuit boards or to other components with the provision of bulky connector legs or pins, and wafer-level hermetic encapsulation. The terms electrical through connection and via are interchangeably used in this application.

[0038]Preferably the starting wafers having said vias are semiconductor wafers, more preferably single crystalline silicon wafers, however not limited to this. The term “semiconductor wafer” also comprises other wafer materials typically used in the field, such as glass wafers and ceramic wafers. The terms wafer and substrate are interchangeably used throughout this application since processing preferably is made on wafer level, i.e. many devices are manufactured in parallel.

[0039]Preferably, the packaged component is made by using a wafer having been provided with vias in accordance with the teachings of the International...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap