Burner the Direction and/or Size of the Flame of Which Can Be Varied, and Method of Implementing It

a burner and flame direction technology, applied in the direction of lighting and heating apparatus, combustion types, combustion using lump and pulverizing fuel, etc., can solve the problems of limiting the number of operating modes, and limiting the complexity and cost of manufacturing the burner. , to achieve the effect of wide variation in the direction and/or aperture of the flame, and limiting the complexity and cost of manufacturing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

Case of Solid Material in the Oven

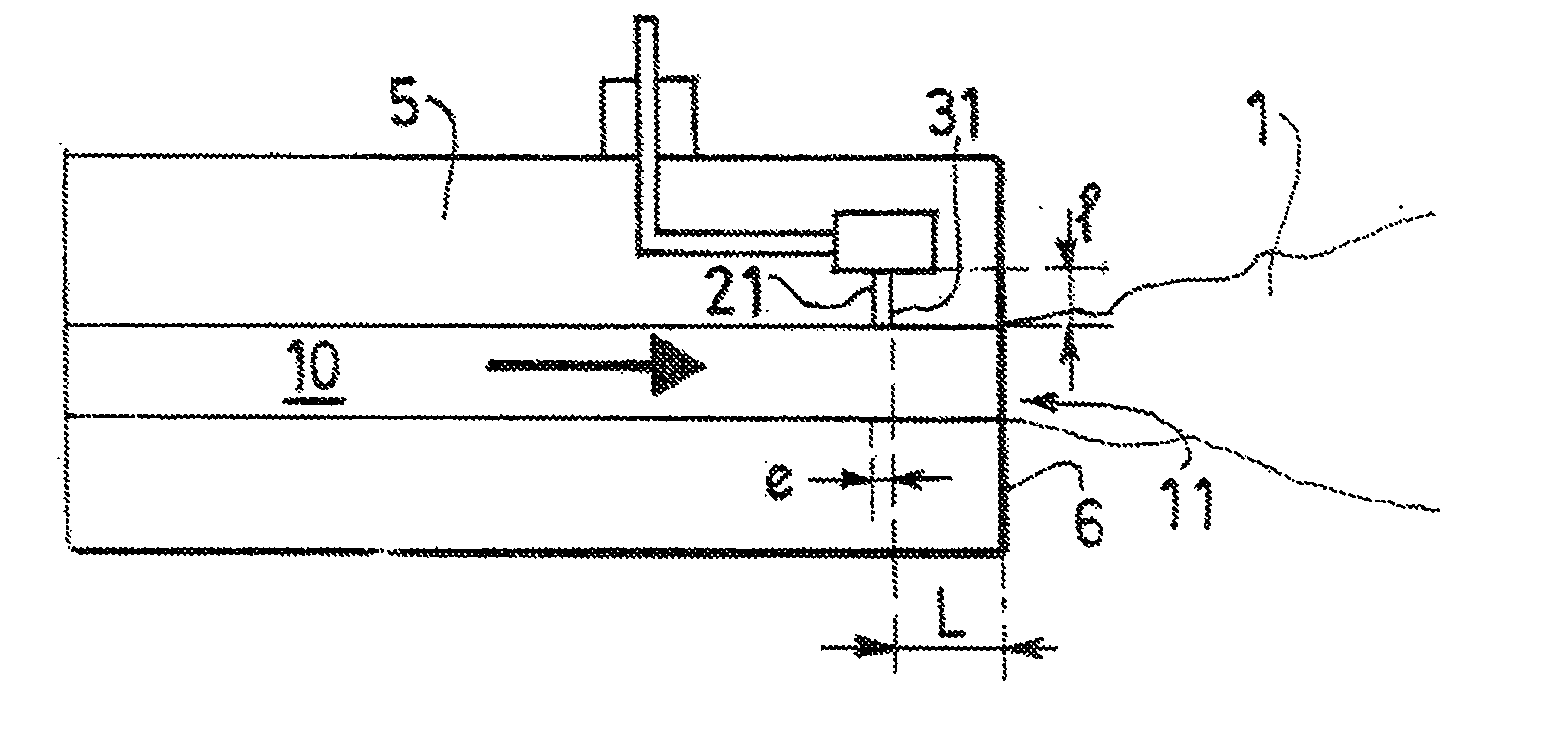

[0137]Burners according to the invention are used for the incidence of the flame to be variable. (The term “incidence” should be understood to mean the angle of the flame relative to the horizontal). When the incidence is zero, the flame is horizontal. When the incidence is non-zero, the flame is inclined under the horizontal and directed toward the hearth of the smelting basin of the oven.

[0138]The burners inject each jet of fluid into the chamber of the oven, but this type of injector can be used only for fluid (oxidant or fuel) of higher impulse when the latter can interact with that of lesser impulse so as to obtain the desired deflection of the flame, typically, the oxidant in the case of an air / gaseous fuel burner, or oxygen / gaseous fuel burner.

[0139]In the first part of the aluminum smelting cycle, when the metal is mostly present in the solid state, the direction of the flame is adjusted for the latter to have a non-zero incidence (axis of t...

example 2

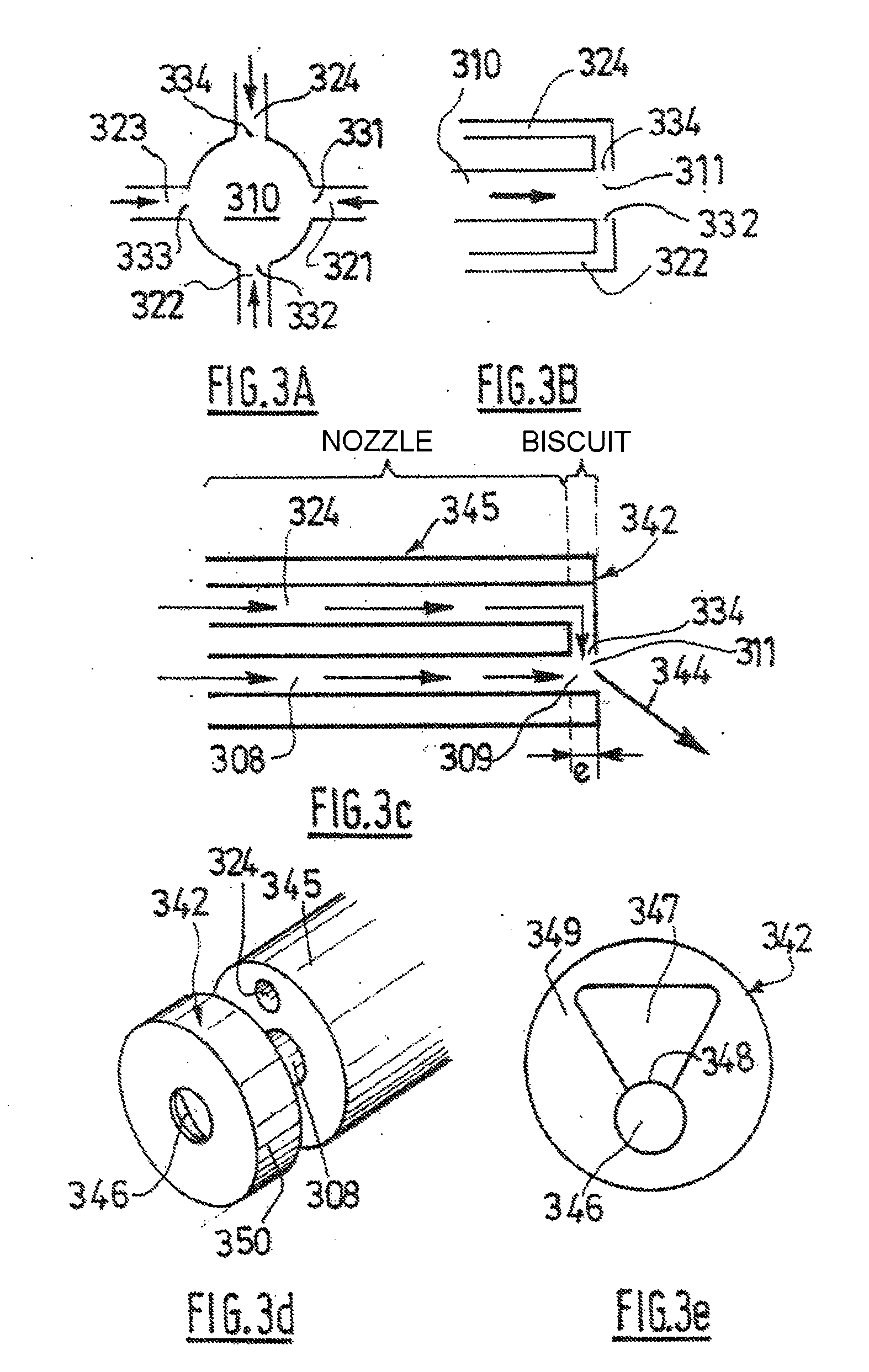

Creating a Uniform Transfer of Energy to the Charge

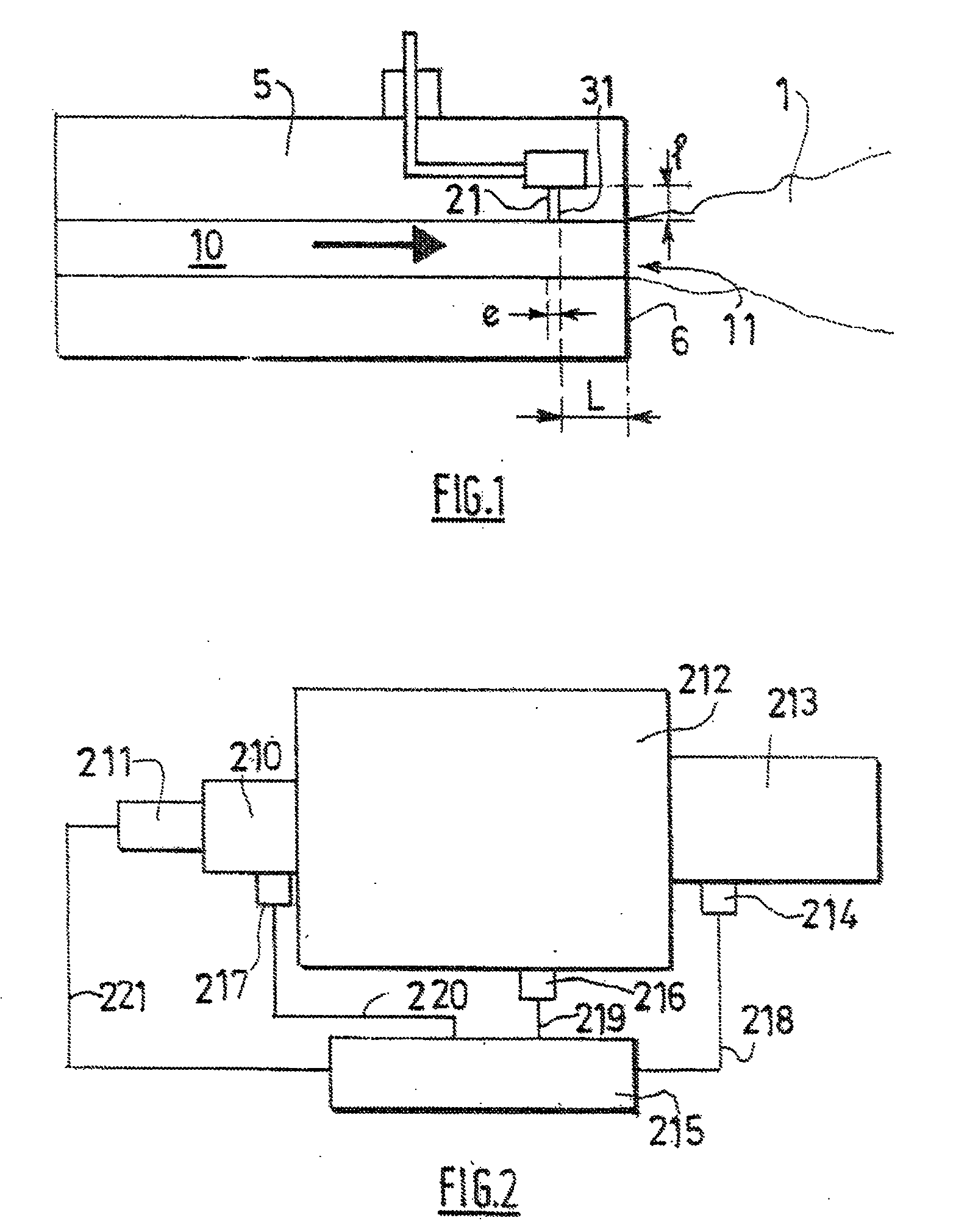

[0147]Burners according to the invention are used for the orientation of the flame in a horizontal plane to be able to be modified on demand according to the control ratio of each burner as illustrated in FIG. 13.

[0148]Each fluid jet is injected into the chamber of the oven through a burner according to the invention, but for jets situated in one and the same horizontal plane or in horizontal planes that are very close together (no more than one to two jet diameters apart), it is possible to use these injectors only for the peripheral jets when the latter can interact with the other jets to be deflected.

[0149]The variation of the horizontal orientation can be achieved in both left and right directions either by equipping each main jet with two lateral actuating jets, or by equipping each peripheral main jet with a single actuating jet, capable of actuating the main jet in the horizontal direction but in directions opposite to each o...

example 3

Flame with Variable Incidence on Charge and Laterally Sweeping the Charge

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com